Heating appliances that use liquid or solid fuel function correctly only if the chimney pipe is installed correctly. The thrust in it should be sufficient and under no circumstances should it tip over. Many users of heating stoves (or those who are just planning to install it) think about what to do if backdraft occurs in the chimney.

The draft occurs in the channel due to the temperature difference between the external and internal air. If it is not enough, or the channel is too short, backdraft may occur, which is very dangerous for human health. Indeed, in this case, all combustion products enter the room.

What to do if there is no draft in the chimney

The main criteria on which the quality of draft in the chimney depends

:

- The cross-section of the pipe (it must be correctly calculated for each specific stove, because if it turns out to be too small, despite the sufficient speed in the pipe, the amount of combustion products removed will be insufficient for maximum heat transfer from the stove; on the other hand, if a person decided to play it safe and installed the pipe too large diameter - the air in it will cool very quickly and condensation may form, which has a detrimental effect on traction).

- The height of the chimneys (the minimum length is 50cm, however, many factors influence this value; detailed calculations and standards are prescribed in SNiP41-01-2003 and SP 7.13130.2009).

- Smooth or rough internal surface (irregularities inside the pipe reduce draft, as they create obstacles to the movement of air, and therefore increase pressure loss along the length).

- The difference in temperature between the outside air and the air inside the stove (hot air rises up the pipe, gradually cooling, which is why draft appears).

- Supply ventilation (for maximum efficiency of the stove, a sufficient air flow is necessary, because combustion products along with the air are emitted through the chimney to the street, which means that the same amount of air must enter the room to maintain stable combustion).

Ways to increase draft in a chimney

The key factor influencing the efficiency of the boiler is the draft in the flue duct. When it increases, for solid fuel boilers, the combustion of coal or firewood improves, which increases the efficiency of the installation. For gas boilers, the draft must be strictly stabilized to ensure normal combustion and not blow out the flame. When constructing a chimney, especially when it is not possible to use the most optimal route, it becomes necessary to use a chimney draft amplifier. What can affect cravings and how to implement this, we will consider further.

Installing a solid, liquid or gaseous fuel boiler, stove or fireplace necessarily involves installing a chimney exhaust system. The main parameters of the chimney are the draft level and the volume of exhaust gases. Structurally, it is an insulated channel, a pipe laid from the exit of the firebox to the external environment outside the building. The draft is created due to the difference in pressure at the chimney inlet and outlet, which is caused by the temperature difference and the difference in levels between the inlet and outlet. The higher the chimney, the stronger the draft. The thicker the channel, the greater the volume of gases it can remove from the boiler.

However, there are a number of reasons why the draft in the chimney may decrease, or even “overturn” when air is sucked from outside into the chimney and combustion products enter directly into the room.

How to check the draft in the furnace and understand whether it is there or not

The sooner you notice the problem, the easier it will be to get rid of it. Therefore, inspect your heating system regularly. Among the obvious manifestations:

- puffs of smoke appearing immediately as soon as you open the firebox door;

- white, gray or even black smoke masses ooze from cracks or pipe joints.

When at least one of these phenomena is observed, it is time to sound the alarm. But even if they are not there, this does not mean that combustion products normally come out and do not stagnate in the outlet channel.

If there are no external signs, but there are suspicions, the lack of traction can be checked in the following simple ways:

- Using a candle, light it, carefully insert it into the firebox and look at the flame. If the light “goes” away from you, even further inward, then the situation is normal; if the tongue remains in place and does not even tremble, the air masses are not circulating properly.

- Using a ribbon or piece of paper, take it by the edge and bring it to the pipe. If the free end pulls into the sleeve, then everything is fine, if it does not move, the hood does not work.

- Using a mirror, you need to carefully bring it closer to the fuel-burning chamber and take a closer look. If moisture appears on its surface, there is a problem with the removal of combustion products.

- Look at the color of the flame: when it is yellowish-golden, everything is good, if it is bright orange or, even more so, red, there is poor air circulation.

After you have checked the lack of traction, you need to find out the reasons for its occurrence.

Causes of poor traction

Conventionally, two large groups can be distinguished: the design features of the chimney and external factors that affect the level of draft.

Design features include such points as:

- Using elbows and tees along the chimney, avoiding obstacles that create aerodynamic resistance.

- Using the wrong chimney section and height, different from the boiler manufacturer's requirements.

- Incorrect installation of the gate (damper) and its adjustment

- Availability of chimney head, umbrellas, spark arrester, etc.

External factors mean:

- The location of the chimney outlet is below the roof ridge, which, in a certain wind direction, can cause the draft to “overturn.”

- The presence of large objects near a chimney, a neighboring building or other structure that creates a vacuum zone or, conversely, increased pressure in the chimney area.

- The predominance of strong winds or, conversely, the dominance of calm weather.

All of this affects the level of traction, often creating additional resistance and reducing it. In any case, it will be necessary to find an adequate way to increase the draft or stabilize it in order to ensure the most efficient operation of the boiler or furnace.

Chimney cleaning

Cleaning the chimney

Up to a certain point the draft was good, but over time something happened? Most likely, the channels are simply clogged. When various materials burn, soot is released. If the surface of the pipe is not smooth enough or there are many turns, then the soot will definitely settle. Accumulating over time, dross will narrow the passage, which will certainly impair passability.

Plaque has formed on the walls of the chimney.

Periodically, the channels need to be cleaned; this can be done by mechanical and chemical methods.

Traditional methods include:

- Peeling with potato skins or the potatoes themselves. In order to implement this method, you need to throw chopped potatoes or potato peelings into a well-heated oven. Usually it takes about one bucket. During the combustion process, steam is released that contains starch - it is this that softens the soot. Some of the carbon deposits fall off on its own; the remaining layer may have to be removed by mechanical means.

- Aspen firewood. They have high heat capacity. You need a few good logs. But before using this method, be sure to check the condition of the sunbed and riser. If you are not sure of their reliability, do not try to clear soot from the chimney using this method. During the process, the channels become very hot, which can lead to a fire.

- Rock salt. It is added as the wood burns. But you shouldn’t expect any special effect, because this option is more intended for prevention.

Kominichek

Among the chemicals, the most popular are “Komichek” and “Log-chimney sweeper”. These products are placed on the coals and left for a certain time, according to the instructions. During the combustion process, compounds are released that destroy soot deposits. Manufacturers recommend that after they burn out, do not remove the coals until the next kindling, because some substances continue to act.

Chemical cleaning methods have their detractors, who say that their use can lead to the destruction of the chimney. Actually this is not true. The principle of operation is not that the reagent flares up to ultra-high temperatures, but that a chemical reaction occurs with the soot due to compounds that are released into the air. This, on the contrary, helps to avoid problems, because if soot catches fire, then a fire cannot be avoided (its combustion temperature can reach 1200˚C, only a ceramic pipe can withstand such a load).

Mechanical chimney cleaning

Methods and devices

During normal operation of the chimney, the pressure of the upward flow should be in the range of 10-20 Pa, which corresponds to the optimal flow of exhaust gases from the combustion chamber. To find out the real state of affairs, anemometers are used that can show the level of draft. Based on the instrument readings and the result of fuel burning, you can accurately say whether it is necessary to increase or decrease thrust, or use stabilizers that will automatically maintain the ideal air flow rate in the channel.

There are many ways to increase draft or bring it into compliance with the standards and requirements of the boiler manufacturer:

- Increasing the height of the chimney;

- The use of deflectors, weather vanes, rotary turbines as a chimney head;

- The use of smoke exhausters powered by electricity;

- Traction stabilizers.

Why is it cold in the house?

It happens that people complain that their heating is not working well. The unit seems to turn on properly, but the batteries are cold. Naturally, this significantly reduces the level of comfort. Let's try to figure out why the batteries do not heat up when the boiler is running. Most often, the reasons that the radiators in the rooms are cold are the following:

- the built-in circulation pump has failed, in this case the coolant heated by the boiler will not be removed in a timely manner and the batteries will remain cold, even if the unit is started at full power;

Advice! Such a malfunction is often detected after boilers have been idle for a long time. During the summer, pump parts may become covered with lime deposits, which will not allow the device to function normally.

- a blockage has formed in the heat exchanger;

- The three-way valve is faulty.

It must be said that the reasons that the heating in the house is poor and the radiators do not heat are not always related to the boiler. The reason for the lack of normal circulation may be the presence of air locks in the system.

Therefore, when installing batteries, they must be equipped with Mayevsky taps, and before starting the heating unit, it is necessary to bleed off any air that may be in the system.

Often the reason that the heating in the house does not work well is ordinary scale. It settles in the heat exchanger tubes, narrowing their lumen and reducing thermal conductivity. Therefore, it is better to use specially softened water rather than tap water as a coolant.

If the boiler does not work well for heating, and hot water regularly flows into the water supply system (we are talking about a two-circuit unit), then the cause of the malfunction is most likely in the three-way valve.

Increasing the chimney height

The simplest and most often reliable way to cope with a low draft level is to increase the height of the chimney. As a result of an increase in the level difference between the boiler and the chimney outlet, the pressure difference also increases, the upward flow of hot gases significantly increases the draft. The optimal height of the chimney is 5-6 meters, provided there is a minimum distance between the boiler and the vertical part of the channel and the absence of various deviations, bends and thinning of the channel.

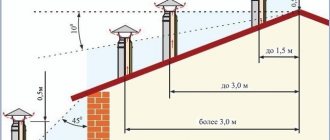

Calculation of the height of the chimney, depending on the location from the roof ridge

In the case of various external factors, such as a high roof profile, ridge, nearby buildings or other objects that worsen the situation, this gives a better result. However, if the chimney is too high, the draft can significantly exceed the required threshold, causing most of the heat to simply go outside, heating the environment, and not the working fluid in the heating system. The fuel will burn worse. To prevent this effect, dampers or draft stabilizers are used, which can be used to reduce the volume of exhaust gases.

Ways to recover and increase traction

The reasons for decreased traction are usually understandable and easily eliminated:

- Chimney blockage . This can occur due to soot formation or the ingress of dust and dirt from outside. Regular cleaning of the chimney, even under the most favorable operating conditions, is the norm. This can be done, for example, with a metal brush on a long wire. The walls of the chimney must be as clean as possible and have a smooth surface.

- Insufficient thermal insulation of the chimney . If insulation is insufficient, most of the chimney is cooled, as a result of which there is no longer a significant temperature difference necessary for sufficient vacuum.

- Errors in chimney design . Most often, its height is insufficient; it should be at least 5 m. There are also height standards relative to the roof ridge (see photo below). Weak draft is also possible if the chimney diameter is insufficient, there are an excessive number of bends, or leaks.

The optimal height of the chimney according to SNiP 41-01-2003.

Separately, it is worth noting the backdraft belt phenomena that extinguish the boiler burner, which arise not only due to the incorrect height of the chimney, but also the lack of a well-chosen wind-protecting deflector on it.

Gas boilersInstructionsBoilers

Deflectors

Special devices attached to the chimney head. Their shape and design are selected so that the air flows directly near the chimney outlet do not interfere with the exit of gases, but, on the contrary, contribute to this. The action of the deflector is based on Bernoulli's law. If there are air currents, they flow around the main part of the deflector and create a vacuum in the area directly above the chimney exit. An excellent option for use in conjunction with solid fuel boilers, where increased draft ensures proper burning of coal and briquettes.

The deflector cannot be installed with gas boilers. Strong wind can significantly increase draft, as a result of which the burner flame can simply go out.

The effectiveness of deflectors directly depends on the presence of wind, so they are virtually useless in calm conditions and even create additional resistance.

Another means of increasing draft without increasing the height of the chimney and also depending on the wind. However, unlike a deflector, a weather vane does not actually create resistance in calm weather. Its design is extremely simple. A small wing is attached to the chimney outlet, covering the head from the wind on one side.

With the help of an additional blade and its location on the other side of the chimney axis from the weather vane mount, it is always turned so as to close the mouth from air flows. They flow around it and create a vacuum at the outlet, increasing thrust.

Reviews from owners of this device indicate its unsuitability due to jamming of the rotating part by smoke deposits or freezing of precipitation.

Solution

Taking into account the fact that the reasons for the occurrence of poor traction are different, it is necessary to select a solution that is appropriate to the problem and capable of preventing it.

If the outlet overpasses are clogged with debris and soot, they should be cleaned. If the chimney is not designed correctly, the structure must be dismantled and reinstalled.

If the problem is poor exhaust of combustion products, there are various ways to improve draft. There are devices to help this process.

Deflector

This unique turbine is mounted on the top of the chimney and, using the power of the wind, pumps smoke from the pipeline shaft.

Deflector capabilities:

- protection of the pipeline from debris, rain and snow;

- increased traction;

- suppression of flying sparks.

The functionality of this device is developed on the basis of physical laws; it creates a forced vacuum during the passage of an air flow in its narrowing channel.

Gases enter the rarefied space in the neck of the chimney, and then are removed from the pipe by increased draft.

The use of the device has a beneficial effect on the heating system, improves heat transfer and promotes complete combustion of fuel. That is why deflectors are very popular and in demand.

Shiber

If there are problems with heating, it is recommended to check how the damper is positioned. This is a special damper to control the traction force. Device functions:

- closing the pipe after finishing the fire to preserve heat for a long time;

- traction control;

- control of the degree of fuel combustion.

Most problems can be solved by setting the damper to the correct position.

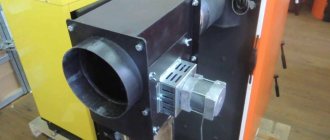

Electric smoke exhausters

In some situations, for example, for use with wood-burning stoves or fireplaces, it is possible to install special electric duct exhaust fans. They are designed to operate in environments with elevated temperatures and the presence of ash, condensate and other combustion products. However, it is unacceptable to install them on the chimney of a boiler operating on solid fuel; the temperature of the gases in it can reach 650-800°C.

Such smoke exhausters are capable of automating the operation of the chimney. A special temperature and flow sensor regulate the activity of the electric drive, thereby always maintaining optimal traction in the system.

Classification of faults

When contacting a service center, it will not be enough to say that the equipment is not working well; you need to describe the symptoms of the malfunction as fully as possible. All breakdowns are divided into several groups, united by common characteristics, they can be:

- Intermittent or final. In the first case, the equipment works, although poorly, without reaching operating parameters. In the second, a complete failure occurs, that is, the gas boiler does not heat the water or does not even turn on.

- Primary or secondary. Primary boiler malfunctions are those that occur for the first time. Secondary faults are failures that occur periodically, provided that no repairs have been carried out.

- Sudden and increasing. The first group includes breakdowns that occurred unexpectedly for the owners, that is, before the failure occurred, the owners did not notice any problems with the boiler. The second group included breakdowns that developed gradually, that is, the owners had long noticed that the unit was not working well, but did not take any measures.

- Obvious and unclear nature. The obvious ones include leaks and failure of some equipment units. Non-obvious faults can only be detected by a specialist with special diagnostic equipment.

Traction stabilizers

A whole class of devices for automatic regulation of gas pressure. They are primarily designed to work in systems with known good or increased traction. Their task is to regulate the volume of exhaust gases depending on the efficiency of the main chimney. In fact, they replace ineffective dampers that constantly require attention and manual adjustment.

The principle of operation of stabilizers is based on mixing cold air from the room into the gases leaving the furnace. This allows you to reduce the temperature of the total mixture, which enters the vertical channel and reduces the flow rate.

Structurally, this can be a device assembled on the basis of a chimney tee, which has an intake valve on the branch. The movable curtain, mounted on a free axis, opens only when the pressure in the system is exceeded, which is regulated using a counterweight.

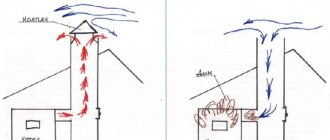

Reverse draft and ventilation

- No one has canceled the natural laws of ventilation:

- Warm air has a much lower density than cold air;

- therefore, warm air tends to rise;

- if somewhere inside the house windows or doors are open to the street with cool weather, when the heating devices are turned on, the air will go there, and not into the chimney (as the user would like).

Ventilation force during air outflow

- The internal architecture of the building is of great importance:

- if the house has many windows, there are balcony doors or stairs to the upper floor - all this will lead to the formation of drafts;

- On areas located above the firebox level, opening windows and doors to the street is not recommended.

Failure to follow such simple tips is a guarantee that air currents that disrupt the draft will be formed.

Providing ventilation with supply air

- Sometimes the following happens:

- the room is sealed (doors are locked, windows are closed);

- when the stove is lit or the gas boiler or water heater is turned on, low-pressure areas draw fresh air from the chimney;

- result - the thrust overturns;

- The solution suggests itself - it is necessary to create the required air circulation. What needs to be done for these purposes:

- install wall supply valves;

- install supply valves on PVC windows;

- place a forced ventilation device on the window to draw air masses from the street into the room (such devices cut directly into the window glass - you can watch the video on the Internet to see how to make the insert);

- slightly open the window, door or window.

The implementation of one of these measures will lead to the fact that the atmospheric pressure in the room will decrease and the reverse draft will disappear.

If there is a gas water heater

- A gas-powered dispenser has a number of features:

- its combustion chamber draws air out of the room;

- the lack of oxygen becomes noticeable quite quickly (the air becomes thinner, oxygen deficiency is felt);

- Air will periodically penetrate from the chimney, which will lead to the fading of the column and smoke in the room.

Sometimes the user rushes around looking for a defect in the gas water heater instead of carefully analyzing the ventilation - its consistency and efficiency.

How to determine the best option

The choice of a specific solution depends on the structural features of the chimney in each individual case. The use of elements such as deflectors, weather vanes, turbines or smoke exhausters is only relevant in the presence of certain factors, such as windy weather or the impossibility of arranging a full height chimney.

The best solution remains, as always, to increase the height of the chimney and use various stabilizers, which, in combination with increased draft, can ensure optimal operation of the boiler. In this case, the influence of external factors is reduced and all possible obstacles to the creation of a natural flow of combustion products are eliminated.

Reasons for attenuation

It happens that the boiler burner lights up normally at first, and then goes out almost immediately. The main reasons for this problem:

- insufficient draft intensity or “reverse draft”, which blows out the burner flame;

- thermocouple malfunction;

- malfunction of automation systems, in particular traction sensors.

Traction problems

If gas flows normally and the burner lights up and then quickly goes out, the first thing you need to check is the draft. You can do this yourself. It is enough to bring a lit candle to the air duct and see how the flame behaves. With good draft, the candle burns evenly and the flame reaches upward. The cause of deterioration in traction may be:

- chimney blockage;

- strong wind outside.

Removing the blockage is quite simple; you just need to clean the chimney. But on how to eliminate the formation of backdraft in bad weather, you need to consult with specialists. Sometimes it is enough to put a special “fungus” on the end of the pipe.

Thermocouple problems

This element is used to protect against overheating. When a certain temperature is reached, the thermocouple is triggered and the unit turns off. After the coolant has cooled, a signal is received to turn on the boiler.

If the thermocouple fails, it can signal the need to shut down almost immediately after startup. If this is the cause of the problem, then the thermocouple will have to be replaced, since this element cannot be repaired.

Sensor problem

When organizing heating in a house, today they almost always use automation systems that ensure the safety of the residents of the house. One of the components of such a system is a draft sensor, which turns off the equipment if the draft is insufficient intensity.

If this sensor fails, the boiler cannot be put into operation, since the gas supply will be blocked. Therefore, repairs will require replacing the sensor.

Effective ways to increase chimney draft

Designing a chimney is complex and responsible, on the correct execution of which the efficiency and safety of using the heating device depends. No heat generator is capable of functioning normally without a pipe that removes smoke from the room. Smoke is a mixture of gases containing residual products of fuel combustion. The appearance of smoke inside a heated room is a sure sign of an incorrect design of the chimney system, which entails the risk of fire and carbon monoxide poisoning. This article will tell you what backdraft in a chimney is and how to prevent its occurrence.

What threatens the lack of normal vacuum in the furnace?

Modern, even the simplest gas heating equipment does not allow combustion with reverse draft or its complete absence. However, with insufficient, poor draft, not all boiler models interrupt combustion, and this is fraught with:

- the spread of natural gas throughout the room due to its under-combustion due to lack of oxygen. In this case, there is always a characteristic smell of gas;

- the entry of toxic combustion products into the room, sometimes, especially in small quantities, they are not noticeable by smell;

- increased soot formation, which leads to accelerated clogging of the chimney, heat exchanger and combustion chamber of the boiler.

How to choose a room thermostat and save up to 30% per month on heating

Measurement methods

If you doubt that the chimney draft of a stove, fireplace or heating boiler is sufficient, you need to check it. The easiest way to dispel doubts is to check it yourself using an anemometer. If the device shows a draft of 10-20 Pa, then it is considered normal . The problem with this method is the low measurement accuracy of inexpensive anemometers; if the draft is less than 1 Pa, then they will show that there is no draft. More accurate professional instruments are expensive; they are used by stove makers.

If you don’t have an anemometer, use one of the popular methods for determining the draft force of a chimney:

- By the smoke. The most obvious sign that there is no draft is the presence of even slight smoke inside the room; a large amount of smoke indicates a high risk of fire and carbon monoxide poisoning.

Note! The draft inside the chimney duct is created due to the difference in pressure outside and inside the room. In a heated room, the temperature is higher than outside, so there is more pressure there. Heated air, supported from below by colder air, is squeezed into a zone with lower pressure, that is, into the atmosphere. If you take measurements in the summer, when the temperature difference between inside and outside is minimal, you will get a lower result than in winter.

Craving as a physical phenomenon

- When there is no artificial ventilation (let’s mentally turn to natural conditions, as everything happens in nature), air masses behave as follows:

- air by default tends to where it encounters the least resistance;

- as soon as aerodynamic “help” appears in the form of an elongated “corridor”, the intensity of air flow increases. They are forced to move to where an empty, unoccupied place awaits them.

- As a matter of fact, chimneys and pipes serve precisely as such corridors. This is a man-made option to forcibly create draft to extract combustion products from the premises:

- as a result of certain engineering calculations, the pipe of a furnace, column or boiler has such characteristics as to create an aerodynamic directed air flow of flue gases;

- draft occurs due to the fact that the air pressure inside and outside the furnace is different.

Violation of draft is not a consequence of poor quality chimney.

Reverse airflow can occur even when using prestigious equipment. In this article you can learn about the pros and cons of a homemade long-burning wood-burning stove. Find out how to independently build stoves for a wood-burning cottage here. Read about the advantages and design features of a brick stove with a water circuit:

Causes of malfunctions

After making sure that there is not a sufficient level of draft inside the chimney system, you need to determine and eliminate the possible cause of this defect. Experienced craftsmen claim that the most common causes of failures in smoke exhaust ducts are:

- Design error. The choice of chimney pipe should be made based on the volume of the firebox. If the diameter is less than the calculated parameter, the weak one will not allow smoke to escape from the room.

- Insufficient pipe length. A pipe length of less than 5 m does not provide a significant difference between the pressure indoors and outdoors, which results in weak draft.

- Incorrect placement of the chimney pipe. I advise stove technicians to lay the chimney vertically, as narrow turns trap smoke inside the chimney, reducing draft.

- Long horizontal sections. If, when laying a chimney, you cannot avoid horizontal sections, then make sure that their length is no more than 100 cm. Otherwise, it will need an amplifier.

The first step when detecting problems in the chimney system is to dismiss the most obvious causes of insufficient draft. When inspecting, make sure that the connections of all pipe segments are tight and that there are no soot blockages. Check that no moisture has entered the smoke exhaust ducts and that the atmospheric pressure is normal.

How to solve the problem of lack of traction

First of all, it is important to determine what exactly the reason is and what its nature is. If there is no normal air exchange at all and the problem is an incorrectly laid out smoke duct, you need to make structural changes:

- Increase the section of the hose - expand it to the level of the firebox pipe, this will increase the activity of circulation of gas masses.

- Extend the pipe - make it rise above the roof (ridge) by at least 0.5 m, and if there are trees or other buildings in the immediate vicinity of the building, then it is better by 1.5 m.

- Simplify the chimney - replace its horizontal sections with inclined ones, remove straight turns (remember, a change in direction is allowed by no more than 45 degrees).

But if this is not the case, and there is no draft in the heating boiler, what should you do then? Most likely, the lack of traction is due to errors made when installing the heating unit. In such a situation, it is necessary to identify and eliminate the defect, and then recheck the quality of air exchange.

If combustion products were initially discharged normally, but over time they began to accumulate in the channel, most likely something is simply clogging the sleeve, and this obstacle will have to be removed.

Try cleaning the chimney

This can be done both “the old fashioned way,” that is, mechanically, and with the help of chemical means.

- Buy a long brush from a specialized store or design one yourself (for this you only need a rag and a strong metal cord). Take this tool and run it along the walls of the pipe. This way, you will remove soot, condensation, frozen moisture and even debris that has accumulated inside.

- Or add a composition to the firebox that will mix with the combustion products and, when the gas escapes, take soot and liquid with it. Naturally, it is important that it is a non-toxic product. Consider the option of natural remedies, for example, when lighting with wood, it may well be the rock salt that everyone is familiar with. Or you can purchase ready-made chimney cleaning products, which are available in a wide range on the market.

So that a few years after installing the heat generator you don’t have to wonder why there is no draft in the stove at home, do not let it clog. Use a brush or chemical at least once or twice every six months - remember, regular prevention is important and often saves you from air exchange problems.

If cleaning doesn't help

If the issue is not soot or debris, or errors in installing the heat generator and smoke duct, then what is it? This means that the problem is in an external factor - in wind pressure from a tree or a nearby building, in heavy gusts of air currents.

Is there a solution to this situation? Yes, this is the installation of one of the auxiliary elements. Below we will look at each one that deserves attention.

Stabilizing devices

The reason why there is no draft in the stove in a bathhouse or in a house may be that the exhaust gases heat up the hose too much, does not create the necessary difference in atmospheres, and as a result does not have time to escape completely, but accumulates near the walls of the channel.

If this is the case, a regulator should be hung at the end of the pipe - a device equipped with a temperature sensor. It works clearly and quite reliably:

- triggers when the temperature rises (which is observed when gas accumulates) and opens the fuse valve;

- Fresh air enters the chimney from the street.

As a result, the pressure difference stabilizes - hence the name of the device, which, by the way, operates in automatic mode.

Deflectors

If there is no draft in the furnace, and the reason is wind pressure, the solution to the problem is to install one of these devices. Already from the name it is clear what it does - it deflects air masses reflected by high interference (the wall of a neighboring house, a trunk or branch of a tree). This is a kind of outlet, thanks to which exhaust gases are completely removed to the outside. Most often, such an element reduces pressure and improves the aerodynamic effect of the emission of combustion products. It is useful even during heavy gusts, which is why it is appreciated.

The high popularity explains the variety of models, among which deflectors-vanes stand out - a kind of hybrid that takes the best from both devices. Thanks to the presence of the upper glass, it perfectly captures the direction of wind flows, and due to the cap it is well protected from precipitation and mechanical debris.

Ferrum's product range includes an umbrella with wind protection, which is easily and tightly inserted into the chimney without the use of self-tapping screws. The price list can be found on the website.

Rotary turbines

If all the reasons for the lack of draft are eliminated or corrected, there is no draft in the furnace anyway, what to do in such a situation? Place this final element - a rotary turbine - at the outlet of the channel: it will forcefully push out the waste combustion products when necessary.

A screw on an electric drive is responsible for removing the gas, the timely activation of which is carried out by the activation of temperature and air speed sensors. The design of the device is modern and at the same time simple and reliable, which is why rotary turbines are popular.

Revision of the ventilation system

It is necessary to reconsider its organization, think about how to correct the shortcomings, in particular, remove drafts. This is relevant when you have gone through all the options, found out that the problem is not in external factors and not in the chimney, but you still don’t understand why there is no draft in the boiler. All you need is:

- frequently ventilate the rooms, and especially the one where the heating unit is located;

- install supply valves on the windows so that they provide fresh air in portions;

- use devices that will forcefully ventilate rooms;

- and all this should be combined with competent prevention - not only with cleaning the pipes, but also with heating the entire system. It is also necessary to carefully monitor the performance of all devices such as rotary turbines or deflectors.

Ways to increase traction

If the draft force is in the chimney duct of the heating device, eliminating this defect is not always easy. Experienced stove makers use the following methods and methods to increase it:

- The first thing to do if you suspect insufficient draft in the chimney is to clean the pipe. To do this, call a chimney sweep or remove soot deposits from the inner surface of the chimney with your own hands using a metal stove brush.

- A significant increase in the power of the chimney can be achieved by increasing the height of the chimney above the roof surface by adding several additional segments. Using the same method, the chimney is removed from the zone of wind pressure from a ridge or higher building.

If you were unable to find a solution to the problem of lack of draft inside the smoke exhaust duct on your own, seek advice from an experienced stove maker who will tell you what to do and correct the defect in the most rational way.

Why does backdraft occur?

Of the reasons and factors why traction goes in reverse, the most common ones should be highlighted. In turn, they can be divided into simple (temporary, easily removable) and complex (requiring drastic intervention).

Complex reasons

- Most often it's this:

- structural defects of the chimney system (the presence of horizontal or too narrow sections in the chimney, incorrect calculation of the cross-section of the pipe, the height of the pipe is below the level of the ridge of the roof of the house) - engineering deficiencies must be eliminated;

- clogging of the smoke exhaust channel - you will have to clean it out;

- Trees growing too tall near a residential building or high-rise buildings are located - the issue of redesigning the entire chimney system needs to be resolved;

- errors when installing indoor ventilation (insufficient supply air) - accordingly, ventilation diagnostics, dismantling and reinstallation will be required.

Simple reasons

There are times when the thrust “overturns” for just a couple of days, although before that everything worked fine.

Reverse thrust occurs due to the fact that:

- cool weather set in;

- the firebox or stove has been idle for a long time and is not working.

How is this physical phenomenon explained? Very simple:

- a fair amount of heavy cold air has accumulated in the chimney;

- the cooled air mass will be the very obstacle that the air does not like to overcome (see the beginning of the article - the correct draft is always directed to where there are no obstacles).

Solution to the problem:

- endure the smoke in the room and continue heating the pipe - soon the cold “cushion” will be broken through and the draft will be restored. Burn 3-4 sheets of paper without firewood - there won’t be much smoke, and the chimney will warm up;

- use a device called a traction stabilizer in such situations. With its help, the secondary air supply will accelerate the movement of air in the chimney.

The stabilizer is equipped with a safety valve that prevents excessive pressure build-up.

How to increase the draft through the boiler, what to use - a deflector, a smoke exhauster or...

Sometimes there is not enough draft through the chimney, the fuel does not want to burn intensely, the wind blows in, smoke is released into the room when the damper doors are opened - why does this happen, and what needs to be done to improve the draft - maybe install a smoke exhauster?

Why is there no traction?

Natural draft depends on the pressure difference in the chimney. And the pressure depends to a large extent on the difference in temperature of the air and gases, or more precisely on the difference in their densities... In winter, when it is frosty outside and warm inside, the air flows well into any raised chimney, the boiler melts without problems. When the firebox is hot and the frost is still good, the draft is usually tolerable even in the most poorly designed systems. In the off-season, traction is also usually satisfactory.

But in the heat of summer, it can be problematic to light a stove or a regular boiler using natural draft. The initial thrust may be completely reversed. The room is filled with smoke, stable combustion is not achieved - what to do?

Also, natural cravings can be significantly affected for the following reasons.

- The chimney is covered in soot and coked.

- Other chimney ceilings - collapsed plaster, compression by structures, bulging and lifting of rusted, burnt shells...

- A hole has formed in the chimney - a leak in addition to the boiler firebox.

- A low chimney was installed - below that required by SNiP.

- A chimney with a small cross-section is installed - smaller than that specified according to the instructions for the boiler, for a given combustion power - the aerodynamic resistance is too high.

- A boiler and stove were installed with too much aerodynamic resistance inside, with a complex system of smoke ducts around the heat exchanger.

- Air supply dampers, blower covers, etc. are closed.

- The draft regulator is closed, the damper at the gas outlet, at the point where the chimney is connected to the equipment, is blocked.

- There is no free flow of air into the room, it is hermetically sealed, during combustion a vacuum is created in the firebox, and the draft stops.

As you can see, if the draft is broken, then you first need to check the serviceability of the equipment, the correct air supply adjustments, the position of the dampers, and be sure to clean the soot from the chimney. How to clean a chimney - recommendations

- But for many people it is important: - how to light a boiler in the summer, for example, to heat water...

- Also, many people are aware of the “diseases” of their boiler-chimney system, but there is a desire to increase the draft on existing equipment - how to do it?

Installing a deflector - helps increase traction

A deflector is a device at the top of the chimney that creates additional vacuum in it due to the force of the wind. Disadvantages of this method of increasing traction:

- If there is no wind, then there is no increase in traction - too obvious a drawback.

- Another hard-to-reach unit appears that needs to be cleaned of soot, which has the opposite effect when dirty, inhibiting traction.

- The method also has a slight increase in draft - only 20 - 25%, provided there is wind on high chimneys.

Is it worth doing this or is it enough to install a regular rain umbrella? In addition, the instability of the traction force is not the best situation, then we will look at why...

However, you can make a deflector yourself from stainless steel, according to the drawings provided.

How to make a TsAGI deflector - manufacturing diagram.

How to make a cone for a deflector

Drawings for the manufacture of a Volpert-Grigorovich deflector.

Install a smoke exhauster to increase draft

There are electric ventilation units to increase draft in chimneys. Large boiler houses are equipped with them according to the designs initially. For boilers, such equipment can be additionally installed on standard pipe diameters.

- There are draft enhancers installed at the end of the chimney in the form of a propeller fan. But the option is unpopular due to the complexity of installation at height and subsequent cleaning there, especially if resinous firewood is used.

- Another version of the smoke exhauster is a centrifugal type, installed at the outlet of the boiler in the hot gas zone. Usually a separate chimney bypass is made for it, blocked by a damper, so that during natural draft the gases do not flow through the fan.

During operation, this device creates a powerful fixed draft that will blow through virtually any system, provided there is free air access to the firebox (into the room), and will not pay attention to wind blowing, for example... But this system has very significant disadvantages.

Disadvantages of installing a smoke exhauster.

- During operation, a stable draft is generated and a large amount of fuel is burned. If there is an emergency power outage, the draft disappears, then a large amount of carbon monoxide can be released into the room. This is extremely dangerous. Such a smoke exhauster must work in conjunction with automation with other boiler room devices, or for a short time under constant human control.

- The impeller gets dirty too quickly and needs regular cleaning, so its use is not practical.

- Obstacles are created to the implementation of slow, long-term combustion.

Ways to increase traction

If the chimney creates insufficient draft, it is necessary to replace it, install sandwich pipes selected in diameter for the given power of the heating equipment (according to the instructions, according to tables), and height in accordance with the requirements of SNiP (half a meter above the ridge when placing the pipe near it... etc. .).

If you need summer fireboxes, you can equip the boiler with a centrifugal smoke exhauster for reliable infrequent starts under the control of a responsible person in hot weather. But there is a simpler solution...

No draft in the boiler? There are ways to solve this problem:

If there is no draft in the boiler, then there are several simple and effective means to ensure that the draft increases significantly and heating circulates freely throughout the entire area of the house through heating registers:

- One of the old, but effective methods is calcination of the boiler, that is, overheating the boiler and retaining the heat in one volume, after which it is necessary to sharply open the damper between the combustion chamber and the boiler, in which case a large amount of heat leaves through the damper and begins to circulate in the necessary directions . The method is applicable if the entire “system” has passed the seal test;

- improving boiler sealing. Lack of draft occurs if there are any voids, “holes” and heat leaks from the boiler. In this case, the heat circulation is not carried out at full capacity and a small amount of heat goes into the boiler, which does not satisfy the heating needs;

- modernization of the boiler and installation of a second venting boiler. In this case, the heat begins to circulate and “stretch” through two pipeline lines: one is a heating line, the second is a return line to the boiler, where a vacuum is formed during combustion. In this case, the heating of the boiler or furnace will take slightly longer than in a boiler without a drain boiler;

- The design of the chimney also significantly affects the draft state. If a large-diameter chimney is installed with a low-power boiler, then there will simply be no draft. These data must be taken into account during the initial laying and construction.

Sometimes the lack of draft leads to a complete replacement of the boiler, when all possible solutions to the problem turned out to be invalid. In some cases, low-power compressors and heat convectors are installed for a short period of time, which are designed to “heat up” the boiler and establish heat convection and draft, but such options are applicable only for home masonry stoves.

conclusions

So, how to increase draft in a chimney? Here are a few simple steps that don't require much time or money:

- Clean the chimney of soot. This is the first thing to do. You can do this yourself, with minimal investment of time, effort and money.

- Provide air flow. Open the window for 5-10 minutes before lighting the fire. This will create the correct movement of air in the room from bottom to top. The window can be closed after the fire has burned out.

- Insulate the chimney if it is not insulated. This will reduce the influence of cold air and also extend the life of the chimney.

As a rule, these simple actions are enough to increase chimney draft . If the problem is related to the design features of the chimney duct, then more serious resources will be required to solve it.

"Flame separation"

Sometimes there is a phenomenon called “separation” of the flame from the pilot burner. This causes the valve to shut off the gas supply and the boiler to turn off. The reasons for this problem may be different, but first you need to make sure that everything is in order with the traction. If the traction is stable, then the reason may be:

- malfunction of burner nozzles;

- excess gas pressure in the supply.

Malfunctions of heating equipment can be different. This may be a global problem, or a fairly easily fixable problem. For example, if a gas boiler leaks, you will have to replace the heating unit. And if any sensor fails, repairs can be carried out very quickly. But even if the cause of the breakdown is known, a specialist must diagnose faults and repair gas equipment!