Possibility of heating using a boiler

A boiler is an electric heating device for hot water supply. At its core, it is a container inside which a thermal electric heater (TEH) is located. To understand whether it is possible to heat a house using a boiler, you need to understand the fundamental differences between a heating boiler and a heating apparatus. In the first case, when the coolant (water) is heated, it naturally circulates inside the tank (boiler). Cold water enters from above and exits from below.

In the boiler, both openings (inlet and outlet) are located on one side, which does not allow water to circulate independently through the heating system. In order for such a tank to perform functions similar to a heating boiler, forced movement will have to be provided by a circulation pump.

The performance of boiler heating is determined by the following factors:

- Boiler power. It is calculated at the rate of 0.1 kW for every 1 m² of room area.

- A pump, the correct choice of which ensures water circulation throughout the entire system at a sufficient speed.

- The ramifications of the heating system itself in the house.

A boiler for heating water with increased power (3-5 kW) is quite capable of heating a small private house or cottage.

Currently, manufacturers of heating devices produce devices adapted for use in heating systems (heating boilers). They have an increased tank volume, the inlet and outlet are separated, their openings are enlarged, and the power of the heating elements is increased to 7-10 kW.

How to ensure water supply through pipes - connection diagram

First, let's look at the internal components of the boiler itself. It includes the following parts:

- coil: located inside the water heater and is required to heat the liquid using circulating coolant;

- thermostat: designed to control the temperature of the water inside the boiler itself; when the control temperature is reached, the device turns off automatically and starts working again when the water cools down;

- insulation: ensures long-term heat retention inside the water heater and does not allow the water to cool quickly;

- water supply pipes: they connect the device and the heating system, connecting to the coolant source.

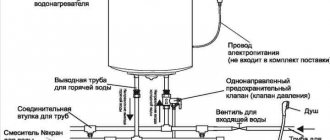

When the boiler itself is already installed in its place, you can begin to connect it to the heating network. It is necessary to remember that the water heater has 4 pipes through which cold and hot water supply passes. They need to be connected according to this diagram.

During one circle with water, the following happens:

- cold water enters the device through 1 pipe;

- using a coil it heats up and remains in the boiler until the thermostat stops heating;

- Water flows through the pipes into the batteries and heat supply occurs.

So you can see that installation does not require much effort. You just need to understand the structure of the device itself. Connecting a storage water heater with your own hands.

Advantages

Such a system has its undeniable advantages. After all, the boiler in this case performs two functions at once, which makes it the most indispensable device in a house or apartment. The device has the following advantages:

- wastes significantly less heat than conventional heaters, this is due to a special layer of thermal insulation;

- simple and convenient installation that does not require much energy;

- saves a lot of money and does not require large installation and maintenance costs; heating boilers are much more expensive than average boilers. Old water heaters are the most economical to use;

- you can independently adjust the required temperature level or stop the heat supply altogether;

- easy to assemble yourself at home, no special tools or plumbing equipment, skills and knowledge in this area are required, just strictly follow the instructions;

- the heating itself comes from the coolant, which reduces the risks of breakthroughs and improper functioning of the system;

- You can use hot water and heating at any time, even if an accident occurs at the station; this is especially common among pipe breaks at thermal power plants in winter - the house will always be warm.

As you can see, this device has a lot of advantages, which, without a doubt, favor the installation of a boiler as a source of heating in the house. Less costs than heating from a management company, but greater efficiency, and most importantly, reliability.

Flaws

Water heaters of this type also have some minor disadvantages. They appear either in the early stages or already during long operation of the boiler. The disadvantages of the technique are as follows:

- the device is subject to corrosion and other unpleasant phenomena that destroy the metal and walls of the pipes, and sometimes even the water heater itself. First of all, boilers that operate continuously without stopping are exposed to this risk;

- it is necessary to spend a lot of labor resources to install the heater: little time, but many tools that must be used during installation;

- designed only for a small heating area due to insufficient power: water heating boilers, of course, cope better with this responsibility;

- it takes a long time to warm up a large amount of water: from two hours to twelve, depending on the power of the boiler;

- It is mandatory to purchase a thermostat, without it the device will not function fully, this indicates additional costs;

- an efficient water heater takes up a lot of space in the room, and sometimes even requires a separate room for placement;

- There is no chance of using the device outside of the heating season, otherwise this will mean additional costs when paying for utilities.

There are as many disadvantages as there are advantages. Accordingly, everything is individual for each user of such a device. Some do not experience any problems, while others have difficulties. Therefore, you need to try different models and only after that draw conclusions about the difficulties of operating the devices.

Advantages and disadvantages

The main advantage of boilers for heating a home is the simplicity of the system and low cost. To install boiler heating, no special equipment is required, and installation can be done independently.

The main disadvantage of boilers is their low power. Conventional household appliances are capable of heating only small houses and cottages, and even in moderate frost outside. In addition, heating elements must operate continuously in the cold season, which leads to their frequent failure. The heaters themselves have a low price, but repairs are quite labor-intensive, which stops the heating system for a long time.

Storage tank as an alternative to a traditional boiler

Design of an indirect heating tank

The storage tank is structurally almost completely similar to a classic boiler. The difference lies in the internal piping that connects to the heating system. In this case, it is necessary to resolve the question - why is a boiler needed in the heating system?

Properly organized heating through a boiler assumes that this element will act as a heat accumulator. The water in the container receives thermal energy through an internal coil connected to the heating system. After the boiler is turned off, the reverse process will occur - the temperature of the coolant from the water in the boiler will increase.

Connection diagram of the boiler to heating

In addition, after the boiler has been correctly connected to the heating system, it will be able to perform the following functions:

- Organization of hot water supply . Since the liquid from the container does not come into contact with the coolant, it can be used on the farm. But to do this, it is necessary to correctly calculate the power of the boiler for heating the house so that this does not affect the heat supply parameters;

- Heating of water using a built-in heating element . In this way, it is possible to maintain the heating level of the coolant even when the boiler is inactive. This can only be done by purchasing an electric boiler for heating.

It is important to initially decide on the purpose of the storage tank - will it be intended for hot water supply, work as a heat accumulator, or combine these functions. Based on the decision made, the optimal volume is calculated and a heating scheme from the boiler is selected.

You can make a storage container yourself. To reduce heat losses, it is necessary to insulate the housing.

Criterias of choice

How to choose a boiler for heating your home? To do this, you need to consider the following factors:

- Design features. The best option for a heating boiler is to place the inlet on top of the tank, and the outlet on the bottom, and their diameter should be more than 2 inches. When the inlet and outlet are located on one side, a pump is installed.

- Device power. When using a boiler to heat water, it is necessary to select a device with maximum power - 3.5-5 kW, which will make it possible to heat a room of up to 50 m². A specialized heating boiler must have a power of at least 7-8 kW.

- Volume of the tank. For heating, only a device with a large tank is suitable, which will make it possible to operate the heating element in a gentle mode - the maximum power is set during initial heating (1-1.5 hours) to form a reserve of coolant, and then decreases. In domestic boilers, the tank volume should be about 70-120 liters, in specialized ones - more than 200 liters.

- Materials used. During operation, the tank material is subject to significant corrosion.

When choosing a boiler, you should pay attention to the presence of a protective coating and the material used:

- Porcelain glass or enamel coating provides good protection against corrosion only if it is intact. Mechanical stress and sudden temperature changes cause cracks and other damage, which creates an active corrosion zone.

- The tank body made of stainless steel or titanium is strong and durable, not subject to corrosion. The main disadvantage is that such boilers have a higher cost.

Installation methods and shapes of boilers

Boilers come in wall-mounted and floor-mounted versions, horizontal or vertical models. The capacity of the product, which is mounted on the wall, is naturally lower: it does not exceed 200 liters. Floor-standing devices can hold one and a half thousand liters. Boilers are mounted on the wall using standard brackets and suitable dowels. The most common boilers are cylindrical in shape.

Working pipes for connecting the system are located at the rear of the unit for convenience and aesthetic purposes. There is a temperature sensor and a thermostat on the front panel. There are models with the possibility of additional connection of heating elements if the power of the main heat source is not enough.

Types of devices

All boilers are divided into 2 main types:

- Flow type. In such a device there is only a small container, and the water is heated “on pass”. This is ensured by equipping boilers with high-power heaters. This type can be used to heat small rooms, but it will require high power consumption and continuous operation of the heater.

- Cumulative type. It is most suitable for heating systems, because... contains a tank in which water is heated. This boiler has a certain inertia, i.e. Heating of the room will begin only when the entire volume of the tank is heated, which will take a certain time. Subsequently, by creating a coolant reserve, you can periodically turn off the electricity supply, which reduces its consumption.

When we talk about boilers, we usually mean electrical devices containing heating elements. However, there is another option when water heating is provided by gas - gas boilers. They are used less frequently, but are quite suitable if there is a centralized gas supply. In this case, you can use the flow-through design of the device.

Keep in mind that the use of gas boilers for home heating requires obtaining special permission from the relevant services and installing a gas flow meter. No permit is required when using electrical household appliances.

Conclusions and useful video on the topic

A used gas cylinder is often used to make homemade devices. We present a video on how to make a BKN from a cylinder body.

Here we describe only one option out of all the possible ones that exist and are successfully used. It should be noted that there are many options for independent designs of indirect heating boilers.

For example, instead of a cylindrical storage tank, rectangular vessels are used. The winding of the coil spiral is not single-layer, but multi-layer. The water heater is supplemented with an electric heating element. Design ideas have no boundaries.

Would you like to share your own experience in making an indirect heating boiler or useful information on the topic? Please write comments in the block below. Here you can ask questions, express your opinion and post photos.

Specifications

A typical design of a domestic boiler includes the following main elements:

- Apparatus body. This is an external element that protects the working container from external influences.

- Working container or storage tank. It is located inside the housing and is separated from it by a heat-insulating layer. Depending on the model and purpose, the tank volume ranges from 10 to 450 liters. The best option for a private heating system is 150-250 l.

- A heating element. For boilers, depending on the volume of the tank, various designs of heating elements are used - rods, spirals, round models, etc. Their important characteristic is power. In boilers for heating water, heaters of 1-5 kW are installed, and in specialized heating boilers - 7-12 kW. When choosing power, it is necessary to take into account the area of the heated room, the type of heating system and its branching, the height of the room and its thermal insulation, as well as external climatic conditions.

- Connection pipes. They provide the input of cold water from the water supply and the output of heated coolant into the heating system. The heating efficiency is determined by the rate of heat transfer, which largely depends on the diameter of the outlet. In heating boilers it is 1/2-2-3/4 inches (10-20 mm), and in heating boilers it is 1.5-2 inches (30-48 mm). The larger the hole, the more efficiently the system works, but only if the power of the heating element is sufficient.

- Control devices. A mandatory element of modern devices is a temperature sensor for heating water in the storage tank. It is included in the heater's automatic power supply control circuit. When the required water temperature is reached, the heating element turns off, and when it drops below the permissible level, it turns on. This allows you to maintain the necessary heat reserve in the tank during periodic operation of the heaters. In some models of devices, it is possible to regulate the power of heating elements, which ensures optimal energy consumption.

The second important type of device is a network load control relay. Long-term overloads in the power supply network cause strong heating of the wiring, which creates a fire hazard. When the load becomes too high, the relay turns off the heater.

When using boilers for heating, the following characteristics are also taken into account:

- The water temperature in the storage tank should be maintained within 65-75 degrees.

- The inertia of the system depends on the type of boiler and the power of the heating element. In tanks with a volume of 200-250 liters, it is 1-2 hours. In flow-through devices, water is heated in 0.5-2 minutes.

- Household appliances must operate from a 220 V network, and the load should not exceed 25-40 A.

Manufacturing of an indirect heating boiler

The process of assembling a water heater may vary depending on the type of design, but in most cases, equipment for gas and electric boilers is manufactured in the following sequence:

- Two holes are drilled in a pre-prepared cylinder using an electric drill with a crown attachment. One hole will be located in the lower part and used for supplying cold water, the other - in the upper part for discharging hot water.

- The resulting holes are cleaned, fittings and ball valves are installed in them. Then another hole is drilled in the lower part, into which a tap is installed to drain stagnant water.

- To make a coil you will need a copper pipe with a diameter of 10 mm. It is better to make a spiral bend using a pipe bender. If such a tool is not available, then you can take any round piece - a large diameter pipe, a log, a barrel, etc.

- The coil is being manufactured according to the previous calculations. The ends of the heat exchanger are bent in one direction at a distance of 20–30 cm. To mount the coil, two holes are drilled in the bottom of the cylinder. Threaded fittings are installed and welded into them.

- Before installation, the coil is lowered into a bucket or large container with water and blown out. If the structure is sealed, then the coil is lowered into the cylinder, aligned with the inlet and outlet openings and welded.

- If the cylinder was cut in the middle, then an anode is mounted in the upper part. To do this, a hole is drilled into which a threaded nozzle is screwed in, and a magnesium anode is mounted into it. If the container is assembled from three separate parts - bottom, lid and central part, then the anode can be installed at the last stage.

- Thermal insulation material is installed on the outside of the boiler. It is best to use spray polyurethane. Before application, all pipes are protected with thick polyethylene and cloth. If funds are limited, then you can use regular polyurethane foam, which, after hardening, is wrapped in reflective insulation.

- Fastenings for hanging on brackets are welded to the back of the boiler. For floor-standing boilers, support legs made of angle steel or reinforcement are welded to the bottom of the equipment.

At the final stage, fittings and taps are screwed on and the top cover is mounted. If possible, you can not weld the lid, but make clamping fasteners from steel wire with a cross-section of 3 mm.

When making a boiler for use with solid fuel boilers, instead of a copper coil, a U-shaped steel pipe is used, which is mounted at the bottom of the device. From the side of the furnace or boiler, the pipe is connected to the outlet pipe. The pipe is taken out from the boiler and connected directly to the chimney.

Installation of equipment

Arrangement of your own heating system using a boiler is carried out as follows:

- Selecting a location and preparing it for installing a storage tank. For this purpose, a flat area of at least 1×1 m in size is prepared with the possibility of unhindered approach and maintenance. The degree of reinforcement depends on the volume and mass of the tank. For tanks larger than 200 liters, it is necessary to build a separate concrete foundation, reinforced with reinforcement. The best option is to form an individual platform with thermal insulation. This condition is not significant if there are mounting feet in the design.

- Tank installation. Installation is carried out in strict accordance with the instructions. It is necessary to ensure rigid, stable and reliable fastening in a vertical position. Tilting the tank in any direction is not allowed.

- Installation of a circulation pump. It is installed when used for heating water boilers. In specialized heating devices, the pump is installed only when the pipes in the heating system are long.

- Connecting the heating system. The outlet pipe of the storage tank is connected to the inlet to the system or pump (if available), and the inlet pipe is connected to the heating outlet. To avoid the appearance of excessive hydrostatic resistance, it is necessary to fully match the dimensions of the tank outlet pipe and the system inlet pipe.

- Connection to the water supply is provided through the inlet pipe of the storage tank. Shut-off equipment must be installed to shut off the water as the tank fills.

- Power supply. The boiler must be powered through an individual panel, in which a circuit breaker and an RCD are installed.

- Checking the tightness of connections. It is produced without heating the water.

When installing a heating boiler, the following recommendations should be taken into account:

- If the storage tank is installed in a special compartment outside a heated room, then its body should be additionally insulated. To do this, it is better to use rolled thermal insulation or polystyrene foam.

- After putting the system into operation, it is necessary to constantly monitor the heating temperature and the operation of automatic control for 10-15 days. This is necessary to clarify the correct installation and quality of the equipment.

- To simultaneously provide hot water supply, it is recommended to provide an additional outlet for hot water at the outlet of the storage tank.

- Heating using a boiler has a reduced pressure in the network, so the number of turns and branches in the system should be minimized.

- To increase the durability and performance of the system, constant maintenance is required - cleaning the tank from settled impurities and heating elements from scale.

Correct use and maintenance

In order for the boiler to serve for many years and not cause problems during operation, you need to use it correctly and take care of the device itself. The integrity of the mechanism should also be checked regularly. It is necessary to do everything that is done to check the performance of any heating boiler. The water needs to be filtered before it is redirected to the water heating tank. This will protect the pipes from further scale and corrosion.

By following simple rules, you can maintain normal operation of the device for a very long time. The following procedures must be followed:

- checking the functionality and integrity of the structure every 30 days;

- control the tightness of connections. Sometimes after each autumn-winter season, when the water heater works non-stop, some parts of the device begin to wear out and become unusable. Therefore, it is recommended to change the gaskets between the connections in the pipes at the end of the heating season; this will ensure more reliable heating throughout the entire room;

- Constantly monitor the maintenance of the same temperature level while heating the water with the boiler. Actual indicators should not differ from the calculated ones by more than 20%, otherwise this will indicate a malfunction of the device;

- regularly clean the water heater and its components from scale and other external reactions that cause wear and tear on the system;

- connect the stabilizer to the boiler so that heating is supplied without interruption.

In addition, the water heater must be cleaned every time. To do this, it is worth disassembling the device and cleaning each element separately. Particular attention should be paid to the coil, as it accumulates the most dirt and scale. If used correctly, the device will last a very long time and provide constant heat supply throughout the house.

Solenoid valve for DHW system with water recirculation

Solenoid valve UNIPUMP BCX-20 3/4″ (normally closed)

Operating medium temperature range – 0…+120 ºС Operating pressure – 0.5…16 bar Power supply parameters – ~220 ±10% V, 50 Hz Protection degree – IP65 Normal closed 20 – DN (nominal diameter) in mm

A normally closed valve opens the way for liquid flow when voltage of ~220 V enters the valve coil (solenoid).

Stages of work on creating a boiler

The boiler drawing may look like this.

Creating a Heat Exchanger

When choosing the diameter of the future coil, it is important that the water in the tank comes into maximum contact with such a pipe. To do this, leave free space between the turns of the pipe.

To make the work easier, you can use a log or pipe around which the heat exchanger tube will be wrapped. One end of this tube is fixed, and then turns are smoothly created, controlling the density of the resulting spiral.

Preparing the boiler tank.

Having chosen a suitable container, you need to make two holes in it for cold water in and hot water out. Ball valves should be built into each of them for ease of operation. You also need two holes for mounting the heat exchanger. Another hole will be needed for the drain valve, which is located at the bottom of the device.