Home / Heating

Back

Published: 05/13/2020

Reading time: 6 min

0

10713

Modern heat supply schemes have an extensive heating network, with several heating circuits. Despite the good thermal efficiency of such systems, serious hydraulic problems arise. Due to high resistances in the network, heating water is not always correctly distributed along the circuits, which causes an imbalance in the system.

The correct piping of the boiler with a hydraulic arrow can level the situation. This coolant distributor operates reliably in three piping schemes and can be installed in any position

- 1 What is a hydraulic arrow

- 2 Purpose of the hydraulic arrow 2.1 In which case you can’t do without it

- 2.2 Operating modes

- 5.1 How to choose a hydraulic gun

What is a hydraulic arrow

A hydraulic arrow (hydraulic or hydrodynamic separator, hydraulic separator) is a high-quality plumbing device that I install in the piping circuit of the boiler unit and the in-house system to distribute heating water flows across several heating circuits, including to an external boiler and heated towel rail.

Separator for multiple circuits

The shape of the design is made with a round or square cross-section and has 4 connecting threaded or flanged pipes: upper inlet, lower outlet, and the rest for distribution heating circuits (CD).

The dimensions of the hydraulic arrow are determined by the thermal power of the boiler and will depend on the number and estimated hourly volume of the coolant according to the CO. Standard equipment of the hydraulic arrow:

- pressure gauge, thermometer;

- temperature sensor;

- thermoregulatory valve;

- shut-off and control valves;

- line for feeding the network;

- drain line.

Improved modifications combine the functions of a flow distributor, temperature control of heating circuits and a separator for releasing air and removing suspended particles from the internal boiler.

To do this, porous deaeration plates are installed vertically at the top of the structure. The sludge collector and magnetic trap are located at the bottom of the housing.

Specifications

After a comprehensive calculation of the heat loss of buildings has been made and the required power for heating the hot water supply and other consumers who do not take part in the process of heating the room has been determined, it is necessary to determine the required power of the heating boiler. This power corresponds to certain values of the input characteristics of the difference and temperatures in the base coolant circuit.

Domestic distribution manifolds and hydraulic separators do not generate thermal energy, but only transfer coolants. Consequently, the total power of the hydraulic separator and the distribution manifold of domestic production is a relative temperature value for individual heating systems. The use of the Proxytherm distribution manifold makes it possible to comprehensively reduce the total financial costs when creating a local heating circuit in a single organization.

Purpose of the hydraulic arrow

Hydroarrow is a component of the heat supply circuit that connects different KOs. The device ensures the minimum permissible pressure drop across the circuits, which makes it possible to safely shut down one or a number of circuits without a pressure surge in the remaining ones.

Therefore, the use of a hydraulic distributor in heating systems eliminates the impact of the pump in the boiler circuit on the performance of circulation pumps operating in the heat removal circuits and vice versa.

In what case can you not do without it?

The hydraulic arrow is effective for home heating schemes that have several independent heating circuits. Very often, especially when installing a European-assembled boiler, the manufacturer requires the mandatory installation of such a hydraulic separator in the wiring diagrams of heating sources.

Conditions for the mandatory installation of a floor-standing boiler water gun:

- for boiler units with thermal power above 50 kW that are under warranty;

- for branched circuits that require the creation of reliable hydraulic conditions and thermal balance;

- with a parallel connection of the hydraulic arrow with consumption circuits for minimal losses in pressure and heat energy;

- to ensure the calculated temperature difference between supply and return;

- to prevent water hammer in the heating network;

- if necessary, equalize the flow of heating water in the boiler and heating circuits;

- if it is necessary to balance the operation of several circulation pumps;

- if necessary, reduce the hydraulic resistance of the system.

Operating modes

There are three modes for piping the heating system with a hydraulic arrow. The first is when the electric circulation pump of the boiler unit pumps the entire volume of coolant in the internal heating circuit.

This option is very rare in reality. A modern automatic control system for heating systems works with thermostats that control the heating output of the boiler; it is practically impossible to ensure a constant flow of circulating water with such regulation.

The second option for the operation of the hydraulic arrow is installed when the water flow in one or more heating circuits is greater than the productivity of the electric boiler pump.

This can happen, for example, when the pumps are selected incorrectly. In this option, in order to ensure the required water flow in the circuit, return flow is supplied to it in addition to the heated coolant.

This option is undesirable for boiler operation, since it will greatly underestimate the water flow from the circuit, and the temperature difference between hot and cold water in front of the boiler will increase, which is not acceptable for all modifications of units.

The third piping mode is the most effective, designed for high productivity of the boiler pump, more than all boilers need.

In this situation, a portion of the supply coolant will be sent back to the boiler through the recirculation line, the water temperature will increase and, when the set temperature is reached, it will begin to operate in minimum mode. The system will achieve thermal balance, so the equipment will function with high efficiency.

Purpose and principle of operation

A hydraulic arrow is needed for branched systems in which several pumps are installed. It provides the required coolant flow for all pumps, regardless of their performance. That is, in other words, it serves for hydraulic decoupling of the heating system pumps. That’s why this device is also called a hydraulic separator or hydraulic separator.

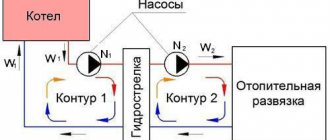

Schematic representation of the hydraulic arrow and its place in the heating system

A hydraulic arrow is installed if the system has several pumps: one on the boiler circuit, the rest on the heating circuits (radiators, water floor heating, indirect heating boiler). For correct operation, their performance is selected so that the boiler pump can pump a little more coolant (10-20%) than is required for the rest of the system.

Why do you need a hydraulic arrow for heating? Let's look at an example. In a heating system with several pumps, they often have different capacities. It often turns out that one pump is many times more powerful. All pumps have to be installed nearby - in the manifold unit, where they are hydraulically connected. When the powerful pump turns on at full power, all other circuits are left without coolant. This happens all the time. To avoid such situations, they install a hydraulic arrow in the heating system. The second way is to spread the pumps over a long distance.

Operating modes

Theoretically, three modes of operation of a heating system with a hydraulic arrow are possible. They are shown in the figure below. The first is when the boiler pump pumps exactly the same amount of coolant as required by the entire heating system. This is an ideal situation that occurs very rarely in real life. Let's explain why. Modern heating adjusts its operation according to the temperature of the coolant or the temperature in the room. Let's imagine that everything was calculated perfectly, the valves were tightened, and after adjustment, equality was achieved. But after some time, the operating parameters of the boiler or one of the heating circuits will change. The equipment will adapt to the situation, and the equality of productivity will be violated. So this mode can last a matter of minutes (or even less).

Possible operating modes of a heating system with a hydraulic separator

The second mode of operation of the hydraulic switch is when the flow rate of the heating circuits is greater than the power of the boiler pump (middle picture). This situation is dangerous for the system and should not be allowed to happen. This is possible if the pumps are selected incorrectly. Or rather, the boiler pump has too low a capacity. In this case, to ensure the required flow rate, coolant from the return line will be supplied to the circuits along with the heated coolant from the boiler. That is, at the boiler outlet, for example, 80°C, into the circuit after mixing cold water, for example, 65°C (the actual temperature depends on the flow deficit). After passing through the heating devices, the temperature of the coolant drops by 20-25°C. That is, the temperature of the coolant supplied to the boiler will be, at best, 45°C. If we compare it with the output temperature - 80°C, then the temperature delta is too high for a conventional boiler (not a condensing boiler). This mode of operation is not normal and the boiler will quickly fail.

The third operating mode is when the boiler pump supplies more heated coolant than the heating circuits require (right figure). In this case, part of the heated coolant is returned back to the boiler. As a result, the temperature of the incoming coolant rises, and it operates in a gentle mode. This is the normal operating mode of a heating system with a hydraulic arrow.

When is a hydraulic arrow needed?

A hydraulic arrow for heating is 100% needed if the system will have several boilers operating in a cascade. Moreover, they must work simultaneously (at least most of the time). Here, for correct operation, a hydraulic separator is the best solution.

If there are two simultaneously operating boilers (in cascade), a hydraulic arrow is the best option

Another hydraulic arrow for heating can be useful for boilers with a cast iron heat exchanger. Warm and cold water are constantly mixed in the hydraulic separator tank. This reduces the temperature delta at the boiler outlet and inlet. This is a blessing for a cast iron heat exchanger. But a bypass with a three-way adjustable valve will cope with the same task and will cost much less. So even for cast iron boilers located in small heating systems, with approximately the same flow rate, it is quite possible to do without connecting a hydraulic arrow.

When can I deliver

If the heating system has only one pump - on the boiler, a hydraulic arrow is not needed at all. You can get by if one or two pumps are installed per circuit. Such a system can be balanced using control valves. When is the installation of a hydraulic arrow justified? When the following conditions exist:

- There are three or more circuits, all of very different power (different circuit volumes, different temperatures required). In this case, even with perfectly accurate selection of pumps and calculation of parameters, there is a possibility of unstable operation of the system. For example, a situation often occurs when the radiators get cold when the floor heating pump is turned on. In this case, hydraulic isolation of the pumps is needed and therefore a hydraulic arrow is installed.

- In addition to radiators, there is a water-heated floor that heats large areas. Yes, it can be connected through the manifold and mixing unit, but it can force the boiler pump to work in extreme mode. If your heating pumps often burn, you most likely need to install a hydraulic arrow.

- In a medium or large volume system (with two or more pumps), you are going to install automatic control equipment - based on coolant temperature or air temperature. At the same time, you don’t want/can’t adjust the system manually (with taps).

An example of a heating system with a hydraulic arrow

In the first case, a hydraulic connection is most likely needed, in the second, it is worth thinking about installing it. Why just think? Because these are significant expenses. And it’s not just the cost of the hydraulic gun. It costs about $300. You will have to install additional equipment. At a minimum, you need manifolds at the inlet and outlet, pumps for each circuit (with a small system, you can do without them), as well as a pump speed control unit, since they can no longer be controlled through the boiler. Combined with the installation fee for the equipment, this “add-on” amounts to approximately two thousand dollars. Quite a lot indeed.

Why then install this equipment? Because with a hydraulic arrow, heating works more stable and does not require constant adjustment of the coolant flow in the circuits. If you ask the owners of cottages whose heating is made without a hydraulic separator, they will tell you that they often have to reconfigure the system - turn the valves, adjusting the flow of coolant in the circuits. This is typical if different heating elements are used. For example, there is a heated floor on the ground floor, radiators on two floors, heated utility rooms in which it is necessary to maintain a minimum temperature (garage, for example). If you expect to have approximately the same system, but the prospect of “adjustment” does not suit you, you can install a hydraulic arrow for heating. If it is available, each circuit receives as much coolant as it requires at the moment and does not in any way depend on the operating parameters of nearby pumps in other circuits.

Installation location

For proper installation of hydraulic arrows, follow 5 general rules:

- For proper operation of the distributor, it does not matter in what position the hydraulic arrow is installed. The only important thing is the direction of the end pipelines, on which the operation of the automatic air vent and the sludge removal system depend.

- The distributor is installed after the boiler valve. The installation location is determined by the heating circuit; it is located as close as possible to the unit.

- If a collector circuit is used, the distributor is placed in front of the boiler unit.

- If it is necessary to connect an additional electric pump, the distributor is placed between it and the outlet pipe for the heating circuit.

- In order to properly connect the solid fuel unit, the hydraulic arrow is connected to the coolant outlet and inlet, then you can adjust the individual temperature for each circuit.

Hydraulic heating device

A hydraulic separator is a vertical hollow vessel made of large-diameter pipes (square profile) with elliptical plugs at the ends. The dimensions of the separator are determined by the power (kW) of the boiler and depend on the number and volume of circuits.

A heavy metal casing is installed on support posts so as not to create linear stress on the pipeline. Compact devices are attached to the wall and placed on brackets.

Stainless steel hydraulic arrow

The hydraulic connection pipe and the heating pipeline are connected using flanges or threads.

The automatic air vent valve is located at the top point of the housing. The sediment is removed through a valve or a special valve, which is cut into the bottom.

The material for the manufacture of the hydraulic arrow is low-carbon or stainless steel, copper, polypropylene. The body is treated with an anti-corrosion compound and covered with thermal insulation.

Hydraulic jib "Meibes"

Calculation of hydraulic arrow

The hydraulic distributor is calculated using formula D to take into account the maximum mode according to the factory parameters of the boiler:

D = 3*d=1000* √ (4*Q)/(π *3600*ω)=18.8*√G/ ω,mm

Calculation of the diameter of the hydraulic valve taking into account the design thermal power of the boiler unit and the temperature difference between the forward and return lines:.

D = 3*d=1000* √ (4*P)/(π *C* ∆T*ω)=17.4*√G/(ω* ∆T), mm

Diameter of the hydraulic arrow pipe for incoming coolant:

d = √ (4*Q)/(π*V), mm

Where:

- D — D of the distributor body, mm;

- D — D of the inlet pipe, mm;

- P is the design heat output of the floor-standing boiler, kW;

- G is the highest coolant flow through the distributor, m3/hour;

- C—heat capacity of water, W/(kg*C);

- V is the speed of water through the CP, m/s;

- Q is the estimated hourly water consumption in KO, m3/h.

Additional functions of hydraulic guns

Improved models combine the functions of a separator, temperature controller and separator. The thermostat valve provides the temperature gradient of the secondary circuits. The release of dissolved oxygen from the coolant reduces the risk of erosion of the internal surfaces of equipment. Removing suspended particles from the flow extends the life of the impeller and bearings of circulation pumps.

The photo shows a cross-sectional model of a hydraulic arrow for heating:

Hydraulic arrow device - cross-sectional view

Horizontal perforated partitions divide the internal volume in half. The supply and return flows touch in the “zero point” zone and slide in different directions without creating additional resistance.

At the top, in the high-temperature zone, there are porous vertical deaeration plates. The sludge collector and magnetic catcher (magnesium anode) are located in the lower part of the housing.

Design options for the water gun: pressure gauge, temperature sensor, thermostat valve and line for powering the system at startup. Complex equipment requires adjustment, regular inspection and maintenance.

The principle of operation of a manifold with a hydraulic arrow for 3 heating circuits

Buy or make it yourself

A ready-made set of European-assembled hydraulic guns with auxiliary equipment in the retail chain costs from 200 to 300 US dollars.

The user who purchases such a design will receive all the advantages of its operation in the heat supply system: fuel economy, reliable thermal and hydraulic conditions in the network and durability of the main boiler equipment.

Simple diagram of a hydraulic separator

Factory assembly solves not only distribution issues, but also protection of the system from water hammer, corrosion and sludge deposits in internal heating surfaces. All structural components are carefully calculated, manufactured using modern technology and adjusted in the factory.

Those home craftsmen who want to save money on distributors have plumbing experience and all the necessary equipment can be advised to make the hydraulic switch themselves, fortunately today there are quite detailed manufacturing methods and schemes on the Internet. The device belongs to complex hydraulic products and when performing them, the following must be taken into account:

- The drives must have a symmetrical, well-cut thread.

- The wall thickness of the pipes is chosen to be the same.

- The quality of welds must be high.

How to choose a hydraulic gun

The hydraulic arrow works effectively only if it is selected correctly. The basic characteristics when choosing a distributor are the thermal power of the boiler and the total hourly water consumption for all boilers. It should not exceed the hourly water flow through the boiler circuit.

Next, pay attention to the design features of the hydraulic arrow:

- cross-sectional shape - square or round

- number of pipes: 4, 6 or 8 inputs/outputs;

- water supply/discharge option;

- method of installation of pipes - on a common axis or with alternation.

Experts advise purchasing ready-made structures with pressure gauges, an air vent and a sump for cleaning the water circuit from sludge for wall-mounted boilers and hydraulic taps.

Heating comb, distribution manifold.

Heating distribution manifold

If we imagine this wiring in its simplest form, then:

This is a pipeline closed at one end and with several outgoing pipes connected to heating devices.

The number of outgoing pipes depends on the conditions of use and the number of radiators. Thanks to the comb, the fluid flow in the pipes is optimized. It also smoothes out pressure drops in the system. The manifold distributor is used in radial distribution due to the presence of separate coolant outlet and supply pipes for each battery. It is this device that ensures uniform heating of the radiators and the possibility of their separate adjustment. In addition to the above advantages, the collector allows you to include additional equipment into the overall system. designs. (for example: pool heating).

Heating distribution manifold

Summarizing the above, we can highlight the following positive aspects of the distribution manifold:

1. Thanks to the design features, uniform heating of the radiators is ensured. It is also possible to adjust the temperature in each individual room. 2. The entire heating network will be protected from water hammer, which will affect its service life. 3. Possibility of installing additional devices to increase its functionality.

There are also two types of collectors based on their operating principle. There are combs for boiler rooms and local ones.

- In the first type, the supply part delivers liquid to individual parts of the heating system and is therefore equipped, in addition to taps, with circulation pumps. In addition, it has various sensors: pressure, temperature control and hydraulic arrow.

Heating distribution manifold with circulation pump

The hydraulic arrow serves to completely replace the cooled coolant with a hot one.

- The second type has smaller dimensions and the principle of its operation is as follows: unlike the first type, the coolant is diluted here. A special sensor is responsible for maintaining the constant temperature, which is triggered if it drops. It allows access to hot water from the boiler by opening a special valve. As a result, the cooled liquid mixes with the hot liquid and becomes the optimal temperature. Instead of a hydraulic needle, an additional circulation pump is used here. To achieve increased efficiency of the heating system in the same house, it is recommended to install both types of combs.

Correct piping of the boiler with a hydraulic arrow

The hydraulic needle, to which it is planned to connect more than 3 heating circuits, is usually manufactured together with manifolds - supply and return. The distributor is installed in such a way as to equalize the pressure between them.

Strapping scheme

The standard scheme for piping the boiler and connecting the hydraulic switch to the heating system is as follows:

- An electric circulation pump is mounted on the supply pipe, which should ensure uninterrupted movement of water in the hydraulic separator.

- After the circulation pump, a hydraulic arrow is mounted to form a small boiler circulation circuit for the floor-standing boiler.

- The section of the network between the hydraulic valve and the boiler on the return line is divided by inserting a check valve, which prevents recirculation of the coolant.

- For complex heat supply systems, additional supply and return collectors are installed.

Thus, the main task of the hydraulic switch is to create a reliable hydraulic regime in the heating circuits of the intra-house network. The basic elements of the piping with a hydraulic arrow are a boiler unit or a group of them and electric circulation pumps. Correct piping of the boiler with a hydraulic arrow will be carried out provided that the water flow in the boiler circuit is 10% greater than the total flow in all heating circuits of the house.

How to select parameters

The hydraulic separator is selected taking into account the maximum possible coolant flow rate. The fact is that at high speeds of liquid movement through the pipes, it begins to make noise. To avoid this effect, the maximum speed is assumed to be 0.2 m/s.

Parameters required for the hydraulic separator

By maximum coolant flow

To calculate the diameter of the hydraulic arrow using this method, the only thing you need to know is the maximum coolant flow that is possible in the system and the diameter of the pipes. With pipes everything is simple - you know which pipe you will use for wiring. We know the maximum flow that the boiler can provide (it is in the technical specifications), and the flow rate through the circuits depends on their size/volume and is determined when selecting circuit pumps. The flow rate for all circuits is added up and compared with the power of the boiler pump. A large value is substituted into the formula to calculate the volume of the hydraulic needle.

Formula for calculating the diameter of a hydraulic separator for a heating system depending on the maximum coolant flow

Let's give an example. Let the maximum flow rate in the system be 7.6 cubic meters/hour. The permissible maximum speed is taken as standard - 0.2 m/s, the diameter of the pipes is 6.3 cm (2.5 inch pipes). In this case we get: 18.9 * √ 7.6/0.2 = 18.9 * √38 = 18.9 * 6.16 = 116.424 mm. If we round, we find that the diameter of the hydraulic needle should be 116 mm.

According to the maximum boiler power

The second method is to select a hydraulic needle according to the boiler power. The estimate will be approximate, but it can be trusted. The boiler power and the difference in coolant temperatures in the supply and return pipelines will be needed.

Calculation of hydraulic arrow according to boiler power

The calculation is also simple. Let the maximum boiler power be 50 kW, the temperature delta be 10°C, the diameters of the pipes be the same - 6.3 cm. Substituting the numbers, we get - 18.9 * √ 50 / 0.2 * 10 = 18.9 * √ 25 = 18.9*5 = 94.5 mm. Rounding, we get the diameter of the hydraulic needle 95 mm.

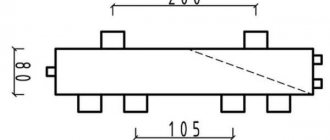

How to find the length of the hydraulic arrow

We have decided on the diameter of the hydraulic separator for heating, but we also need to know the length. It is selected depending on the diameter of the connected pipes. There are two types of hydraulic arrows for heating - with taps located one opposite the other and with alternating pipes (located offset from one another).

Determining the length of the hydraulic arrow from a round pipe

It is easy to calculate the length in this case - in the first case it is 12d, in the second - 13d. For medium-sized systems, you can select the diameter depending on the pipes - 3*d. As you can see, nothing complicated. You can calculate it yourself.