Hello, friends. Customers often ask questions related to heating with water heated floors (WHP). The quantity and quality of these questions allowed me to form a whole list of misconceptions. It is unfortunate to note that many heating system design engineers are just as susceptible to these misconceptions, let alone simple self-builders.

These are the misconceptions and questions:

- A water-heated floor in a house cannot cope with heating.

- Warm floors are harmful to health.

- Warm floors cannot be more economical than radiators.

- In small rooms there are only radiators.

- The warm floor is dusty.

- A warm water floor dries the air.

- High price of water heated floor.

- There is no need to install warm floors under the furniture.

- What diameter and laying pitch should I choose?

- What thickness of screed is needed?

- What program can I use to calculate the laying pattern?

- What to do if the water heated floor breaks?

- Which coating with VTP should I use?

- How to make an HTP in an apartment building?

- How to insulate interfloor ceilings?

Let's figure it out together.

A water-heated floor without radiators will not cope with heating

This misconception goes back to the past, when windows were made of wood, and little attention was paid to insulating walls, attics and basements.

In such conditions, attempts to keep up with fashion naturally led to disappointment. That is, floor heating without taking into account the heat losses of the building will lead to failure.

Modern building codes and materials have reduced heat loss to an acceptable 50-70 W/m2 of house area. The coldest five-day period in a given area is taken as the starting point.

Thus, a well-insulated building can be heated exclusively by high-pressure heat sources, even beyond the Arctic Circle.

Video where a house is heated only with heated floors at an outside temperature of -40 °C.

Determining heat loss

In order not to make mistakes in the calculations, we recommend ordering a special thermal engineering calculation, which takes into account the following points:

- The thickness and material of the steles.

- Material and thickness of the foundation.

- The area of windows, doors and their degree of insulation.

- Climatic conditions.

Thermal engineering calculation is one of the most difficult, so it is better to entrust this matter to professionals.

Harm to health from warm water floors

This myth also has a basis. The surface underfoot, which exceeds the temperature of the human body, in the long term will provoke varicose veins, as well as a lot of negative consequences.

But who will let him warm up like that in an insulated house?

The set of rules SP 60.13330.2012 “Heating, ventilation and air conditioning” regulates surface heating to 26 °C.

European standards are softer, they allow heating up to 28 °C.

These standards are valid for premises with permanent occupancy. Utility rooms and bathrooms allow heating up to 31 °C.

The fact is that 50-70 W/m2 per meter of area, with the correct installation spacing and pipe diameter, is the maximum 28 °C.

Review of popular manufacturers

The final cost of 1 square meter of warm water floors also depends on the choice of components produced by different brands. At the moment, on the domestic market you can purchase a Rehau warm water floor, produced in Germany. The German brand guarantees high quality products and excellent consumer characteristics of the system. The affordable price of a Rehau water-heated floor allows you to save money already at the first stage of a home heating project.

Among other advantages that a Rehau warm water floor has, it is worth highlighting the following qualities:

- availability of a warranty from the manufacturer;

- environmental friendliness;

- quick installation;

- efficiency;

- Possibility of use in heating circuits of varying complexity.

Manufacturers from other countries also operate on the market, these are:

- German brand Kermi;

- brand from Finland Uponor;

- German company Oventrop;

- Turkish manufacturer Unipex;

- Ecoplastic brand from Poland, etc.

The choice of manufacturers is quite large and the consumer may not be limited to foreign brands, because in addition to those listed, companies from the Russian Federation and neighboring countries sell their products on the market at more affordable prices.

Why is underfloor heating more economical compared to radiators?

It would seem that we are heating a room of one area, where will the savings of 15-20% come from?

It's all about heat flow distribution. The radiator system is usually heated to 55-75 degrees. The heat flow is aimed at cutting off the cold coming from the windows. Convection created by the radiator lifts hot air to the ceiling, and as the air cools, it sinks to the floor. The effect is especially noticeable where the height of the room exceeds 4 meters; the temperature difference at the bottom and under the ceiling can reach 10 degrees. If people flew, such heating would look natural.

Now let's look at what happens to the floor. Its temperature of 24-28 degrees is evenly distributed over the surface. Convection is weak and the main heat transfer occurs due to infrared radiation (not to be confused with radiation). The legs perceive the most energy; already at chest level the temperature is slightly lower. “Keep your feet warm and your head cold”

Simply put, VTP heats the space that is necessary for a person and nothing extra.

Infrared film floors

The system is based on a carbon layer that covers the film. On the sides the sheets are framed with a copper busbar. It works on the principle of heating a carbon layer with electricity, followed by heat release to the external environment.

We recommend: What are the advantages of Heat plus underfloor heating?

General advantages:

- resistant to sudden temperature changes;

- IR film heats up quickly.

The downside is the rapid cooling of both film and rod sheets.

Infrared film floors

Infrared floors are divided into…

Film:

- the system is quick and easy to install;

- during dismantling, it is possible to reuse the removed structure;

- if a separate part of the system breaks down, the entire circuit will not stop functioning, since the parts are not interconnected and do not depend on each other;

- The film can be easily divided into parts of the required sizes for ease of installation, both in small passages and in large rooms.

Minuses:

- You need to choose your flooring wisely, as it may be too thin or too thick. In the first case, it may be deformed, in the second, the heating efficiency will be reduced;

- The heated floor must be laid on a completely dry surface.

Rod:

- automatic increase and decrease in energy efficiency due to increased or decreased ambient temperature;

- Laying under large pieces of furniture is permitted. Overheating is excluded;

- even if two or more parts fail, the system will function properly.

Disadvantage: mats cannot be combined with a foil backing, since due to the interaction of individual elements, both the film and the backing will be deformed.

Bedrooms should be heated only with radiators

“Experts” claim that furniture, namely sleeping places, interferes with underfloor heating and it is necessary to use radiator systems.

This myth is more difficult for me to explain than others, but I will try to dispel it from personal experience .

Few people, when building a private house, will make bedrooms or offices smaller than 12-15 m2. This area is quite enough to heat the room. Unless of course the windows in the room are French. As we know, the main heat losses of a house occur through windows.

Storerooms and utility rooms usually have small windows, resulting in low heat losses. The temperature requirements there are also low.

The only place in the house where my wife complains about heating with water-heated floors on frosty days is the bathroom on the 1st floor, with an area of 5 m2. The temperature there is room temperature, as in the rest of the house, but this is not enough for taking a shower.

Please note that the house is filled with furniture. So I think the myth about furniture preventing heating is far-fetched.

Wise choice of materials

For ease of classification, all materials for water heated floors should be divided into “accessible” and “closed”. The second one is a pipe. It will be immured in a screed, which increases the requirements for its reliability.

#1. Pipe selection

Basic requirements for a pipe for water underfloor heating:

- One circuit - one pipe.

- Joints and seams are unacceptable.

- The maximum pipe length in the circuit is 100 m.

Almost all water floors are assembled from pipes with a diameter of 16 to 25 mm. Based on material, they are divided into metal and polymer-composite.

Metal pipes

There are only two options in this category: copper and corrugated stainless steel.

Copper pipes for water heated floors are an ideal option in almost all respects. Only their cost and the complexity of installation work cover the advantage of using them.

Corrugated stainless steel is a relatively new material, but with powerful potential and good recommendations. These pipes are also more expensive than their polymer counterparts, but the rupture is not catastrophic.

Properties common to metal pipes:

- high thermal conductivity;

- immunity to overheating;

- resistance to high pressure;

- electrical conductivity.

Polymer composite pipes

Purely polymer pipes are polypropylene and cross-linked polyethylene (can be reinforced), and composite pipes are metal-plastic.

They work well in standard operating mode, but are afraid of prolonged overheating at elevated pressure. In an underfloor heating circuit, the operating mode for polymer pipes is optimal - the coolant temperature is much lower than the limit values.

#2. Choice of insulation

Rigid polymer foams are almost always preferred. Mineral wool thermal insulators have comparatively low thermal conductivity, but they are susceptible to dampness and tend to caking.

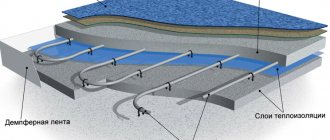

There is also a choice among polystyrene foams, but in practice, specialized heat insulators made from extruded polystyrene foam are almost always used. They can be produced in the form of smooth slabs or mats with bosses. In the first case, the pipe is fixed with mounting anchors or brackets, and in the second it is pressed between the protruding stumps of the bosses.

The pipe is held very firmly. The heat insulation sheets must be fixed to the base and the joints taped.

A damper tape is laid around the perimeter of the room. In addition to compensating for the thermal expansion of the screed, it also acts as a heat insulator.

#3. Other components and manifold

The manifold regulates the flow of coolant into the circuit. This is a whole conglomerate of parts and devices designed to connect several circuits.

Each circuit is controlled independently: the thermostat receives data from temperature sensors or an external control unit, and then changes the clearance in the pipe through a servo drive.

In general, the collector can have different designs: brass, stainless steel or polymer. But plastic ones are not in demand.

The flow meter included in the collector serves to equalize the coolant flow in circuits of different lengths. The setup is complicated, but one-time.

A three- or two-way valve is connected to the system before the manifold to mix hot and cooled water.

The pump can only be a circulation pump. The defining parameters are flow and pressure.

Circular pump

The flow rate is calculated using the formula: V = 0.86 * W/TΔ, where W is the installed thermal power, and TΔ is the difference in supply and return temperatures. For example, a cottage requires 20 kW of thermal power, set TΔ to 5˚C, we get (0.86 × 20)/5 = 3.44 m3/h. If we increase TΔ to 10˚C, then (0.86 × 20)/10 = 1.72 m3/h.

The pressure is calculated using a more complex formula, because on the equipment this parameter is indicated in “vertical column meters”, and the system operates with a pipeline located in a horizontal projection.

#4. Boiler selection

Basic parameters of the boiler: power and type of fuel. For individual houses there is an average rule when choosing a boiler - 0.1 kW/m2. Those. for a cottage of 200 m2 you will need a boiler with a capacity of 20 kW.

But as the quality of the house’s thermal insulation improves, the boiler power may be reduced.

Professional design of a water heated floor is more profitable because it allows you to more accurately select a boiler based on performance, avoiding cost overruns. After all, the heat loss of an object with the specific characteristics of the enclosing structures will be calculated.

The type of fuel affects automation and efficiency. Absolute controllability is only achievable in electric boilers. But electricity is the most expensive energy carrier. It is most profitable to heat with gas.

Even solid fuel boilers (pellet boilers) are subject to automation.

The most profitable boilers for underfloor water heating are low-temperature or condensing. They have two advantages:

- They remove heat from combustion gases through a second heat exchanger.

- The maximum outlet water temperature is 60.

The efficiency of condensing boilers exceeds 100%.

#5. Poor quality materials and possible consequences

Nobody wants to buy low-quality goods, but everyone wants to save money. This is what can lead to tragedy. Failure of the safety group in the water heated floor system in a certain combination with other factors can result in a boiler explosion and fire.

Cheap metal-plastic pipes purchased from an unknown supplier can be successfully laid into a circuit, then checked by crimping. But after they are filled with screed and put into operation, they may leak or even burst. This is not a fire, but major repairs are guaranteed.

The collector can be assembled with your own hands from components from different manufacturers. It can work very well for a year, two or three. But the guarantee that it will function at all is given not by the manufacturer, but by the assembler of the device.

Branded equipment can also break down and fail. But this happens in exceptional cases, and, depending on the type of warranty, the company compensates for the costs of repairing and restoring the system.

Warm floors dry out the air

It's hard to pinpoint where these misconceptions come from, but it does dry out shoes. You can also dry your shoes on a radiator. Does this prove the dry air theory?

The intensity of heat transfer is characterized by the amount of heat transferred per unit of time through a unit of surface at a temperature delta between the surface and the environment.

Radiators have a small area but a high temperature, while underfloor heating is the opposite. How armchair critics concluded that the air is dry remains a mystery to me.

The air with both types of heating can be dry or humid, it all depends on the quality of ventilation and humidity outside.

Recommendations

When choosing a heated floor, take into account the functional features of the system. Also be interested in the possibility of combining heated floors with other building materials.

The advantages of heated floors often come with many disadvantages, so be careful. And no matter what floor you want, purchase products only from trusted manufacturers.

- Related Posts

- How are pipes for underfloor heating made of cross-linked polyethylene laid?

- How is the length of a heated floor pipe calculated?

- How is polystyrene foam used for heated floors?

- How to install Grand Meyer underfloor heating?

- How to install an electric heated floor?

- What is the pipe consumption for underfloor heating per m2?

Water heated floor is expensive

Like most legends, this story comes from the past. Today prices have dropped significantly. The main cost part when installing an HTP is the pipe and distributors. You need a lot of pipes!

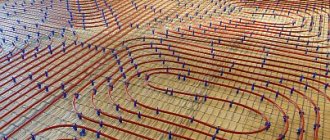

With a laying step of 200 mm - 6 linear meters per square area, with a laying step of 150 mm - 7 m/p. Let's multiply these numbers by the square footage of the house and get kilometers. But this is no longer a problem, as it was 10-15 years ago.

Domestic manufacturers have appeared that offer a meter of pipe at a price of 25 rubles. For especially thrifty people, here is a small life hack.

Good distributors, the Chinese comrades have learned to produce them. Domestic manufacturers are breathing down their necks.

You will do screeding and insulation of the first floor with any design of the heating system, so we do not include their cost in the estimate.

Bottom line: a reasonable estimate for a no-frills VTP will cost 10-20% less than an estimate for radiator heating. In addition, installation of high-voltage heating elements is much simpler for DIY installation.

Pros and cons of heated floors in a cottage

Evaluation characteristics are used only when comparing alternative solutions. Warm floors have only one real competitor - radiator heating:

| Radiators | Water heated floor | |

| Project cost | Cheaper by 20-40% both in equipment and in labor. | The price increase starts from the design stage. But this is a one-time expense! |

| Heat distribution and room heating | Heating of rooms is local, and convection currents are responsible for a comfortable temperature throughout the room. | An absolute advantage. The very principle of the underfloor heating system declares that the room is heated over the entire area at once. |

| Life time | Manufacturers provide a 50-year guarantee on high-quality radiators. But even cast iron radiators from the 60s continue to work. | The equipment warranty is 50 years. But water-based heated floors entered the Russian market about 25 years ago, so experimental testing is yet to come. |

| Availability of repairs | No difficulties even with a minimal set of tools. | An extremely time-consuming and difficult task even for professionals. |

| Inertia - adjustment | The radiators themselves react almost instantly to changes in coolant temperature, but this does not affect the heating of the entire room. When the heat supply is turned off, the radiators will cool down first. | The system responds much more slowly; noticeable changes may take up to 1.5-2 hours. But the heating will be felt immediately throughout the entire area of the room. |

| Economical | The situation is quite nasty. If two absolutely identical houses lose the same amount of heat, then to compensate they need to receive the same amount of heat from the heating system. With a typical solution, energy bills will be approximately the same. But water heated floors have the opportunity to realize the inherent potential of the system! | |

| The coolant temperature reaches 95-97˚C. The efficiency of the hot water boiler is ≈85%. | The maximum coolant temperature does not exceed 60˚C. This allows the system to be equipped with a condensing low-temperature boiler. Its efficiency can exceed 100%. | |

| Aesthetics | Even the most modern radiators will be in plain sight, which limits the designer's creative ideas. | Ideal, because the water heated floor system is not visible at all. |

| Comfort | Only next to the heating radiator. | Comfort of stay is noted by 100% of users. |

The tabular data is reliable provided that the heating systems of the cottage were installed by professional builders and on identical sites.

Should I install warm floors under furniture or not?

If we are considering electric heating cables, then laying them under furniture is contraindicated. Under a cabinet or sofa, heat transfer is minimal, which means we will get local overheating and failure of the heating element. But I would not recommend using an electric floor as your main heating system. It is more suitable for creating comfort in individual rooms.

A water heated floor in a private house is not afraid of overheating at all; it is mandatory and necessary to do it under furniture. The heat that does not disperse under the kitchen set will move to an area free from furniture and dissipate there. If you make a rearrangement, you will not have cold spots.

In addition, cold, damp corners in a country house, for example, behind a sofa, are a gift for the growth of fungus and mold.

Cable mats

Advantages of heated floors:

- Ideal for tiles and any type of floor covering;

- simple installation;

- parts of the system are independent of each other (if a section fails, the system will not fail completely).

The disadvantage of mats is their high cost, especially for mats with a two-core cable.

Manufacturers install both single-core and double-core cables. When choosing, keep in mind that a two-wire one will be more efficient.

The water heated floor broke. What to do?

VTP will refuse only for two reasons:

- First, we drilled the pipe. There is only one answer: hammer the screed and fix the leak. PE-RT can be easily soldered with a polypropylene iron; PEX will require a coupling.

- The second reason is distributor failure. It happens! Everything is simpler here - we repair or change the distributor. It should be especially noted that the number of installation connections and additional equipment for a water heated floor heating system is several times less than for radiator heating.

Hence we conclude: the simpler the heating system, the more reliable it is.

Air heated floors

This underfloor heating method was developed in Sweden and has gained recognition in many countries around the world, including the Scandinavian countries, Germany, Canada, Japan and Russia. The so-called Legalett system connects the foundation slab structure with a closed air-heated floor.

Interesting! Bedroom design with a dressing room in a modern style – 60 photo ideas

Laminate and other coatings for water-heated floors

As a covering for high-tech materials, tiles, porcelain tiles, PVC tiles, and linoleum are best suited. They transfer heat without loss.

But laminate or parquet boards are also suitable. The only thing that is required is to raise the temperature of the coolant supply by 1-3 degrees.

The main thing to pay attention to is that these coatings are recommended for use with VTP. Otherwise, they may lose their appearance, and even worse, they will smell of chemicals. I've heard that they use thin carpets, but I haven't used them myself.

Advantages and disadvantages

The advantages of heated floors include:

- the effect of using the heating system increases;

- losses of thermal energy during transportation of coolant are eliminated;

- a large heat transfer area makes it possible to reduce the surface temperature, which provides greater fuel or energy savings;

- it becomes possible to independently regulate the temperature in the room;

- the absence of convection reduces the circulation of dust and helps clean the air in the room.

The disadvantages of heated floors are considered to be:

- difficulty of assembly. Installing some types of heaters is tantamount to reassembling the floor. in addition, many designs change the floor level by 5 cm or more;

- Electric types of heaters actively consume electricity, which is reflected in the payment. At the same time, if there is a power outage, the house remains without heating;

- water structures require expenses only at the assembly stage. However, repairing such systems is extremely difficult, especially if they are immured in a screed. In addition, the installation of water systems in MKD apartments is prohibited by current rules;

- Most floor coverings, due to their specific nature, serve as a thermal energy cutoff. To work with underfloor heating systems, special types of laminate, linoleum and other coatings are required.

Expert opinion

Torsunov Pavel Maksimovich

The disadvantages of heated floors are due to the peculiarities of their design. When choosing the appropriate option, you need to study the features of all types of heaters in advance in order to immediately stop using unsuitable systems.

What type of floor should I choose for my apartment?

If you decide to install it in an apartment, then water ones should be immediately rejected.