What is an open chamber gas boiler?

Gas boilers of this type, also called natural draft devices, operate by using atmospheric air as a source of oxygen for combustion. It is thus taken from the room where the boiler is installed in the required quantity due to natural draft, which is formed due to the movement of air from the premises to the outside.

Gas boiler with open chamber

Combustion products in devices of this type are discharged through a special chimney: its presence in the boiler design is mandatory. This may somewhat complicate the installation of the unit in residential premises: there must be good ventilation there, otherwise the operation of the boiler due to the active use of air can negatively affect the health of people in the rooms.

It is therefore recommended to install gas boilers in special rooms located in those parts of the building that are located at a sufficient distance from living rooms. These premises must comply with established safety standards. Chimneys are also installed in them.

Open chamber boilers are quite easy to maintain. They are relatively inexpensive. An alternative to them may be units with a closed combustion chamber. Let's study their features.

Video description

You can clearly see the difference between single and double-circuit boilers in the video:

Is it possible to use single-circuit boilers to heat water for domestic needs? Yes, many modern models allow this. But you'll have to buy a boiler. It needs to be connected to the boiler, and in any case, the entire process, starting with the selection of a suitable model, should be entrusted to a specialist. Most consumers, however, in such situations usually simply take a separate boiler that runs on electricity.

An example of a combination of a heating boiler and an indirect heating boiler

Which option is better? Mostly they prefer double-circuit boilers: they are more convenient. But keep in mind that such models are always more expensive. The choice, in any case, depends on consumers.

Floor and wall boilers

Boilers can also differ in location in space: there are gas floor- and wall-mounted heating boilers for private homes. The latter take up less space and are generally more compact. In addition, they can be installed almost anywhere if certain requirements are met. Also, for wall-mounted boilers there is no need to organize a separate chimney: usually everything is solved through a pipe through which combustion products are removed.

What is the difference between floor-standing gas boilers for heating a house (that’s what they are officially called)? They are usually more powerful and noticeably heavier. Such models require more space: firstly, for the lining, and secondly, for the chimney. And this is not to mention the set consisting of a single-circuit boiler and a boiler. In addition, such units are quite noisy, so they are usually installed in a separate room (boiler room).

What is a closed chamber gas boiler?

This type of boiler also uses atmospheric air to burn gas. However, the combustion products of the units in question are discharged not through a traditional chimney, but through a coaxial one. This is possible thanks to the activation of the horizontal smoke removal function. A coaxial chimney is easier to install than a traditional one. Air is taken from the atmosphere by a special fan, and the action of natural draft is not used.

Gas boiler with closed chamber

The advantage of boilers of this type is that, unlike units with an open system, they do not have to be installed in special rooms; if necessary, they can be installed in residential ones. True, the rooms must have sufficient area, since a gas boiler is a very large unit.

The main design element of the fan, which removes the smoke generated in the boiler, is the electric motor. Therefore, in the room in which the gas boiler is installed, there must also be a free outlet.

Disadvantages of devices

Due to the need for constant draft, drafts occur. In addition, its strength depends on weather conditions (temperature, wind). The operation of the hood in the kitchen also affects the draft. There are other disadvantages too.

Expensive installation

Boilers with an open chamber are dangerous to install in residential premises.

For them, it is advisable to equip a separate boiler room , the size of which depends on the power of the device. The combustion chamber is thought through at the design stage of the house.

It must have windows . You will also need a reliable system for forced ventilation of the room. This significantly increases the overall installation costs.

Important! Wall-mounted models of gas boilers are also allowed to be installed in the kitchen if its volume is more than 7.5 m 3 and the ceilings are higher than 2 meters. A window with an area of at least 0.6 m2 is required.

Sometimes, to increase reliability sensors are added to gas boilers that monitor undesirable phenomena that interfere with operation (for example, weakening of draft). If necessary, the boiler automatically turns off. Such a system also requires additional costs.

Presence of a vertical chimney

A vertical chimney is necessary to remove exhaust gases. It has certain requirements:

- The cross-section of the pipe is not less than the diameter of the smoke exhaust pipe.

- The height to the first turn is at least 0.5 meters and two pipe diameters.

- A certain height of the pipe above the roof.

Photo 3. Wall-mounted gas boiler with an open combustion chamber. It is equipped with a chimney made of steel pipes.

It is determined by its location on the roof:

- no more than 1.5 meters from the ridge or on a flat roof - 0.5 m;

- from 1.5 to 3 meters to the ridge - not lower than its height;

- further than 3 meters from the ridge - not lower than a conventional line drawn from the ridge at an angle of 10° to the horizon.

Attention! The material used is steel or special polymer materials . A brick pipe will not work. It will quickly collapse under the influence of condensation.

Arranging a suitable chimney for a gas boiler is quite difficult . In addition, it is associated with certain material costs.

Comparison

The main difference between an open chamber and a closed chamber in gas boilers is that the first element of the unit’s design operates due to natural draft and involves the removal of gas combustion products through a traditional chimney installed in a special room. Preferably located at a distance from living rooms.

The second type of chamber in gas boilers involves directing air from the atmosphere into the unit using a fan, and also provides for the removal of the resulting smoke. As a result, combustion products can be removed through a coaxial chimney. It has a less complex design, as a result of which the boiler of this type can be installed in residential premises.

Having determined what the difference is between an open and a closed chamber in gas boilers, we will reflect the conclusions in a small table.

Video description

Visually about choosing power in the video:

So how to do the calculation? In general, it is best to contact experienced specialists with this. The fact is that when calculating, you need to take into account a huge number of different factors:

the presence or absence of thermal insulation, as well as its type;

year the house was built;

selected method of water heating;

And that's not all! It also matters whether the boiler is selected for townhouses or for ordinary houses (the former are usually warmer, although there are plenty of nuances here too). The calculation is also affected by the presence of other heating sources in the building, for example, heated floors. In addition, an experienced specialist always clarifies what the average room temperature should be. After all, there is a big difference between + 15 and + 23 degrees Celsius.

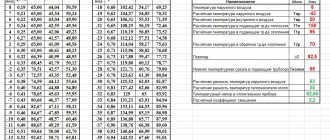

You can make an approximate calculation like this: you need to multiply the area of the house by the climate zone indicator, and divide the resulting amount by 10. This option is suitable for standard buildings with a ceiling height of up to 3 meters.

Let's say the building is located in the northern regions of Russia. There the climate coefficient is 2 kW. Therefore, the boiler must have a power of 20 kW. But for a double-circuit one, this figure must be multiplied by ¼. That is, the result is 25 kW. And remember that he is exemplary!

For an initial assessment of power, you can use the table

Which boiler is best for a private home: the issue of the chimney

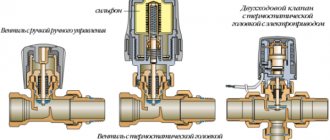

Boilers with an open combustion chamber, as a rule, do not have a chimney. But in this case, it is necessary to ensure the removal of combustion products. And keep in mind that some part may still get into the air in the room. Therefore, for the safety of people, it is best to install such boilers in a separate room.

If we are talking about a closed chamber, then forced draft is created there. And since the size and cross-section of the chimney do not affect the passage of air flow (blowing depends on the fan), installation is carried out using a coaxial pipe. It is easy to install and has a small diameter.

Turbine boilers are another option that is popular. Here the air flow is provided by a special fan. Combustion products are discharged directly to the street. Moreover, the hole is usually small (it is visible from the outside).

Table

| Open chamber in a gas boiler | Closed chamber in a gas boiler |

| Functions by using natural traction | Does not involve the use of natural draft, since air from the atmosphere is directed into the boiler using a fan |

| Involves the removal of gas combustion products through a traditional chimney | It involves the removal of gas combustion products, reduced in volume by removing the resulting smoke, through a coaxial chimney |

| A boiler with an open chamber must be installed in a special room - where it is possible to install a traditional chimney; in many cases, it is desirable to locate it away from the living rooms | A boiler with a closed chamber can be installed in a residential area (but provided that it is possible to connect a fan, which directs air into the chamber and dissipates smoke in the unit, to an outlet) |

A reliable heating boiler is the key to warmth and comfort in the home

Each consumer solves this problem in his own way, but one thing can be said with confidence: with an obsolete boiler, all energy saving measures will not give a noticeable effect. A reliable boiler, regardless of the fuel used, is the heart of any heating system. The warmth in the house, which we so need during the cold season, depends on its work. But so that the cost of heat does not ruin the family budget, the old boiler must be replaced with a new, modern and economical one.

The range of boilers is unusually large, and the consumer can choose a model designed both for heating a private home and for organizing autonomous heating in an apartment.

Harvest and storage

Harvest at the stage of technical maturity, leaving the stalk if they are going to be stored for a long time. Tomatoes are stored in a cellar or basement, where it is dry and cool. Vegetables can be wrapped in wax paper and placed in wooden boxes. There is no need to wash tomatoes before storing them. You should definitely make sure that there are no cracking or darkening on the fruits; one vegetable can cause the others to rot.

In conclusion: this variety is not suitable for canning; it is considered a salad variety and is eaten fresh. It will perfectly complement the first or second course, vegetable salad or casserole.

Floor heating boilers

These are, as a rule, high-power boilers - from 18 kW. IT CAN ONLY BE PLACED IN THE BOILER ROOM. The boiler room is a separate room. SNiPs prescribe certain requirements for boiler rooms in private homes .

Based on the number of circuits, floor-standing installations are single- and double-circuit. Double-circuit boilers, unfortunately, are characterized by unstable operation of the DHW circuit. After all, DHW, unlike a heating circuit, is not required all the time, but it requires a lot of power. Often, the second circuit can provide hot water to only one tap point, and when the second tap is turned on in parallel (for example, in the kitchen), the water becomes very cold. Models with a built-in boiler are more stable. In such models, there is a supply of hot water at any time, and the moment the tap is opened, the heating immediately turns on, i.e. The water is first consumed from the boiler and then heated by the burner. But it is still better to make a DHW system from an external indirect heating boiler. This system is more durable. Indeed, in dual-circuit models, the burner will turn on every time you open hot water, and this leads to rapid wear of the system. It's like you're driving a car and at every traffic light you turn off the car instead of idling.

Floor-standing boilers usually do not have an expansion tank, a circulation pump or a safety group. All these units must be installed separately, in the boiler room.

In floor-standing boilers, exhaust gases are usually removed using natural draft. This means that air access must be provided to the boiler room to ensure combustion, and an insulated chimney pipe must be installed according to the necessary requirements.

So which boiler should you choose? If you have a large house - more than 200 m2, with a water-heated floor system, or even more so with a swimming pool, then it will be better and more reliable to choose a floor-standing gas heating boiler with all the necessary automation.

Uninterruptible power supply or electric generator?

The main disadvantage of a wall-mounted boiler is the inability to work without electricity, which can be easily eliminated in two ways:

- By purchasing an electric generator (gasoline or diesel). But we must keep in mind that imported boilers with a closed system are not suitable for electricity generated by conventional generators. In order for the boiler to make friends with the generator, a stabilizer is also required, which converts the generated voltage into the desired type of sinusoidal shape in compliance with stable standard values.

- By purchasing an uninterruptible power supply (UPS). Since wall-mounted boilers consume, as a rule, insignificant electrical power to ignite the burner flame and operate the fan, when the power goes out, you can use an uninterruptible power supply rather than buying a generator for this.

- silent operation,

- ease of connection,

- no operating costs,

- the ability to provide autonomous operation for a long time,

- no need for consumables.

If the UPS is made using “onlain” technology (double converter), then it produces “pure sine” not only in battery mode, but also from the mains voltage.

Device selection

When choosing a specific gas boiler model, you should consider the following characteristics:

- power;

- location method;

- number of circuits;

- features of burners;

- built-in automation.

The power of the gas boiler determines how much room can be heated. If there is not enough of it, it will be too cold. And if you work too much, not only will it be too hot, but your fuel costs will also increase.

To determine the required power, a heat calculation is done. This is a calculation of heat loss through the roof, walls, windows and doors, etc. They largely depend on the materials used and the quality of insulation. And approximately the power is determined by the following formula: 1 kW is enough to heat 10 m2 of a room with a ceiling height of about 2.5 m.

Low-power models of gas boilers are available in wall-mounted versions. They take up less space and do not require a separate room. Such boilers are suitable for an apartment or small cottage.

Floor-standing models of gas boilers are located in separate combustion chambers. Dimensions depend on the power of the equipment. They are suitable for large country houses, including permanent residence.

Photo 4. Floor-standing gas boiler with an open combustion chamber. The device is connected to the water heating circuit.

Burners differ in flame adjustment. They are divided into:

- single stage;

- two-stage;

- and multi-stage.

The first type of gas burners has two possible positions: on/off. The second one adds operation at half power. In multi-stage ones the range is wider: 10-100% of performance. The more control options, the more economical the heating. But the cost of the boiler itself increases.

Automation includes not only adjusting gas burners, but also monitoring draft and coolant temperature. It reduces fuel consumption, but increases the cost of equipment and the likelihood of breakdown.

Important! Automatic operation requires electricity. If there are frequent interruptions with it, it is better to focus on simpler models that do not need it

About the negative aspects

An important disadvantage of forced-air instantaneous water heaters is their energy dependence. That is, after a power outage you will be left without hot water. You will need an electric generator or a reliable uninterruptible power supply. The remaining disadvantages of these units are not so critical:

- Buying a turbocharged gas water heater will cost twice as much as an atmospheric one. But if we compare the purchase and installation as a whole, then in the absence of a chimney duct, a coaxial pipe will cost much less than building a brick chimney or laying an insulated sandwich.

- Fans on models from some manufacturers are noticeably noisy.

- A modern forced-air heater is a complex device; its maintenance and cleaning is best left to trained service personnel. Without knowledge and skills, it is not recommended to delve inside the column yourself to find faults.

Display of a pressurized gas water heater and touch control buttons

Since we are not comparing a gas water heater with an electric storage water heater, we do not mention obtaining permits from gas services to connect water heating equipment. The procedure for registration and connection to the main line is mandatory for any gas-using installations.

But problems with installing a coaxial pipe on the façade of an apartment building are quite real. Having made a hole without authorization (even in the place required by the standards, observing all the indentations), you may encounter claims from local services, motivated by damage to the facade, drilling of the supporting structure of the house and lack of design documentation.

You can learn more about water heaters with a closed combustion chamber by watching the video:

Heat exchangers

The main element of heating boilers are heat exchangers. It is the heat exchangers that are designed to transfer energy from the burned fuel to the coolant. Naturally, metal is used to perform this function:

- Steel – Steel heat exchangers are easy to manufacture and therefore inexpensive. However, steel rusts, so the service life of steel products is short and the weight is high. The efficiency is inferior to all other materials. Steel products are preferred by domestic boiler manufacturers;

- Copper is a very convenient material for a heat exchanger, it does not corrode, heats up and cools down quickly. Copper heat exchangers are most often used in imported boilers;

- Cast iron is also not susceptible to corrosion, but due to its fragility and insufficiently careful use, cracks appear on it. Cracks can also appear due to uneven heating during scale formation during long-term operation.

Find out how to install autonomous gas heating in an apartment, how big the savings are when installing a gas boiler