Construction of solid fuel top combustion boilers

A top-combustion boiler unit belongs to the class of solid fuel heating devices, layer-type fuel combustion. The design of the firebox ensures long-term combustion of solid fuel, which means that daily maintenance of the top-burning boiler is not required.

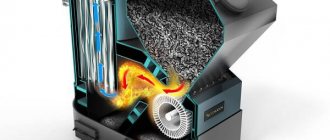

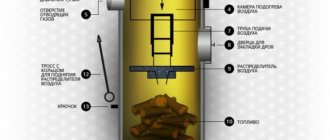

Structural features - the internal volume of the vertical body is used as a firebox. It is designed in such a way that the combustion process of solid fuel proceeds from top to bottom.

This becomes possible due to the fact that air is supplied with a slight deficit directly into the combustion zone. Due to the lack of air, the process of smoldering of solid fuel occurs, and flammable gases are released from it.

They burn out in the upper part of the combustion chamber, releasing the maximum amount of heat. This organization of the combustion process increases heat transfer and reduces specific fuel consumption due to reduced heat loss due to chemical and mechanical underburning. The combustion chamber is divided into 2 parts by an air distributor shaped like a pipe.

On one side of it there is a platform with blades for turbulent air supply, and at the other end air enters. Top combustion boilers have cyclical fuel loading. Until the first fuel fill burns out, a new portion of coal or firewood cannot be added.

Where are they used?

Long-burning solid fuel boilers are used for heat supply to municipal, industrial, commercial and public facilities. The installation conditions for such modifications of heating boiler houses are much simpler than gas ones and do not require special permits.

However, they require the installation of a separate combustion and fuel storage room so that the coal or firewood is dry before being fed into the firebox.

To generate thermal energy, long-burning boilers can also use wood waste, briquettes and pellets.

Depending on the size of the firebox, fuel is added to the unit once a day, and some modifications once every 3 days. If there is a bunker fuel supply, the loading process can occur automatically. Boilers can provide not only the heating load, but also hot water supply with the inclusion of an external indirect heating boiler in the circuit.

Installation and important nuances

To ensure a long-burning stove operates safely, follow these rules:

- At a heating distance, the use of flammable and combustible objects is prohibited.

- The chimney must be dismountable for cleaning.

- Before you begin, test to determine the optimal operating mode.

To remove smoke, use a pipe with a diameter of 15 cm and a length of 5 meters. With a smaller cross-section of the pipe, smoke will not be removed well, but with a larger cross-section, a strong draft will appear. A control valve should be installed on the chimney. Also, do not forget to remove accumulated condensate; this should be done regularly. If the chimney is of a non-demountable type, it must have doors for cleaning. You can easily prevent excessive condensation by making a sandwich-type chimney. To do this, a layer of glass wool should be laid between pipes of different diameters, and the pipe should be covered with a deflector on top to prevent rain and snow from getting in.

If there are children in the house, the stove should be lined with bricks. The masonry will act as a protective screen so that no one gets burned if accidentally touched, and the walls and objects will be protected from overheating. It will also be an excellent heat accumulator. Thus, a brick will accumulate thermal energy and release much less heat into the room than an iron body. The foundation must be installed if the floor under the stove is made of flammable material. It is not necessary to deepen it much, since the weight is not very large.

Principle of operation

Increasing the duration of the combustion process is achieved not only by a large firebox. The organization of furnace combustion in the form of layered combustion with upper combustion and upper supply of blast air has a significant impact on efficiency and heat transfer, so gas-air flows do not circulate at all in the lower fuel layers.

Operating principle of a boiler unit with long-term combustion of solid fuel: The air required for fuel combustion is taken directly from the combustion chamber and passes through a preheating stage in the upper heating chamber of top-combustion boilers.

A pipe air distributor is built into the heating chamber to supply hot air to the combustion device. The feeding system can be gravitational or forced.

The air distributor is equipped with channels directed vertically. Before loading fuel, it is raised using a built-in mechanism, then fuel is poured in and the distributor, which rests on the upper fuel level, is lowered. As it burns out, it falls down the combustion space. This movement of the distributor provides air supply to the top layer of hot fuel.

In the contact zone of the air distributor with the fuel layer there is a steel disk - a staskoblin. Bypassing it, the fire enters the pyrolysis chamber located between the disk and the air heating chamber.

Here, flammable substances burn out completely, transferring heat through the walls of the firebox to the heating fluid circulating in the built-in heat exchanger. Flue gases are discharged through the gas outlet pipe into the chimney. The ash is collected in the ash box located at the bottom of the boiler unit, under the firebox. The volume of the box allows it to be cleaned at intervals of 2 to 5 loads.

How to choose a top combustion boiler

The model range of solid fuel top combustion boilers cannot be called wide, since their production is quite new and manufacturers of boiler equipment relatively recently began to produce such models. In practice, almost all modern models have similar designs.

When choosing a boiler brand, users should pay attention to particularly significant aspects:

- The material of the boiler heat exchanger is usually steel or cast iron. The first ones are installed in cheaper versions and are less durable for no more than 15 years. Cast iron options have a service life of over 25 years/

- The boiler operating efficiency and efficiency are selected as high as possible from the available range of 85-92%.

- Dependence on electricity, non-volatile units must be installed in areas with low reliability of electricity supply, and it must be taken into account that such boilers will operate with natural circulation through water and smoke exhaust.

- Fuel loading volume, good boilers provide loading once every 3-7 days.

DIY pyrolysis rocket stove made from cans

A camping wood chip burner will always come in handy, especially since it does not require special materials or skills. Even a teenager can make it. However, for those who first tackled the issue of heating with “rocket” stoves, this will be good practice, since the operating principle is identical:

- We take two tin cans of different diameters and heights (the difference is 20–25 mm).

- Cut a hole equal to the diameter of the smaller can in the bottom of the larger can.

- We make a network of holes in the bottom of the smaller jar.

- We make a belt of holes on the wall of the smaller can at 1/5 of its height from the open edge.

- We make a belt of holes on the wall of the larger can at 1/7 of the height of its open edge.

- We insert the smaller jar into the bottom of the larger one so that the bottom of the smaller one fits the open edge of the larger one. The burner is ready.

You probably already guessed that, in principle, this is a coaxial gas pipeline system. By adding various accessories to such a burner, you can increase the volume of the fuel compartment or boil water.

If you cut a hole in the wall of a larger container and install a fan, you will get nothing more than a turbocharged RP.

Using this “pocket” option, you can conduct experiments and comparative measurements - how the material burns by itself and how it burns using secondary air.

Calculation of required heating power

Calculation of the thermal power of the boiler unit must cover all heat losses of the building with a margin of at least 20%. If the boiler must produce thermal energy to heat water, the power must accordingly increase in terms of the volume of water used in each specific case.

Calculating the heat loss of a building is quite complex; it depends on the climatic region of the facility’s location and the material of the walls and roof.

For an approximate calculation in the central region of Russia for houses with brickwork of at least 2 bricks and an interfloor height of 2.7 m, you can use the practical formula at the rate of 1 kW per 10 m2 of facility area with a margin of 20%.

For example, for a cottage with an area of 150 m2, the heating power of the boiler unit will be equal to:

150:10x1.2 = 18.0 kW

For a family of three, a domestic hot water tank of at least 100 liters with a power of 5.8 kW is required.

Thus, the total load on the boiler will be:

18.0 + 5.8 = 23.8 kW

Tools and accessories

To make your own stove, you must first determine the place where you want to place the device. This must be a room in which electricity is installed and it has a large area. Now about the materials. The easiest way is to use a steel barrel with a volume of 200 liters for the stove. But in general, the volume does not matter much; all that is required is the heat transfer of the device; you can use a gas cylinder and even a fire extinguisher. But it’s all about the volume – from a 27-liter cylinder you can make a stove for heating a bathhouse, or from a fire extinguisher a device for a very small room. The thickness of the metal is also of considerable importance, since the thicker it is, the longer the furnace will work. If nothing suitable is available, use steel sheets or thick-walled pipe. The metal must be free of damage and traces of rust.

Some other materials are also required:

- Pipes, fittings or an angle for the legs if the stove is round.

- Sheets of steel with a thickness of 0.5 cm according to the size of the end side of the furnace.

- Material for creating a sealed door.

- A pipe with a diameter of 10 cm, which will be 15 cm longer than the device.

- Pipe 5 m and with a diameter of 15 cm for the chimney.

Measuring equipment you will need is a plumb line, tape measure, building level, as well as a trowel, hammer and mallet.

The better way to heat

The most important advantage of using solid fuel boilers is their versatility in terms of fuel used: firewood, briquettes, pellets and coal.

When choosing a fuel, you need to proceed from its calorific value:

- coal, 15-25 MJ/kg;

- firewood, 15-17 MJ/kg;

- wood pellets 12-17 MJ/kg.

It is equally important when choosing fuel to take into account its combustion time in the firebox. When using firewood and briquettes, the average operating time of the boiler on one refill does not exceed 30 hours. At the same time, using pressed pellets, it is capable of heating a house for at least 72 hours.

High-tech automated coal-fired boilers can heat rooms for 5 days or even more, which significantly increases the practicality of using such units.

Today, combined modifications powered by both solid fuel and electric heating elements are especially popular.

Such thermal power equipment is characterized by practicality, versatility and easy operation. Firewood or coal is used as the base fuel, and in their absence, heating elements are turned on, which ensures the required temperature in the house.

Heat pumps

Such heat is extracted from nothing, just from the air. This is an air conditioner in reverse. The pump itself does not produce heat, it only extracts it from the medium and sends it in the desired direction.

Operating principle

The principle of operation of the pump is to take heat from the environment in which it is placed. However, the pump needs starting energy. For example, in order to move 10 kW of thermal energy, it needs to consume about 3 kW of electricity.

The difference is impressive! And if electricity is available, it allows you to choose a heat pump for economical heating of a private house without gas.

Features and prices

However, the problem is that in severe frosts such a pump malfunctions. Works well in frosts down to −15, stops working at −30. There is one more drawback - with practically free energy, the pump itself is very expensive - from 200,000 to 1,500,000 rubles.

Top 5 best models

In the trading network today you can find both relatively inexpensive and simple domestic boiler units, as well as fully functional automatic boilers from Western manufacturers of popular companies: Stropuva - a Lithuanian manufacturer, Buderus - a German boiler brand, WATTEK - a Czech boiler ACV - a Belgian manufacturer of boiler equipment and the Austrian brand Wirbel.

The most popular manufacturers of Russian companies producing long-burning boiler units are Magnum, Novosibirsk Metalworking Company, ZOTA, produced by the Krasnoyarskenergokomplekt company and Teplov Universal of the Kostroma plant.

Stropuva S 15 U

A small Lithuanian boiler with a thermal power of 15.0 kW, capable of heating a house up to 150 m2, is the best unit for heating small private houses. The S 15 U brand is versatile and can operate on any solid fuel.

The best characteristics of the boiler are ensured when using coal; when it is loaded into the combustion chamber of 217 liters, the boiler is capable of operating for 7 days with an efficiency of 86 to 90%, producing a coolant with a temperature of 75 C.

When working with firewood, you should use only dry wood to prevent the formation of tar on the walls of the firebox. The boiler has a mass of 205 kg and a service life of more than 10 years.

Price: 91,500 rub.

Liepsnele L20-U

Lithuanian boiler unit, with a more powerful unit of 20.0 kW, an analogue of Stropuva, with more advanced characteristics and therefore expensive equipment for the unit. It has the most voluminous firebox - 320 liters, and an efficiency almost equal to a gas boiler - up to 91%. The cast iron heat exchanger ensures a service life of up to 25 years.

Fuel versatility allows the use of any solid fuel, but the longest period of operation at 1 filling station, up to 7 days, is provided by coal. The maximum temperature of water leaving the boiler is 80 C.

The low working pressure of the hot medium, 1.5 atm, allows its use only in heating systems with natural coolant movement.

Price: 110,000 rub.

Galmet Top

Polish top combustion pyrolysis boiler with a thermal power of 20 kW, for heating a house with an area of 160-200 m2. This is a very modern universal modification with a 100% level of automation, a smart PID controller, an electric blower fan and weather-dependent automation.

The outlet temperature of the coolant is 55-80 C. The distinctive ability to control two heating circuits: warm floor + hot water, and also has a built-in recirculation pump.

Despite very high-quality thermal insulation, the manufacturer was unable to achieve high efficiency of the boiler; it does not exceed 87% for coal fuel. The heat exchanger is made of steel, so the service life is also not long - 15 years.

Price: 89,000 rub.

Week KO-60

A very popular model in Russia and the CIS countries with a name that is responsible for a week’s work from one load, while the chamber volume does not exceed 160 liters. The power is very high for such dimensions: peak 60 kW, and in long-burning mode 25 kW, controlled automatically and can heat an area of up to 350 m2.

The highest efficiency - 92% is achieved when using high-quality coal. This is also facilitated by the working control panel for the thermal processes of the Prond Proton 405.01 boiler and the WPA X2 blower fan to create pressurization of the boiler.

The heat exchanger and body of the unit are made of very thick combustion steel, which increases service life, although it leads to an increased weight of 420 kg.

Price: 130,000 rub.

Station wagon TA-40

Bottom combustion water heating boiler with top loading Teplov Universal 40 kW from the Kostroma plant has the ability to heat any residential and industrial premises up to 400 m2 with simultaneous preparation of hot water supply. The fuel boiler is universal, capable of operating on any solid fuel.

Automated or non-volatile unit layouts are available for sale. The efficiency of the boiler is not higher than 82% in manual mode; when using automation it exceeds 85%.

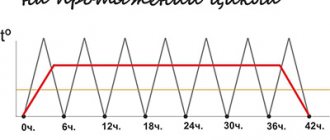

The boiler software is capable of maintaining the temperature in the house throughout the day, as well as distributing power according to the “heating - hot water” priorities in 4 modes. Price: 103,500 rub.

Solar heating

It is possible to convert solar energy into thermal energy only if the sun shines frequently and for a long time over the roof of your house. Unfortunately, 80% of Russian territories have nothing to do with this. However, even in warm climates you cannot rely solely on solar heating; a backup source is definitely needed.

Principle of operation

Light-absorbing batteries are installed in place “under the sun,” which process solar energy directly into thermal energy and then transfer it to the coolant. There are two types of solar collectors - vacuum and flat. Vacuum ones are considered the most efficient and economical. Using solar energy is an achievement of science.

The advantage of solar heating is the low price of solar collectors. Flat devices can be purchased at prices ranging from 1,500 to 60,000 rubles. Vacuum ones are much more expensive - about 80,000 rubles. However, if you consider that you don’t have to pay for fuel, the price is quite reasonable.