So, after reflection and careful analysis of possible options, a decision was made to solve the problem of autonomous supply of hot water to the apartment by installing a storage electric boiler. In the store, the required model was selected and purchased, the most suitable in terms of volume, level of automation, layout, and external design.

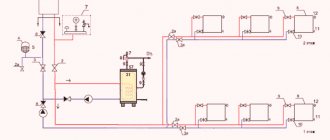

Connection diagram of the boiler to the water supply

Now it remains to solve the problem of how to connect the boiler to the water supply and power supply. You can, of course, use the services of craftsmen, advertisements for which can be found in abundance in any local newspaper. Why not try it yourself? If you have certain skills in locksmith work, then this seems to be a completely feasible task.

Issues of connecting to the power supply network require separate consideration. In this article, the emphasis will be on the correctness and safety of connecting the boiler “over water”.

Recommendations for placing the boiler

Household water heaters (water heaters) are divided into instantaneous and storage models. The first ones are compact and are usually installed under the sink in the kitchen or bathroom. On one side, a hose from a cold water tap is connected to them, and on the other, an outlet to a mixer or shower head. Connecting such equipment to water is as easy as connecting a toilet or shower stall. You just need to tighten a couple of nuts on the pipes, not forgetting about the FUM tape.

Connection diagram for storage water heater

With boilers (storage analogue) everything is somewhat more complicated. The connection diagram here is slightly different. This equipment is a boiler filled with water, in which the liquid is heated due to the operation of a gas burner or heating element. First, such a column is filled from the cold water pipeline, and then, as it heats up and is necessary, it releases “boiling water” heated to 40–750 C into the hot water pipe.

Types of boilers and water heaters

A storage water heater is installed in apartments and private houses:

But the closer it is located to the cold water supply riser, the easier it will be to connect the boiler to the cold water supply system. The distance from the pump to the water supply is shorter - fewer pipes will have to be laid. The main thing is that the wall on which you plan to mount the water heating equipment is able to support its weight.

Options for placing a boiler in the house

Types of water heaters

In individual houses, in the absence of a central water supply, water is obtained from wells or borehole sources, pumping it into the household water supply using submersible or surface electric pumps (pumping stations). At the same time, for a comfortable stay, the consumer needs hot water, which can be obtained in various ways. A popular option for a water heating unit is a gas water heater, which is installed if the house is connected to a centralized gas supply main.

If there is no gas in an individual house or apartment, the only convenient option for heating water remains (there is no point in considering a heating boiler due to the technological difficulties of obtaining consumable hot water in it) - the use of various types of electric water heaters (boilers).

Another method of heating cold water for homes without electricity and gas is wood-burning (solid fuel) heaters with the common popular name Titan.

Rice. 2 How to connect Titan - piping and design of a solid fuel dispenser

According to the principle of operation and design, all water heaters are divided into two large groups:

Flow-through. They are a tubular electric heating element (TEH) in the form of a non-insulated spiral, placed in a pipeline through which water flows, and is turned on only when water is consumed.

To ensure through heating of a large volume of water to a high temperature, you will need significant electrical power of the device, about 10 kW (it is still not enough to heat the volumes of water required to simultaneously fill a bathtub, take a shower and wash dishes). Not every wiring in a private house can withstand this power (for a comfortable supply of hot water, you will need 20 kW of heater power), and even more so in an apartment.

To supply electricity to the water heater, you will have to run a separate line using a large cross-section wire from the electrical panel, which is not always acceptable and leads to significant financial costs. Therefore, a flow-through heater is a device for small volumes of hot water consumption.

Rice. 3 Main components of an instantaneous boiler water heater

Cumulative. The design of this type of boiler consists of a container of various volumes, inside of which a heating element is placed. The water in the storage tanks is in a constantly heated state; when water is consumed, the tank is emptied and filled at the same time - this allows you to immediately use large volumes of water, which increases the comfort of living. Also, storage water heaters do not require a lot of power to operate, and tanks of any volume have a heat-insulating outer shell to reduce heat loss and protect against burns when touched.

Connection to a water pipe

To connect the water heater to cold water and hot water supply you will need:

- wrenches (it’s better to take a couple of adjustable ones);

- FUM tape;

- tees for inserting into existing pipelines;

- two shut-off valves;

- safety and check valves;

- plastic pipes or metal braided hoses;

- pipe cutter and soldering iron for plastic or corresponding fittings;

The process of connecting a boiler to water supply systems comes down to connecting two pipes (cold water inlet and hot water outlet) to the threaded pipes on the heater body. And the main point here is the correct insertion of tees for these branches into the existing water supply pipeline.

The procedure for connecting the boiler to hot water consumers

Insertion into a metal-plastic pipe

If the water supply is made of metal-plastic pipes, then compression or press fittings will be required. When connecting a water heater, the first ones are easier to work with; you need to tighten the nuts with wrenches. And the latter are more reliable, but form a permanent connection.

To install the tee, you will need to cut out a section of the appropriate size on the pipeline. To do this, it is better to use a pipe cutter, but you can also use a hacksaw with fine teeth. You just need to make sure that the aluminum layer of metal-plastic does not protrude later on the cut edge. The foil can be pulled inside the pipe, causing the latter to become narrower.

Boiler connection diagram and consumables

Polypropylene

If you need to connect the boiler to a water supply system made of polypropylene pipes, you will need a soldering iron. The incision is made in the same way as in the case of metal-plastic. Then the tee is heated on one side and soldered to the pipe, and then its second end is soldered. On the side there is a free end with a thread for connecting the outlet from the water heater.

Options for water supply schemes through the boiler

Steel pipes

You will have to tinker with steel pipes. Here you need to either take a grinder and then cut a thread to connect the tee with a die or clamp, or install an overhead clamp (“vampire”, tee-clip) and drill the pipeline.

The first option for connecting a water heater to a water supply is more difficult to install and more reliable in operation, while the second is faster and simpler, but not as durable. But here’s how to connect the washing machine drain to the sewer system - you can simply hang the drainage hose on the bathtub, or you can install a tee with a side outlet. In the second case, the reliability will be an order of magnitude higher.

With steel water pipes, everything is in many ways similar. However, both the inserted tee and the overhead clamp give approximately the same result. Moreover, if you have no experience working with an angle grinder, then it is better to use the second option.

Steel pipes are not easy to connect, so most often this option is for connecting to a boiler for industrial needs or intensive use

Choosing a location for installation

In order for the water heater to operate smoothly, and for its operation and maintenance to meet the requirements of safety and convenience, it is necessary to choose the right place for its installation. First of all, the following number of factors are taken into account:

- Dimensions. The boiler should be located so that it can be easily accessed. This is necessary not only at the time of installation and fastening, but also in the future for maintenance, repair, and replacement.

The boiler must be installed so that it is convenient to maintain, repair and configure Source dekormyhome.ru

- Reliable fastening. A storage type water heating unit must be supported by a permanent structure - a floor or a wall. Both safety and stability of performance during its daily service will depend on this.

- Strong fixation. The installation of the housing must be carried out taking into account the characteristics of the material of the building structure. If, for example, the wall has a plasterboard covering, and the anchors included in the kit are designed only for concrete, then the fastening with their help will be very weak. They need to find a more reliable replacement.

- Minimum distance to the consumer. To reduce heat loss from heated water in the pipeline, it is necessary to locate the boiler as close as possible to the main source of consumption - for example, a shower or kitchen sink.

- Accessible control. The control panel and settings of the device should be in direct and convenient access. Since the operation of a water heater in a country house is not limited to installation and connection of the decoupling, during operation it is often necessary to adjust its parameters to changing conditions.

A modern water heater is equipped with an accessible, intuitive control system Source castorama.ru

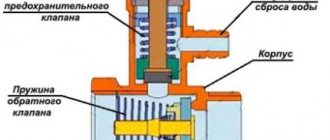

Safety valve installation

If everything is done correctly, then at the boiler outlet for cold water supply, the fittings should be installed according to the following diagram (from top to bottom of the heater):

- A tee with a tap for draining water from the boiler in case of an emergency.

- Safety valve (steam pressure).

- Check valve (to prevent water from flowing back into the pipeline).

- Shut-off valve (to isolate the heater from the water supply).

A safety valve usually comes with the water heater and is needed to prevent the boiler from rupturing due to excess steam. And the reverse allows you to avoid draining water back into the water supply when it turns out to be empty for one reason or another. This ensures the safety of the electric heating element.

Boiler connection diagram via safety valve

At the DHW outlet, a shut-off valve will suffice. But you can additionally install a drain valve. Although it doesn't make much sense. Inside the boiler, the end of the hot water intake pipe is always higher than the one intended for cold water. Therefore, in any case, more liquid will drain from the cold water inlet than from the hot water outlet.

What is a boiler and how it works

A boiler (from the English boiler) is a water heating unit in a hot water supply system, which is a container with a built-in heating element. Tubular electric heaters (TEHs) or coils through which hot coolant passes are most often used as a device for heating water.

To supply water from the broiler to plumbing fixtures and household appliances, it is necessary that it be in a container under a certain pressure.

Rice. 4 Structural design of a standard wall-mounted storage boiler

There are two main types of boilers based on the type of water heating:

Electric with heating elements. An electric heating element is placed inside the unit, which heats the water masses through direct contact.

Indirect heating. This type of equipment does not require electricity to function; inside the tank there is a coil that is connected to the heating main. Water is heated when it comes into contact with the surface of a coil connected to the boiler through indirect heating, hence the name of the boiler.

Rice. 5 Main components of an indirect heating boiler

Errors when installing a water heater

Among the main mistakes of improper installation of a boiler are:

- Replacing the safety “stall” valve with a non-return valve (this option will not protect against overheating and explosion of the boiler).

- Insufficient reliability of the fastenings (there are a lot of photos of toilets broken from falling water heaters on the Internet).

- Installing a shut-off valve or long hose between the boiler fitting and the pressure relief valve.

In the latter case, if you install a valve, then when closed it will not allow excess steam to pass to the safety valve. An explosion with such a connection scheme will be inevitable. And if you insert a hose in front of this valve, then when the pressure increases, the latter may rupture.

Connection diagram for an electric boiler to the network

Connecting an instantaneous water heater

In a flow-type boiler, water passes through its shell, and the heating element turns on only when the water flow moves in the body of the device. Therefore, overheating in this system is practically impossible and a pressure release valve is not installed in the heater.

A shut-off ball valve and necessarily coarse sand filters are placed in the cold water supply pipeline of a flow-through water heater - the absence of filter elements is a gross violation of operating rules and may cause the service organization to refuse to fulfill its warranty obligations.

Rice. 9 Examples of installation of instantaneous water heaters

System testing

After connecting to the water supply pipes, the water heater must first be checked before putting it into operation. To do this, close the DHW supply valve from the riser, and then open the hot water tap in the sink to allow the air from the boiler to escape. Then only water from the cold water supply is released into the heater. If it flows from the mixer a minute later (after filling the storage tank), then everything is connected properly. You can plug in the water heater or light the gas.

Before testing, you should check the circuit again

Types of domestic boilers

When installing a storage boiler connected to the water supply in an apartment or individual house, two types of its placement are used, which is also reflected in the design of water heaters:

Wall-mounted. Typically, small-volume tanks are hung on the walls in apartments where there is not enough free space. Traditional locations for heating boilers are the kitchen or bathroom. Also, wall-mounted units can be located on the wall surface in a vertical or horizontal position.

Floor-standing. Large-volume units are usually placed on the floor, designed to heat water in individual cottage-type houses, which have much more free space than city apartments.

Storage boilers differ in tank volume, which is selected based on the following considerations:

- To use hot water in one technical appliance, washbasin or kitchen sink, a tank capacity of 10 - 15 liters is sufficient.

- A 50-liter tank allows you to take a shower; usually this volume is used for a family of one or two people.

- A 100-liter tank should be enough to take a bath or supply water to several points at the same time - shower, kitchen sink, bathroom sink. The 100-liter volume is designed to comfortably accommodate a family of three to four people.

Preparatory work

There is nothing overly complicated about connecting the heating tank to the water supply, so you can carry out the installation work yourself.

At the initial stage you need to do the following:

- Study in detail the instructions supplied with the water heater.

- Attach the structure itself to the load-bearing wall.

- Connect water pipes to the water heater. The task will be much simpler if the thermal reservoir is located near the water supply. If it is located differently, you will need to use pipes made of metal-plastic or propylene for the liner.

- Prepare the most necessary tools. For example, a device for cutting pipes, a tape measure, an adjustable wrench, a soldering iron or a welding machine for soldering pipes.

- Buy additional materials at the hardware store - shut-off valves, fittings, tee taps, a hose for connection, an American coupling, flax tow, insulating tape.

Tools for installation work

To connect the water heater without problems, you need to prepare in advance everything you need for installation work.

List of materials and tools:

- Measuring instrument (tape tape, measuring tape or ruler).

- An electric drill with drills, a hammer drill or any impact tool.

- To attach the thermal reservoir to the wall, you will need fasteners. For example, the same anchors, brackets.

- To connect the parts you will need a mounting wrench. The kit can additionally include pliers and an adjustable tool.

- To cut into the pipeline you need to have connecting and transition tees.

- Buy shut-off valves for the inlet point into the thermal reservoir. In the future, you can turn off the equipment whenever necessary.

- Connecting materials for strength and impermeability. This is paste, tow made of flax, tape for sealing joints.

- Bendable, flexible hoses are needed to enter/exit water into/from the thermal reservoir.

When preparing tools and materials, an individual approach to connecting a heating unit to the water supply should be taken into account. For example, the project may include a bypass option or the connection of other pipes.

In such a situation, pipes are purchased according to their technical capabilities. When choosing, remember that materials have different resistance to elevated temperatures.

What is required to connect?

In order to connect the water heater to the water supply system, you will need to stock up on a set of necessary tools and materials.

During the installation process you will need:

- pipes of the required diameter;

- pipe tees;

- shut-off valves;

- sealant for plumbing work;

- flexible hoses;

- pipe cutter - manual or electric;

- soldering iron;

- several keys of different sizes.

More about the boiler as an indirect heating device

Diagram of an indirect water heater.

A double-circuit boiler always works on only one of the circuits, which is a disadvantage that remains in the scheme of a single-circuit boiler with a boiler, but the boiler still compensates for some of the shortcomings of double-circuit boilers.

Thus, in a double-circuit boiler, water in the second circuit is heated in flow mode, and to achieve the required temperature it takes from 30 to 60 s, which leads to a certain loss of water. The boiler, in conjunction with a single-circuit boiler, is a heat accumulator and, like a thermos, retains it for a long time.

Only an uninterrupted supply of gas or electricity and properly functioning primary heat sources can guarantee the normal operation of the DHW boiler. Boilers running on solid or liquid fuel are more reliable in this regard, since the amount of stored fuel must be calculated according to the required energy for heating the house, taking into account the hot water supply.

Providing hot water supply after the end of the heating season using the same heat source is impractical, if only because of its ineffective use, when a maximum of 50% of its installed capacity is sufficient. For this period of time, a wall-mounted gas boiler of low power, equipped with a heating element, should be provided. In addition, unlike powerful boilers, wall-mounted gas boilers have low inertia, which is useful for quickly heating water. The required power of the heating element only for heating domestic water will be significantly less. You can also purchase a boiler with a heating element installed in it.

FAQ

Can a water heater be installed in an unheated room?

No. The temperature difference between the outside and inside will lead to simultaneous expansion and contraction of the metal surface of the tank. It may burst at the weld seams, and if there is enamel on it, it will begin to peel off due to unevenness and crack.

Will the boiler operate with low inlet water pressure or low electrical voltage?

Yes. The water heater can even operate from a water tank installed directly above it. Water flows by gravity, and that's enough. If the voltage is lower than required, the unit will also heat the water, only much more slowly.

What should you do if water flows from the check valve in a stream?

This happens when there is high pressure in the water supply network. If it is higher than 6 bar, a reducer must be installed to reduce it. It is also possible that the cause is a faulty check valve.

I only need a water heater for the summer season. Can it deteriorate without use over the winter?

Low temperatures do not affect the condition of the water heater, but only if it is properly preserved. In winter, the water from the tank must be drained to prevent damage to the tank when it freezes.

Is it possible to install the safety valve of a storage water heater directly at the inlet, but at a distance of 25 cm?

Placing a valve at the inlet is a safety issue. You can also install it below the entrance. But manufacturers prohibit this for safety reasons. If the relay does not work and the boiler overheats, it will uproot the metal plastic before the valve operates and releases the steam.

Is it possible to install a water heater below floor level, for example in a basement?

The boiler can be placed anywhere. But keep in mind that it can work at temperatures not lower than +10, otherwise it will burst in the cold. If the power suddenly goes out or you release all the hot water and the basement is cold, this is a 100% landfill unit.

Features of connecting a floor-standing device

Such units are rarely used in everyday life, since the smallest of them have a tank volume of 100–150 liters.

In addition, they take up a lot of space and have high power, and this places serious demands on electrical wiring and safety automation. Connection to the electrical network must be made exclusively through a separate panel. All connections to the tank in a floor-standing water heater are located on the side or rear vertical wall. The direct principle of connecting to water for floor-type heaters is similar to wall-mounted models.

Installation methods

Connecting a water heater in your home is possible in two ways - to the water supply or without it using a buffer tank. Let's look at the features of each of them in more detail.

Buffer tank for connecting a boiler at the dacha Source moikolodets.ru

Connection to container

If a private house does not have a connection to a centralized water supply or supply from it occurs periodically, according to a schedule, and also when the site is equipped with an autonomous water intake system from a well, well or reservoir, the boiler must be connected to a buffer tank. The following requirements must be met:

- The capacity of the container should be several times larger than the water heater.

- The lower water level in the tank should be higher than the upper level of the boiler - to create natural pressure and convenient operation. If the difference is more than 2 meters, the water heater model must include a safety valve on the inlet pipe.

- If the height difference is less than 2 m, the tee-connector with the container is placed above the boiler, if more, then below. In this case, the safety valve in the decoupling circuit is excluded.

If the tank is used all year round, its walls must have reliable insulation to protect against icing in the cold season. To automatically monitor the filling level, the tank is equipped with a float mechanism with a sensor.

Design features and types

Electric storage water heaters are thermally insulated tanks with heating elements (heating elements) inside. They are equipped with fittings for cold water supply and hot water supply. The automation unit is responsible for maintaining the required temperature. And automatic temperature control. Indirect heating structures are additionally equipped with a working coolant area and connection lines to the heating system.

Storage water heaters can be wall-mounted or floor-mounted, horizontal or vertical. Each type of installation has its own characteristics. But in general the procedure is similar.

When installing a wall-mounted unit, it is necessary to preliminary calculate the load and compare the results obtained with the design parameters of the wall of the room on which the device is mounted. Installing a tank without calculations threatens to turn into a fatal mistake: a filled boiler can collapse along with the flimsy partition on which it was mounted.

According to the instructions on the equipment, the load must be calculated taking into account four times the weight of the boiler system. If the supporting wall is frankly weak, the water heater circuit must be supplemented with reinforced racks - through fasteners.

Crimping

This term refers to a control test that confirms the performance of equipment and plumbing. When it is carried out in an apartment or private house, a special device is used, with which water is pumped into the system and the pressure is manually increased. This is done in the following order:

- The pressure tester is connected to a water supply line filled with water. The pressure rises to 4-5 atmospheres.

- The system is inspected to identify leaks and eliminated as soon as they are identified.

- A further increase in pressure to 10-12 atmospheres is carried out after their elimination.

- In this state, the heater and pipelines to it are left for a day.

How to connect a boiler in your apartment yourself

The water heater is considered ready for operation if the maximum achieved pressure in the water supply does not change during the day.

What should you consider before starting installation?

Good preparation is the key to successful heater installation. First, it is recommended that you carefully study the manufacturer's instructions, paying particular attention to safety issues.

The next important point is the choice of location for installing the heater. Here are some useful points:

- The device must be accessible for servicing at all times.

- To install a wall-mounted model, you should choose a wall that can support double the weight of the device when fully loaded.

- It is necessary to diagnose the condition of the wiring, correct any identified deficiencies and compare the characteristics with the manufacturer’s requirements.

- Study the condition of the water supply system: pipes and risers, since the operation of the heater depends not only on the quantity, but also on the quality of the incoming water.

If the location for the heater is chosen correctly, it will be easier to install and maintain.

Features of the electrical circuit

In order to accurately install a water heater in your dacha, you must also have an idea of how to connect it to the electrical network. To do this, you must first take into account the following requirements:

- Due to its fairly high power, the boiler must be connected to the network via a separate branch.

- To ensure complete safety, the unit housing must be grounded. Therefore, the power supply must be supplied with a three-wire cable through a 3-pole socket with a connected ground wire.

Choosing a place to connect the boiler

After purchasing the desired model, you can begin making the installation connection. Initially, the water heater is attached to the surface. The wall must be made of concrete or brick to support the load of a filled water heater.

Choose a convenient place:

- The water heater must be mounted on a reinforced surface. A container filled with water can weigh more than 100 kg;

- The water heater is located on the wall near the entry point of the heated water;

- When installing, you need to focus on the practical features and dimensions of the model. Boilers can be located both vertically and horizontally. Communications can be connected at the top or bottom;

- Water heaters can be installed at different heights. But here you need to take into account the pressure of the supplied water. If it is weak, then it is risky to hang the boiler from the very ceiling, since water may not flow into it;

- The container should be located in an unobstructed location so that it is not difficult to maintain or repair.

Video instruction

Perhaps for some, mounting such a unit, and even more so connecting it to communications, will seem like labor-intensive and incomprehensible work. However, for this. To carry out installation correctly, it is enough to have minimal knowledge and it is not necessary to have a large assortment of expensive tools.

If you feel that you lack experience in carrying out such work, you can watch the video, which clearly shows step-by-step installation instructions from specialists.

Column, double-circuit boiler

The instructions for connecting a gas water heater or a double-circuit boiler to cold water and hot water systems are the same as for an electric flower: the inlet pipe is connected to the cold water supply, the outlet pipe is connected to the hot water supply. Of the additional fittings, only a coarse filter is installed at the inlet: it will prevent clogging of the heat exchanger with sand or scale.

The photo shows a gas double-circuit boiler: there is a coarse filter at the inlet

However: if the filter is located at the water supply inlet, in front of the water meter, this is quite enough to purify the water from suspended matter and large debris.

Filter in the water meter well