Hot water is one of the important components of a comfortable life for a modern person. Utilities are responsible for its uninterrupted supply in cities, but what about those who are not connected to the centralized network?

There is only one way out - to purchase and install a water heater. Such devices are varied, but as practice shows, electric storage models are in particular demand among buyers.

Installation of the equipment is quite simple and will not cause any particular difficulties for a home craftsman. And yet, let's take a closer look at how to install a storage electric water heater.

The main mistakes made when installing a boiler

If the homeowner decides to independently connect the storage water heater, under no circumstances should the following things be done:

- replace the components supplied with the device;

- connect the device to the AC power supply if there is no water in the tank;

- disassemble the device when connecting a water heating device to the electrical network;

- turn on or use an ungrounded device;

- operate equipment with inappropriate water pressure parameters in the central water supply;

- Completely drain the water from the tank while the storage boiler is operating.

And most importantly, under no circumstances should safety precautions be neglected when connecting a boiler - a fairly powerful electrical appliance. If you have any doubts about the correctness of carrying out installation work yourself, it is advisable to seek help from professionals.

To understand what water heaters are, how to connect such devices and what are the benefits of using them, you do not need to be a professional electrician or builder. All installation work can be performed by every person who is at least slightly familiar with the structure of the water supply system and can understand the simplest electrical circuits. The main thing is attentiveness, following all safety rules and, of course, desire, without which it is better not to take on such work on your own.

https://youtube.com/watch?v=HA9JlpwQXTI

Choosing a place to install the water heater

It is recommended to install boilers as close to water risers as possible. This will help reduce the length of water pipes for piping, reduce installation costs and hydraulic losses in the network. Then the device will be able to provide good pressure of hot water.

Electric water heaters are installed on load-bearing walls made of brick or other durable stone. Despite the fact that the structure itself is not heavy, when filled with water, it acquires significant weight and is capable of collapsing a weak partition.

If all these rules are taken into account, then in a small apartment there are not many free spaces left for the correct installation of an electric boiler:

- In the toilet, above the toilet, near the risers, as high as possible, almost under the ceiling, so as not to injure people.

- In a combined bathroom with a bathtub, next to the plumbing and faucet.

- Small structures up to 30 liters can be installed under the kitchen sink.

- In the corridor under the ceiling, you can place a horizontal structure.

The procedure for connecting a water heater - preliminary work

Preliminary work begins with the installation of the water heater. Moreover, first you need to choose the optimal location of the column or boiler.

The first type of heating devices - the column - should be located close to the free valve of the household gas pipeline (no further than 2-3 meters), in a well-ventilated room.

A storage boiler can be installed literally anywhere. After all, electricity and water can be supplied anywhere. But before connecting the boiler to the water supply, it is necessary to take into account the heavy weight of the filled heater and the accumulative “nature” of this device, which limits the volume of hot water consumed.

Having decided on the location of the water heating device, you need to attach the column or boiler to the supporting surface. For the boiler, this stage proceeds as follows:

- Holes are drilled in the wall for anchor bolts, the position of which can be determined by “trying on” the empty (and light) water heater to the surface.

- Next, the boiler is “attached” to the wall, driving mounting anchors into the holes through the eyes in the heater brackets.

- You then simply tighten the anchor bolts, locking the fastener into the hole.

- Finally, you connect the heater to the mains. To do this, it is advisable to draw a separate line from the central panel using a 4 mm three-core cable. Well, as a plug and socket you should use a separate residual current device - a fuse, to which the electrical line and cord from the boiler are connected. Moreover, the installation of a separate line and RCD must be completed before connecting the boiler to the water supply.

A gas water heater requires a lot of trouble:

- First, you put a galvanized sheet on the wall, the dimensions of which coincide with the supporting edge of the speaker body. However, galvanization can be replaced with tiles or fire-resistant plaster.

- Next, you “try on” the speaker to the wall, marking the location of the fasteners along the lugs of the brackets of your speaker body.

- The next step is drilling the mounting holes.

- Next, you mount the column on the anchor bolts, driving them through the eyes and tightening them until they stop.

- The last stage - connecting the dispenser to the gas pipeline - is carried out only by a representative of the territorial gas industry. Self-connection may cause an accident or a fine for illegal tapping into a gas pipeline.

After completing the installation of the heater, you can proceed to connecting it to the “cold” water supply.

Varieties

Modern household water heaters are classified according to 4 main characteristics:

- Constructions.

- The type of energy used for heating.

- Installation method.

- Mechanism of action.

Let us examine in detail their main features for each criterion.

Design and energy type

Based on structural differences and the type of energy used to heat water, boilers are divided into 4 main types:

- Electric storage.

A thermostatic container of cylindrical or flat shape, the water in which is heated by an electric heater installed in the lower part. Among the most popular. The control system can be either the simplest mechanical or electronic with a digital display.

Main components:

- Thermally insulated double-walled housing.

- Inlet and outlet pipe.

- Thermostatic element.

- heating element.

- Anode.

Electric water heater with an electronic settings panel Source rumarkets.pro

Installation and connection of such a boiler at the dacha makes it possible to preheat the required volume of water, including at night in automatic mode. The device does not contain a combustion chamber and does not have associated disadvantages, for example, the need to remove exhaust gases. However, the installation procedure is quite labor-intensive and imposes a number of requirements on the mounting location.

- Electric flow-through.

It is characterized by compactness, lightness and simplicity of the device. The weight of the device usually varies between 1-5 kg. Water passes through the heating module without being delayed. Therefore, to maintain outlet temperature stability, constant pressure in the water supply system is required.

The device consists of the following main components:

- A heating element in the form of a tube through which water flows is heated.

- Temperature indicator.

- Relay.

- Flow sensor.

Electric instantaneous water heater connected to a shower Source vipvannaya.ru

The specifics of the device and the principle of operation of the unit force manufacturers to use powerful heaters - up to 9 kW. Therefore, installation involves the mandatory installation of wiring of the appropriate profile. In addition, frequent use will lead to excessive energy consumption.

- Gas storage.

It is a separately functioning gas equipment. In order to install a storage water heater of this type in your country house or in your home, you will need to hire a special service. In addition, to ensure safety, the selection of location, room layout, and type of wall covering must meet certain technical requirements.

The unit includes the following parts:

- Double thermostatic tank with insulation between the walls.

- Inlet and outlet pipes.

- Gas-burner.

- Thermostat.

- Combustion products exit pipe.

- Anode.

- Gas module.

For proper operation of the heater, proper installation of the smoke exhaust system and ventilation is required.

Wall-mounted gas boiler Source pechiexpert.ru

- Gas flowing.

Another type of water heater that runs on household gas. It is based on a burner and a heat exchanger coil heated by it. Passing through it without delay, the water is heated and supplied at the outlet to the consumer. The heating level is regulated by the intensity of the flame and the pressure in the water supply.

- Indirect heating.

A storage tank that is not equipped with its own heating element. Water enters it in a heated form from an external thermal circuit. As a rule, this is a heating boiler. However, there are modified versions of tanks when heating elements are additionally introduced into it, heating of which occurs due to alternative energy sources - wind, geothermal or solar generators.

It consists of the following components:

- Tank with double thermally insulated walls.

- Thermostat.

- Inlet and outlet pipes.

- From 1 to 3 heat exchange circuits.

- Device to improve circulation.

3 types of indirect heating boiler Source mosoblgaz.ru

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

Installing an indirect heating water heater in a country house is possible if you have a powerful heating boiler and the need for a large supply of hot water. The tanks have a large capacity from 0.2 to 1 m³. Therefore, they are always installed on the floor and attached to the wall. At the same time, the strength of the structures must be appropriate.

Advice! When calculating the volume of a storage water heating tank, it is necessary to take into account all types of consumers - washing dishes, laundry, cleaning, bathing, showering, etc., as well as the number of people living in the house. In this case, hot water is not used in its pure form, but only diluted with cold water. Therefore, the volume at the outlet of the tap will be at least a third or a half greater than the capacity of the boiler. For example, a 120 liter tank will produce 180-240 liters of ready-to-use water.

Installation method

According to the installation method, units of this type are divided into 4 main categories:

- Wall.

Models with a capacity of up to 200 liters are allowed for wall mounting. Moreover, the heavier the unit, the more demands are placed on both the fastening system and the surface. Preference is given to load-bearing structures made of concrete, brick and wood.

An example of installing a wall-mounted boiler Source td-viko74.ru

The requirements for flow-through models are not so stringent. They can be mounted almost anywhere, following the instructions. Installation above the sink, bathtub, or in a closet is allowed.

- Floor.

Heavy storage-type water heaters - regardless of the connection diagram with or without water supply - are allowed to be installed at the dacha or in your home only on the floor. Such models come from the manufacturer complete with a special stand.

The requirements for the floor surface, its evenness and strength are set in accordance with the level of load from the unit. Distortions during its installation are not allowed. Therefore, installation is carried out strictly according to the building level.

- Vertical.

Installation of the model is possible only in a vertical position. Since the heating element is located in the lower part, this ensures optimal heating of the water without significant temperature changes. Fastening is carried out at 2 or 4 points.

Vertically installed boiler in the bathroom Source pol-doma.com

- Horizontal.

It is compact compared to the above version. Can be mounted under the ceiling. Therefore, bathrooms and other small rooms are often equipped with models of this type. The disadvantage is the lateral location of the heating element. Because of this, the heating of the water is uneven.

Mechanism of action

According to the principle of operation, water heaters are divided into 3 types:

- Cumulative.

The device is based on a tank with a heating element. The latter is usually located at the bottom of the container. Thanks to this, the water is heated more evenly. The supply occurs from below, the intake from the top, which corresponds to the natural distribution pattern of water flows.

The unit's thermostat regulates the heating level. When it reaches the desired value, the heating element turns off; when it cools down, it turns on, on the contrary. When the valve is turned on, hot water flows out of the tank, and cold water from the water supply flows in its place under pressure.

Storage water heater design Source otoplenie-gid.ru

- Flow-through.

A instantaneous water heater is much easier to connect than the option discussed above. It does not take up much space and is light weight. Its operating principle is based on heating a cold water stream as it passes through a tubular heating element.

- Indirect heating.

In an indirectly heated boiler, water passes through a coil tube located in a large volume of heated water. As a result, the flow is heated and supplied to the needs of the consumer. At the same time, water enters the container itself in a heated form from the heating circuit. Sometimes the tank can be equipped with a special additional heating element.

Preparing to connect

When planning to install a boiler yourself, you need to carefully work out the work plan. This stage is a very important one and any mistake made by the master can complicate the further process.

The stage includes the following actions:

- The master performs calculations and selects the necessary anchors. The thickness of the mounting bolts is set depending on the weight of the filled tank. Since the fasteners will be constantly under load, it is necessary to allow for an error in the calculation. It is better to take massive anchors.

- Make a hole in the wall and screw a metal base plate to it. The unit will hang on it.

- A metal strip is attached to the heating device, which is mounted on the wall. For reliability, it is tightened with bolts.

It must be taken into account that the heater must be positioned strictly horizontally or vertically. Even a slight tilt is unacceptable, so marking is carried out using a mounting level. After completing the preparatory work, they begin to connect the device to the water supply system.

Types of electric water heaters

There are two large groups: flow and storage. Instantaneous water heaters heat the water that passes through them. In this regard, they have relatively small sizes, but very high power - up to 24 kW, but this is the maximum. For washing dishes and taking a shower, a power of 4-6 kW is enough, for taking a bath - 10-12 kW. So to connect such equipment, a dedicated power line with an RCD is required.

Water heaters of various types

Storage water heaters are also called “boilers”; they have a reservoir and a small power compared to instantaneous ones - from 0.8 kW to 4 kW. However, a separate power supply line is also desirable for them. The size of boilers depends on the volume of water contained in the tank. They have a cylindrical shape, and the cylinder can be positioned vertically (cheaper option) or horizontally (cost more).

The location for installing the water heater is chosen mainly depending on the existing connection conditions. Most often this is either a bathroom or a kitchen: both rooms have water supply. Secondly, the location is chosen for aesthetic reasons: so that the equipment is not too conspicuous. From this point of view, they usually choose a toilet or a bathroom. If there is space, this choice is optimal.

Electrical connection

To begin with, we want to introduce you to the basic rules for connecting a water heater to the electrical network. Compliance with these recommendations will allow installation to be carried out as safely and efficiently as possible.

- The socket for the boiler must be located in a place inaccessible to water splashes. Experts strongly advise using special waterproof sockets for these purposes.

- The water heater can only be turned on when the ground is connected to the electrical outlet. This can be done using a three-core wire (in this case, the socket must also be designed for three poles).

After making sure that all safety rules will be followed, you can proceed directly to work. The procedure will be as follows:

- measure the distance between the installation location of the water heater and the outlet;

- disassemble the device plug into elements;

- remove the insulating material from the cable;

- we strip the veins using side cutters;

- armed with a soldering iron, we connect the wires to the plug contacts (red - to phase, yellow/green/black - to ground; blue - to zero);

- remove the water heater panel and open the contacts;

- we strip the conductors at the opposite end of the cable;

- connect them to the contacts of the device and return the panel to its place.

You can connect to the electrical network differently - connect the water heater directly to the panel. In this case, you need to proceed as follows:

- lay the cable from the device to the electrical panel;

- We install an automatic machine near the water heater;

- we run the cable through the machine;

- remove about 100 mm of insulating material from the cable;

- we expose the phase from the machine;

- We connect the phase from the machine to the upper terminal, and from the water heater to the lower terminal;

- remove the insulating material at both ends of the cable, free the cores;

- remove the boiler cover, connect the wires to the device terminal;

- turn off the current supply and connect the heater to the electrical panel.

The following video shows water heater connection diagrams and their descriptions, which will help you understand how to connect the boiler correctly.

Video description

Video on how to properly install electrical protection for a boiler:

- The cross-section of the cable conductors must correspond to the power of the boiler heating element.

- Low-power water heaters can be connected via a waterproof socket connected to the panel with a separate cable.

- Medium and high power models must be connected via an RCD. In the event of a breakdown on the housing, the device will automatically turn off the current supply to the unit.

Helpful information! Floor-standing boilers have a larger capacity, and therefore more power. Therefore, safety requirements when connecting them to the electrical network are more stringent. So, the cable connection for them must come from a specially mounted separate electrical panel.

What is required for installation?

Before installing an electric or gas boiler, you need to allocate a suitable place for it, taking into account the following points:

- placement of a water heater in an apartment or private house should be done taking into account ease of use and maintenance;

- it must be taken into account that when emptying or repairing the apparatus, a significant part of the water may spill onto the floor;

- It is convenient to connect the water heater yourself when the water supply and electrical networks are nearby and in the same room;

- Do-it-yourself installation and connection of a gas boiler involves connecting a pipeline supplying natural gas to the room.

Based on the listed conditions, the installation and connection of a storage water heater can be performed in the following areas of a private house or apartment:

- kitchen - above the sink;

- bathroom - above the bath;

- boiler room - above the tiled floor.

Before deciding how to connect the boiler to the water supply, you need to hang it from the wall. To complete all work, you will need an electric drill with an impact function (or a hammer drill), carbide-tipped drill bits and a standard set of plumbing tools, including a gas and adjustable wrench. The boiler connection diagram is assembled from the following elements and materials:

- check valve with safety valve in one housing (usually included with the boiler);

- bronze tee DN 15 (1/2");

- ball valve DN 15 (1/2") - 3 pcs., 2 of them - with American connection;

- pipes for connection (usually metal-polymer);

- FUM tape, flax or special thread for sealing joints.

https://youtube.com/watch?v=HA9JlpwQXTI

There is also an electrical diagram for connecting the boiler, according to which it is necessary to purchase differential circuit breakers for a current of 16 A (2 pcs.), a socket and plug with a grounding contact, as well as a power cable of the required length. The connection of a device operating on natural gas is carried out using a gas hose.

Tools and materials required for installation

When you plan to install a water heater yourself, you cannot do without tools. It doesn't matter what brand the boiler is. Let it be “Termex”, “Electrolux” or “Ariston”. The installation principle of storage water heaters is the same.

You will need the following tool:

- adjustable wrench and set of wrenches;

- impact drill or hammer drill;

- straight and shaped screwdriver;

- pliers;

- roulette;

- level.

You will need the following materials:

- flax or fum tape for packing threaded connections;

- Ball Valves;

- connecting tees;

- two flexible hoses or a plastic pipe for connection to the water heater pipes.

If the installation of the boiler cannot be done without replacing the wiring, you will need a cable, an RCD, a socket, and a 16 A circuit breaker.

Features of connecting a flow-through boiler

The flow-through design of an electric boiler, as in the photo, is installed directly into a branch of the water supply system intended for supplying hot water.

- The water supply in the central pipeline is cut off.

- At the point where the heating device is inserted, the pipe is cut, creating a rupture.

- Shut-off valves are attached to the ends of the breaks, which will allow repairs to be carried out in the future without shutting off the central water supply.

- Hoses connecting the boiler with shut-off valves are screwed onto the inlet and outlet pipes of the flow-through water heating system.

When independently carrying out work on dismantling heating equipment, instead of the central water supply, turn off the tap installed on the inlet pipe and only after that on the outlet pipe. Also, when using a flow-through water heating device, first turn on the water and only after that the heating device. If there is no need for hot water, then turn off the power supply and then the water.

Figuring out how to connect a boiler correctly is not that difficult, the main thing is to have the desire. But to be more confident, you can practice on pipe scraps so as not to spoil the main elements of the system. This will allow you to gain experience and avoid stupid and unnecessary mistakes.

Examples of connecting a boiler to a water supply

Storage-type equipment: device and principle of operation

The device is a thermally insulated tank of arbitrary shape. A heating element is built into it, which heats the water to the temperature set by the owner.

Electric water heaters are a practical solution for uninterrupted hot water. It is only important to correctly determine the volume of the device

It varies from 35 to 85C. In a thermally insulated container, the heated liquid maintains its temperature for 2-3 hours. After the water has cooled by 0.5C, the automation is triggered and the heater is turned on to heat the liquid.

When the set temperature is reached, the device turns off. This mode of operation allows the device to save energy.

Heaters built into the tank can be tubular or spiral. The first option is more reliable, it is not afraid of air locks, but over time it will definitely become covered with scale.

Spiral devices are not afraid of scale and they heat up an order of magnitude faster. The tank can be steel or plastic. Its internal surface is covered with enamel or glass ceramics.

To prevent the welds of the steel container from rusting, special anode rods are inserted into the tank to prevent the iron from oxidizing. They need to be changed every 5-8 years.

The standard design of the water heater includes a thermostat, which is responsible for maintaining the set temperature. The device control system can be either manual or automated.

The device can be equipped with an additional function for quickly heating water. Storage water heaters differ in volume, which, in turn, affects the rate of water heating.

The larger the volume, the longer the equipment will warm up the liquid. It is advisable to accurately calculate the need for hot water so as not to force the device to run idle and at the same time not experience a shortage of it.

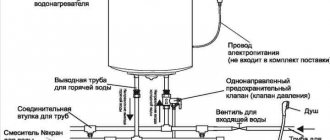

The diagram shows the general structure of an electric storage water heater

Step-by-step instructions for installing a storage boiler

The installation diagram for a storage boiler is a little more complicated. Here you will need to correctly route the pipeline, securely secure the tank, and make electrical connections.

Choosing a location for the tank and its installation

The storage container takes up a certain space in the room, so it must be placed efficiently so as not to take up unnecessary space. But at the same time, the boiler should be located as close as possible to the water supply points. The remote location of the water tap from the heater increases the wait for hot water to arrive.

Convenient placement of a storage boiler with a separate bathroom

The mounting location is selected according to the layout of the room:

- The layout in a private house is different from apartments. Here the bathroom, toilet and kitchen can be located far from each other, and one boiler must supply hot water to all rooms. Here you need to determine the important room where heated water should be supplied first and install a water heater closer to it;

- The traditional layout of the apartment provides for the combination of all these rooms, so choosing the location of the tank here will be easier.

Most often, the tank is installed above the toilet. It does not take up useful space and is located close to the sewer, which makes it convenient to drain water from the safety valve. The unit is secured to the wall with anchors. A water tank has a lot of weight, so if the wall is loose, an additional support is welded under it from a profile pipe.

Connecting the water supply

The optimal connection option is considered to be a circuit with the ability to drain water from the container.

The step-by-step execution of the work looks like this:

- The house is disconnected from the cold water supply, and the hot water riser in the apartment is additionally shut off. The collection of all components of the circuit begins from the water heater suspended on the wall. To seal the connections, flax or FUM tape is wound around the threads.

- At the bottom of the tank there are two threaded pipes. On the right is the cold water inlet, marked in blue, and on the left is the hot water outlet, marked in red. Packing begins with cold water.

- A brass tee is screwed onto the inlet pipe. It must be turned with a transverse hole in a convenient direction to drain the water. A ball valve is screwed into the same hole through a brass adapter. A pipe with a hose for draining water is connected to it. A ball valve is also screwed into the downward thread of the tee to shut off the supply of cold water inside the container.

- Now it’s time for the most important thing – the safety unit. The boiler is equipped with a safety valve, which is mounted immediately behind the lower valve on the tee. To install it correctly, there is a guide arrow on the body. On the side of the valve there is a fitting for bleeding water. A transparent reinforced hose is attached to it with a clamp and lowered into the sewer.

- Original valves are not always reliable, so they often buy a “safety group” separately. It consists of a check valve installed on the tap coming out of the bottom thread of the tee. The safety valve is installed separately on the middle outlet of the tee.

- Next, it remains to supply cold water. This can be done with any pipes, for example, metal-plastic or eco-plastic, if desired. In order not to cut the main water supply pipe, the connection can be made through a tee, installing it on the threaded connection of the toilet tank or washbasin tap.

- The hot water unit is assembled in the same way as the cold one, only without a valve. In a private house, from the outlet of hot water from the boiler, pipelines are laid to water supply points. In the apartment, the water heater outlet is connected to the hot water supply pipeline. In this case, when the boiler is operating, close the tap on the riser supplying centralized hot water.

At this point, the water heater is connected to the water supply system, all that remains is to connect the electrical wiring and can be used for its intended purpose.

https://youtube.com/watch?v=HA9JlpwQXTI

Consider the types of water heaters

Water heaters for apartments and private houses are distinguished by the type of energy carrier - these are electric and gas appliances. Electrical equipment can be storage and flow-through, while gas models operate only as flow-through devices. Heaters come in vertical and horizontal shapes, floor and wall-mounted. To correctly connect heating equipment with a tank of the required volume, it is recommended to use the following table.

Before choosing one or another model of water heating equipment, you need to have an idea of how different types of devices work.

Indirect heating devices

Indirect heating heaters operate from coolant from the heating network, which passes through the tank along a spiral heating element. It is made in most cases from copper, which has high thermal conductivity.

The coolant at this moment has its maximum temperature, since it enters this circuit directly from the boiler. The water temperature in such a water heater in most cases does not exceed 80 degrees. During intensive use of hot water, it can be reduced at the time of pumping to replenish the level in the boiler.

The peculiarity of the operating conditions is that the heating process is not carried out in a continuous mode. This means that water is not heated when there is no heating season. But it is possible to isolate the boiler circuit in a private house into a separate network and heat it at this time at the minimum operating mode of the boiler.

In addition, in any heating system, it is desirable to install a backup heating unit using an alternative fuel. Usually this is a lower power boiler.

It can be switched to a water heater via a separate circuit. At the same time, the plumbing and heating system becomes somewhat more complicated, but not so much that connecting the water heater with your own hands becomes impossible.

Indirect heating is used as a backup hot water supply system during the heating season.

Storage water heaters

The name suggests that a storage boiler has a container in which a certain volume of hot water is accumulated, necessary to meet the needs of everyone living in an apartment or house.

A thermostat is installed in the tank, which controls the heating elements, maintaining a constant temperature of the working volume of water (about 700 C.). For example, for a family of 5 people it is enough to install a storage water heater with a 50-liter tank. There are models with a volume of 150 liters.

The advantage is that the drives have a large performance reserve. Large tanks are capable of supplying hot water simultaneously for washbasins, showers and bathtubs, as well as for kitchen sinks for the entire duration of connection.

The only drawback of such units is that after the working volume of hot water is completely consumed, you have to wait for full filling and heating for an hour to an hour and a half.

Flow-through

The devices are equipped with small containers. The heating element of the flow-through heater is turned on at the moment the tap is opened. Rapid heating occurs due to the flow of liquid through a hot spiral. Unlike storage devices, flow-through models, due to the short-term effect of heating elements, cannot heat water to high temperatures.

The valve on the tap regulates the replenishment of the water level in the tank as it is consumed from a centralized water supply or a reserve tank on a personal plot.

Despite this, instantaneous heaters prove their effectiveness as backup power during seasonal and emergency shutdowns of hot water supply. They are in great demand among summer residents, who install them in shower stalls.

The disadvantage of a flow-through heater can be considered its low performance. For example, a bathtub can only be filled with warm, but not hot water, with high energy consumption.

Gas

Geysers are instantaneous water heaters. They began to be installed en masse in the USSR in the early 60s of the last century, when the country began construction of multi-storey gasified residential buildings. Heating in such devices is carried out as follows - water from the water supply enters a spiral water conduit around a copper box-shaped screen, inside which the gas burns in burners (grid-irons).

In the initial position, the gas wick is constantly burning. When you turn the tap, the water coming from the water supply opens the valve, and the gas begins to flow into the grate, where it ignites from the wick. For different models, the water temperature is controlled manually or automatically. But for everyone, when the water supply suddenly turns off, the automatic shuts off the gas supply.

The advantage of geysers can be considered high performance and efficiency. Their ability to quickly provide hot water is highly valued by consumers. Geysers can operate efficiently and safely only in conditions of centralized water and gas supply.

Connection to different types of pipes

It should be taken into account that the diagram for connecting the boiler to the water supply may differ. It depends on the pipes. The most difficult work will be if steel pipes are installed in the apartment. They are difficult to shorten or lengthen without additional equipment. The master may need a grinder and other equipment. Each case is discussed in detail on video.

Polypropylene pipes

To carry out the work, you will additionally need a soldering iron and a wood file. Tees and couplings for connections must be selected from the source material. A polypropylene coupling with metal thread is the best solution; it is reliable.

The work process is simple if the pipes are on the surface. If the communications are embedded in the wall, the top covering will have to be opened to carry out the work. It is impossible to make a connection without damaging the finish. This will require the apartment owner to spend additional money on cosmetic repairs.

Metal-plastic pipes

Metal-plastic pipes most often pass along the surface, so there is no need to additionally tap the walls. Fittings are required for installation. Any connection scheme can be used. Tees are used for insertion. A heating device is connected to them through auxiliary pipes or flexible tubes

Steel pipes

You can do without welding when working with steel pipes. To do this you will have to buy a special tee. It looks like a clamp with a bend. The principle of use is simple, it is put on the pipe and the position is fixed with clamps. For a tight fit, a seal is used. It is prohibited to use dry welding for this purpose. The reliability of this substance is not enough for the system to fully operate.

Before installing the adapter, the pipes must be thoroughly cleaned of dirt, rust and traces of old paint. A threaded hole is made in the pipeline. It is needed to connect the tap and underwater hose.

Connection sequence

When installing a heating device, a safety valve is required. It will reduce the risk of a dangerous situation and ensure full operation of the device.

When ensuring self-installation, you need to proceed according to the following scheme:

- a tee is connected to the pipe;

- install a shut-off valve to drain remaining water;

- connect the tap to the adapter;

- connect a fuse with a drain outlet;

- install a shut-off valve.

In some cases, a filter and thermostat are connected. A special filter is required if the water in the pipeline is hard. It will prevent the formation of scale on the heating element and the walls of the container.

How to work with different types of pipelines

Not so long ago, the question of what to make a water supply from practically did not exist. There have always been metal pipes of various types for this purpose.

And for faster, high-quality installation, additional parts were used - fittings to connect various pipeline elements into a single workable system. They have always been divided into threaded and welded.

Installation of metal pipeline systems

Metal water supply networks can be made of two main materials - steel or copper. Cases of installation from other types can be considered exotic.

The main connection method for steel pipes is threaded and welded. To eliminate the use of thread-cutting tools, in some cases welded threaded ends are used. The main assembly, including for pipelines of complex configurations, is carried out using fittings.

This type of connection in pipelines, such as flange, is practically not used for heating and hot water supply systems in country houses and apartments.

If it is necessary to make bends, it must be taken into account that its minimum radius for steel pipes is 2.5 times the pipe diameter. For bending at home, you can use manual mechanical or hydraulic pipe benders.

Copper pipes are installed in the same way as steel pipes. The difference lies in the connection method. Copper parts are mounted by soldering.

In this case, the ends of the pipes are often flared to ensure a reliable connection. This technological operation is possible due to the high ductility of the metal.

Connection using threaded fittings is also used. In this case, flaring of the ends is also used, but it is done at an angle of about 45 degrees.

The advantage of copper water pipes is:

- Resistance to hydraulic shocks;

- No lime deposits on the inner surface of the pipe walls.

- Durability – service life is up to 50 years.

The disadvantages include the high cost of materials.

Installation of polypropylene pipelines

Polypropylene, as an alternative material for installing water supply and heating systems, appeared several decades ago and immediately became a popular substitute for metal pipes. This became possible due to ease of installation, low weight, simplifying delivery, and long service life.

A special feature of the manufacturing material is its resistance to bending, so installation is carried out strictly along straight lines. Fittings made of the same material are used for connections.

Threaded fittings have also been developed and are used, the main application of which is to use them at the transition points from a metal pipeline to a polypropylene one, for example, when installing pipeline elements with metal casings. These can be taps, plugs, monitoring and control devices, and so on.

When using polypropylene as the main material in heating networks and hot water supply systems, it should be taken into account that the maximum temperature it can withstand without consequences is no more than 90 degrees.

This is quite enough to heat any room. When polypropylene pipes are used in extreme conditions in heating and hot water supply, their durability is about 20 years; in low-temperature water supply systems it can reach 50 years.

The connection of polypropylene pipeline elements is made by soldering. A special soldering iron is used for this.

For pipes of various diameters, the heating time in the soldering iron is from 5 to 10 seconds. It is necessary to hold the joint motionless when connecting for 15-20 seconds.

Soldering installation is carried out on a workbench, while individual network links are assembled and installed into the system “by hand”. This is less convenient and you need to use the services of an assistant.

This installation procedure excludes the installation of closed heating networks - if leaks occur, the wall will have to be destroyed.

Installation of metal-plastic systems

The use of an aluminum layer in the wall of a water pipe for both cold and hot water is caused by the need to protect the metal parts of the system from oxidation.

Oxygen from the air is able to penetrate plastic in atomic form and dissolve in water. At the same time, it acquires aggressive properties and actively oxidizes the metal, promoting failure.

To protect against this, aluminum foil is used, which is applied to the workpiece along the adhesive layer. The material is applied in a spiral, the joint is welded with a laser.

A second adhesive layer and an outer layer of plastic are applied on top of the foil. This creates an obstacle to the penetration of aggressive substances, and the method is called oxygen protection.

The installation of metal-plastic pipes differs from that described above only in the need to strip the metal layer before soldering. A special device is used for this.

The physical properties of metal-plastic pipes allow the use of bends during the installation process. This allows you to create seamless sections of water supply, in which connections are made only at the exit from the channel, hidden in the wall or floor.

This method is widely used when installing heated floors and hidden plumbing. For this reason, metal-plastic pipes are produced in coils up to 600 meters long.

The principle of drawing water from a tank

There is one correct scheme for connecting a storage water heater, taking into account the features of its design and allowing, if necessary, to quickly empty the tank. This need arises for the following reasons:

- scheduled cleaning of the tank and heating element from scale;

- occurrence of a malfunction;

- moving or replacing the device with a new one;

- emptying a water heater in a country house or in a house with periodic heating in winter.

Connecting the water heater to the water supply, the diagram of its installation and placement must take into account that water is drawn from the upper zone of the tank. This is explained by the fact that at the top the water is the hottest, and in the lower zone it is replenished with a cold flow if there is a water supply in the hot water supply system. Selection occurs through a vertical tube, the cut of which is located in the upper zone.

Water from the container must not be allowed to return to the cold water supply system, so the boiler is connected to the water supply through a check valve. If the pressure in the network drops as a result of turning off the water, the valve will prevent the contents of the tank from flowing back into the pipe.

As a result of the standard connection of the boiler to the water supply, it will not be possible to quickly empty it by opening the hot water tap. Even unscrewing the hot water pipe from the fitting will not have an effect, since the water intake is located too high, and there is a check valve on the cold side. The drainage problem is solved by a simple diagram of connecting the water heater to the water supply system, assembled at the installation stage of the device.

Application of check valve

This mechanism belongs to the safe operation system.

Its use on a pressure device is necessary. When heated, the water in the boiler noticeably increases its volume, resulting in an increase in pressure in the vessel. The extreme manifestation of this process is its rupture. As a result, the room is filled with steam and hot water, which can cause significant harm to people.

When critical values are reached, the valve installed on the boiler opens the spring damper to discharge water, which is discharged through the fitting. To dispose of it, a hose is installed on the fitting and connected to the nearest discharge into the sewerage water supply. It must be securely fastened, since the discharge can be carried out with great pressure. After releasing excess water, the spring valve closes.

The valve also has a lever for releasing water, which can be used manually.

Preparation

If you have not previously installed a boiler, then first of all decide on its future location, then select tools and materials.

Selecting a location

When searching, follow these guidelines:

- The wall must be strong, preferably load-bearing, in order to support the large weight of the tank (add the weight of the water to the weight of the device).

- Free access to communications and to the device is important, since the water heater will have to be serviced in the future.

- Do not connect the boiler to bad wiring. Typically, the power of models is from 3 kW.

- Do not connect the tank to rotten or rusty pipes.

- Choose a place closer to the pipeline so that you don’t have to cut into the system from the next room.

- An acceptable choice for installation is a bathroom or kitchen, less often a toilet or hallway.

It's actually not that complicated. Regular high-quality wiring will easily withstand an average power electric heater. There are no installation requirements or restrictions for this device.

We still recommend running a separate line from the meter to the tank to relieve the burden on the main wiring.

Tools

Tools and materials needed to install the boiler.

If you do everything from scratch, you will have to work hard. First, cut into the pipeline with cold water, make the wiring for hot water, and only then start connecting the indirect heating boiler. You will also need special tools and materials:

- metal-plastic pipes;

- tow;

- paste;

- sealing tape;

- flexible hoses for connecting the boiler and water supply;

- tees;

- Ball Valves;

- check valve;

- hammer drill (a drill is recommended only for lovers of masochism, since you will have to drill fairly deep holes in a strong concrete wall);

- roulette;

- level;

- screwdriver;

- gas or adjustable wrench;

- a set of regular keys.

How to install a instantaneous non-pressure water heater

Prepare tools and materials

- Water heater;

- spanners;

- hammer drill or impact drill;

- drill for concrete or wood;

- dowels or screws.

Select installation location

Non-pressure flowers, as a rule, are capable of providing only one water collection point, so there is no question of choosing a location. The device is installed instead of a faucet on the washbasin in the bathroom or kitchen, as well as next to the tap in the shower.

Secure the water heater

The device in the faucet form factor is the easiest to install. To do this, turn off the water on the mixer and remove the flexible hoses from it. Unscrew the faucet mounting bracket and remove it from the sink.

YouTube channel "Dachnik"

Assemble the water heater according to the instructions: attach the spout, screw in the inlet fitting and insert it into the hole in the sink. Screw in the fastening nut and tighten it to secure the flower.

Wall-mounted models will have to be mounted with dowels or screws, depending on the type of wall. Using a template or measuring the distance between the brackets, mark and drill holes. Secure the water heater with dowels or screws.

Connect to water supply

Everything is simple here too. The connection boils down to connecting the flexible hose, which you removed from the mixer, to the water heater fitting. Place the rubber gasket under the union nut and tighten it first by hand and then with a little force using a wrench.

YouTube channel Status 81

The wall-mounted flower can be powered from the same flexible faucet connection or from the shower. To do this, unscrew the watering can from the hose and connect the free end to the inlet of the water heater.

Important point! There should be no shut-off valves after the water heater. The water is turned off exclusively by the flow pipe itself or the tap to which it is connected. Otherwise, due to the lack of flow, the heating element may overheat and fail.

Connect to the mains

Compact non-pressure models usually have a ready-made wire with a plug, so the connection boils down to inserting the plug into a grounded socket. Since the water heater is a powerful device, it is prohibited to connect it through tees and extension cords. Due to the high current, the contacts in them can overheat, melt and cause a fire.

Do a test run

Turn off the tap on the hot water riser. Open the faucet and run water through the appliance. Wait a few seconds until there is a steady stream. Switch the appliance to heating mode by turning the lever or pressing the button. Check that the water is heating up.

Boiler installation.

Using the method described below, you can connect a storage water heater from companies such as Elenberg, Eltron, Etalon, Ferroli, Gorenje, Polaris, Stiebel, Thermex, Vega, Termex, Ariston, Atmor and others. It is considered the most effective option for connecting a simple vertical boiler, but first, let’s look at the design of the device.

The boiler consists of the following parts:

- heating element - element that heats water;

- Tank - maintaining the water temperature at the required level;

- Thermostat;

- Water drainage and supply systems.

The most important thing when choosing a boiler is the method of attaching it to the wall (vertical or horizontal) and the volume of the tank. Vertical devices are most often used: they take up less space than horizontal water heaters and connect to the water supply system much easier and faster

Features of choosing a water heater

The choice of water heaters in specialized stores, markets and on the Internet is now huge; they differ from each other in volume, power, type of installation, price and other parameters.

It is quite natural that anyone wants to purchase a model that would combine a reasonable price and decent quality, and at the same time have a number of useful functions.

So, what should you consider when buying a boiler , regardless of its type, manufacturer and cost:

- the design must be reliable;

- It is desirable that the water heater be universal in terms of installation, especially if you are planning to move from your apartment to your country house for the summer;

- both storage and instantaneous water heaters must simultaneously supply water to the shower and tap;

- it is desirable that the design includes a safety valve as a protective measure against malfunctions;

- the boiler must be made only from high-quality materials;

- the design must be such that the device can be installed at home with your own hands and online;

- the product must be attractive in appearance and be of high quality;

- When purchasing a water heater, be sure to ask what conditions exist for its correct operation, so that in the future it does not become unusable ahead of time.

Indirect heating boiler - what kind of unit?

This phrase means a tank filled with water, which is equipped inside with a heat exchanger coil connected to a boiler responsible for heating the house, or to another system within which some coolant circulates. The water in such a unit becomes hot due to the fact that the liquid supplied directly from the boiler to the heat exchange coil gives up its energy to the liquid located in the boiler tank itself. That is, it does not heat up directly, but only absorbs heat from another source. This is where the name for this unit came from – an indirect heating boiler.

Water heated in the unit can be used for a variety of household needs. Moreover, it remains in a heated state for a long time, since the system itself maintains the desired temperature level. By the way, you can install such a boiler not only in a cottage, but also in an apartment, hotel or other premises.

The boiler itself is a metal or plastic container, parallelepiped or cylindrical. The capacity of the tank can be anything and sometimes amounts to thousands of liters.

The water container is usually enclosed in another housing, and thermal insulation material is often laid between these two structural elements. It helps retain heat longer and also protects the outer casing of the tank from extreme heat. The water, which is directly responsible for heating the liquid in the boiler tank, usually circulates through a heat exchanger coil. The tank elements are protected from corrosion by the presence of a magnesium anode. To control the pressure in the unit, a so-called safety valve and thermostat are installed. Water circulation occurs thanks to the presence of a special pump system.

So BKN is a kind of “thermos” for water in the house. It does not heat the water itself, but is able to keep the liquid heated by the coolant in a warm state.

Connecting a geyser

Home craftsmen should be aware that all work related to the installation of gas equipment can only be performed by gas service workers (Gorgaz) who have a special permit. Information on this topic cannot be instructions for installing a geyser with your own hands.

Even if the owner shows independence and installs the gas water heater correctly himself, he cannot avoid troubles from the gas service, including the imposition of penalties.

In the 60s of the last century, the USSR carried out mass construction of five-story panel buildings, the so-called “Khrushchev buildings”. As a rule, these houses were gasified, and a gas water heater was installed in each apartment. Over time, gas water heaters became outdated and they began to be replaced with new modern gas water heaters.

Installing new equipment in the place where the old column was is quite simple. The gas and water pipes practically do not change their position, with the exception of some adjustments to their connections to the pipes of the new water heater. Tools you may need are a hammer drill to install new brackets, wrenches and pipe wrenches.

The new column is hung on brackets. Using couplings, bends and gaskets, a gas pipe and water supply are connected to the boiler pipes. A flexible hose is used to connect the hot water outlet pipe to the water tap. The exhaust pipe is connected to the outlet of the column.

After all connections have been made, perform a test run. During the first switch-on, check the draft in the hood and the absence of water and gas leaks. If violations are detected, the device is turned off and the violations are eliminated.

Self-installation of a boiler

You can install an electric boiler yourself. This will require plumbing and electrical work.

Preparatory stage

This stage of work includes calculating the volume of water consumed, choosing a good location for the device (it is necessary that the user can easily reach all connecting elements of the system to simplify maintenance of the device).

If the boiler is storage, you need to make sure that the wall can support its weight with water (partitions that are too thin or plasterboard will definitely not work). The closer the device is to the water supply pipes, the better, since you will not have to lay an additional section of the water supply pipeline.

To work you will need:

- building level;

- ruler or tape measure;

- perforator;

- adjustable wrench;

- pliers;

- tees-fittings;

- shut-off valves;

- connecting hoses (for water drainage);

- additional pipes (if necessary), you must first ensure that the pipes are able to withstand the required load;

- sealing tape, tow or special paste (for sealing connecting elements).

After making sure that the location is chosen correctly and all the necessary materials and tools are available, you can proceed directly to the installation, working according to the finished scheme.

Installation and connection of a water heater

The first thing to do is to place the device at the mounting location: the distance between it and the ceiling must be at least ten centimeters, otherwise it will be simply impossible to hang the tank on the fasteners.

Carefully mark the attachment points (with a pencil or marker). You need to drill holes at the marked points and tighten the fasteners to the required depth.

The photo shows the main elements of connecting the boiler

For fastening, it is better to use steel hooks that come with the device. If they are not provided, then you need to choose a mount based on the weight of the boiler. Afterwards the tank is hung on them using grooves specially provided in its body.

Before installing the tank, you need to make sure that everything is in order with the threaded connections, since they are often unscrewed by 1-2 turns. In this case, it is recommended to drive the threads with a die 1/2 inch, but carefully, without excessive force.

Next, connect the device to the water supply. These works may have their own characteristics and differences depending on what material the pipeline is made of.

For polypropylene, metal-plastic and steel pipelines, you will need to use a special tool designed specifically to work on each of these materials. Also, for inserting into the pipeline, you will need to select various auxiliary parts (tees, couplings and fittings).

But the order of work is the same in all cases. First, turn off the water supply. The pipe is cut, and a branch is installed at the cut site. To do this, a tee is soldered into the pipeline. Pipeline branches are equipped with an MPH coupling, to which a shut-off valve is connected. The shut-off valve is connected to the boiler pipes directly or using flexible hoses.

Installation of shut-off valves

To ensure that water is supplied to the tank from a cold pipeline, the following steps are performed:

- installation of a tee on the tank pipe;

- connecting the drain valve to the side of the tee;

- installation of a check valve or explosion valve on a tee;

- shut-off valves are mounted in series behind the valve;

- connection of shut-off valves to the water supply system.

It is recommended to perform these manipulations at a branch from the central pipeline. This will prevent damage to water taps during installation.

Equipment Maintenance Principles

Problems can appear at any time. This factor depends on the correct operation of the equipment.

For proper operation of the equipment, it is necessary to regularly clean the filter and carry out annual maintenance:

- Turn off the boiler

- Clean it from dirt,

- Blow out the pipes.

If necessary, tighten the fasteners.

It is possible to increase the service life and not violate the warranty of the equipment, subject to professional maintenance.

Positive and negative qualities

By installing a water heater yourself, you can save a lot of money, this is the main advantage. But self-installation has other advantages.

Since the work is carried out by the owner of the house himself, when servicing or needing to replace a faulty water heater, you will not need to understand the connection system.

In the future, replacing the heater will be completely simple. In addition, installation work will increase your skills in performing various household tasks.

Among the disadvantages of installing a water heater yourself, one can note the possible occurrence of problems with connection to both the water supply system and the energy or gas supply.

In addition, incorrect work can lead to the system not working.

There are several factors to consider before installing a water heater.

You need to immediately decide on the type of water heater.

An electric storage heater, also known as a “boiler,” consumes less electricity, but it has fairly large dimensions, so you should immediately decide whether there is room for its installation.

A instantaneous electric water heater is much more compact and it is easier to find a place for it. But it consumes more electricity.

When choosing a storage heater, you should immediately decide whether the wall on which it will be located will support significant weight.

You should immediately take an interest in the wiring of the house. If it is old, it is unlikely to withstand a heavy load. Therefore, it may be necessary to replace the electrical system at home.

The wire cross-section will help determine whether the wiring can support the load.

So, in order for the wiring to withstand the load created by a 2 kW boiler, a wire with a cross-section of at least 2.5 mm is required. If a flow-through heater is installed, the wiring should be even thicker.

You should also take an interest in the water supply system. If, when laying it, they provided separate terminals for connection, then this is very good.

If there are none, but the system consists of plastic pipes, then inserting the leads is not so difficult. The most difficult situation will be with metal pipes.

But if the water supply system is already outdated, then it is quite possible that it will have to be completely changed. It is also important to know how to install an outlet in the bathroom.

Briefly about the main thing

A water heater is a device for heating water for domestic purposes - washing, washing, cleaning, showering. Modern models are divided into storage, flow and indirect. The most widespread models are the accumulative type. Each variety has its own principle of operation, design features and recommendations for use.

Water heaters are classified according to 4 parameters:

- Type of construction.

- A type of energy.

- Installation option.

- Operating principle.

Water is heated by an electric element or a gas burner. In addition, the boiler can accumulate hot water from an external heat exchanger. Before installation, it is important to choose the right location - first of all, taking into account the size, type of unit, distance to the consumer and ease of maintenance and operation. The device can be connected either to a buffer tank or to a water supply. Connection to the electrical network must be carried out in compliance with electrical installation standards and safety regulations.