As you know, kitchen hoods come in classic and recirculating types.

The first discharges air into the ventilation shaft or directly to the street. The recirculation system simply pushes it through itself, trapping fat. It is designed with filters to remove odors from the air.

The main questions and problems arise when installing and connecting the classic version. We will consider it in as much detail as possible.

To begin with, we will briefly list the main mistakes that await you along this path. Below we present ways to solve them and the most popular installation methods.

Mistakes when installing a kitchen hood

1 Blind connection of the air duct to natural ventilation is the most common mistake.

Some people, of course, leave a grille for natural air movement, but still manage to block it with the air duct itself. 2 Connecting an air duct of too small a diameter through an adapter to a powerful hood with a large outlet flange.

Recommended dimensions for round air ducts are d=125mm. For rectangular ones - 204*60mm.

3 Exit the air duct to the street through a homemade hole in the wall.

In most cases, this is prohibited by the rules. Specific points will be given below in the text.

You can, of course, lay a separate box along the facade straight to the roof. But is it worth it? Although in restaurants and cafes located on the ground floors of high-rise buildings, this solution is widely used.

By the way, the ban on venting air to the street through a wall does not apply to private houses, but only to high-rise buildings.

4 Complex route geometry with a large number of transitions and curvatures.

First of all, this will affect the noise. Although, of course, the turns themselves are not the greatest evil. And sometimes you can’t do without them.

It is the turns that follow one after another, without acceleration sections, that are dangerous.

5 Connecting an overly powerful hood (for example, 1000 m3/h) to a standard ventilation duct, which is capable of passing about 300 m3/h.

Remember that a productivity of 200-300 m3/h is quite enough to effectively remove all odors, with minimal load on the ventilation of the house.

6 Installing the hood at the wrong height.

The installation height directly depends on what kind of stove you have - gas or induction hob.

7 Assembling a plastic ventilation duct without a good seal, or joining parts with superglue.

Believe me, sometimes this structure has to be disassembled.

8 Upper, rather than lower, location of the slots in the decorative grille in the same frame as the air duct.

Why this is a mistake, and when it is still possible to do this, is discussed below.

9 Lack of a separate outlet in the upper part of the wall for the hood.

As a result, connecting it haphazardly, through carriers and extension cords. Do not forget that in the end this is not a portable device, such as a fan, heater or mobile air conditioner.

This means that the wiring for it needs to be done stationary and wisely.

10 Incorrect installation of check valve.

It must be embedded and installed in compliance with the appropriate angles and inclinations. Otherwise it will work every other time.

In general, installation of a hood can be divided into two main stages. The first is its connection to electricity. The second is the air duct structure and everything connected with it.

Let's look at each of them separately.

How to install ventilation in the kitchen

As mentioned above, the ventilation system of the kitchen area is simple. There are no complex elements or wisdom in it. The main element of this system is, of course, the hood. But there are other elements that are necessary to create a ventilation system.

Required ventilation elements:

- Air ducts (pipes) Recently, specialists have been choosing plastic pipes for work. But if you want, you can also use iron ones. It is more convenient to use pipes with a rectangular cross-section rather than a round one.

- Check valves Air can be controlled using this element. Usually, they are installed to prevent drafts from entering the room.

- Transition funnels They are used only in large and technically complex ventilation systems. They can connect air ducts of different sizes or a pipe and any device.

- Diffusers Lately, craftsmen have been using only automatic diffusers. but there is also a manual (i.e. mechanical) device. With it you can regulate the flow of air that enters the room. For example, in winter you need less of it, because the room will suddenly become cold, but in summer it’s the opposite. A diffuser is installed on the supply valve of the ventilation system.

- Ventilation grilles Often, this is just a decorative element used to cover an unsightly hole in the wall or hide a ventilation fan. Grilles are installed on vents both indoors and outdoors.

Turns This is a connecting element with which you can turn the air duct in absolutely any direction.

But that's not all. There are small but necessary elements that are simply necessary for work. They may come in handy, but you can cope without them or replace them with something else that is at hand. These are various fasteners, sealant, polyurethane foam and much more.

All the necessary tools should also be at hand (a hammer drill, various screwdrivers, a drill, bits and much more.)

Connecting the hood to electricity

This stage is the simplest. It’s very good when initially planning your kitchen, you carefully planned the location of all sockets and electrical points.

You can find out how to avoid making a bunch of basic mistakes and maintain all distances in a separate article.

If you do not have a free socket for the hood, you will have to install it. To do this you will need the following materials:

- three-core cable VVGngLs 3*2.5mm2

For home wiring, use a cable of this particular brand (with the index Ls).

- regular 16A socket with grounding contacts

The hood itself, unlike other kitchen appliances, is a low-power device. Accordingly, it is not at all necessary to pull separate wiring under it directly from the switchboard.

The same cannot be said about the hob or dishwasher.

It turns out that this unit can be connected from a common socket group from the nearest distribution box.

Pull a groove or cable channel from the distribution box to the location of the future outlet and mount the socket box.

This outlet is located on top, almost under the ceiling, slightly above or to the side of the hood itself. The choice of a specific location will depend on the length of the cord and the requirement for the minimum installation height of the exhaust unit above the stove.

Often you have to cut a hole in the nearest kitchen cabinet for this purpose.

Next, remove the insulation from the cable, mark the cores and connect them together in the junction box.

All that remains is to connect the outlet correctly.

The wiring for the kitchen unit is ready. Let's move on to the air duct.

Obvious advantages

A branded filter for kitchen ventilation will reliably protect all family members not only from dust, but also from plant pollen, which in turn will reduce the risk of allergies.

The air reaches the apartment residents in an improved condition, and the occurrence of unpleasant drafts is excluded. Using one device, you can not only clean the feed, but also heat it to a certain temperature; its versatility makes the device practical.

Combination with natural ventilation will lead to good results, and during cooking, steam and harmful substances will not accumulate in the working area.

Incorrect connection of the exhaust duct to the ventilation

The main problem during installation is to correctly connect the air duct without disturbing the natural ventilation in the apartment.

Some of the craftsmen generally advise taking the whole thing out into the street, through the nearest wall. However, according to SNiP it is prohibited to do this.

It clearly states that such a hole cannot be placed closer than 8m from the adjacent window. Since this window is considered a device for supplying outside air.

Here, read the paragraphs of the set of rules SP54 and SP60.

That is, drill a healthy hole in the wall, spend a lot of nerves and money, and the neighbor will complain about you, and you will be obligated to repair it all.

How do most consumers connect? An ordinary corrugation is taken, placed on the outlet, stretched and attached to a flange, which is screwed to the ventilation hole.

That's all. Simple, cheap and wrong. What are the disadvantages of this method? First of all, the noise.

When air passes through such a ribbed corrugation, it makes extremely unpleasant sounds.

But most importantly, when your device is turned off and not working, natural ventilation is forced to draw air from the apartment through the hood. Not only can your box be clogged, but in the summer there is sometimes no traction at all (due to the same temperature at home and outside).

Moreover, you are actually putting an oily mesh, motor, turbine, etc. in the path of the air. Also, air suction will not occur at the ceiling level, but at the level of the middle of the kitchen.

Although the collection of all odors of waste products should be carried out from the maximum height.

It is quite clear that in this case there will be no traction. That is, with your own hands you are depriving yourself of natural ventilation.

This threatens the occurrence of fungus and increased humidity. In the off-season, your doors will simply begin to swell and close poorly.

There will also be a lack of oxygen and constant poor health. At the same time, someone falls into mysticism and begins to think that they have been damaged or the apartment has bad energy, but in fact, there it is - improper ventilation!

Initially, in Soviet times, when designing our multi-story buildings, engineers expected that air would flow into the apartment due to leaks in wooden windows.

However, with the installation of plastic windows and sealed doors, we thereby blocked this channel of fresh air in the house. You will also close the ventilation and you will live like in a submarine.

To correct the situation in such cases, it is recommended to install a supply valve on a plastic window.

Instead of clogging, you can do everything more intelligently. What alternative options are used for this?

Advantages of the natural version

High-quality ventilation in the kitchen with a hood of this type is always in working order, it does not break down and does not depend on electricity. The main substances that are released during the cooking process leave through it.

In small quantities, gas leakage from the oven is not a problem, and if the cooking is not too intense, the vapors will also escape.

Saving money will be a pleasant addition, because in most houses built according to SNiP, such a system has already been introduced from the very beginning. It works autonomously and for it to work properly you just need to clean the communications on time.

No unnecessary noise is created, since additional fans are not needed for operation, and family members will not hear the sound of the device.

Note!

- DIY kitchen: step-by-step instructions, selection of furniture + rules for installing the kitchen

- Kitchen with gas stove: design features, photos of the finished renovation

- How to make a kitchen with your own hands - examples of beautiful and modern renovations

Hood duct and grille with non-return valve

The first is that instead of corrugation, a plastic pipe is taken (for example, d-125mm), and through one or several bends it is led into the hole in the ventilation duct. In this case, a certain division is made in the hole itself under the ceiling.

An entrance to the pipe is mounted on top, and a small rectangle is left below through a grate with a valve for natural inflow.

Moreover, the grille should be at the bottom, and not at the top. Otherwise, the air flow from the hood will blow upward and lift the so-called non-return valve.

Although, of course, if you have a more advanced valve design - a circle or rectangle with an offset axis, and not simple strips of polyethylene, or there is a solid partition, then you can safely install it as you want - on top, side, bottom.

However, in fact, this whole structure often does not work as intended. When you turn on the exhaust unit and create pressure, a small part of the dust still seeps through the cracks and micro-holes, after which it safely ends up in your kitchen on the dining table.

No check valves are 100% effective. The bulk of the air, of course, goes outside, but the gradual formation of dust inside the apartment is a fact.

And even when the hood is turned off due to the reduction in the diameter of the original hole, natural ventilation through narrow grilles will be much worse.

Everything can be done much better.

Natural and forced ventilation in the kitchen – what to choose?

The answer is obvious - it is best when both types of ventilation in the kitchen are available and work in tandem. Natural ventilation in a kitchen with a gas stove is especially necessary. Despite their common purpose, these two types of hoods most often cannot replace each other. Without proper natural ventilation, the air in the room can only be purified when forced exhaust is turned on, which is why harmful substances and excess moisture are simply not removed in full.

However, having a working, correctly installed natural hood, you can already be completely calm about your safety. Forced ventilation is more likely to be responsible for comfort, since it can be turned on as soon as necessary to remove unwanted odors and fumes from the room.

Naturally ventilated kitchen with gas stove

If you have a gas stove, a small excess of natural gas is produced; natural ventilation successfully removes it and prevents it from accumulating. For prevention, it is necessary to periodically check the ventilation duct for the presence of sufficient draft - to do this, simply attach a piece of paper to the hole. If it sticks, the traction is satisfactory.

Advantages of natural hood in the kitchen:

- Continuous, uninterrupted operation

- Providing general ventilation of the room, in combination with ventilation ducts in bathrooms

- Good removal of all types of dangerous fumes and excess moisture. Acceptable removal of unpleasant odors

- No additional installation costs or electricity usage required

- Operation is absolutely silent and does not cause any discomfort to residents

Despite many positive factors, it also has a number of disadvantages:

- There may be a decrease in the efficiency of the hood in the hot season, after prolonged frosts.

- In the presence of a number of unfavorable conditions, reverse draft is possible, when air begins to flow from the street into the room, and not vice versa

- The volume of air removed by the hood per unit of time is quite small, which is why kitchen hoods often cannot cope with unpleasant odors that arise during cooking.

- For proper operation of the hood, a normal flow of air from outside is necessary. Modern metal-plastic windows are sealed hermetically and cannot provide a normal volume of air outside. Therefore, you must remember to open the windows while cooking.

- The ventilation duct may be clogged with snow or debris. Neighbors who have removed the ventilation shaft for some reason may block the duct for other residents

- It is necessary to regularly monitor the draft level and, if necessary, clean the channels

Forced ventilation in the kitchen: advantages and disadvantages

The undoubted advantage of a forced ventilation system is its high performance, which allows you to quickly clean the air in the room.

By installing a forced hood directly above the hob, harmful volatile substances are removed before they spread throughout the kitchen.

Among the main disadvantages of forced ventilation it is necessary to mention:

- Higher cost compared to the natural ventilation option.

- Dependence of operation on the constant availability of electricity in the network.

- The presence in the design of mechanical equipment that can occasionally fail.

- High noise level of the operating fan.

Correct connection of the air duct to the ventilation system

For this you will need:

- plastic air duct

- offset check valve

- tee splitter

In the end, you should end up with something like this.

How does it all work? When the hood is turned off, the valve will be open and warm air from the kitchen will quietly flow by gravity into the ventilation duct. As soon as you turn on the exhaust hood, the valve immediately closes automatically, blocking the air flow into the room.

In this case, all odors from the stove will easily go outside. When switched off, the pressure in the box drops and the valve automatically opens, connecting the ventilation shaft to the apartment.

Beneficial features

High-quality built-in ventilation for the kitchen has a number of advantages, including a reduction in the following influencing factors:

- Unpleasant child.

- Evaporation of water.

- Removing odors.

Most dishes require a process of cooking or stewing, which introduces moisture into the air. The steam gradually settles in the room and turns into water droplets, which, in turn, fall on the walls and window slopes.

If left unchecked, mold or mildew will develop and your wood furniture may deteriorate or last much less time. When heated, oils and fat release certain substances and settle on the floor and textiles, and if this happens in all rooms at once, disastrous consequences cannot be avoided.

Assembly instructions - all numbers and performance

How does this all come together in practice? For capacities up to 300 m3/h (low speeds of most hoods), a d-125mm pipe is sufficient. On the device itself, the outlet hole may be larger.

For example, for 650 m3/h you will need a d-150mm pipe. However, you are unlikely to find such plastic pipes, and if you use the next standard size d-160mm, it will turn out to be a huge and awkward structure that spoils the entire interior and design of the kitchen.

Moreover, you will have to drill a factory hole for the ventilation duct in the wall, expanding it.

Therefore, in most cases, the optimal diameter of 125 mm is chosen. And you don’t need more.

The forced throughput capacity of standard channels and shafts with dimensions of 100*150mm is 400 m3/h.

An air flow of more than 450 m3/h simply will not fit there (it was tested in practice), even if it says 1200 m3/h on your hood!

Remember also that you cannot underestimate the diameter of the air duct too much compared to the outlet pipe on the hood. Otherwise, the vibration and noise will be so strong that the structure will have to be re-glued every month.

The connection of different diameters is made using special adapters.

Let's start assembling. First, install the adapter on the hood and connect the vertical section to it.

To improve its sound insulation, it makes sense to go crazy and stick a 5mm thick heat-sound-insulating material on top.

It wouldn’t hurt for them to cover the inside of the decorative casing and the noisiest part - the adapter. This is where the greatest turbulence occurs.

Next, add 90-degree elbows and other straight sections of duct as necessary to ultimately exit toward the hole in the wall.

All this is glued together with silicone, no superglues. There should be no gaps anywhere.

We reach the tee. A valve is installed in it from the side of the room.

Keep in mind that this is a gravity valve! It opens not due to air flow, but due to its weight.

One half of it is heavier than the other and at the same time it is installed at a slight angle of 2 degrees.

Existing disadvantages

Supply ventilation in a kitchen in a private house will cost the owner quite a lot, the mechanism with which each model is equipped is very complex, which is why the price is undemocratic. Filters also do not last forever, although they will last quite a long time, but the time for replacement will come and this will entail additional expenses.

Large room sizes will require the installation of a large device; the use of small analogue devices, according to consumer reviews, has proven to be worse; the units are of lower quality.

In winter, in severe frost conditions, the body becomes covered with ice, which affects the correct operation and air flow.

Preparing the ventilation shaft hole

Before all installation work, it is advisable to plaster the entry into the ventilation shaft itself and remove all sharp corners. This will give the entrance maximum aerodynamic qualities.

You should end up with approximately the same surface as a standard 90 degree round elbow.

It is recommended to add ceresit liquid (ceresit CT99) to the plaster solution.

This hole will be exposed to fat and moisture. And ceresite contains components that prevent the formation of mold.

However, do not use gypsum plaster under any circumstances. Its use in ventilation shafts is a direct path to the appearance of mold and fungi.

Attach sections of a standard air duct to the tee on both sides. From the side of the wall, 5-7 cm, wall it up in the ventilation duct. The exit itself is decorated with a square frame.

Influence of external factors

And also, do not forget about the noise level, otherwise each switching on will cause negative emotions, and you will want to turn on the equipment less often.

When installing a kitchen ventilation outlet is supposed to be near the stove, it would not be superfluous to check the presence of a protective coating against high temperatures. This will directly affect the service life of the device.

Why does the check valve sometimes not work and close?

On the kitchen side, a check valve is mounted on the tee. In the factory version it will be quite long. In this case, it is better to shorten it so that this “gun” does not stick out too much.

The valve is inserted inside a section of a standard air duct d-125mm, and this air duct is put on and siliconized onto the tee.

If this whole structure seems too cumbersome to you, and the protruding pipe with the valve is not very aesthetically pleasing, you can do it a little differently. You make the air duct not with a round pipe, but with rectangular channels.

In this case, you install the above check valve on a straight section, as close as possible to the turn.

You can't achieve a factory connection here, so you'll have to farm collectively. Buy a rectangular tee with a round outlet on one side. Next, this round timber is cut off and a check valve is glued in its place.

The valve is placed strictly at an angle (2 degrees). Otherwise, it will open every once in a while or not open at all.

Many people have encountered this problem and easily solved it this way.

The damper itself is also mounted with a vertical deviation. The upper turning point, based on the hour dial, is at 13.00 (1 o'clock), and the lower one is at 17.00 (5 o'clock). This is if your flow direction is from right to left.

Otherwise, the circle is placed at the 11 o'clock - 7 o'clock position.

For more reliable operation and stable opening of the damper, you can stick some kind of weighting material (no more than 2 grams) on one side. Glue it close to the edge.

By the way, do not throw away the previously cut round pipe. It is tightly inserted onto the valve from above, after which a decorative grille diffuser is mounted on it.

What nuances might there be with this method? If your hood stands exactly above the entrance to the ventilation shaft, and the duct pipe goes straight, without any turns in the horizontal plane, then the valve installed on such a straight section does not work normally, at least at 1st speed.

You will simply have nowhere to get the increased pressure to close it. The air will fly through this “turn” in a straight line. You definitely need an angle.

The valve cover and its rotating mechanisms are easy to clean and do not be afraid of them becoming overgrown with grease. For this to happen, you will have to fry huge wild boars on the stove and stew them in your oven for several hours a day, no less.

If you don’t want to see a protruding “hollow” under the ceiling at all, then, as an option, you can install a tee so that the middle elbow rests against the wall, otherwise, where the valve is located, it would look to the side. In this case, also close the hole with a decorative cover.

Everything will look much nicer. However, due to the additional rotation, the performance of natural ventilation will deteriorate slightly. And the grill will reduce it by another twenty percent.

In addition, it will no longer be possible to clean the channel by hand or with a vacuum cleaner. But many do this deliberately and even hide the entire structure in a wooden or plastic box.

As they say, beauty requires sacrifice.

Changes that came over time

Before plastic windows, wooden frames were used, outside air flowed into the apartment quite freely, and the operation of the hood was stable, but modern devices provide complete sealing, and in order to achieve good ventilation, you need to constantly open one of the doors.

This is especially unpleasant to do in severe frosts; harmful drafts can harm your health.

Why does the air from the kitchen get to the neighbors - is the hood to blame?

Despite all the advantages, such a hood connection system has many critics. They believe that in this way you are rudely interfering with the overall ventilation system of the entire house.

For example, everything will be fine with you, but have you thought about your neighbors? Allegedly, due to this connection of the hood to the ventilation, all odors from your kitchen will automatically penetrate into the apartments through the riser above.

They started frying pies, and all the neighbors already knew about it. However, all critics are mistaken based on misconceptions about the ventilation system in apartment buildings.

They think that from bottom to top there is one common channel 110*150mm with “holes” for each apartment.

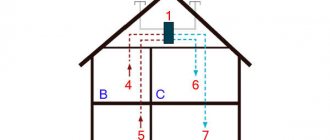

In fact, in 5 floors, all the channels are individual and you are unlikely to be able to blow out extraneous odors from your neighbors. In houses of 6 floors and above, there is already a ventilation system with air removal through satellite channels, connecting to a common collection channel through one floor.

This common channel has a cross-sectional area 6-8 times larger than individual shafts in apartments with dimensions of 110 * 150 mm.

Schematically, such a ventilation system for a multi-story building can be represented like this.

Yes, in such buildings, if several hoods are turned on at the same time to the maximum, reverse draft may occur. But this is an extremely rare case.

Look - the natural draft from apartments, at best, ranges from 100 to 150 m3/h. You have a nine-story house. The first seven floors are embedded in a common channel measuring 510*270mm, or even more. The total natural flow in it is about 1000 m3/h.

And then, instead of the usual draft of 150, you turn on your hood at 300 m3/h. Do you think it is capable of creating reverse draft in this case and starting to expel air to the neighbors?

To do this, it is necessary that all 6 floors do the same thing, and at maximum speed.

Then one apartment will be unlucky and its inhabitants will have to smell all the aromas of their neighbors’ cooking. But this option is unlikely.

Despite all this, sometimes the air from your kitchen actually gets into other apartments in the house. Or, on the contrary, you have a great feeling that your neighbors are grilling you for lunch today. Why does this happen and where to look for the reason?

This happens for several reasons. For which ones, read in more detail under the spoiler.

Why does the smell from your apartment penetrate to your neighbors?

Recommendations from the experts

Before you start creating the ventilation system in question, you need to double-check all the calculations made several times in order to avoid making a mistake, which can then be costly. Experts also advise using only proven components from well-known manufacturers. Otherwise, there is a risk that a fan may fail, which will disrupt the entire operation of the ventilation system.

If you cannot perform any procedure with your own hands, you should not hesitate to contact a specialist. It is better to spend a little time and money on consulting a professional than to make a mistake on your own that could disrupt the operation of the entire system.

Consider small details

You must immediately find out from your sales consultant all the additional capabilities of the equipment in order to use the functions to the fullest and ensure maximum protection of all rooms from smoke and steam.

Some models have built-in timers that can be easily programmed for a specific time. Before settling on one of the options, experts advise thoroughly studying the possibilities and needs of the home, and then starting from this when purchasing.

Hasty actions can lead to irrational waste that will not lead to a positive result. In certain cases, it is better to entrust the calculation of the power of the equipment to professionals, having made preliminary measurements of the room personally or with the help of friends.

Using pipes

When you make ventilation passing through the wall, you cannot do without the use of pipes. At the same time, make sure that each room has its own air duct device. One exit is located above the foundation about a couple of meters above. Another exit can be located on the roof and removes air masses from the room. It is to this that all channels are connected.

It is necessary that the pipe system rises approximately a meter above the roof. Directly under the ceiling covering there are entrance openings that can be closed using flaps that regulate air flow.

It is possible to combine the exhaust systems of a sauna, as well as a kitchen, bathroom, and toilet. Such combinations are possible in the attic room. Make sure that strong seals are installed at each connection point. It is also possible to install such connections inside the ceiling covering so that the lights reach the roof through the attic. In the attic itself, insulation of passing pipe systems is carried out.

Sometimes pipes are made of polymer coatings, galvanization or concrete material. During installation, the pipes are lowered between the walls and then filled with cement. It is necessary that the outlet of the ventilation pipe be made as airtight as possible. For this purpose, a rubber as well as a silicone element is used. The exhaust air duct, and the outlet can also be connected via a corrugated pipe.

If necessary, plastic ventilation ducts can be made into the wall covering, even if the latter is not thick. You can also make an opening from 120 mm asbestos cement, into which a pipe is lowered, subsequently reinforced with cement.

The pipe itself can be made by wire fastening a pair of slate half-waves of the required size. The pipe itself is fastened to a pedestal laid out equally with the partition. However, another option is also possible, when a pair of bricks are laid on the sides of the partition and the structure is installed.

Ventilation installation