In this article, I will tell you how to correctly install the collector distribution of water supply pipes in an apartment. What causes water hammer, why does the temperature drop in the shower and how to do everything correctly so that you don’t have anything like this.

This article will be useful to those who are planning to install water supply pipes in an apartment with their own hands and do not yet know where to start, as well as to those who have purchased an apartment in a new building and plan to make high-quality repairs and a reliable water supply system there.

Not all craftsmen who undertake turnkey renovations in an apartment will be at all concerned about the correct installation of the water supply. For many, the main thing is to make the price tag cheaper than others and how everything will be done fades into the background.

Installation according to the collector circuit

Principle of organization of collector systems

Do-it-yourself collector distribution of water supply in an apartment is carried out according to the following principle - the central branch does not have branches, but is connected to a collector, to which, in turn, the supply lines for each device are connected.

When installing heating systems, collectors are installed in special cabinets (when implementing a scheme for houses with several floors, collectors are installed on each floor). Cold and hot water supply systems are installed in the same way. In apartments, water supply collectors are conveniently installed behind the flush cistern in the toilet. The collector principle of supplying water or coolant is also called radial, and it has its own characteristics for water supply and heating systems. These nuances deserve close attention.

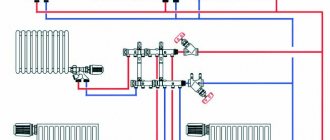

Manifold cabinet design diagram

Installation of collector water supply

The junction of the collector with the central pipe is equipped with a ball valve to allow a general shutdown of the water supply. The valve is complemented by a pre-filter (coarse) filter, which traps large insoluble inclusions that can damage other equipment.

If you follow the flow of water, after the coarse filter there should be a liquid flow meter (meter), and after it there should be another filter that removes smaller inclusions (compared to the first).

The next element of a well-designed water supply pipe distribution system in an apartment is a check valve, which prevents the reverse flow of liquid from the collector into the central pipe when the water supply pressure decreases.

Only after the equipment listed above is the connection to the collector made. Each collector outlet is equipped with its own tap to turn off the branch’s water supply.

The photo shows an example of water distribution in a collector-type apartment

When choosing and installing a collector, one of the determining factors is the number of water consumption points. It must correspond to the number of outlets, and to be able to connect additional plumbing equipment in the future, you should choose collectors with a large number of outlets. Those of them that are not used in the system until a certain point are provided with stubs.

If the central branches of both cold and hot water supply enter a house or apartment, the installation of water supply distribution in a collector-type apartment is identical in both cases. If there is only a central cold water supply, one of the outlets of the cold water collector directs the liquid to the water heater, from where the heated water flows into a separate collector for hot water distribution.

A radial water supply project must take into account not only the number of water consumption points, but also the distance from the collector to each of them. The optimal point for installing the collector is the location closest to the maximum number of consumption points, so that the distances are approximately the same and the outlets do not require too many pipes.

A description of the types of pre-filters is here.

If you have to choose a water heater, we recommend reading this material. In it you will find a comparative analysis of storage and instantaneous water heaters.

Collector heating

The collector heating circuit is implemented as follows:

- The boiler supply fitting is connected to the pressure pipeline, which supplies the coolant to collector No. 1.

- The outlets of the first collector are connected to the upper fittings of the radiators installed in the house.

- A second collector is mounted next to collector No. 1, the taps of which are connected to the lower radiator connectors.

- Manifold No. 2 is connected to the injection pump, and it, in turn, is connected to the receiving fitting of the boiler.

- At the highest point of the circuit, an expander is cut into it, corresponding to the heating circuit (open or closed).

The diagram shows the heating manifold wiring

If there is a central water supply and heating, the collector wiring diagram for heating devices is implemented in a similar way, with the exception of the absence of a boiler, expander and pump.

For the system to operate efficiently, it is important to choose the correct location for installing the collector. It is optimal to place it in the geometric center of the house; the distances from it to all radiators, which are usually located under the windows, will be approximately the same

Tee circuit and its features

Technically, the tee scheme for distributing water supply in an apartment is a serial connection - one pipe departs from the riser, to which plumbing and other water-consuming equipment are connected using tees.

The advantages of such a system are:

- economical (with a series connection, a minimum number of pipes is required),

- ease of installation.

The tee scheme for distributing water supply in an apartment also has its disadvantages:

- a large number of connections and serial connection make it difficult to find leaks,

- there is always a risk of pressure drops in the system and a decrease in pressure at the points furthest from the riser when several taps are turned on simultaneously,

- if it is necessary to carry out repair work, a complete shutdown of the water supply will be required, which represents a certain inconvenience,

- Installing tees is not always convenient in small spaces.

An example of a tee water supply wiring diagram.

Tee water supply diagrams are recommended for small apartments . With a small number of consumption points and their location close to each other, many disadvantages become less relevant - in this case it is much easier to coordinate water consumption, which means the risk of pressure loss is minimized.

When installing a tee circuit, the tees are often hidden in the walls or under the floor, which complicates inspection of communications, and during repairs inevitably leads to damage to the finish.

Installation stages

All work to create the wiring of the water supply system in the apartment has the following sequence:

- First of all, emergency valves must be installed on the riser.

- Next, meters are installed, as well as water filters.

- The next step is to install the manifold, after which ball valves are installed at the outlets.

- Now all plumbing fixtures are connected.

- The last stage is to check the entire system for functionality.

If the water supply distribution is to be created in a new building or in an ordinary apartment where the entire system is being completely replaced, then it will not be difficult to do everything yourself.

Please note: if you are installing pipes in a fairly old building, first of all you need to check the condition of the main riser there, since it may be necessary to initially replace it due to wear.

What is tee wiring?

With tee pipe routing, the water supply network is built sequentially: two main pipes with cold and hot water are diverted from the common riser, and from them, with the help of tees, to the points of use. This scheme is much simpler and cheaper than the previous one, but also has many of its disadvantages.

This wiring is best suited for a small living space. The use of tees in a private house can lead to inconvenience due to increased volumes of water consumed compared to a small one-room apartment.

Advantages of tee wiring

- It is cheap. Only two main pipes are needed

- Tee wiring is more compact. It doesn't require much space. The water supply is easily hidden inside the walls, its visible parts are in the cabinet under the washbasin or behind the toilet.

- Compared to manifold wiring, assembly of tee wiring is carried out in a short time.

Disadvantages of tee wiring

- When several taps are turned on at the same time, the water supply pressure will drop. Jumps can be minimized by expanding the diameter of the main pipe in relation to the outlet pipes. But then the cost of building materials will increase. If the pressure in the house itself is weak, then even such manipulation will not produce results.

- You can only turn off the entire water supply system. Of course, you can install your own shut-off valve at each point. But in this case, consumption will also increase, and ease of use will become even less convenient. After all, every time you have to climb, again, under the kitchen sink or behind the toilet. In the end, this can also be more expensive than installing collector wiring.

- A large number of tees is always accompanied by a certain risk. When using pressed, push-on fittings, cross-linked polyethylene pipes or polypropylene joints, it can be argued that the fastening is dead and unlikely to ever leak. But the probability of failure on tees is still higher than on a solid pipe.

The choice of one or another water supply pipe layout depends on many factors: how water is supplied to the house, whether auxiliary engineering plumbing is needed to compensate for water hammer, with what intensity the water supply system is operated, how many points of water use there will be, what condition the system is in and what exactly is expected to be obtained as a result. You should also not forget that the method of laying the pipes will depend on the type of water supply pipes. So, if the main pipe is routed through the bathroom, and a return pipe is installed in the kitchen, then the optimal solution would be to connect the kitchen plumbing in series, using a tee type of wiring, and install it in the bathroom depending on the intensity of consumption.

Advantages and disadvantages

First we need to talk about the disadvantages of the collector system. Why is not all apartments equipped with a collector distribution of water pipes? The answer here is quite simple: you have to spend a lot of money to create the system. There is much more work to be done than when creating a tee system.

So, to power a washbasin and toilet, for example, you will need five meters of pipes for tee wiring, and nine meters of pipes for collector wiring. In addition, special shut-off valves for manifold wiring are expensive.

If renovations in an apartment do not involve a global replacement of water pipes, then you will feel the difference between one pipe on the wall and six pipes.

Therefore, most often a collector system is created when the entire water supply system is changed and it is possible to hide the pipes in special boxes or in the wall. Undoubtedly, collector distribution of water pipes has advantages.

In a small apartment, such a feature may not mean anything to the owner. However, when it comes to hotels and large establishments, such a system is a real godsend.

And what then should you do if, for example, in a hotel, a pipe bursts in one of the rooms? Cutting off the water supply to an entire hotel is suicide, especially if the establishment has a high star rating. The hotel's rating will drop the moment the water is turned off. But if you close the water supply to one room from the collector, that’s a different matter.

The collector system is particularly beneficial for heating systems. For example, you can reduce the temperature on one of the radiators using a throttle valve. In the water supply system, you can limit the use of water, for example, on the sink, where children often like to play. What if they leave the tap open and walk away?

No, the apartment will not flood, but in a few hours, until the adults discover the open tap, about seven to eight cubic meters of water can flow on the meter. If the tap is opened halfway, the numbers on the meter will be half as large.

One more situation can be imagined. With tee wiring, a shower and toilet are connected. You take a shower, the hot water is diluted by the pressure of cold water. Then at this time your wife went to the toilet and flushed the toilet with water from the tank.

What will be next? The cold water pressure will immediately be distributed equally between the shower and toilet. The fact that water will fill into the toilet slowly is not a problem. But getting caught in boiling water from the shower is not very pleasant. In the case of collector wiring, the water supply to the shower and toilet will be the same in any situation.

Common installation mistakes

It is best to entrust the design of a water supply system, both collector and tee, to professionals familiar with building codes and capable of performing hydraulic calculations. But even the best project will be useless if mistakes are made during its implementation.

Shut-off valves are part of any water supply scheme: both sequential and collector. They are installed at the entrance to the water supply system, as well as in front of each plumbing fixture.

For example, some would-be craftsmen, driven by the thought of unreasonable savings, neglect the requirement to insulate hot water pipes that are laid under the floor or in the thickness of the walls.

As a result, part of the thermal energy is transferred to the materials surrounding the pipe, which deteriorates the quality of the water. In addition, condensation from the surface of pipes without thermal insulation can damage the finishing of the room.

During installation work, experienced craftsmen recommend covering the ends of pipes that have not yet been installed to prevent debris from getting into them. The absence of this protective measure may lead to the fact that immediately after installation the water supply system will have to be thoroughly and for a long time flushed or even repaired.

When soldering polypropylene water pipes, you should remember that slight dirt or moisture at the soldering site can significantly impair the quality of the work

If soldering of plastic pipes is necessary, all work should be performed in a clean room to avoid contamination. It is also unacceptable to solder pipes that contain even a small amount of moisture. A drop of water or particles of debris at the soldering site can significantly weaken the connection and degrade its quality.

You should not design the water supply system in such a way that all pipes pass through the ceiling through one common hole. This may degrade the performance of the water supply. Professional designers never make such mistakes.

When drawing up a wiring plan, it is necessary to ensure that the pipes do not block access to the joints. This will make repairs much easier in the event of a leak.

An insufficient number of locking devices can also cause a lot of trouble during installation work. Such fittings must be present in front of each device to which water is supplied, as well as for each riser. If the house has more than one bathroom, you can install a shut-off valve for each of them.

Simultaneously with the water supply system, sewerage is usually designed and installed. It is necessary to ensure that the pipes and risers of individual systems do not overlap each other. This will make maintenance and repair work easier in the future.

Distribution manifold

Now let's find out why distribution manifolds are needed for water supply. We already know that they allow you to power several water points independently of each other; but how is this useful?

Advantages

Unlike a sequential (tee) system, the scheme of a collector water supply system allows you to avoid a drop in pressure when water flows through an arbitrary device. Simply put, when you turn on the tap in the kitchen, you don’t hear the pained and bitter cries of a family member taking a shower from the bathroom.

Collector water supply scheme for a private house: each device is connected to the collector with its own connection

In addition, a manifold-fed water supply with taps in the manifold cabinet allows you to turn off any plumbing fixture from one point. This is very convenient in public buildings, shopping centers or mini-hotels: if there is a water leak, you can turn it off without even having access to the relevant premises.

Flaws

Alas, the collector water supply scheme has several unpleasant features:

- Material consumption. Obviously, the total length of the water supply connections will be several times greater than with a tee circuit;

- If you install a collector for the water supply, the lines have to be laid hidden (in grooves or screed). Agree that a dozen parallel pipes on the walls of the bathroom and kitchen are a bit of an excess;

Cold water and hot water supply lines are laid in screeds, grooves or routed throughout the basement

Concealed installation entails the difficulty of localizing and eliminating leaks. If the neighbors below begin to get their ceiling wet, it will cost you a lot of work to find a fistula in the water pipe laid in the screed;

Openly laid water supply lines can be changed without damaging the finish

Installation

How to install a collector for the water supply of an apartment with your own hands and route the pipes to the faucets, toilet cistern and other appliances?

A cut-off ball valve, a coarse filter and a water meter are sequentially mounted in the riser (see Water supply meter: everything you need to know about these devices). If necessary, they can be supplemented with pressure reducers and pressure gauges;

In this water supply system, the installation of the collector was accompanied by the installation of a pressure gauge

Collector water supply system: size of taps into the riser - DN 20

Distribution manifolds for water supply (cold and hot) are attached to permanent structures with clamps;

Assembling the water supply manifold: ball valves need to be installed on the terminals

Distribution manifold - Valtec water supply manifold is equipped with ball valves at all outlets

- The tap threads or manifold outlets are equipped with adapter fittings to which connections to plumbing fixtures are connected;

- When installed hidden, the connections are thermally insulated. Insulation will avoid the appearance of cracks in the screed or sealing of grooves due to cyclic heating by hot water pipes, and will also reduce heat loss.

Please note: all connections are thermally insulated

What pipes should be used for water distribution?

As we have already mentioned, the water supply scheme we are interested in—collector—implies hidden installation of connections. However, for reasons of fault tolerance, all serviced fitting connections must be installed openly.

The list includes:

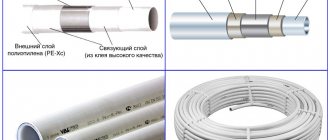

- Cross-linked and heat-resistant polyethylene;

- Metal-plastic;

The collector water supply system in the apartment is mounted with metal-plastic on press fittings

Corrugated stainless steel pipe (see Corrugation for water supply pipes: one step away from perfection).

Corrugated stainless steel for water supply

The metal-plastic pipe in the photo collapsed due to water hammer

The only exception to the general rule is polypropylene. Polypropylene pipes are supplied in straight sections, but their connections are maintenance-free and are as strong as a solid section of water supply, so they can be safely laid in screeds or grooves.

Polypropylene manifolds for water supply can be connected directly to polypropylene connections, without additional fittings

Proper layout and design

The task of organizing water supply in a residential area is quite simple. It is necessary to transport water from the centralized system to the point where water is collected by consumers. The list of such places in different residential premises may be different. A simple option includes two washbasins located in the bathroom and in the kitchen, a faucet in the bathroom, and a toilet cistern.

Modern apartments require more complex systems. Almost every home today has auxiliary household appliances, the functioning of which requires water from the tap. Every family has an automatic washing machine; most housewives want to install a dishwasher in the kitchen.

In the bathroom, in addition to the bathtub itself, shower cabins are often installed, equipped with auxiliary functions, for example, hydromassage. It has become fashionable to install a bidet near the toilet. In spacious apartments there may be several sanitary facilities. Two auxiliary toilets and an additional shower increase the comfort of living quarters and, accordingly, the load on the system.

Design Features

As a result, the requirements for the quality and performance of the water supply network are increasing. Many household appliances react sensitively to changes in water pressure, which depends on the correct design of the pipeline layout. A professional water supply project for an apartment will increase the parameters of the water supply network, reduce the consumption of materials for its installation and operation, and also simplify the repair and maintenance of the water supply system.

There are two options for laying water pipes in an apartment:

- A sequential circuit, also called a tee circuit.

- Collector circuit.

Each of them has its own advantages and disadvantages. Therefore, they are used for various cases and in certain conditions. Sometimes these two schemes are combined and a combined water supply is obtained.

Types of water supply pipes

The main types of pipes used in organizing water supply:

- Copper pipes connected using special solders. The lines are resistant to corrosion and can withstand heating up to 250°C. Pipes are elastic, which allows you to create pipelines of complex configurations. The disadvantage of the material is the formation of a galvanic couple upon contact with aluminum or steel elements. When used in multi-storey buildings, one should take into account the high current conductivity; if the neighbors’ equipment breaks down, the pipeline becomes energized.

- Metal-plastic pipes consisting of several layers of plastic with an aluminum gasket. The products are highly elastic; threaded bushings or crimp elements are used for connection. The products are not used for hidden installations, since the rubber seals at the joints lose their elasticity and allow water to pass through. The advantage is the absence of corrosion; the smooth internal surface prevents the formation of deposits.

- Products made of polybutylene that can withstand heating up to 90°C. The elements are connected using soldering technology, the seam is characterized by increased strength. Due to the high cost, polybutylene products are not widely used; the pipes are used in the construction of heated floors.

- Polyethylene reinforced pipes designed for pressure up to 3.5 atm. Use in water supply networks is not recommended, since the material is not highly durable. The parts are used for distributing water in personal plots or in domestic buildings; the material allows the liquid to freeze. When connecting, it is necessary to install a reducer that reduces the pressure of the water flow to a safe level.

- The lines are made of polyvinyl chloride, which is characterized by high chemical resistance and allows operation at temperatures up to 80°C. The disadvantage of the material is its low resistance to ultraviolet radiation. Soldering or glue is used to connect pipe fragments, but the strength of the joint does not allow water to be supplied under pressure above 3.5 atm. Pipes are used for water supply to technological premises or when organizing irrigation systems; a reducer is provided in the main line to reduce pressure.

- Pipes made of polyisopropylene, allowing elements to be connected by soldering. The material is low cost and allows pressure up to 12 atm. and temperature up to 130°C. The surface of the pipes is rough, but plaque does not form in the inside of the lines. The products are used for organizing risers and for distributing water inside residential or office premises.

When selecting pipes, you should take into account the cross-section of the internal channel, on which the throughput depends. To determine the parameter, it is necessary to find out the required pressure in the lines; the coefficient of pressure drop inside the pipe and at the joints is taken into account. When planning the laying scheme, straight sections should be used, but excessive lengthening and cluttering the branch with reinforcement lead to a drop in pressure.

In what cases is a collector heating system acceptable?

There is no standard solution when drawing up a diagram of a collector system, and there are also no generally accepted planning standards. The selection of equipment should be carried out by specialists, taking into account the specific tasks that need to be solved.

The opinion of experts should not be ignored: such a system cannot be recommended for heating in multi-storey buildings.

Heating system options in multi-storey buildings

The problem is that heating in the apartment is provided by the supply of coolant to at least two risers. A prerequisite for the system under consideration is the connection of all radiators to one riser.

Having left one source of heat, you will need to shut off the others, i.e. brew them. The entire load will be concentrated on the left riser, and a closed hydraulic circuit will be formed within a particular apartment.

All radiators located on the upper floors will be cut off from the centralized heating system and no coolant will flow into them. Naturally, residents of the upper floors will express dissatisfaction and will demand the forced restoration of the previous communications.

Tools, materials, dismantling old

Special tools for assembling residential pipelines are described above. To purchase materials, of course, you will need to calculate the footage, nomenclature and quantity locally. Dismantling old pipes is done in the usual ways. It is better to do this after installing and registering the water meter, so as not to turn off water to the floors for a long time.

We will give only one piece of advice: do not use valves with a lever. It is made of silumin or plastic and tends to break off at the most inopportune moment, just when you urgently need to close it. Take ball valves with a butterfly handle. The round, grooved handles also do not break, but wet or sweaty hands slip on them.

Laying methods - hidden and open system

Pipes in the water supply system can be laid in closed or open ways. The choice of one of the methods does not affect the quality of the connections or the functionality of the entire system and depends only on personal preferences.

It would seem that it is not difficult to decide and the closed method is preferable as it is more aesthetic and allows saving up to 10 cm of usable space. Why is an open pipeline still used when installing a water supply system? Let's try to give an answer.

Hidden wiring allows you to hide pipes and not spoil the aesthetic perception of the interior of a house or apartment. The hidden method is used when assembling a water supply system from PP pipes. They hide the contour behind a decorative wall, for example, made of plasterboard, or they groove the walls and insert pipes into the resulting niches, sealing them with facing material or plaster over a mesh.

The pipeline should not be tightly adjacent to the surfaces - always leave a small gap for possible repairs. When installing a pipeline into a monolith, it is recommended to place them in a casing, inserting the pipe into the pipe.

The disadvantage of the method appears when there is a need to repair or replace hidden elements of the system - the plaster or tiling has to be opened and then re-decorated.

In addition, in the event of damage and leaks, the problem may not be detected immediately and lead first to a loss of operational technical characteristics of the structures, then to flooding of the premises.

It is better to start installing a water supply system with a pre-drawn diagram - otherwise errors in calculations or assembly will lead to the need to cut new grooves and re-install the pipes

To avoid such difficulties, when installing the wiring, only whole sections of the pipe are hidden, placing connecting fittings in open areas. Inconspicuous doors are made in places where shut-off valves are installed. This gives access during maintenance to pipe connections, which are the weakest links in the system.

It should also be noted that pipes made of not all materials can be hidden under a layer of plaster - only products made of polypropylene, metal-plastic or copper are suitable for this.

Open pipe laying is carried out after finishing is completed. The method involves the uncovered laying of pipes and water supply elements. It looks ugly and reduces the usable area of the room, but at the same time this method is very convenient for maintenance, repair and dismantling of elements.

Redevelopment and rearrangement of plumbing in the house with such a plumbing arrangement will also not cause difficulties.

Open wiring makes it possible to quickly detect the location of a leak and eliminate the cause of breakdown or damage to system elements

Products on the market

Depending on the material, the cost of products ranges from 400 to 2500 rubles. Collector groups for 200-300 outputs can cost 10,000-40,000 rubles.

There are models from different manufacturers on the market, the popular ones include:

- Watts;

- Uponor;

- Giacomini;

- APC;

- Luxor;

- Fado;

- Caleffi;

- Valtec;

- Bianchi.

The stores offer not only combs, but also accessories. Products without taps are economical. They are used to install individual wiring and make it possible to select suitable parts. Purchasing a product with shut-off valves will make the installation process easier. When assembling the units, the need to install valves disappears.

To adapt the device to the home system, components are purchased. These include valves, valves, and pump groups. Mechanical drives, plugs and pipes are required.

Manifold cabinets are used for wall mounting and maintaining an aesthetic appearance.

Common installation mistakes

It is best to entrust the design of a water supply system, both collector and tee, to professionals familiar with building codes and capable of performing hydraulic calculations. But even the best project will be useless if mistakes are made during its implementation.

Shut-off valves are part of any water supply scheme: both sequential and collector. They are installed at the entrance to the water supply system, as well as in front of each plumbing fixture.

For example, some would-be craftsmen, driven by the thought of unreasonable savings, neglect the requirement to insulate hot water pipes that are laid under the floor or in the thickness of the walls. As a result, part of the thermal energy is transferred to the materials surrounding the pipe, which deteriorates the quality of the water. In addition, condensation from the surface of pipes without thermal insulation can damage the finishing of the room.

During installation work, experienced craftsmen recommend covering the ends of pipes that have not yet been installed to prevent debris from getting into them. The absence of this protective measure may lead to the fact that immediately after installation the water supply system will have to be thoroughly and for a long time flushed or even repaired.

When soldering polypropylene water pipes, you should remember that slight dirt or moisture at the soldering site can significantly impair the quality of the work

If soldering of plastic pipes is necessary, all work should be performed in a clean room to avoid contamination. It is also unacceptable to solder pipes that contain even a small amount of moisture. A drop of water or particles of debris at the soldering site can significantly weaken the connection and degrade its quality.

You should not design the water supply system in such a way that all pipes pass through the ceiling through one common hole. This may degrade the performance of the water supply. Professional designers never make such mistakes.

When drawing up a wiring plan, it is necessary to ensure that the pipes do not block access to the joints. This will make repairs much easier in the event of a leak.

An insufficient number of locking devices can also cause a lot of trouble during installation work. Such fittings must be present in front of each device to which water is supplied, as well as for each riser. If the house has more than one bathroom, you can install a shut-off valve for each of them.

Sewerage is usually designed simultaneously with the water supply system. It is necessary to ensure that the pipes and risers of individual systems do not overlap each other. This will make maintenance and repair work easier in the future.

What will you need besides pipes and fittings?

An effective system cannot operate safely without:

- main valve of inlet shut-off valves;

- multi-stage purification filtration station;

- devices for adjusting and setting operating parameters;

- flow control instruments;

- devices for protection against the consequences of accidents;

- other additional equipment.

Each of these elements is necessary for the system to operate smoothly, be monitored, configured, and protected.

Main valve, inlet shut-off valves

This is a device that operates in two positions (open, closed). The task is to cut off the water supply from the riser if it is necessary to carry out repairs or in the event of a long absence of apartment residents. An alternative is valves that smoothly regulate water pressure and operate in an intermediate position. But such valves are more expensive than conventional ball valves.

Filtering devices

The minimum set consists of two types of filters:

Coarse cleaning

Installed at the inlet after the ball shut-off valve. The purpose of the filter is to catch large solid contaminants (rust, scale, etc.).

Fine cleaning

Absorbs small solid suspended particles. Special cartridges with fiber filler are used as filter elements.

Each filter requires periodic maintenance. During rough cleaning, the particles are retained by a metal mesh, which must be removed and washed. There are filter models equipped with a self-cleaning system. You have to buy new fine cleaning cartridges.

Regulating devices

The task of the stabilizing reducer is to maintain a comfortable pressure in the distribution pipes - this is from 3 to 4 bar. You can also use an electronic version - this is a pressure switch, which will eliminate the possibility of water hammer. A sharp surge in pressure can damage washing plumbing fixtures and wiring elements.

Check valves also fall into the category of control devices. They are needed if boilers are to be connected, and they protect the system from spontaneous drainage of water from the tank into the riser when the water supply is turned off.

Metering devices

The use of meter models is regulated by GOST. Installing it is not enough; flow metering devices must be calibrated and sealed. This is done by special water utility services. The device is equipped with a strainer and a check valve. When installing, there must be straight pipes on both sides. This will eliminate measurement error.

Emergency devices

This is a “smart electric valve” - this device protects the wiring from breaks and leaks, and the apartment from flooding. If a hose or pipe bursts, the pressure will drop sharply, and the device will immediately cut off the water supply.

Other auxiliary devices of sanitary cabinet

Properly organized plumbing in an apartment allows you to control operating parameters during operation of the water supply system. For this purpose, pressure gauges are used that measure the water pressure in the pipes. When there are several of them, the presence of a difference indicates a blockage that can be eliminated.

The manifold-distributor is a separate element that is involved in flow distribution. The number of outputs depends on the number of consumer devices. Ideally, each outgoing branch is equipped with a ball shut-off or check valve, depending on the need. Pressure gauges and emergency protection devices are also installed here.

Pipe layout classification

To achieve maximum efficiency of the coolant in the radiator, you should carefully approach the installation. There are several types of heating system wiring, differing in design and number of pipes involved.

Classification of heating system wiring:

- plinth

- single-pipe;

- two-pipe;

- collector

There are also four options for mounting circuits:

- Hidden. In this case, the pipes are recessed into grooves in the wall or screed.

- Open. The pipes are placed outside, this option is less labor-intensive.

- Vertical.

- Horizontal.

Natural and forced flow of water in the pipeline is possible.

- Open. In this case, the expansion tank comes into contact with the environment. Because of this, you need to constantly monitor the water level in the middle.

- Closed. In this design, constant internal pressure is usually established. The expansion tank includes a rubber bulb with a metal casing. In this case, the liquid does not come into contact with the external environment.

Types and types of water supply collectors

Collectors may differ from each other both in their design and in the materials from which they are made. That is why when choosing these devices you need to be as careful and careful as possible.

Brass manifold

The following materials can be used in the production of a water supply collector:

Stainless steel. Its main advantages include resistance to corrosion. In addition, this metal can withstand high temperatures and contact with fire. In terms of overall dimensions, the combs, made of stainless steel, are quite small. That is why they can be easily and without any problems installed inconspicuously in the right place in the house.

It is also worth noting that this material is environmentally friendly. Products made from it have a very attractive appearance. Brass

This material is distinguished by its high strength, which exceeds that of stainless steel. The advantages of brass also include its resistance to corrosion and high temperatures. Combs made of this alloy are characterized by high cost. That is why they are not available to all buyers. Polypropylene. The advantages of such collectors include low weight and resistance to corrosion. The disadvantage of this material can be considered primarily low strength. It is also worth paying attention to the poor resistance of polypropylene to high temperatures.

Also, water supply collectors differ in the method of fastening. The comb model must be selected based on the material the pipelines are made of. In this regard, it is worth highlighting the following types of collectors:

- combs for installing faucets and other plumbing fixtures;

- combs with compression fittings, allowing you to connect pipes made of metal-plastic and polyethylene;

- combs for installation of pipelines made of polypropylene;

- combs for Eurocone, allowing you to connect pipes from almost any material.

Collectors for water supply may also differ in design, implying a particular number of outlets. There can be from 2 to 6. If some of them are not required, such outputs can be closed using plugs.

Some expert advice

After deciding how to install water supply in the apartment, it is necessary to draw up a design for the water supply system. Regardless of the method of pipe routing - collector or radial, its development is best entrusted to professionals who understand building codes and are able to make hydraulic calculations. But even the best design solution must be implemented correctly.

Mistakes made can lead to irreparable consequences:

- In some cases, in order to save money, craftsmen neglect the need to insulate hot water pipes laid in the thickness of the walls or under the floor covering. As a result, installing pipes in an apartment without thermal insulation leads to the fact that thermal energy is partially transferred to nearby materials and the quality of water deteriorates. In addition, condensation that collects on the surface of the pipeline without insulation can ruin the finishing of the room.

- When performing installation work, experts recommend covering the ends of pipes that have not yet been installed so that dirt and debris do not get inside them. If this precautionary measure is neglected, then after the installation is completed, the water supply system will have to be flushed for a long time and thoroughly, and in some cases, repaired.

- If it is necessary to solder plastic pipes, it must be done in a clean room where there is no possibility of contamination. Such work cannot be done when there is even a little moisture on the pipes. If water distribution is carried out in the kitchen or in another room, then particles of debris or a drop of water at the soldering points will significantly weaken the strength of the connection. As a result, the water supply will not be of high quality.

- Experts advise not to design a water supply system so that all pipes are laid in the ceiling through one common hole. This leads to deterioration in the performance of the water supply system. By the way, professional designers never make this mistake.

- Also, serious problems during installation work can result from an insufficient number of locking devices used. This type of fittings must be present in front of each plumbing fixture to which water is supplied. It is also installed for each riser that provides water supply to the apartment.

- If it is planned to install not one, but several bathrooms at a residential property, it is advisable to install a shut-off valve for each of them.

Typically, professionals simultaneously design the layout of water supply and sewer systems. The main condition that must be observed is to ensure that the risers and pipelines of each of them do not overlap each other. In the future, compliance with this requirement will facilitate repair work and maintenance of utilities.

General installation tips

Before installing the pipeline, it is necessary to install all fasteners and complete welding work. Pipes that were stored or transported at sub-zero temperatures before installation are kept for at least 24 hours at temperatures above 10°C. Before starting installation, it is necessary to level them and prevent deflections in the future.

Pipes are secured to walls and supports with clamps or hooks. The distance from fasteners to threaded connections must be more than 5 cm

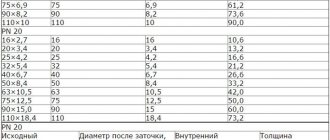

For water risers, pipes with an outer diameter of at least 20 mm are used, for floor wiring - with a diameter of 16 mm and 14 mm. It is better to use as few dismountable connections as possible. It is necessary that all connecting elements correspond to the type (series) of pipes and, like fittings and revisions, are located in accessible places.

Horizontal sections of the water supply system must have a slope towards the drainage fittings to allow water to drain; the slope is made towards the device through which air will escape when the system is filled with water. When installing vertical structures, do not allow them to tilt more than 2 mm per meter.

When installing the pipeline vertically, the hot water supply pipes are placed to the right of the hot water supply pipes. When installing horizontally, the cold water supply is placed below the hot water supply to avoid the formation of condensation.

Close the channels or embed the pipeline only after a test run of the system and checking it for operability, leaks and damage.

When operating a hot water supply, a phenomenon called thermal expansion occurs, which is especially typical for products made of polypropylene. This can cause pipes to lengthen, leading to damage and leaks.

Correct placement of fasteners and self-compensation of such pipeline sections as bends, turns, and “snake” gaskets prevent deformation.

Technical characteristics of PLP collector units

| B rand | View | Supply manifold diameter, mm | Distance between taps, mm | Number of taps | Type of execution | Diameter of connection to risers, shut-off valves, filter, mm |

| Floor heating | ||||||

| PLP | UKE | 50 | 100 | 4 | l | 25 |

| PLP | UKE | 50 | 100 | 5 | l | 25 |

| PLP | UKE | 50 | 100 | 6 | l | 25 |

| PLP | UKE | 50 | 100 | 7 | l | 25 |

| PLP | UKE | 50 | 100 | 8 | l | 25 |

| PLP | UKE | 50 | 100 | 9 | l | 25 |

| Floors for water supply | ||||||

| PLP | UKE | 50 | 100 | 4 | l | 25 |

| PLP | UKE | 50 | 100 | 5 | l | 25 |

| PLP | UKE | 50 | 100 | 6 | l | 25 |

| PLP | UKE | 50 | 100 | 7 | l | 25 |

| PLP | UKE | 50 | 100 | 8 | l | 25 |

| PLP | UKE | 50 | 100 | 9 | l | 25 |

| PLP | UKE | 50 | 100 | 10 | l | 25 |

| Apartment | ||||||

| PLP | UCC | 50 | 100 | 2 | l | 25 |

| PLP | UCC | 50 | 100 | 3 | l | 25 |

| PLP | UCC | 50 | 100 | 4 | l | 25 |

| PLP | UCC | 50 | 100 | 5 | l | 25 |

| PLP | UCC | 50 | 100 | 6 | l | 25 |

| PLP | UCC | 50 | 100 | 7 | l | 25 |

| PLP | UCC | 50 | 100 | 8 | l | 25 |

| PLP | UCC | 50 | 100 | 9 | l | 25 |

| PLP | UCC | 50 | 100 | 10 | l | 25 |

Solar collector savings opportunity

It is possible to connect several coolant heating sources to the heating circuit. Often solid fuel boilers operate in parallel with electric ones. this allows you to maintain the operating mode of the heating system at night or in the absence of owners for several days.

But this mode cannot be called economical - electricity is one of the most expensive resources. Modern developments make it possible to use solar energy to heat the coolant by installing a solar collector.

The solar collector is an installation that can be used all year round, even in cloudy temperatures. On sunny days it is most effective and heats up to the temperature of the boiler supply circuit - up to 70-90 degrees.

Homemade solar collector

A solar collector is a fairly simple device; it is not difficult to make it yourself. In terms of efficiency, a homemade solar water heater may be inferior to industrial models, but given their price - from 10 to 150 thousand rubles, a solar collector made by yourself will very quickly pay for itself.

To make it you need:

- a coil made of a metal tube, usually copper, you can take a suitable one from an old refrigerator;

- scraps of copper pipe with a 16 mm thread on one side;

- plugs and valves;

- pipes for connection to the collector unit;

- storage tank with a volume of 50 to 80 liters;

- wooden planks for making a frame;

- sheet of expanded polystyrene 30-40 mm thick;

- glass, you can take window glass;

- thick aluminum foil.

The coil is freed from freon residues by washing it with a stream of running water. A frame with a size slightly larger than a coil is made from a wooden lath or block. Holes are drilled in the lower part of the frame to remove the coil tubes.

On the reverse side, a sheet of polystyrene foam is attached to it with glue or self-tapping screws - this will be the bottom of the collector. This material has excellent thermal insulation characteristics, which will help reduce heat loss.

The top of the solar collector is covered with glass, securing it to glazing beads or slats. Pipes are attached to the ends of the coil for connection to the heating manifold unit. This can be done using adapters or flexible liners.

The collector is placed on the southern slope of the roof. The pipes lead to a storage tank equipped with an air valve, and from there to the heating distribution manifold.

Video: how to make your own solar heater

A manifold heating system is the most efficient way to connect different heaters to one or more heating sources. With its help, you can ensure stable temperature and comfort in the house, as well as uninterrupted and coordinated operation of all elements of the system.

Advantages of the scheme

Heating systems for a country house

The advantages of this coolant supply scheme are ease of use. Operation of the system and control of heating devices are as comfortable as possible:

- The temperature of each circuit element can be controlled centrally. Being near the collector, the homeowner can limit the supply of coolant to any register or turn it off completely. It is convenient to control the temperature in each room.

- Each branch that extends from the collector feeds only one radiator. Therefore, small-diameter pipes can be used to lay highways. In most cases, highways are laid in a concrete base. This heats up the floor.

- If necessary, using a collector it is easy to form several independent circuits with different temperature indicators. For this, it is preferable to use the so-called hydraulic arrow - a type of collector. It is distinguished by a large internal diameter of the pipe.

The installation of this version of collector heating is somewhat unusual. It is proposed to create short circuits between the hot water supply and the return lines.

The water heated by the boiler constantly circulates along the contours of the hydraulic arrow. In this case, the hot coolant can be collected at different distances from the collector, creating a temperature difference even in a single room. This option can be used for complex heating of a house - using traditional systems and “warm floors”.