Ventilation refers to communications, the installation of which is planned at the stage of creating a private house construction project. This is justified by basic sanitary and hygienic requirements. Without proper air exchange, comfortable living is simply impossible.

We will tell you how to insulate a ventilation pipe to ensure its normal operation in winter. From the article we present you will learn which thermal insulation materials meet modern requirements. You will understand how to choose the best option for insulation.

Interested DIYers will find brief instructions on how to install a thermal insulation barrier. Those who decide to insulate the hood themselves will receive information proven in practice. Compliance with our recommendations is a guarantee of a successful result.

In what places do pipes need to be insulated?

places for insulation of ventilation pipes

Insulation always remains mandatory for the surface of the air duct outside the heated volume. This is especially true for areas such as the cold attic and roof. Work is not required when passing through attics and heated second floors. These components require insulation inside heated rooms:

- Pipes through which air flows to devices.

- Fan installations.

- Supply ventilation ducts.

The action is mandatory for buffer zones, which include:

- Boiler rooms.

- Storage rooms.

- Cellars.

- Auxiliary objects.

Technique of work execution. Step-by-step instruction

When thermally insulating air ducts that are located outside the heated premises, insulation is carried out from the outlet to the deflector. If the pipe goes through the attic and passes through the roof, it must be insulated along the entire length of the section in the attic. The same requirements apply to the zone that goes through an unheated room.

The heated supply system is equipped with appropriate material throughout. The use of boxes is often resorted to in attics. Thermal insulation in this case has the form of casings and consists of foamed polyethylene. Among the advantages of this approach are the affordable cost and the ability to purchase goods at any hardware store. It is recommended to select a casing based on the size of the pipe.

Foamed polyethylene can deteriorate when exposed to ultraviolet radiation. To eliminate this effect, it is necessary to cover the outside of the structure with aluminum kitchen foil. When insulating supply air ducts, it is necessary to measure the diameter and height of the system from the outside. Next, prepare a casing of the required size. If an umbrella is installed, it must be removed. The casing is stretched to the base of the pipeline. The umbrella can then be returned to its place.

Foil is applied to the system from bottom to top. This will increase the service life of the structure. Using copper or stainless steel clamps, you can fix the winding. If the work is carried out in central Russia, this solution is best suited. If we are talking about a more severe climate, you will need reinforced insulation like mineral wool. It works well on domestic and industrial ventilated ducts. If desired, the material can be used inside and outside. A typical example is Isover coatings.

Why is condensation dangerous?

ventilation system condensate

During exhaust ventilation, condensate has other consequences and composition when it comes to stove and fireplace pipes. The main composition is pure water, to which dust is mixed. Soot and acid-forming oxides are added to it when it comes to kitchen hoods. Such components are not highly aggressive, but increase the rate of destruction of internal parts.

Stainless steel pipes also corrode faster. But the total lifespan of such products reaches tens of years, so in practice it is difficult to establish exact figures. Galvanized steel structures are less resistant to acids. You shouldn’t focus too much on the condensation inside.

Sealed and correct installation is important for the pipes themselves. Acid solutions do not cause damage to plastic products.

Thermal insulation of ventilation ducts is selected according to three main criteria:

- Thermal conductivity.

- Fire safety.

- Material cost.

In the modern market, preference is most often given to a mineral base. Each variety has its own characteristics, negative and positive sides.

Conclusion

Which insulation you choose is up to you to decide. The author's sympathies are given to foil materials based on polyethylene foam, but this is more a matter of habit. In the video presented in this article you will find additional information on this topic.

In a private house, the attic can be very warm and used as an additional room. But most often it is used as a storage room. The pipelines that run across its area make it difficult to change its purpose. If you decorate them correctly and sew them up with boxes, you will be able to make this room more cozy and comfortable.

Mineral wool

thermal insulation of ventilation ducts with mineral wool

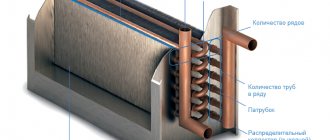

Manufacturers use the term to designate insulating materials based on basalt or slag, glass fibers. They are usually produced in the form of flexible mats or slabs that cover the air duct.

On the negative side:

- Gradually cakes, even if the rooms are completely dry.

- Constant contact with moisture leads to loss of some properties.

- Strongly absorbs water, it stays in the composition for a long time.

- The presence of phenol-formaldehyde resins in the composition.

- Lightweight and brittle material, even during installation it forms a large number of small fragments. The roof is no exception.

But there are also advantages:

- Low prices.

- Fire safety, ability to withstand temperatures up to +450 degrees.

- Strength.

- Elasticity.

- Noise and heat insulation at a high level.

Rolled insulation in the form of mats is most often used when it is necessary to insulate round-shaped structures.

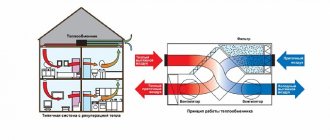

Types of ventilation systems

Ventilation systems are divided according to the principle of operation into exhaust, supply, and supply and exhaust. There are no differences in the installation of thermal insulation for them. Depending on the location of installation, ventilation systems can be domestic or industrial. The area, air exchange of pipelines, and the volume of harmful fumes in production are many times higher than in residential, office or commercial premises - more powerful equipment is required. Another difference is that household ventilation systems often use plastic pipes, while industrial ones use galvanized metal pipes.

Metal ventilation pipes especially need protection from condensation. In the process of cutting into pieces of the required length, the galvanization layer is broken. Contact with moisture causes the metal to quickly rust, and the pipe becomes unusable within 2 to 3 years.

Fig.3 Industrial ventilation system

Basalt wool

basalt wool for chimney insulation

Composition of rock fibers in molten form. Mineral group insulation whose properties have been improved. Sold in the form of slabs and mats, like other varieties. Installation also involves the same actions as in the case of mineral wool. The chimney can be reliably protected.

Some manufacturers produce ready-made basalt fiber cylinders, which speed up installation. There is a foil coating, or the products are made without it. The price is higher compared to mineral wool. Cheap brands can be dangerous to the health of others.

The material has more advantages:

- High thermal insulation coefficient.

- Durability.

- Fire safety.

Aluminum foil on one side and special water-repellent compounds provide additional protection. Even the roof sometimes allows such insulation.

Installation procedure

The method of installing insulation directly depends on the selected material. Scotch tape is used to secure basalt wool. When installing a ready-made foam shell, special attention is paid to sealing the connecting seams.

It is not necessary to install a heat insulator on the entire ventilation system. It is important to ensure the proper level of protection from the effects of negative temperatures in certain sections of the pipeline:

- Ventilation outlet to the roof. This is where the greatest heat losses occur;

- Passage of the main through an unheated room. Most often this refers to the attic;

- Areas of direct contact between the pipe and the outer wall of the building.

In all other cases, installation of insulation is not necessary. It is important to periodically check for possible condensation on the inner surface. If it appears even after sealing the air ducts, an additional layer of insulation will be needed.

Foamed polyethylene

Outwardly it resembles foam rubber, but its cells are larger. Available in several varieties:

- Pipe insulation.

- Self-adhesive.

- Foiled.

- Ordinary.

Allows dismantling and reuse if necessary. Elastic and durable material that retains its original characteristics for a long time. Lasts up to 10 years and is easy to install.

The only disadvantage is melting when and ambient temperatures

Briefly about the main thing

When insulating air ducts, the main thing is to choose a high-quality insulator that has a minimum of disadvantages and a low price. If you are just about to install ventilation, then it is better to purchase RIP plates in a rigid design. With special locks on the edges. A warm air duct is assembled from them, which will last for more than 50 years without human intervention.

It is better to insulate finished ventilation from pipes with extruded foam. The shells are quite dense and durable, but are afraid of sunlight. Therefore, it is better to place them in the attic or basement. If they are not touched after installation, they can also last for more than half a century.

Foamed synthetic rubber

foamed synthetic rubber

A material whose main function is to insulate pipes. 90% of the structure is closed pores. It differs from PPE in increased flexibility, although in appearance the materials are very similar to each other. Available in the form of sheets and rolls, mats and tubes. There are brands to which glue is added on one side.

Foam rubber has the following positive aspects:

- Low prices.

- No secretions containing harmful substances.

- Self-extinguishing material of high flammability class.

- Mold resistance.

- Moisture protection.

Styrofoam

A type of foam mass, including polymers or plastic. But the main volume in this case is occupied by gas. Allows the option when one of the sides is covered with foil. Rigid material with a release form in the form of slabs or pipe insulation. The only disadvantages are that it burns too easily and attracts rodents. This foundation has many more advantages:

- Low prices.

- Rot protection.

- Easy cutting and installation.

- Light weight.

Installation of insulation can be carried out using the principle of brickwork. To connect the elements to each other, a special glue is used; its usual varieties are not suitable.

Fastening method using welded pins and washers.

1. Preparing the duct housing.

2. Pattern.

3. Checking and setting up welding equipment.

4. Preparation of pins and clamping washers.

5. Welding the pins.

Additionally: Pin welding diagram.

6. Hanging mats.

7. Fixation of washers.

8. Stitching mats.

9. Welding pins through insulation.

- Preparing the duct housing. Before proceeding with installation using welded pins and washers, you must ensure that the duct housing is made of steel with a thickness of at least 0.8 mm and has the correct shape, and is securely attached to the supporting structure of the building or structure. Flange connections must be reinforced with heat-resistant sealant, basalt tape or asbestos cord. The outer surface must be treated to remove dirt, grease and dust. If the air duct is partially primed or painted, these areas must be cleaned.

- Pattern. The mat must be cut with an overlap of at least 100mm around the entire perimeter. It is not recommended to place mat joints at the bottom of the duct to cover the maximum perimeter of the duct. In other parts, cutting and joining of mats is possible.

- Checking and setting up welding equipment. Before you start working with the welding machine, make sure it is working correctly; select the appropriate head size and adjust the voltage on the machine depending on the thickness of the mat.

- Preparing pins and clamping washers. The pins must be straight and level. If there are irregularities, they need to be corrected or the pins replaced. The number of locking washers must correspond to the number of pins being welded. All washers must have a cross-shaped cut to secure them to the pins.

- Welding pins. The pin welding points are outlined based on the design features of the air duct (size, cross-section configuration, etc.). When placing welding pins on the walls of the duct, it is recommended to adhere to the following rules:

- the maximum distance between the pins vertically and horizontally is 350 mm;

- the maximum distance from the edge of the duct to the first row of pins is 100 mm.

- Hanging mats. Pre-cut mats must be hung on the welded pins. The mat is hung in such a way that the air duct cross-arm is under it, and the flange connections of the air ducts are covered with the mat.

- Fixation of washers. The sharp ends of the studs are cut off with wire cutters, leaving a margin of 2-3 mm for fixing the washer, or protective caps are put on. The washers are covered with a piece of mineral wool mat and secured with aluminum tape.

- Stitching mats. The mats are sewn together with wire, and the joints are sealed with stone wool scraps and fixed with wire. In addition, aluminum cattle can be used. Outdoors, it is necessary to provide a covering layer of duct insulation.

- Welding pins through insulation. To fasten the mats through the stitching mat, combination pins with a locking cap are used.

Expanded polystyrene

insulation with polystyrene foam.

A type of polystyrene foam, only with improved characteristics. Differs in the following characteristics:

- Service life up to 5 decades.

- Operating temperatures from -50 to +75.

- During static bending, a high strength limit is observed.

- Over 30 days, the water absorption coefficient is 0.4%.

- Thermal conductivity is at a high level.

The installation rules, advantages and disadvantages largely coincide with the information that has already been provided regarding polystyrene foam.

Requirements for material characteristics

In order for the insulation to serve for a long time, not to become damp before its time, not to become moldy, and to perform all the tasks assigned to it, it must have the following qualities.

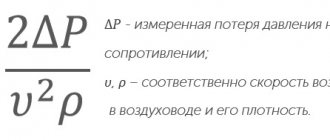

One of the most important characteristics is the thermal conductivity coefficient , expressed in W/m•°C. The degree of cooling of the air in the pipes depends on it. Manufacturers, taking into account different installation conditions, produce thermal insulation materials of various thicknesses and densities.

The table shows popular building materials used for thermal insulation of air ducts. Using the given data, it is possible to determine the dependence of the thermal conductivity coefficient on the density and thickness of the material

The second important parameter is vapor permeability . If the air ducts are prone to condensation, it first penetrates into the insulation and increases its moisture content, which increases thermal conductivity.

If for insulation you have chosen porous, fibrous materials that easily absorb moisture, take care of additional vapor barrier. The simplest option is to wrap the insulated area with plastic film

The next characteristic is acoustic efficiency . Air moves inside the ducts, causing vibration and noise. A running fan also creates sound waves. They are transmitted through the air and through the rigid structure of the air duct into the surrounding space and create discomfort for the residents of the house.

To reduce the noise level as much as possible, you need to think through the design features of the air ducts, make them straight, with a minimum number of turns. Noise can be significantly reduced by using sound-absorbing insulation.

Do not lose sight of such quality as resistance to biological influences . The less suitable the material is for the formation of mold colonies and the proliferation of various microorganisms, the longer it will last, and along with it the structure of other building materials - for example, wood or concrete - will be preserved.

Mold not only causes the destruction of natural materials, but also negatively affects your well-being. If you plan to place a living room in the attic, ensure normal temperature and humidity levels

For thermal insulation material, such a parameter as operating temperature . It differs for different insulation materials, but the average range is from -35°C to +60°C.

And one more characteristic - sanitary and hygienic properties . Thermal insulation should not distribute toxic gases harmful to health. From this point of view, materials that contain components of natural origin are valued - for example, felt or mineral wool.

PIR boards

PIR boards – ventilation duct insulation

New generation insulation, which is characterized by a rigid cellular structure. Both sides of the materials are covered with foil.

The positive aspects and characteristics are described as follows:

- Rot resistant.

- No risk of damage during installation.

- Low- and moderately flammable material.

- Service life up to 5 decades.

- 120 kPa is an indicator of compressive strength.

- No more than 1% water absorption.

- High thermal conductivity coefficient.

The question of choice is always decided in favor of external insulation. The reason is that the technology for carrying out work is too complex in the case of analogues.

thermal insulation of air ducts

Theoretically, work can be carried out inside and outside the system equally. But the outdoor option is chosen more often. The final quality of the material depends on the thickness of the layer. When choosing, you need to rely on several indicators at once:

- Temperature regime.

- Aggressiveness of the environment.

- Humidity, and so on.

The calculations are carried out by specialists, the formulas are given in the current SNiPs. The final result depends on a large number of factors, so it is not recommended to deal with the issue yourself.

Features of thermal insulation

The technology for protecting ventilation pipes from cooling depends on the type of insulation and its performance properties. In this case, it is necessary to follow the sequence of work and carefully perform all operations.

Insulation with mineral wool

It happens as follows:

- the surface of the ventilation pipes is cleaned of dirt and dust;

- a strip of the required size is cut from the roll, which depends on the diameter of the air duct;

- thermal insulation of ventilation pipes made of mineral wool is carried out in one layer, while you need to ensure that the material adheres tightly to the surface;

- The air duct is wrapped with foil insulation over the mineral wool;

- glue the resulting seams with aluminum tape.

- The pipe is wrapped in one layer of mineral wool insulation.

- On top of a layer of cotton wool, wrap the pipe with foil insulation (4 mm thick), which will help retain heat and prevent cold air currents from entering.

Particular attention should be paid to sealing the structure, since mineral wool, when interacting with moisture, deteriorates its thermal insulation properties

Polyethylene foam insulation

This method is one of the most popular because it combines ease of implementation and efficiency. For insulation, foamed polyethylene is used in the form of shells, with which the following actions are carried out:

- measure the insulation of the required size;

- cut the shell along a special seam;

- install the resulting elements around the pipe;

- glue seams and joints using glue or mounting adhesive tape.

For pipes with a square cross-section, it is much more convenient to use polyethylene in rolls.

Polyethylene foam shells

Basalt fiber insulation

With its help you can not only protect air ducts, but also gas pipes. Basalt fiber prevents the occurrence of fires and the spread of fire. How to insulate gas pipes? To do this you need:

- prepare additional wire and aluminum foil;

- wrap the pipe with basalt fiber and then cover it with a layer of foil;

- secure everything with wire, including the longitudinal seam;

- secure the layers of insulation with bandage buckles made of packaging or aluminum tape.

You can also use basalt fiber with a metallized layer to insulate air ducts.

Insulation using basalt fiber

Expanded polystyrene insulation

In this case, the insulation resembles a shell, and the insulation of ventilation pipes is carried out as follows:

- measure out the shell halves of the required size;

- cut polystyrene foam along the marked lines;

- The shell halves are placed on the pipe, shifting them by 20-30 cm.

- close the side connections, ensuring tightness.

Protective shells made of polyurethane foam with foil outer layer

Polypropylene and polyurethane foam insulation are a similar form but have lower thermal conductivity and fire resistance. Fixation of individual parts is carried out using special bandages. Polyurethane foam can also be sprayed onto the pipe surface.

Air duct protection has a significant impact on its service life. By correctly selecting the material for insulating the ventilation pipe, and following the technology for carrying out thermal insulation work, you can ensure the effective functioning of the system for a long time without damage or repair.

Methods for insulating street air ducts

The thermal insulation design in this case must necessarily include the following components:

- Fastening elements.

- A covering layer that often requires additional UV protection.

- Thermal insulation layer.

The materials and operating rules repeat much of what is used inside.

If the installation is carried out outdoors, then you cannot do without waterproofing for mineral wool. An acceptable choice is roofing felt.

Special attention is paid to the place where the air duct passes through the roof. Master flash is the best option for isolation in this case. When passing through the attic floor, thermal insulation is also considered a mandatory requirement.

Initial data for calculations

When the diagram of the ventilation system is known, the dimensions of all air ducts have been selected and additional equipment has been determined, the diagram is depicted in a frontal isometric projection, that is, axonometry. If it is carried out in accordance with current standards, then all the information necessary for the calculation will be visible on the drawings (or sketches).

- Using floor plans, you can determine the lengths of horizontal sections of air ducts. If the heights at which the channels pass are marked on the axonometric diagram, then the length of the horizontal sections will also become known. Otherwise, sections of the building with laid air duct routes will be required. And in extreme cases, when there is not enough information, these lengths will have to be determined using measurements at the installation site.

- The diagram should show, using symbols, all additional equipment installed in the channels. These can be diaphragms, electrically driven dampers, fire dampers, as well as devices for air distribution or exhaust (grills, panels, umbrellas, diffusers). Each piece of this equipment creates resistance to the air flow, which must be taken into account when calculating.

- In accordance with the standards, air flow rates and channel sizes must be indicated on the diagram next to the conventional images of air ducts. These are the defining parameters for the calculations.

- All shaped and branching elements must also be reflected in the diagram.

If such a diagram does not exist on paper or in electronic form, then you will have to draw it, at least in a draft version; you cannot do without it when doing calculations.

How is indoor air duct insulation performed?

insulation of air ducts indoors

Air ducts are often placed indoors, in this case insulation is also indispensable. The technology is not much different from projects that are carried out outside. The only difference is the absence of a mandatory requirement for the installation of an external protective layer. An exception is made only for aggressive operating environments and additional conditions that make the situation more complicated.

Most often, the materials are similar to those used for floors and walls. The air ducts are covered with a special membrane to provide waterproofing. Next comes the insulation, to which foil is added in another layer or a membrane. The first option is preferable; it helps create a kind of vapor barrier.

Purpose and types of thermal insulation

Insulation of air ducts allows you to maintain a comfortable microclimate and favorable temperature conditions in the premises, prevents the formation of condensation on the surface of the pipes and prevents their destruction. It also reduces the level of noise and vibration that occurs due to air movement during the operation of the ventilation system.

Depending on the location of the materials in relation to the air ducts, internal and external thermal insulation are distinguished. Insulation from the inside is different:

- the need to use ventilation pipes of larger diameter;

- carrying out additional compaction measures if materials with a loose structure serve as thermal insulation;

- tendency to form bacteria and spread them through the air duct;

- low fire resistance.

Internal insulation of ventilation pipes

Ventilation pipes insulated from the outside do not have these disadvantages. They are easily cleaned of dust and dirt and treated with special compounds that prevent the formation of bacteria. In addition, the cost of external thermal insulation is much cheaper than internal.

External insulation of ventilation pipes

When insulating from the outside, pipes can become a source of noise, but this can be easily avoided by installing special devices as mufflers.

Typically, thermal insulation of gas pipes is carried out externally, taking into account the purpose and material of the structures.

How to calculate the required thickness of insulation?

Surface heat transfer and thermal conductivity are the main indicators that need to be taken into account. Each material in this regard has its own characteristics that distinguish it from existing analogues. The lower the thermal conductivity, the thinner the layer required for installation.

Making the right choice of materials in accordance with the standards is not as difficult as it seems at first glance. But the installation of thermal insulation itself also requires a competent approach, otherwise it will not be possible to fulfill all the requirements. Before carrying out construction work, it is recommended to check the ventilation and its operation - is full power maintained, is there any contamination? No amount of insulation helps even if the pipes themselves were initially installed incorrectly. Then it is worth correcting the existing problems.

Recommendations from experts

When choosing a suitable material for thermal insulation of a ventilation system, consider:

- The thermal conductivity coefficient should be as low as possible.

- Moisture resistance. The loss of insulating properties due to moisture absorption can nullify all the advantages of the material, including the low price.

- Difficult to install. The cost of specialist services depends on the danger of the material and the characteristics of its fastening. Insulating with cheap insulation can end up costing more than the highest quality insulation. If the work is supposed to be done independently, then the investment of time and effort is important.

- Fire safety class. This indicator can be decisive when choosing between two insulation materials with similar characteristics, if we are talking about a room with a high risk of fire.

According to experts, the best option for insulating vent pipes is foamed polyethylene. Foam rubber surpasses it in all characteristics and has no disadvantages.