In an underfloor heating system, one of the key roles is played by the underfloor heating collector. Let's figure out how to choose and connect a collector or heating comb correctly, and how to avoid typical mistakes when installing a distribution unit yourself. We asked the specialists of the Miralex store, which offers a wide range of components for water heated floors, to tell us which models of collectors are popular today and meet all safety requirements.

Collection group Source roomester.ru

Purpose

A warm floor is usually a system that includes several heating circuits - at least one for each room. With a large floor area or to control heating separately in different zones of the same room, two or more circuits are used.

Heating comb, distribution manifold - names of the device that ensures the flow of coolant into the circuits of the floor heating system. The distribution unit consists of two combs - one of them is responsible for distributing the coolant heated by the boiler over the connected heating circuits, the second collects the cooled coolant and supplies it to the return pipe for return to the boiler.

Mounted distribution unit Source ad-cd.net

In addition to the main function of distributing and collecting coolant, the collector unit can solve a number of other problems. Depending on the configuration, it can:

- be responsible for deaerating the system;

- ensure regulation of the coolant supply in the required volumes;

- regulate the flow of circulating fluid using manual or automatic flow meters.

This allows you to maintain optimal temperature conditions in each room, depending on the requirements for the microclimate, and eliminate airing of the heating system, which results in a decrease in the efficiency of its operation. Shut-off valves are also installed on the supply and return manifolds - through them the circuits are filled with coolant, the system is pressure tested, and the liquid is drained.

Manifold group with automatic air vents Source tvo.by

Mixing valves

When connecting the manifold, two types of mixing valves are used: two-way and three-way. They are designed for mixing liquids: hot, which comes from the boiler, and cooled, respectively, from the heating circuit. They are controlled manually or automatically - requiring additional installation of a servo drive or control device.

Three-way ones are used, as a rule, for collectors intended for heating large rooms with an area of more than 200 square meters. m. Such schemes also include weather-dependent sensors, which are programmed to determine the required floor temperature based on external conditions.

Two-way ones are used for rooms with a smaller area - less than 200 m2. In such a scheme, the floor temperature is controlled by a valve. If necessary, he himself adds hot liquid coming from the boiler or, conversely, water from processing. If the collector is configured correctly, overheating of the floor is completely eliminated. Two-way valve circuits provide smooth and stable adjustment.

There are many other collector schemes and installation types.

Additional devices

In order for the underfloor heating system to function correctly, the hydraulic resistance in its circuits must be the same, for which it is recommended to install loops of approximately the same length. However, in practice this is not always possible to do. If circuits of different lengths are directly connected to the collector, the main part of the coolant flow will go through the shortest one. This is explained by the fact that it has the lowest hydraulic resistance.

Flow meters installed on the supply comb on each of the pipes to which the underfloor heating loops are connected help to avoid the problem. Flow meters allow you to regulate flows by narrowing and expanding the lumen through which liquid enters a specific circuit. The use of flow meters makes it possible to install loops of different lengths without compromising the functioning of the underfloor heating.

Block with flow meters on the feed comb Source leroymerlin.ru

Why do you need a collector?

Essentially, a collector is a pipe with holes for the inlet and outlet of the coolant; it is also called a distribution and mixing unit. The function of the device is to maintain the required temperature level in the system and control the water flow.

The device is designed to mix water coming from the boiler, where it is heated, with cooled liquid coming from the return line to the required level for heated floors. After all, in a boiler the coolant usually warms up to +90 degrees, and for a heated floor this is a high temperature.

It requires +40 - 45 degrees, so you can’t do without a collector. If water flows directly from the heat source into the circuits, this will lead to overheating of the system and its failure.

In addition, the circuits have different lengths, and their need for thermal energy is different. Therefore, a special unit is needed between the boiler and the pipeline, which will distribute the flow of hot water through the loops.

Design features

The comb has a hollow body with outlets for connecting circuits. Shut-off and control valves are installed at the ends and connecting pipes. The manifold for underfloor heating consists of a supply and return comb. The supply distributor is usually installed above the return distributor, but can also be mounted below - this depends on the characteristics of the installation location of the manifold and the type of mixing unit being connected.

One end of the heated floor loop is connected to each outlet of the distribution comb - the second end of the pipeline is connected to the outlet of the return comb. It collects the cooled coolant and directs the flow to the heating boiler.

Cabinet with connected collector block Source yandex.net

The base part of the manifold is a piece of pipe with two or more threaded elbows. At the same time, a variety of device models are available for sale, differing in final configuration, assembly complexity, functional parameters and cost.

With fittings

Budget models include combs with threaded pipes, equipped with fittings for connecting underfloor heating circuits. The underfloor heating pipeline can be made of cross-linked polyethylene or metal-plastic.

Comb with pipes Source okstock.ru

With built-in taps

The heating comb of a simplified design can be equipped with integrated two-way ball valves. Such a collector is not designed to adjust the operating parameters of individual circuits - using a tap you can only completely shut off the coolant flow in order to turn off a certain loop.

Budget models of combs (with fittings or built-in taps) can only be used for secondary underfloor heating systems, which include one or two short circuits. Also, without modifications, they can be installed in systems where several loops of the same length are involved - with the same hydraulic resistance and temperature requirements.

The design of such collectors does not provide for the installation of additional equipment on each outlet to adjust the operating parameters of individual underfloor heating circuits.

Comb with ball valves Source www.tklimat.com

With control valves

Improving functionality entails increasing cost. A higher price category includes a comb for heated floors, equipped with control valves on each outlet. This device makes it possible to manually regulate the intensity of the supply of heated coolant to each of the heating circuits.

When choosing a model, pay attention to the possibility of replacing a manual control valve with an automatic one. Many manufacturers provide for the installation of actuators designed to operate in conjunction with temperature sensors or as part of a home climate control system. Automatic control valves are driven by servo drives based on a signal from an electronic device - central or autonomous.

Comb with manual control valves Source mvi-rus.ru

With flow meters

Combs with flow meters on the outlets allow you to connect pipeline loops of various lengths and ensure uniform coolant circulation in all circuits. The markings applied to the flow meters simplifies system balancing and makes it possible to achieve fine temperature control.

Flow meter with graduations Source plastic-s.ru

See also: Catalog of companies that specialize in heating systems.

Twin assembly

The twin assembly includes supply and return distributors. Depending on the configuration, the underfloor heating manifold can be equipped with:

- automatic or manual air vent;

- security group;

- “American” - quick-release threaded connecting elements for connection to a mixing unit or primary heating circuits.

Twin assembly Source zoon.ru

Assembly with mixing unit and pump

The temperature of the coolant in the heated floor system does not exceed 35-40°C. Since almost all heating boilers, excluding condensing gas boilers, cannot operate in this mode and heat the coolant to higher temperatures, a mixing unit is installed. The temperature of the coolant is lowered to the required values by mixing cooled coolant in the required proportions with the heated coolant.

If the house only has underfloor heating, it is enough to install a mixing unit as part of the boiler piping. In the case where the heated floor operates in conjunction with radiator heating, a heated floor collector with a mixing unit is installed.

Pumping and mixing unit Source prom.st

The mixing group is made on the basis of a two-way or three-way control valve. The distribution unit includes a circulation pump specifically for the forced supply of coolant to the underfloor heating circuits - the common pump for the radiator system and heated floor, which is part of the boiler piping, is not able to cope alone.

On a note ! It is worth paying attention to the fact that the reliability of installation depends on the quality of shut-off and control valves. One of the most reliable manufacturers of components is the Cimberio brand.

The best option is to purchase a ready-made pair of combs with fasteners, with technical holes for installing additional control and adjustment equipment or an already completed manifold. This will reduce the risk of installation errors of the underfloor heating distribution unit and simplify its installation.

Collector block with mixing unit Source festima.ru

Flowmeter functionality

A rotameter or, to give a full definition to this unit, a float rotameter, at first glance, is a common mechanical device. The design of the product is based on a plastic case (there are models made of brass), inside of which there is a polypropylene float. The body is equipped with a transparent bulb on which a marking scale is applied. The movement of the float up and down inside the device indicates a certain value on the scale, by which one can judge the volume of coolant circulating in the pipeline system - whether it is enough for the full operation of the heating circuits.

Traditional flow meter for underfloor heating manifold in various versions: on the left - in a plastic case, on the right - in brass.

From a theoretical point of view, the heating system can operate without this device. In this case, you will have to manually adjust the volume of water entering the circuit, based on your personal feelings when the air temperature in the room changes.

- individual circuits of the water floor will be supplied with coolant without taking into account the characteristics of the room, as a result of which the temperature values of the floor surface of heated rooms will differ;

- the energy consumption used to operate heating devices (electricity or gas) will be increased.

For example, you plan to heat the bathroom and children's room at the same time. An autonomous gas boiler will heat water for the bathroom and nursery in the same way, at the same temperature. However, the bathroom is smaller in area and will require less boiler water to heat it than to supply a heated floor in a nursery. You can achieve optimal supply of coolant to heated floors in each room using a flow meter. Consequently, due to the operation of this device, it will be possible to achieve individual temperature values for comfort in the bathroom and children's room.

Assessing the operation and principle of operation of the device, the following conclusions can be drawn:

- the device operates completely autonomously, without requiring additional power sources;

- the operating principle of the flow meter allows you to create optimal coolant flow for heating circuits, significantly reducing the energy consumption of heating devices;

- the design of the device provides visual control over the amount of water in the pipelines;

- the collector together with flow meters for underfloor heating significantly facilitates control over the operation of the entire system, is easy to install and unpretentious to maintain.

Manufacturing materials

The reliability and durability of the collector directly depends on the material from which it is made. A comb for heated floors can be metal or polymer. Each option has its own advantages and disadvantages.

Polypropylene

A manifold made of polypropylene pipe is an extremely economical option. In addition to the affordable price, one can note the light weight of the device. Models with fittings and combs with shut-off ball valves are available for sale. To connect metal products, combined fittings are used.

The disadvantages of polypropylene collectors include:

- thick walls, due to which the passage cross-section is smaller than that of metal combs of the same size;

- less strength and durability compared to metal models;

- oxygen permeability - even if polypropylene is reinforced with fiberglass reinforcement, there is diffusion of oxygen, which provokes corrosion of steel elements of the heating system and boiler.

Collector block made of polypropylene Source chudopol.ru

How can water floors be installed?

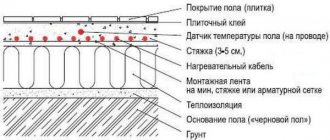

Warm water floors can be laid in different ways - by laying and using concreting. Let's take a closer look at each of them.

- Concreting. The pipes through which the coolant circulates are laid as required on the prepared base and filled with concrete screed. The main disadvantages: labor-intensive “wet” work, the heavy weight of the system and the complexity of its dismantling.

- Laying method. Involves laying pipes in a specially assembled deck.

It can consist of plastic modules or wooden blocks with grooves prepared in them for installing pipes. Wooden mounting modules can also be found on sale. The main disadvantage is that the system takes longer to warm up than a concrete one.

The principle of operation of the device in the assembly

There are several working schemes for assembling a distribution unit, but the operating principle of the device remains virtually unchanged. Let's consider one of the standard assembly options, in which the manifold for a heated floor is equipped with:

- Shut-off valves for the distribution manifold and return.

- Taps for draining the working medium from the supply and return lines.

- Three way valve.

- Circulation pump.

- Pressure gauge.

- Flow meters for each circuit.

- Manual control valves for each circuit.

Unit #1 - water heating boiler

The boiler selected for installation must have sufficient power to cope with the heating of the coolant during peak operation of the circuits. In addition, it should have a small power reserve.

Approximately, this value should be the total power of all maintained heated floors, increased by 15-20%. In addition, a circulation pump is needed. Most often, it is already included in most boiler models.

An additional device may be needed only if the area of the heated room is more than 120-150 square meters. m. In case of preventive maintenance or repair of the boiler without draining water from the entire system, shut-off valves are installed at the outlet and inlet of the heating device.

Video description

The capabilities of the collector, its configuration and operation are shown in the video:

Adjusting the supply of working medium

Flow meters (rotameters) make it possible to ensure uniform heating of loops regardless of their length, even if circuits that differ markedly in length and hydraulic resistance are connected to the comb.

For short pipelines, the fluid supply is regulated by reducing the passage opening; for long branches, on the contrary, the flow intensity is increased. This parameter is determined on the scale of the balancing rotameter for each circuit, after which the throughput of the flow valve is adjusted.

Adjustable flow meters are installed on the feed manifold only if it is equipped with manual valves for adjustment. They are not necessary if:

- branches of the same length are connected to the collector, and regulation of distributed flows is not provided;

- the collector block is equipped with automatic control valves with servo drives - in this case, the automation is controlled by an electronic thermostat and manual equalization of the heating of the branches is not required.

Settings

As a rule, a special balancing table is attached to the diagram, on the basis of which the comb can be adjusted according to two parameters: circuit length and heating load.

The table relates the circuit number and the number of revolutions from the position of the balancing valve - “closed”. Set up the comb like this:

- remove the cap from the valve that serves to protect it;

- close the valve all the way - use a hex key for this;

- determine the number of revolutions for a given circuit;

- turn off the valve to this number;

- The remaining circuits are configured in the same way.

Correct configuration and connection of the collector are necessary for long-term operation and efficient operation of the system.

Criterias of choice

When choosing a heating distribution manifold for an underfloor heating system, you need to know in advance how many circuits you plan to connect. It is recommended to select devices with a reserve of one or two outputs in order to be able to adjust the system design and split an extended circuit into two branches or connect additional equipment (pressure gauge, thermometer). No more than nine loops can be connected to one collector; if there are more loops, two or more distribution blocks are installed.

Maximum comb size Source sgon24.ru

Next, you should pay attention to the material used to make the comb. Reliable and durable cases are made of stainless steel, chrome-plated or nickel-plated brass, and bronze. It is recommended to give preference to products manufactured in accordance with Russian GOSTs, or products from well-known manufacturers that have a certificate of compliance with European standards. Each comb should be carefully inspected to identify possible flaws - cracks, corrosion, surface defects.

The list of reliable brands includes: Kermi, Valtec, Rehau, Valliant, Rossini, FIV. When purchasing branded products, it is advisable to buy ready-made manifold blocks so as not to overpay for individual parts and to avoid problems associated with the incompatibility of elements from different manufacturers.

Distributor made of metal fittings

If you use metal fittings instead of polypropylene, you will be able to slightly reduce the size of the structure and do without a soldering iron. But here another pitfall awaits you in the form of cheap thin-walled tees, which are scary to handle with a pipe wrench - low-quality material can crack. If you buy high-quality fittings, then the total price of the product will be closer to the factory manifold, although the savings will still remain.

For manufacturing, you need to select internal/external thread tees made of good brass, shown in the photo, and ball valves with a low stem and a butterfly handle. The same radiator valves will go to the second part of the comb. The assembly technology is simple: pack the threads with flax or thread and twist the fittings together, and then install the taps and other parts.

Advice. When assembling, try to direct all the side bends in one direction, as well as the valve stems, so that the homemade manifold looks presentable. When screwing on pipeline fittings, remove the handles and adjusting caps so that they do not cling to adjacent taps.

Installing flow meters on a comb of brass fittings is a difficult issue. Then the supply line will have to be assembled from crosspieces and special adapters for rotameters will be installed. Some of them are also made for Eurocone, so the adapter will have to be machined. It is easier to balance the system without flow meters.

As you can see in the photo, there is nowhere to put the rotameter here

Assembly and installation

It is recommended to install a cabinet with a manifold block in such a way that the heated floor loops are approximately the same length. If the distribution device is located above the level of the heating circuit, air from the system will be automatically removed through the air vent. In the case where the cabinet is planned to be hidden in the basement or placed on the floor below, you will have to install an air vent on each circuit, complete with a ball shut-off valve, as well as on the return line.

When assembling the collector block, pay attention to the tightness of the connections. If the equipment does not come with rubber sealing rings, the threads are sealed by winding.

Next, the underfloor heating manifold is installed in a special cabinet. The guides, equipped with bolts and nuts for fastening the combs, are moved in accordance with their length. If the collector block is mounted without a cabinet, use clamps with dowels or brackets. At the same stage, if necessary, a mixing unit is installed and a circulation pump for the heated floor is installed. Finally, the circuits are connected and the system is tested.

Tips from the professionals

When installing this device, you should pay attention to the following recommendations:

Dimensions of a wall-mounted cabinet for a manifold unit

- the thickness of the collector box must correspond to the dimensions of the unit;

- You must remember to leave free space for bending pipes from each installed circuit. It must be provided directly under the block;

- The device box is placed at a point that is at the same distance from all contours.

If you use a ready-made collector group, you can significantly simplify the installation of this device. It is very easy to install it yourself without the help of specialists.

Is it worth automating the system?

First of all, it's worth talking about weather sensors. They allow you to adjust the coolant temperature based on the temperature outside the window of your home. You could do this yourself, but frosts come unexpectedly, for example, when you are sleeping, so in the morning the house can become significantly colder; it is in such situations that weather sensors will not allow you to freeze.

Weather sensors are often installed with indoor temperature sensors, which shift the valve 1/20th if the temperature in the house is lower than necessary.