A ventilation device is necessary to organize constant air renewal. This is especially important if there are gas-flame appliances in the house - heating boilers, water heaters and stoves. When starting to install ventilation devices, you need to carefully study the rules for their arrangement and strictly follow them during design and installation.

- 2 Requirements for ventilation in a private house with a gas boiler

- 3 Standardization of ventilation during operation of gas boilers

- 4 How to arrange ventilation for a gas boiler room in a private house

4.1 Natural supply ventilation

4.1.1 Video: how to make a ventilation duct for a boiler room

- 4.3.1 Video: which pipes to use for ventilation

- 5.1 Table: dependence of the duct diameter on the required air flow

- 6.1 The main reasons for the deterioration of draft in the ventilation system

Fire safety

The combustion area must be kept clean, and there must be sufficient artificial lighting inside the room to provide good illumination for work and public areas.

Storage of any flammable materials in such premises is prohibited. When pipes freeze, they can only be heated with steam or hot water. The use of open flame is prohibited. Special requirements are imposed on the operation and maintenance of smoke ventilation systems; they must be checked and cleaned periodically:

- Every year in August – cleaning of smoke channels from soot contaminants and checking draft.

- Quarterly - cleaning of brick chimneys.

- The integrity of the ventilation ducts is inspected annually.

The entrance doors of the furnace room must open outwards. Windows - must have easily removable packages. At the entrance of the gas pipeline in the combustion chamber, a protective electromagnetic valve, a fire alarm and indoor gas sensors are installed.

Why do you need a smoke exhauster?

For any heating unit, draft is important, the efficiency of the boiler decreases, combustion products enter the room; To prevent this from happening, a smoke exhauster is used. It can be installed on almost any ventilation system.

Smoke exhausters are divided into three types:

- a flow-through smoke exhauster is installed on the boiler inlet pipe and is turned on as needed manually or automatically;

- centrifugal traction machine;

- natural draft amplifier, equipped with an axial fan and installed at the end of the pipe.

The smoke exhauster is preferable for direct combustion boilers using solid fuel

, he copes well with the tasks assigned. For electric or pyrolysis boilers, the meaning of installing a smoke exhauster practically becomes meaningless.

Add to bookmarks

Hood for a gas boiler yourself

Many owners are wondering how to make a hood with their own hands. To complete the task you will need tools and the slightest skills. To organize your work you should prepare:

- fan (it is desirable that the design has a check valve);

- grid with small holes;

- a pipe that will provide air removal.

Please note that the pipe is selected to match the diameter of the fan. The progress of creating a hood with your own hands involves performing the following operations.

- Draw the outline of a circle that will serve as the hole for the pipe. The diameter should be slightly larger than the pipe itself.

- Drill holes along the drawn contour in even increments, as well as one inside.

- Then you need to carefully squeeze out the middle to be able to insert the pipe.

- The resulting gaps between the wall and the pipe should be filled with mortar or foam.

- Install the fan directly.

- The final step is to fix the grille, which will protect the room from the penetration of debris and insects.

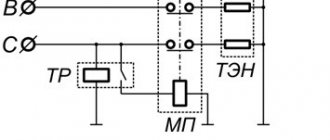

For a more visual understanding of the mechanism described above, there is a diagram of the ventilation system.

Ventilation system diagram

What you need to consider when organizing a hood in your home

If you decide to install a hood in your home that exhausts exhaust air outside, you may encounter some legal aspects of this process.

To install a hood, you need to make a hole through which air will escape, and also adjust the outlet of this air. Two questions arise: is it possible to make a through hole in the wall of an apartment building and is it allowed to remove dirty air outside the apartment?

If the diameter of the hole does not exceed 200 mm, then it does not require a permit. Such openings are allowed to be made for ventilation and air conditioning of premises. However, it will not be possible to vent the hood through such a hole - according to the law, this may interfere with the comfort of neighbors, through whose window your exhaust air may escape. Before installing the hood, it is necessary to design the exhaust duct and go through the approval procedure.

The simplest and most convenient option is a hood with an exhaust duct in the wall.

The video shows how to properly organize the exhaust duct:

We calculate the air duct so as not to make mistakes

As already mentioned, a complete replacement of the air in the room where the boiler is installed should be done in a maximum of 20 minutes. It is this requirement that obliges us to calculate the minimum ventilation cross-section before starting installation or even design. There is a constant ceiling height at which ventilation is considered optimal. This value is equal to six meters. If the value is lower, a correction factor is used.

Let's calculate it using an example.

The room where the boiler is installed has dimensions of three by four meters with a ceiling height of 3.5 m. We calculate the volume - 3x4x3.5 = 42 cubic meters. m

We determine the correction factor using the formula: k=(6-h) *0.25+3

We get: (6-3.5) *0.25+3=3.6

We will find the estimated volume of air required for safety by multiplying the actual volume of the room by a correction factor of 3.6 * 42 = 151.2 cubic meters

Now we come to the last calculation. The cross-sectional area of the air duct is calculated as the ratio of the calculated volume to the product of air flow velocity and time. Moreover, speed and time must be in the same units. Taking the minimum air speed as 1 m/s and knowing that there are 3600 seconds in an hour, we get: 151.2/3600 = 0.042 sq. m

When using a round pipe, the formula for converting area to diameter is: D=2√S/π, where

D is the required diameter;

S – found cross-sectional area;

π is a constant approximately equal to 3.14; As a result, we get:

2√0.042/3.14=0.231m

The nearest larger diameter from the range of pipes for ventilation is 250 mm. It is he who will be the solution to our problem.

Of course, you can avoid these calculations if you use tables or the services of professionals, but this, as they say, is at the discretion of the person for whom the hood for a gas boiler is being built in a private house.

What about the height above the roof?

If the ventilation comes out vertically above the roof of the house, the question about its position would be quite logical. The following parameters will be relevant here:

- Level relative to the ridge;

- Removal from the chimney;

- Level above the roof.

Let's designate the coordinates based on construction standards, the experience of professionals and the elementary laws of physics. A hood for a gas boiler in a private house, or rather its outlet pipe, must:

- Rise at least 50 cm above the roof ridge if the chimney is at least 1.5 meters away and at the same distance where the parapet is located.

- Be level with the ridge or higher than it if the chimney is located from one and a half to three meters from both the ridge and the parapet

- Be below a line drawn from the ridge of the roof at an angle of 10 degrees, if the height of the chimney is higher than three meters from the top edge of the roof.

- In the case of a flat roof, the requirements for the hood are simple - be at least half a meter above it.

On a note

The height of the hood can be adjusted if there is a large and high wind vane on the chimney - decorative protection from precipitation or birds.

A hood for a gas boiler in a private house, despite being quite complex, can easily be installed, as they say, with your own hands

Simple calculations, accuracy and attention when working - this is what will add comfort, safety and aesthetic appeal to your home

Calculation of ventilation cross-section

To correctly calculate the cross-section of the boiler room ventilation system pipeline, you will need the following data:

- The cubic capacity of the boiler room, depending on the height of the room. According to SNiP requirements, its height should not be less than 6 meters. Obviously, in the conditions of a village house such a requirement is impossible to fulfill. When calculating, it must be taken into account that when this indicator decreases by 1 meter, the amount of air required for fuel combustion must be increased by 25%;

- Air mass flow velocity (at least 1 m/s).

- Air exchange rate. The value depends on the height of the boiler room.

The result of the calculation will be the air requirement, on the basis of which, using special tables, the cross-section of the ventilation system pipeline can be determined.

The calculation is made using the relationship V = L x SX (6 - H) x 1.25 xn, where:

- V is the volume of air for fuel combustion;

- L is the length of the room;

- S is the width of the room;

- H is the height of the room;

- n is the frequency of air change in the boiler room, equal to 3.

Thus, when determining the air requirement, the actual size of the room and the increase in air turnover are taken into account. Having received the desired value, the diameter of the air duct can be selected from the table.

Table: dependence of the duct diameter on the required air flow

| Air duct diameter, mm | Air flow in m3/hour at speed in m/s | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| 100 | 28,3 | 56,5 | 84,8 | 113 | 141 | 170 | 198 | 226 |

| 125 | 44,2 | 88,3 | 132 | 177 | 221 | 265 | 309 | 353 |

| 140 | 55,4 | 111 | 166 | 222 | 277 | 332 | 388 | 443 |

| 160 | 72,3 | 45 | 217 | 289 | 362 | 434 | 506 | 579 |

| 180 | 91,6 | 183 | 275 | 366 | 458 | 549 | 641 | 732 |

| 200 | 113 | 226 | 339 | 452 | 565 | 678 | 791 | 904 |

| 225 | 143 | 286 | 429 | 572 | 715 | 858 | 1001 | 1145 |

| 250 | 177 | 353 | 530 | 707 | 883 | 1060 | 1236 | 1413 |

To ventilate rooms with gas appliances, it is advisable to install a duplicate ventilation system so that one of them works under any circumstances.

When there is a power outage, ventilation of the premises will be carried out through natural circulation channels.

Video: calculation of air exchange in a boiler room

Natural circulation in a room with a gas boiler

It is necessary to install a polypropylene pipe into the vent. If the heating equipment has a power of 30 kW, then the pipe is suitable with a diameter of Ø15 cm. A metal mesh protects the entrance from the outside. To prevent foreign odors and debris from entering the room, a valve is installed inside the pipe.

Combustion products go directly into the exhaust pipe installed above the heating equipment. The supply air pipe is designed to bring fresh air into the combustion chamber, so this air duct is installed immediately behind the firebox. The efficiency of natural ventilation in a boiler room directly depends on weather conditions. And according to the standards, the air in such a room must be renewed 3 times every 1 hour.

It is impossible to calculate the air exchange rates for this ventilation system. In practice, it often happens when, for natural ventilation, a hole is made through a wall with a diameter of 150 mm, a ventilation pipe is inserted into the hole, it is protected from the outside with a mesh, and a check valve is mounted on the other side. From a financial point of view, this option is quite inexpensive, and the performance is very good.

How to choose the type of chimney

Choosing a gas boiler chimney for our user with the nickname gladiator was not easy, there was too much to consider, and the initial data did not allow us to arrive at the optimal result.

You can lay out a brick chimney and then insert a stainless steel sleeve into it, but according to calculations, a floor made of floor slabs simply will not withstand the load from a brick chimney;

You can install an expensive ceramic chimney system from a well-known one.

You can make a sandwich, but if it’s inside a building, but how can you secure the floors between floors and then not think about what the temperature is there; and how do you know when it’s time to remove the pipes from the wall and change the system? You can make an external chimney, but it would be a pity to spoil the appearance of a private house.

GladiatorFORUMHOUSE Member

Previously, a simple galvanized or brick chimney was made for a gas boiler, but now you don’t know what to choose from.

When choosing a chimney for a gas boiler, experts on our portal recommend taking into account:

- type of combustion chamber, boiler power;

- design features of the house;

- reasonable combination of price and quality.

The choice of boiler depends on the type of gas combustion chamber.

An open firebox is often found in floor-standing gas boilers. Such devices always need good draft, and here a brick and ceramic chimney is preferable; although a sandwich will work too. And we must take into account the design features of the building: a brick chimney is difficult to install and is hygroscopic; and the ceramic chimney is very heavy.

Closed combustion chamber . According to our experts, such devices need a coaxial chimney or sandwich.

The sandwich for a gas boiler looks like a universal model; everyone recommends it.

Alexey TeleginForumHouse user

For gas, a sandwich is ok, but it’s better to make it from acid-resistant 316 steel.

Teplov and SukhovFORUMHOUSE user

For a gas boiler in home use, a sandwich made of 316 steel will last a very, very long time. But change the boiler.

But it is better to choose a chimney for a boiler together with a specialist - this is a more responsible and mature approach. As our experts say, the approach to choosing a chimney system for a gas boiler must be comprehensive, “design/installation/operation” must be taken into account. And it is advisable that everything is done under the guidance of an invited professional.

TraksFORUMHOUSE User

The chimney will be assigned to you by gas workers and reflected in the design. But in addition to a specialist who will accept the completed work, a third-party professional is needed here.

Answers to any complex chimney questions can be obtained here: “Consultations on design standards and rules. If you have any questions about chimneys, just ask.”

More about multilayer pipes

If you have prioritized the sandwich pipe option, we suggest using a few practical tips:

- The pitch of pipe fastenings to the wall should be in the range from 100 to 150 cm;

- The number of inspection wells must provide full access to all sections of the pipe;

- It is advisable not to allow horizontal sections of ventilation pipes and chimneys longer than one meter. Otherwise, you will have to install forced draft (fan).

Ceramic hood for gas boiler

Another option for the material from which the hood for a boiler in a private house is made is a ceramic pipe. The advantages here include environmental friendliness and durability. In this case, pipes made of this material are not used as a whole. You will still need organic or polymer insulation, and stone, metal, brick and something else as a decorative layer. In this case, condensate drains will also be needed, which will add cost to the already expensive material. Before this, we considered options when the hood for a gas boiler in a private house and the chimney existed separately. However, there is an option for a coaxial pipe that allows you to combine two processes and two purposes into one.

The essence of this invention is to place a pipe designed to remove volatile combustion products in one housing with a pipe providing clean air. There are several advantages at once:

- The exhaust gases, moving through the inner pipe, are cooled by air coming from outside. This not only increases the efficiency of the boiler, but also reduces the aggression on the surface of the entire chimney.

- The second advantage of a coaxial pipe is its compactness. Saving space never hurts, but lower labor costs when installing one pipe - instead of two - will have a noticeable impact on the budget.

One significant drawback follows from the design feature - the system does not provide horizontal sections. This means that, having made a decision in favor of “two in one”, you need to be prepared for some costs for laying a pipe to the detriment of the adopted plan (move the kitchen, boiler room or put up with a pipeline that is sticking out itself).

How to choose material for the hood?

For these purposes, brick, galvanized and stainless steel and ceramics can be used. Let's take a closer look at each of them, and also study what other options the market and engineering offer.

Brickwork hood

Although brick is used by builders when arranging ventilation, its properties do not allow them to save on other materials. Firstly, brickwork is not durable. The most comfortable conditions for her are constant contact with hot gases. Otherwise, condensation will form, which leads to its rapid destruction. Secondly, a brick chimney is labor-intensive to install, has a complex design and is unreasonably high in cost. Therefore, if you are faced with the task of arranging a chimney for a gas boiler, it is better to pay attention to other options. In this situation, a shaft is made of bricks. This same option can be chosen if for some reason heating the house with gas is currently impossible, but in the future it is planned to use it.

If brickwork is chosen as the material for the shaft, then the chimney itself is assembled from single-circuit galvanized pipes. The thickness of their walls is selected taking into account the temperature of the outlet gases.

Components of a chimney inside a brick shaft

Steel hood

In this situation, steel pipes are very convenient. They are easy to install when compared, for example, with brickwork. The wall thickness is selected depending on the heating. Gas boilers produce quite hot exhaust gas, about 400-450˚C, so the thickness of the walls should be 0.5-0.6 mm. However, there are pitfalls here too. Of course, steel is resistant to the negative effects of condensation. But on average, its wear resistance is much lower than, for example, the wear resistance of ceramic products. In addition, thin-walled pipes burn out quickly if used with solid fuel devices, so this option is not optimal when using different types of heating elements for different periods of time. Steel choose:

- during reconstruction;

- if there is no space for a ceramic hood.

Since steel ventilation ducts often spoil the exterior of a private house, they are covered with brickwork or other finishing materials.

Steel pipes are marketed in two variations - single-circuit and double-circuit. The second option is called a “sandwich” in slang. It consists of two pipes nested one inside the other, the gap between which is filled with fire-resistant basalt wool. The thickness of the inner pipe is determined by the temperature of the outlet gases (recall that this value is 0.5-0.6 mm for the devices discussed in the article).

Installation of a steel double-circuit chimney

“Sandwiches” are considered more economical among all steel hood options. This conclusion suggests itself if we take into account good thermal insulation, which increases the efficiency of the heating device.

Double-circuit steel chimneys are made of stainless and galvanized steel. Both metals are combined in “sandwiches”, since using only stainless steel is not economically feasible. The difference between galvanized and stainless steel is the latter’s higher resistance to condensation, which negatively affects its price. Otherwise, the properties of these two materials are not inferior to each other.

It is critically important that the internal part of the double-circuit structure is made of stainless steel; the material of the external part does not play a special role. This is due to the properties of zinc. Its heating above 419.5°C is dangerous. In this situation, the metal oxidizes, and further chemical reaction leads to the release of toxic fumes. Everything becomes even worse with high humidity, which cannot be avoided when commissioning a gas boiler. Therefore, when purchasing a sandwich structure, pay attention to this.

In principle, you can make a double-circuit chimney yourself without any special skills. To do this, wrap the stainless steel pipe in fire-resistant heat-insulating material. When choosing the latter, you can pay attention to basalt fiber, expanded clay or polyurethane. Then place everything together in a galvanized pipe of larger diameter.

Installation diagram of a steel hood

Features of installing a steel ventilation column:

- The segments are assembled using the “pipe to pipe” method in order, starting from the bottom;

- For the convenience of subsequent cleaning of the post, provide a sufficient number of inspection wells;

- For stability, wall brackets are attached in approximately 150 cm increments;

- When designing, pay attention to the horizontal segments - they cannot be more than 1 meter long unless forced draft is provided.

Stainless steel ventilation duct

Ceramic hood

This type of hood is the most versatile, so it is an ideal option if you plan to switch from or to gas fuel. They are easy to clean, resistant to dirt, due to their high gas density, and to aggressive chemical compounds, so you don’t have to worry about toxic substances getting into your living rooms. And, of course, ceramics are durable.

But there are also disadvantages. Ceramic pipes have high moisture absorption. If you choose them, you will have to provide good external ventilation and equip the structure with condensate drains, otherwise the invested effort and money will not be worth it.

Ceramic alone is not used in chimneys. To make the most of its positive properties, it is combined with mineral wool and stone. Simply put, the ceramic pipe is wrapped in insulating material and then placed in an expanded clay concrete shell.

Structure of a ceramic chimney

Ceramic hood design

Coaxial ventilation structure

When designing ventilation for gas boilers, pay attention to the compact “pipe-in-pipe” design, or, in other words, a coaxial chimney.

Operating principle of a coaxial ventilation system

Components of a coaxial chimney

Coaxial systems, due to their characteristics, are suitable for heat generators with a closed combustion chamber (which is a gas boiler). Oxygen necessary for combustion enters through the outer pipe, and exhaust gases are removed through the inner pipe. This design has its advantages:

- safety (exhaust gases are cooled by cold air circulating in the outer pipe);

- the incoming air heats up and increases the efficiency of the boiler;

- high efficiency means that the coaxial design is more environmentally friendly than others;

- can be used with the appliance in the kitchen (it is located outside the room and does not affect the comfort in it).

Features of installing a coaxial chimney

- You cannot use a horizontal coaxial chimney if you do not plan to install forced draft;

- try to get by with no more than two knees;

- if there are several boilers, create a separate chimney for each; combining them is undesirable.

Types of ventilation for operation of gas heating equipment

Convection can be natural or forced. Spontaneous air flow is ensured by the presence of windows, vents, doorways and an exhaust duct, the outlet of which is mounted in the room with the boiler.

The natural ventilation system consists of an air duct that connects the outlets from the kitchen, boiler room and bathroom to a pipe on the roof. The width of the box is not calculated, but selected according to SNiPs, because For an accurate calculation, it is necessary to take into account the direction and speed of the wind, atmospheric pressure and other parameters. With a boiler power of 30 kW, an air duct with a width of 150 mm will be required, with a boiler power of 100 kW - 230 mm.

The hood is mounted directly above the device, and the pipeline is mounted behind the fuel chamber.

To calculate the blower parameters, you need to multiply the volume of the room by the loss and air change coefficients. The cost of resistance during the passage of the chimney is about 40%, therefore, with room parameters of 4x2x2.2 m, the fan power should be at least 74 m³/h.

Features of chimney construction

Proper arrangement of the ventilation system in a boiler room with gas equipment cannot occur without a chimney. It must meet the following requirements:

- The chimney must protect the room from dust, fumes and dirt. Care should be taken to ensure maximum tightness of the pipe itself. For this purpose, a two-layer chimney technology made of a metal box and an asbestos-cement pipe is used.

- The height of the street part of the chimney should be located above the maximum point of the roof. The minimum distance from the roof ridge is 2 m.

- The diameter of the ventilation shaft of the house is made larger than the size of the exhaust pipe of the boiler itself. Each type of equipment has its own calculation standards.

This is especially true for the required diameter of the exhaust system. For gas boilers whose power does not exceed 30 kW, it is advisable to use a pipe up to 130 mm. If the boiler is 40 kW - 175 mm, and with 55 kW - 195 mm

If the equipment power exceeds 80 kW, it is important to install a pipe with a diameter of 230 mm

Other features are also important for building ventilation with your own hands. When choosing a design for a chimney, sheet steel is the best option. Stainless steel or galvanized sheets are suitable. The structure itself should be simple without obstacles, its thickness should be equal in any part of it, and an inspection window should be made on the side of the boiler room.

Where you can and where you can’t install a gas boiler

The rules for installing a gas boiler provide the following requirements for installing a HEATING boiler, regardless of whether it also provides DHW or not:

- The boiler must be installed in a separate room - a furnace (boiler room) with an area of at least 4 square meters. m., with a ceiling height of at least 2.5 m. The rules also state that the volume of the room must be at least 8 cubic meters. Based on this, you can find indications that a ceiling of 2 m is acceptable. This is incorrect. 8 cubic meters is the minimum free volume.

- The furnace room must have an opening window, and the width of the door (not the doorway) must be at least 0.8 m.

- Finishing the furnace with flammable materials and the presence of a false ceiling or false floor are unacceptable.

- The combustion chamber must be provided with an air flow through a through, non-closed vent with a cross-section of at least 8 sq.cm. per 1 kW of boiler power.

For any boilers, including wall-mounted hot water boilers, the following general standards must also be met:

- The boiler exhaust must exit into a separate flue (often incorrectly called a chimney); using ventilation ducts for this is unacceptable - life-threatening combustion products can reach neighbors or other rooms.

- The length of the horizontal part of the flue should not exceed 3 m within the combustion chamber and have no more than 3 rotation angles.

- The flue outlet must be vertical and raised above the ridge of the roof or the highest point of the gable on a flat roof by at least 1 m.

- Since combustion products form chemically aggressive substances when cooling, the chimney must be made of heat- and chemically resistant solid materials. Use of layered materials, e.g. asbestos-cement pipes, permissible at a distance of at least 5 m from the edge of the boiler exhaust pipe.

When installing a wall-mounted hot water gas boiler in the kitchen, additional conditions must be met:

- The height of the boiler suspension along the edge of the lowest pipe is not lower than the top of the sink spout, but not less than 800 mm from the floor.

- The space under the boiler must be free.

- A durable fireproof metal sheet 1x1 m should be laid on the floor under the boiler. Gas workers and firefighters do not recognize the strength of asbestos cement - it wears out, and the SES prohibits having anything containing asbestos in the house.

- There should be no cavities in the room in which combustion products or an explosive gas mixture can accumulate.

If the boiler is used for heating, then the gas workers (who, by the way, are not very friendly with the heating network - it always owes them for gas) will also check the condition of the heating system in the apartment/house:

- The slope of horizontal sections of pipes must be positive, but not more than 5 mm per linear meter of water flow.

- An expansion tank and an air valve must be installed at the highest point of the system. It is useless to convince you that you will buy a “cool” boiler that has everything provided for: rules are rules.

- The condition of the heating system must allow it to be pressurized under a pressure of 1.8 atm.

The requirements, as we see, are strict, but justified - gas is gas. Therefore, it is better not to think about a gas boiler, even a water heating one, if:

- You live in a Khrushchev block or other apartment building without a main gas duct.

- If you have a false ceiling in your kitchen that you don’t want to remove, or a permanent mezzanine. On a mezzanine with a bottom made of wood or fiberboard, which in principle can be removed, and then there will be no mezzanine, gas workers turn a blind eye.

- If your apartment is not privatized, you can only rely on a hot water boiler: allocating a room for a furnace means redevelopment, which only the owner can do.

In all other cases, it is possible to install a hot water boiler in an apartment; wall heating is possible, but floor heating is very problematic.

In a private house, you can install any boiler: the rules do not require that the furnace be located directly in the house. If you make an extension to the house from the outside to serve as a furnace room, then the authorities will only have less reason to find fault. You can install a high-power floor-standing gas boiler in it to heat not only the mansion, but also the office premises.

For middle-class private housing, the optimal solution is a wall-mounted boiler; it does not require, as for a floor one, to install a brick or concrete tray with sides of half a meter. Installing a wall-mounted gas boiler in a private house also avoids technical and organizational difficulties: a fireproof closet under the furnace can always be fenced off, at least in the attic.

Selection and installation of equipment

The selection of equipment will depend primarily on the following factors :

- area ;

- Permissible distance to combustible devices;

- Type of room (separate room, free-standing room or existing one - for example, a kitchen or attic);

- Budget (for example, monoblock ventilation is significantly quieter than other types, but it will cost more)

The boilers themselves are:

- Gas;

- Solid fuel;

- Pellet (pellet-based, essentially solid fuel boilers);

- Diesel;

- Electrical;

- Combined (using several methods).

Combination boilers are an excellent option in a home where there are interruptions in electricity or gas supply Source brjansk.buyreklama.com

Currently, gas boilers are most often used in private homes, and we are talking about low-power boilers. This is due to the relatively low price of gas in gasified areas, and the convenience of using this heating method (the combustion temperature is lower, which allows the use of cheaper materials in production). To install it you will need permits. In addition, the boiler can be installed simultaneously with water heating (with a boiler) only for rooms up to 200 m2.

Is a window needed in the boiler room of a private house according to the standards of the Republic of Belarus?

The need and size of a window in the boiler room of a private house are regulated by clause 21.12 of Amendment No. 7 to the above sanitary norms and rules (SNiP) of the Republic of Belarus.

In a room with installed gas boilers, for ventilation it is imperative to provide an opening window facing the outside (to the street) with a minimum area of 0.25 m2.

Important! For heating boilers with a coaxial chimney and a closed combustion chamber, the presence of a window in the combustion room is not necessary. The coaxial chimney pipe for a gas boiler is made according to the “pipe-in-pipe” principle

The double-circuit design allows you to forcibly remove combustion products and suck the required amount of atmospheric air into the closed combustion chamber of the heating apparatus from the street

The coaxial chimney pipe for a gas boiler is made according to the “pipe-in-pipe” principle. The double-circuit design allows you to forcefully remove combustion products and suck the required amount of atmospheric air into the closed combustion chamber of the heating apparatus from the street.

You will learn further about how to correctly design the entrances to a private boiler room.

Types of ventilation systems

Equipment is classified according to its mechanism of action. The type is determined at the building design stage. The ventilation system is the combined operation of exhaust devices and inflow sources. So it could be:

- supply;

- exhaust;

- supply and exhaust.

For ventilation of a boiler room with a gas boiler, only the last option is acceptable. The use of exhaust elements exclusively is suitable for living spaces with windows and bathrooms.

By circulation method:

- natural;

- mechanical;

- combined.

Natural circulation of air flows is based on pressure differences. The inflow is carried out through a hole located at a level of 30 cm from the floor. Warm masses rise upward and freely leave the space through a hood located near the ceiling. For ventilation of a gas boiler room, this may be quite sufficient.

Also read with this article: Why does the wind blow out a gas boiler?

Natural movement is also called movement resulting from wind pressure. For example: a certain volume enters the building from the windward side and exits from the leeward side. Distinctive feature: operation does not require special equipment or electricity.

Forced ventilation devices can supply and extract air from local areas. These are fans, electric motors and other devices.

By type of device design there are:

- duct: with an extensive network of air vents;

- ductless: there are no ducts; for example, you can install a fan in the wall.

The choice is determined by the degree of air pollution. Thus, the ventilation of the room where the gas boiler is installed is calculated based on current standards.

The correct operation of all equipment is checked by an inspector from a specialized service.

Natural ventilation of boiler rooms

This is the simplest and least expensive option. Air from the street enters through a passage located close to the floor and is exhausted through the hood. Installation of a self-regulating supply valve is mandatory when installing a boiler room in a private house.

Installation is simple and easy to do yourself:

- At a height of 30 cm from the floor, drill a hole along the diameter of the valve with an allowance of 10 mm.

- The valve is installed with a slight slope outward, the free space is filled with polyurethane foam.

- When the foam hardens, install the damper.

To prevent blockages, grilles are used, which reduce the performance of the valve, which is why many models have a fan. The minimum distance from the unit to the inlet is 1 meter. This way, temperature changes will not affect the operation of the automation.

We recommend reading the article: What to do if the gas boiler does not turn on

The chimney is installed directly above the unit, and an exhaust hole is formed nearby. The calculation of natural ventilation in the boiler room of a private house is made using a simple formula, but it does not always provide a sufficient degree of safety.

Forced ventilation system

The artificial method is a set of devices: fans, heaters, filters. Essentially, this is climate control equipment.

Ready-made engineering solutions can have a number of additional functions, for example: start when the burner is turned on. For uninterrupted operation, it is recommended to install a generator.

Boiler room

Gas equipment is connected directly to the boiler room. Relative to the house, furnaces can be located:

- inside - built-in;

- nearby on a separate foundation - attached;

- at some distance - separate.

Depending on the location, the premises are subject to certain requirements aimed at ensuring safety during operation.

Built-in

According to SNiP, gas equipment with a power of up to 350 kW is allowed to be installed inside the house. Boilers up to 60 kW can be placed in any room. As a rule, this is a kitchen or domestic premises. More powerful heat generators are located on the first or ground floors, in the basement.

The ceiling in the room should not be lower than 2.5 meters. Ventilation is calculated to replace air three times within an hour, that is, the cross-section of the ventilation ducts should ensure the rate of natural circulation of an amount of air equal to triple the volume of the room.

The size of the window opening minus the sashes must meet the explosion safety requirements. In accordance with it, the area of easily removable structures, in this case glazing, is calculated from the condition of 0.03 m² per 1 cubic meter of room.

When the power of the heating unit is over 150 kW, the room is equipped with a separate exit. Regardless of the characteristics of the boiler, a passage along the front of at least 1 m is left.

Attached premises

An attached boiler room with heating units with a power of up to 350 kW is placed along the blank wall of the house. Set aside at least 1 meter from the nearest door or window opening. The furnace structure should not be rigidly adjacent to the foundation, walls and roof of a residential building.

The material for the walls of the boiler room is selected taking into account the minimum fire resistance limit - 0.75 hours. The structures should not burn or support combustion.

The height of the boiler room inside is at least 2.5 m. The equipment is placed so that it is convenient to service it. The size of the free area in front of the boiler is 1x1 meter.

The attached premises are equipped with a separate exit to the outside. The door should open to the street.

Natural light is a must. The glazing area is at least 0.03 m³ per 1 m³. The hood must support three hourly air exchanges.

The door leading to a residential building is made of fireproof materials. It must comply with the third type of fire safety.

Installing a gas boiler in the kitchen

When installing a gas stove, water heater and boiler with a power of up to 60 kW in the kitchen, the following requirements are imposed on the room:

When installing gas-using equipment, they are guided by the manufacturer’s passport. The walls must be made of fireproof materials, and the distance to the unit must be at least 20 mm.

It is allowed to install boilers near walls made of combustible materials, provided that the surface is protected with a 3 mm thick asbestos sheet and roofing steel or plaster. In this case, at least 30 mm should be removed from the enclosing structures. The insulation is extended beyond the dimensions of the equipment in height and width by 10 and 70 cm.

The floors under the boiler also protect against fire. Sheets of asbestos and metal are laid on them so that their boundaries exceed the dimensions of the body and protrude by 10 cm on all sides.

The main reasons for the decrease in draft in the ventilation system

If design errors are excluded, and efficiency gradually decreases, one of the elements has probably failed.

The most common malfunctions:

- Loss of engine power. Failure can be determined by fan rattling or other signs of wear.

- Settings failed. If the phenomenon was not noticed by the control algorithms, the reason is in the control unit.

- Pollution. Most often, this misfortune befalls filters of supply valves. As a result of dirt adhering to the fans, the geometry of the blades is disrupted and efficiency decreases. The outer grilles may be clogged with leaves or insects.

- Reduced cross-country ability. The channel cross-section has changed. This can happen in any area if you do not order service cleaning. The hood from a gas boiler in a private house needs to be serviced at least once a year.

Short-term changes can occur due to strong wind, rarefied atmosphere outside, or fog. To protect against backdraft, it is possible to install valves, but they must be compensated by fans. In addition, the outlet openings are protected with caps.

It is best to entrust the design and installation of ventilation to professionals. If mistakes are made, a whole bunch of troubles can arise: dampness, odors, destruction of materials, a threat to human health and life. Modern design methods eliminate errors and consider the building as a whole. Thus, it is possible not only to meet safety requirements, but also to ensure a comfortable microclimate and reduce the costs of disparate operation of engineering systems.

What kind of doors should there be in the boiler room?

If this is a separate room in a residential building, then the doors leading from the furnace room must be fireproof. This means that they must hold the fire for 15 minutes. Only those made of metal meet these requirements.

Factory or homemade - it doesn’t matter so much, as long as it fits the parameters

If the furnace room has an exit to the street, there should be unsecured doors. Moreover, SNiP says “weakly fortified.” This is necessary so that during an explosion the box is simply squeezed out by the blast wave. Then the energy of the explosion will be directed to the street, and not to the walls of the house. The second advantage of easily “removable” doors is that gas can escape freely.

Doors to the boiler room are sold with a grille at the bottom

Often the project sets an additional requirement - the presence of a grated hole in the lower part of the door. It is necessary to ensure air flow into the room.

Air supply devices

In a room with a gas stove in a private house or apartment, you simply cannot do without special devices that provide air flow. This is explained by the fact that natural ventilation in most cases is not able to cope with its task of supplying the kitchen with fresh air, since such ventilation systems mainly depend on weather conditions and temperature conditions outside.

The inefficiency of such a system is especially evident in the summer, when there is practically no air exchange and the kitchen is filled with various odors, gases harmful to the body, and there is condensation on the walls. It is in this case that a mechanical ventilation system comes to the rescue, helping to enrich the room with fresh air through the operation of special devices.

Among the above devices, the following are very popular:

- Inlet type window valve. The valve is mounted in the window sash; operation can be carried out either manually or automatically. The main disadvantage of such a device is that in severe frosts it can be susceptible to icing.

- Supply type wall valve. To install the valve, it is necessary to make a hole in the external wall. There are models of equipment that simultaneously filter air masses. The valve can operate either manually or automatically.

- Ventilator. Placed on the bottom leaf of the door, made of plastic. Operation is carried out from the electrical network. The device not only filters air masses, but also heats them.

Ventilator - a device that filters and heats air masses

General standards for the room where the heating boiler will be installed

A gas boiler requires a separate room in the house. Typically, this room is located on the ground floor or basement, but this is only suitable for a one-story mansion. If the house has more floors, it is better to build a separate extension, especially since the boiler itself will heat it. Requirements for installing gas boilers are as follows:

- In one room no more than 4 square meters, only one gas boiler can be installed.

- The ceiling height must be at least 2200 millimeters.

- The room should be very well lit, with a natural glow. There must be at least 0.03 m2 of window area per 1m3, and a hood must be installed.

- Doorways must be at least 80 centimeters for ease of entry and exit.

- The distance from the boiler to the front door is calculated from 1 meter to 1.5 meters.

- During operation, any repair and maintenance work is possible, so that they are carried out in accordance with the requirements, you must leave a free space of at least 1.5 meters in advance.

- To avoid vibrations during heating, the gas boiler is installed strictly horizontally, ensuring maximum stability.

- Walls and floors must be smooth and free of flammable mixtures. They are usually additionally covered with heat-resistant material.

- The ignition and pump on the heating boiler are connected using an electrical supply, so the presence of a grounded socket in the room where the device will operate is strictly necessary.

- Like any stove heating there is a chimney, so access for cleaning and maintenance should be as convenient and spacious as possible

Pros and cons of the two systems

Natural ventilation

To equip such a hood yourself you do not need any special skills, but it has a number of advantages:

- The absence of mechanisms makes such air exchange reliable and durable.

- There is no need to spend money on purchasing devices.

- Easy to use.

- Quiet during operation.

At one time, such a hood fully met its requirements, but with the advent of new gas equipment, the view on this changed.

The following significant shortcomings were discovered:

- Dependence of optimal air circulation on the season and climatic conditions.

- Inability to regulate air flow.

- Penetration of foreign particles through the system.

We recommend reading: Barn Ventilation

And also when the air supply decreases, there is a possibility of increased humidity in the room.

Artificial ventilation

Artificial exhaust is the best option when installing gas boiler houses, since:

It is possible to independently adjust the air supply

The importance of this ventilation in enclosed spaces. Pleasant microclimate in the room

Possibility of regulating air exchange using the remote control. Independence from weather conditions.

If the house has a boiler with a coaxial output, then the built-in fan in it automatically creates a favorable atmosphere for human habitation.

The only drawback of such a system is the rather high cost of this installation.

What do SNiPs say?

The installation of smoke ducts for gas boilers is regulated by SNiP 2.04.05-91, as well as DBN V.2.5-20-2001

- One boiler - one chimney. Combining, installing tees, etc. is prohibited.

- Combustion products must be periodically cleaned out; for this purpose, pockets with a depth of 250 mm are equipped.

- The height of the pipe is at least 5 meters.

- The elevation of pipes above the roof must be arranged taking into account.

- The diameter of the chimney pipe must be no less than the diameter of the pipe outlet of the boiler itself.

- The system is checked and cleaned annually before the heating season.

If you comply with all requirements during installation work, you can be sure that the gas service specialists will not have any questions for you. On cold winter evenings, your family will be warm and safe.

To learn how to choose and install a chimney correctly, watch the video:

https://youtube.com/watch?v=yKKaZneQDa0

Regulatory framework of the Russian Federation

Installation of ventilation systems is mandatory regardless of the type of heating equipment used (clause 9.38 of SNB 4.03.01-98). Installation of heating and ventilation equipment is carried out under the supervision of representatives of gas services.

If during commissioning tests defects in the ventilation system and technical inconsistencies with the design documentation are revealed, commissioning of the heating system will be refused.

The Gas Inspector's responsibilities include visual inspection of equipment, safety functions, controls, and carbon monoxide monitoring. If necessary, the owner of the premises may require the inspector to provide certificates-permits to work with an anemometer or SRO

Ventilation provides a constant intense flow of fresh air. The operation of exhaust systems is regulated by a number of regulations.

Legislative acts and GOSTs

The regulatory framework relating to ventilation and air conditioning of gas equipment is quite extensive. These legal acts include:

- Federal Law No. 384;

- Government Decree No. 1521 on ensuring mandatory compliance with 384-FZ;

- Government Decree No. 87;

- Government Decree No. 410 on safety measures for the maintenance of gas equipment;

- SNiP (II-35-76, 2.04-05);

- SanPiN 2.2.4.548-96. 2.2.4;

- ABOK standards and recommendations in the field of ventilation, etc.

But legislative acts may change, so when installing ventilation equipment for a gas boiler room, you should monitor their latest editions in official sources.

All standards and regulations that will be applied when checking ventilation equipment can be clarified with the gas service of your locality

Also, all ventilated systems in rooms with boiler equipment must comply with the following GOSTs and SP:

- GOST 30434-96;

- GOST 30528-97;

- GOST R EN 12238-2012;

- GOST R EN 13779-2007 on air conditioning and ventilation in non-residential buildings;

- GOST 30494-2011 on microclimate in residential and public buildings;

- SP 7.13130.2013 on requirements for ensuring fire safety;

- GOST 32548-2013 (interstate standard);

- SP 60.13330.2012 (refers to SNiP 41-01-2003), etc.

Project documentation must be drawn up on the basis of these regulations. To ensure that it does not contradict official requirements and standards, it is necessary to carry out thermal calculations and calculate the main parameters of the exhaust system at the project development stage.

Certification of ventilation equipment

When purchasing exhaust and fresh air supply devices, you should check their documents. A declaration of conformity must be issued for ventilation equipment sold in the Russian Federation.

This document confirms that the devices comply with all current requirements of the Customs Union set out in the following technical regulations:

- TR CU 004/2011 on the low-voltage equipment used and the safety of its operation;

- TR TS 020/2011 on electromagnetic compatibility of the equipment used;

- TR TS 010/2012 on the safety of machinery and equipment.

This product declaration is mandatory, but in addition to it, the manufacturer or importer of ventilation equipment can undergo an official voluntary certification procedure for compliance with GOST standards. The presence of such a certificate, obtained on a voluntary basis, indicates the high quality of the product and the reliability of the manufacturer.

A voluntary certificate of conformity for air ducts can be requested when purchasing ventilation equipment for a gas boiler room. It indicates all technical characteristics of the product

But voluntary certification requires additional capital investments, so they often save on it. In accordance with Federal Law No. 313 and Government Decrees No. 982 and No. 148, mandatory certification of ventilation equipment has been abolished.

Requirements for boiler houses for installing solid and liquid fuel boilers

The requirements for volume, dimensions and materials for the boiler room are the same. However, there are several specific ones that are related to the need to organize a chimney and a place to store fuel. Here are the basic requirements (mostly they are specified in the boiler passport):

- The cross-section of the chimney should not be less than the diameter of the boiler outlet pipe. Reducing the diameter along the entire length of the chimney is not allowed.

- It is necessary to design a chimney with the smallest number of bends. Ideally it should be straight.

- There should be a supply hole (window) at the bottom of the wall for air to enter. Its area is calculated based on the boiler power: 8 sq. see per kilowatt.

- The chimney can be discharged through the roof or into the wall.

- There should be a cleaning hole below the chimney entrance for inspection and maintenance.

- The chimney material and its connections must be gas-tight.

- The boiler is installed on a non-combustible base. If the floors in the boiler room are wooden, lay a sheet of asbestos or mineral wool cardboard, with a sheet of metal on top. The second option is a podium made of bricks, plastered or tiled.

- When using a coal-fired boiler, the wiring is only hidden; installation in metal pipes is possible. Sockets must be powered from a reduced voltage of 42 V, and switches must be sealed. All these requirements are a consequence of the explosiveness of coal dust.

Please note that the passage of the chimney through the roof or wall must be made through a special non-combustible passage unit

Liquid fuel boilers are usually noisy

It is worth saying a few words about liquid fuel boilers. Their work is usually accompanied by a fairly high noise level, as well as a characteristic odor. So the idea of putting such a unit in the kitchen is not the best idea. When allocating a separate room, you should make sure that the walls provide good sound insulation and that the smell does not penetrate through the doors. Since the internal doors will still be metal, make sure there is a high-quality seal around the perimeter. Perhaps noise and smells will not interfere. The same recommendations apply to attached boiler rooms, although they are less critical.

Why insulate a chimney pipe

If the chimney pipe for the boiler is cooled in the cold, then the temperature of the exhaust gases decreases - which means the draft decreases. This problem can be solved by insulating the pipe. How to insulate depends on the material from which the chimney is made:

- Brick structures are plastered, and if the attic is not insulated, then stone or basalt wool with foil on top is used;

- Ceramic chimneys are protected from the cold with mineral wool and ceramic blocks, metal ones are insulated with any non-combustible materials;

- The most difficult thing is with asbestos structures - they can explode if they overheat, so they must be insulated competently and carefully.

What are the conditions for ventilation?

The ventilation requirements for rooms in which a gas water heater is located, or a kitchen in which a gas stove is often turned on, are similar.

Conventional diagram of connection to the chimney

No more than two geysers can be connected to one chimney, regardless of their placement distance; the hood for a gas boiler must be hermetically sealed: even a small gas leak can cause damage to the lives of residents; all components of the system must be thermally insulated to avoid the risk of fire; the places where the chimneys are connected should be treated with a sealing agent that is resistant to high temperatures; It is important that chemicals exit the chimney at a distance of 50 cm for each level.

It should be noted that for arranging the ventilation of a room with a gas boiler with an open combustion chamber, there are some peculiarities:

- a ventilation chimney should be installed in the equipment room, the purpose of which is to remove carbon monoxide from the room;

- Supply ventilation is installed to provide fresh O2 access to the boiler room.

The installation of a double-circuit boiler also requires a ventilation system

Such precautions will protect the gas unit from possible problems.

Removal of combustion products from several boilers

The operating rules for heating systems indicate that when using several gas boilers, each of them must be connected to a separate chimney. However, if such boilers are installed in already built houses, a more flexible approach is allowed: several floor-mounted or wall-mounted units can use a collective exhaust system, provided that a distance of 75 cm in height between the combustion product input points is maintained. In this case, the cross-sectional area of the chimney must be no less than the area of the widest outlet pipe of all connected boilers.

Installing a chimney for a gas boiler is no less important a procedure than choosing the heating unit itself or calculating and designing the route of the heating system. If you follow all the rules given in the article, you will receive an effective and safe exhaust gas removal system that will ensure comfort and coziness in your home, no matter how frosty the weather rages outside.

Why can boilers with a closed combustion chamber be installed in rooms without windows?

In your article https://strmnt.com/montazh-i-ustanovka-gazovyx-kotlov-trebovaniya-i-pravila.html there is the phrase “There are exceptions: if the heating boiler has a closed combustion chamber, then the volume of the boiler room is not standardized, and the presence windows with access to the outside are not necessary.” Please tell me SNiP and GOST, where this information can be found. If possible, a specific point. Thank you.

In modern heating systems using gas as fuel, as is known, two types of boilers are used: with open or closed combustion chambers. Moreover, the premises for the installation of boilers with a closed combustion chamber are subject to less stringent requirements than for equipment of the first type.

Environmental friendliness of boilers with a closed combustion chamber

In boilers with an open combustion chamber, the air of the room in which the equipment is installed is used to ensure the combustion process, and combustion products are discharged naturally through a chimney common to the building. Boilers of this type are installed in a separate room with a window and an exhaust ventilation duct, which allows for an influx of fresh air and effectively removes toxic waste gases.

A boiler with a closed combustion chamber is a sealed unit into which the air necessary for gas combustion is supplied directly from the street through its own air duct. Combustion products are also discharged through an individual chimney, without entering the common house chimney or coming into contact with the air of the room.

Due to its high environmental performance, it is not only possible to install equipment of this type in boiler rooms and in any other premises, even residential and without windows, but it is also recommended as a base for creating individual heating systems even in apartment buildings.

Types of chimneys for boilers

There are different types of chimneys that are used in these cases:

A brick chimney is made of fireclay bricks, which are placed either on clay mortar or glue. In most cases, it is made with a stainless or galvanized steel sleeve inside to protect the brick from the destructive effects of carbon dioxide.

Region190FORUMHOUSE participant, master inspector at VDPO

Over time, the brick will begin to crumble due to carbon dioxide, so the chimney must be lined. In the market you can be deceived with the steel grade; it is better to buy AISI 316 directly from the factory. This acid-resistant steel works reliably with any brand of boiler. Not a single inspection master will ask you about the steel grade or demand a certificate; we do not have the authority to do this, and it is impossible to visually distinguish 316 from 425.

The main disadvantage of such a chimney is that it is heavy, you will have to make an additional foundation, and it is bulky, and you will have to look for a stove maker who will lay it out. Previously, such chimneys were often made for gas boilers; now (if funds allow) homeowners prefer ceramics.

Ceramic chimney . This is a complex structure that includes a ceramic smoke exhaust duct, an air layer (or insulation) and an expanded clay concrete shell. Expanded clay concrete protects the fragile ceramic pipe and serves as insulation (and ceramics have high thermal conductivity).

Andrey50FORUMHOUSE member

Cool specialists with extensive experience in chimneys say that ceramics are the best, but unreasonably expensive.

It is much easier to install such a structure than a brick chimney; it is durable, fireproof (can heat up to 120 degrees), but it is also heavy and bulky, and also expensive.

Asbestos-cement chimney. For this type, it is important to have tight joints inside the channels and good insulation to prevent condensation from forming.

RegularUser .FORUMHOUSE

During my construction period, asbestos-cement pipe was the cheapest option. The main problem here is how to hermetically join the segments; I couldn’t get it to be hermetically sealed. Simply pouring concrete is not an option. It should be a sealed sleeve, clamp, insert, anything that provides a reliable and tight connection. Be sure to insulate your asbestos-cement pipes. Do not forget that the design of the chimney should not allow condensate to drain into the boiler and be sure to make a condensate collector at the bottom at the base of the pipe.

Single metal - chimney made of galvanized or stainless steel.

Sandwich chimney. Such a chimney is made of two metal pipes, one is inserted into the other, and insulation is laid between them. Smoke flows through the inner cylinder. This type is required for use as an external chimney and in unheated rooms.

Coaxial. In this chimney, one pipe is inserted into another without laying insulation. But this is a single rigid structure, united by jumpers along its entire length. Smoke exits through the inner pipe, and air enters the combustion chamber through the outer pipe; the room air does not participate in the operation of the gas boiler, the microclimate is maintained.

Mr LeshiyFORUMHOUSE Member

Sandwich is an insulated chimney made of two stainless steel cylinders, between which insulation is stuffed. Coaxial - the same two cylinders, but without insulation inside. Exhaust gases are removed through the inner cylinder to the outside, and air is supplied into the combustion chamber through the gap between the cylinders.

Structural insulation

To insulate the surface of the chimney in contact with the floor and roofing material, foiled basalt wool and fire-resistant mastic are used. It is pasted over the passage pipe and the gaps of the holes in the ceiling are filled.

If a regular steel pipe was used to construct a chimney located outside the house, then such a chimney is insulated along its entire length.

Ceramic gas outlet

This is the most versatile design that can be used with all types of boilers. The material is resistant to aggressive products formed during combustion. It is necessary to take into account the highest temperature for which the products are designed. For solid fuels, you need models that can withstand 600°; for boilers running on gas, 450° is sufficient. First of all, they provide for the installation of a condensate drain.

Ceramic pipes are installed mainly in brick structures or hollow cinder blocks. If they have two holes, one of them is used for ventilation or oxygen supply for a burner with a closed fuel chamber. The pipes are insulated with mineral wool to reduce the appearance of moisture and increase draft. Models are sold in a steel case. They can be placed in the middle of the house without the construction of specialized channels.

The smoke exhaust duct consists of individual elements 0.5–1 m long. On the upper part there is a coupling into which the next section is placed. Various product options are available:

- 1. Round for installation in concrete blocks. They have a cavity where a pipe and an asbestos seal are placed. To connect the components, reinforcement is placed in the holes.

- 2. With right angles for installation in brickwork. Their size is 20×20 cm.

- 3. With steel body. The pipes are connected with clamps.

- 4. Integral design with sleeve. It has ventilation channels and holes for installing fittings during installation.

The use of ceramic pipes for gas exhaust without enclosure and thermal insulation is not possible. They strongly absorb moisture, so a shell on the outside is required.