Ventilation in the boiler room is a mandatory requirement for the safe use of gas heating appliances. Failure to comply is associated with a number of problems, both administrative and an increased likelihood of an emergency.

Since the accumulation of carbon monoxide and other combustion products poses a danger not only to the direct owner of the gas boiler, the compliance of the ventilation system with SNiP standards is carefully checked by gas services at the stage of equipment acceptance.

In turn, using a boiler without the appropriate permission can lead not only to administrative, but in some cases to criminal liability.

Carbon monoxide is very dangerous, so the ventilation system of a gas boiler room in a private house must work flawlessly Source tula.sm-news.ru

Ventilation is the key to safe and efficient operation of equipment

Ventilation in the kitchen with a gas stove or boiler protects not only people’s health.

For high-quality combustion of gas, oxygen is required. If it is deficient, a lot of carbon monoxide and under-oxidized substances are released into the air during the combustion process. You can notice this by the yellow color of the flame, high with abundant soot.

The efficiency of gas equipment decreases - the same amount of fuel burns, but less heat is released.

An even greater danger is posed by natural gas itself, which can get into the air in the room, for example, if a draft blows out the fire on a burner, the gas supply hose to the stove cracks, or the gas boiler breaks down.

The choice of a gas ventilation system in a private house or apartment depends on the type of boiler and the characteristics of the boiler room.

Why do you need an air circulation system?

In such a small and sealed boiler room, very effective ventilation is needed; there are most likely dimensional violations here

Despite the development of high-tech gas boiler equipment, the number of poisonings and deaths from carbon monoxide is high. General weakness and headache are the least a person can feel. Ignoring generally accepted standards reduces the performance of heating equipment. Only with a continuous air supply is normal operation of the boiler ensured, and if there is a lack of oxygen, the fuel does not burn completely. This means that heat generation will be minimal.

It is necessary to understand that if, even at the initial stages of designing a building in the scheme, the boiler room is located separately from the house, the air that circulates in the room will be used by the boiler. When installing non-plastic doors and windows, there will be enough air in the boiler room. When installing modern plastic windows and doors, fresh air will not circulate from the street. When the boiler is running, it discharges the air, which means that the power of the equipment will decrease. There is a high probability that carbon monoxide will enter the boiler room

This example confirms the importance of a ventilation system in any room

Date: September 25, 2022

Purpose of ventilation

Boiler room ventilation consists of two functional subsystems: the influx of atmospheric air and the removal of flue gases from the heating boiler.

Purpose of the smoke exhaust system:

- Supply of oxygen in the air in the required quantity for complete combustion of fuel. Oxygen deficiency reduces the efficiency of the boiler plant due to losses caused by incomplete combustion of fuel. In addition, unburned fuel particles pass through the gas path of the boiler and smoke exhaust channels, causing premature wear of equipment surfaces, introducing soot into chimneys and polluting the environment.

- Removal of harmful flue gases formed as a result of the combustion process. If the technological rules for operating boiler equipment in terms of combustion modes are not followed, carbon monoxide enters the room with the formation of a dangerous concentration of harmful substances in the air, which is a threat to the health of others.

- Performs the functions of extracting a gas boiler in a private house in case of emergency leaks of flue gases or natural gas into the combustion chamber. This situation is possible in the event of a violation of the integrity of the gas pipeline, separation of the gas flame from the burner, as well as a drop in vacuum in the furnace.

When should you invite specialists?

When arranging ventilation ducts in a private house, you can go in two ways:

- invite specialists who will complete everything turnkey;

- deal with all the issues yourself, completing the work on your own.

Each option is appropriate for specific conditions. All design options for the ventilation duct system can be divided into traditional and the latest ready-made systems. In the first case, you need to select equipment based on calculations. Here we must not forget about the smallest details that will be useful when assembling the system.

Secondly, we are talking about a comprehensive solution from a specific manufacturer. For example, the German Selfwind ventilation system, which is purchased as a ready-made kit for a certain area of the house. All components required for assembly have been selected. The system itself resembles a collector heating system, only many tubes surround the entire house from the inside.

These flexible plastic ducts with a diameter of 75 mm or 50 mm are pulled together into a manifold. They are poured with a concrete screed on the floor, and those areas that run like a circulatory system throughout the house are skillfully masked by the designers.

In the future, this technology provides an ideal microclimate in each room with the ability to regulate humidity, temperature and other parameters

If you choose such a complex ventilation system, which costs several thousand dollars for a country house with an area of 800 m2 or more, then there is no point in saving on installation. And it will take a lot of time to arrange such ventilation.

When building a house with your own hands “from scratch,” laying out ventilation shafts from bricks and providing holes for installing supply valves is not difficult. In the future, all areas of the natural ventilation system are equipped with special valves and, if necessary, hoods. This option is relevant for houses with an area of up to 250-300 m2.

Complex and expensive polymer ventilation duct systems are equipped with all the necessary parts for installation

Requirements for ventilation in a boiler room with a gas boiler

When the power of a gas boiler exceeds thirty kilowatts, it is necessary to design a special room to house the boiler room. In this case, it is necessary to ensure SNiP standards number II-35-76. Among the main requirements:

- ventilation for a gas boiler requires an exhaust pipe outlet on the ceiling of the boiler room;

- the chimney channel must have a separate additional entrance for cleaning, located 250 mm lower from the main entrance;

- when calculating the area of the supply channel from the street per kilowatt of unit power, take 8 cm square of the ventilation grille cross-section;

- when organizing supply ventilation from adjacent rooms, the open cross-section of the grille should be thirty square meters. cm per kilowatt of boiler power.

Is ventilation necessary in a gas boiler room?

gas boiler room of a private house

Even a small amount of carbon monoxide can worsen the well-being of residents. Chronic fatigue, headaches and pain in the eyes are the least that people feel who often inhale combustion products. Leaks of explosive and flammable fuel are no less dangerous.

Poorly designed ventilation not only threatens the life and health of people, but also reduces the performance of equipment.

Operation of a gas boiler is possible with a constant supply of oxygen to the boiler and timely removal of combustion products. When there is not enough air, fuel burns worse. While consuming the same amount of gas, the boiler produces less heat in a poorly ventilated room.

Weak ventilation exhaust in a boiler room with a floor-standing gas boiler leads to the accumulation of burning and soot inside the equipment, the cross-sections of the air ducts are reduced, the draft worsens and some of the combustion products are drawn into the room.

Equipment for a gas boiler room in a private house

Gas boilers use air from the boiler room. If the boiler room is separated from the main house by wooden unsealed doors or has old-style windows, air entering through the cracks in the frames is sufficient. But if modern windows and doors are installed, air will not come in from outside. When fuel burns in the room, the air will be discharged and the efficiency of the boiler will decrease. The fumes from the boiler can go into the boiler room and from there into the living rooms. Therefore, it is necessary to think about how to ventilate the boiler room.

Requirements for ventilation in a private house with gas

Wall-mounted gas boiler

In addition to the presence of ventilation, special requirements are imposed on the premises of a gas boiler room.

The boiler room may be equipped with:

- in the extension to the cottage;

- in the attic;

- in a separate building;

- in a specially designated room.

If the equipment is designed for liquefied gas, the basement or basement will not be suitable. Liquefied gas has a higher specific gravity than air. Therefore, when there is a leak, it sinks to the lowest parts of the house and here it can explode. This feature of the fuel must be taken into account before ventilating the boiler room.

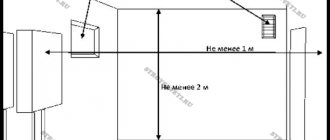

Low-power gas boilers (no more than 30 kilowatts) do not require a special boiler room; you can hang or install them in the kitchen if the room meets the following requirements for ventilation of the boiler room of a private house:

- area from 15 sq. meters;

- ceiling height at least 2 m 20 cm;

- window area from 3 sq. cm per 1 cubic meter of room volume;

- the window opens or is equipped with a window;

- for the flow of air from neighboring rooms, holes are made in the lower part of the door;

- the equipment is installed near a wall made of non-combustible material at a distance of at least 0.1 m.

According to the requirements, supply ventilation in a boiler room in a private house is required. If the equipment power is above 30 kilowatts, a separate boiler room is installed.

How to do it yourself?

Schemes and calculations

Natural ventilation scheme:

- The air supply is located opposite the hood.

- The air is exhausted through an exhaust pipe, the beginning of which is on the ceiling, and the end is above the roof ridge. If the ventilation system is located on the wall, then this should be done as close to the ceiling as possible.

Mechanical ventilation scheme:

- The pipe with the fan must be discharged either through the roof to the street or through the wall outside the house.

- The air duct exits into the existing ventilation shaft with a fan.

During the heating season, it is recommended not to turn off the exhaust fan, leaving it to run on a regular basis.

Calculation of ventilation for a boiler room with a gas boiler is carried out taking into account the area of the room, the frequency of air exchange, and the number of family members regularly living in the house. Using these parameters, you can calculate the required hood cross-section for a gas boiler.

Attention Formula for calculating the amount of air exchange:

L (boiler power, kW/h) = N (air renewal rate) × S (room parameters) × H (boiler room ceiling height, m).

Attention Formula for calculating the number of family members:

L (boiler power, kW/h) = N (number of family members) × Lн (minimum air consumption per person, m³/h).

Generally accepted minimum air consumption standards per person:

- sleep – 20 m³/h;

- rest – 40 m³/h;

- vigorous activity – 60 m³/h.

Boiler room ventilation diagram:

Materials and tools

Basic materials and tools:

- Hammer or drill with a crown attachment.

- Saw for processing pipes.

- Tools for marking - ruler, pencil.

- Air ducts and adapters for them.

- Protective grilles.

- Adapter with check valve.

- Protective sleeves for slabs.

- Self-tapping screws, dowels, mounting clamps.

- Sealant or polyurethane foam.

- Hacksaw.

- Protective equipment: gloves, glasses.

Installation

Installation of natural ventilation:

- The installation location is outlined. The necessary calculations are made, a diagram or drawing is created.

- A pipe is applied to the wall, its dimensions are noted.

- A perforator is used to make a through hole with a slope of 60 degrees outward to drain the condensate (with exhaust ventilation, the slope is not made, the pipe is installed evenly).

- A pipe with insulation and a grille on the outside is inserted into the finished through hole.

- A housing with a check valve is attached to a part of the pipe inside the house and the wall with dowels (how to make a check valve for ventilation with your own hands?).

Installation of forced ventilation:

- A through hole is made in the wall with a slope towards the street. It is recommended to use a hammer drill or a drill with a diamond bit.

- A pipe is installed in the hole.

- The gaps between the wall and the pipe are filled with sealant or foamed.

- A duct fan is installed.

- Electrical wiring is laid and connected.

- The rest of the equipment is installed - filters, sensors, sound absorber.

- Grates are attached to both sides of the pipe.

separate article

Gas boiler room ventilation standards according to SNiP

Exhaust fan

All requirements for ventilation of a gas boiler room are set out in SNiP 2.04.05, II-35.

- There must be ventilation in the gas boiler room; the air duct outlet is located on the ceiling;

- Near the chimney channel, another one is made, 30 cm lower. It serves to clean the chimney;

- Air flow is provided from the street through a ventilation duct or from the adjacent room through openings in the lower part of the door;

- The air flow for ventilation is calculated based on the boiler power: inflow from the street: per 1 kilowatt of power - from 8 sq. centimeters of air;

- influx from the neighboring room: per 1 kilowatt of power - from 30 sq. centimeters of air.

The remaining rules for equipping a boiler room in a private house can be found in the relevant regulatory documents.

Conclusions and useful video on the topic

The video will introduce you to the basic requirements of gas services for the ventilation equipment of boiler houses in the Russian Federation:

Installation of exhaust equipment requires precision. But you need to understand that each gas service has its own interpretation of norms, standards and laws.

Before installing the heating equipment of a private home and the ventilation system in a gas boiler room, it is better to consult the gas service from which you will have to obtain permission for commissioning.

Tell us about your own experience gained during the installation of a gas boiler room. Share the technological nuances that helped you create a trouble-free air exchange system. Please leave comments in the block form below, post photos related to the topic of the article, and ask questions.

Natural ventilation with gas boiler

Scheme of natural ventilation of a gas boiler room.

Usually, natural draft is used to ventilate the gas boiler room of a private house. So, with a boiler with a power of up to 30 kilowatts, a vent with a diameter of 15 cm is sufficient for the influx. A plastic pipe is inserted into the vent, and the entrance is covered from the outside with a metal mesh to prevent the penetration of rodents and debris. Inside, a check valve is attached to the pipe, which prevents air from being drawn out into the street.

The hood is also done. An umbrella is attached to the upper end of the exhaust pipe to protect from rain and snow. Some craftsmen also install a check valve on the exhaust pipe to prevent air from entering the house through it.

To ensure that clean air enters directly into the combustion chamber, the supply air duct is installed behind the fuel compartment. The exhaust pipe is placed directly above the boiler, where combustion products rise.

The above ventilation device for a boiler room in a private house is very simple to implement and in most cases quite effective. But the system cannot be controlled and this is its main disadvantage. According to SNiP ventilation in the boiler room, the air must be renewed three times per hour. It is impossible to calculate the air exchange with the natural ventilation system of the boiler room. In addition, air exchange depends on pressure, outside air temperature and wind strength.

Exploitation

When operating gas boiler ventilation systems, the design temperature conditions and air exchange rates for residential buildings where gas boilers are installed must be consistent with current SNIP standards, fire and sanitary safety rules.

A natural supply and exhaust ventilation system must guarantee the removal of the required volume of air from all rooms at outside temperatures of +5 C and below. When operating forced ventilation using gas heaters, it is not allowed to allow a difference in supply and exhaust volumes of more than 10%, in one direction or the other. The heads of the main exhaust ventilation shafts for a gas boiler room in a private house in systems with natural air circulation are equipped with deflectors. Anti-corrosion protective painting of metal pipes and their structural elements is carried out no more than once every 3 years.

Professionally performed ventilation in a private house with autonomous heating is not a luxury, but a vital necessity.

It is designed to provide not only the flow of fresh air, but also the removal into the atmosphere of harmful, toxic flue gases generated during the operation of the boiler. The health of those around you will depend on the quality of its work, so it is better to entrust its installation to specialists.

Chimney for ventilation of a gas boiler room

The correct chimney for boiler room ventilation

A chimney is one of the most important elements of a competent ventilation system for a boiler room in a private home. Therefore, its design needs to be discussed separately.

SNiP ventilation in the boiler room are also developed for chimneys:

- The chimney does not allow gas and fumes to pass through. No combustion products should enter the air in the boiler room. To increase the tightness of the chimney, some owners plaster it or insert asbestos-cement inside the metal pipe. Its diameter depends on the power of the boiler;

- The chimney pipe must extend beyond the level of the ridge so that the draft is sufficient. The chimney outlet must rise above the roof ridge by 2 - 5 meters, otherwise suction is possible;

- The diameter of the ventilation chimney in a gas boiler room must be larger than the diameter of the chimney of the boiler itself and depends on its power. You can use the following proportions: with a boiler power of 24 kW - diameter 120 mm;

- at 30 kW – 130 mm;

- at 40 kW – 170 mm;

- at 55 kW – 190 mm;

- at 80 kW – 220 mm;

- at 100 kW – 230 mm.

For those who decide to equip the ventilation of the boiler room of their own private home with their own hands, simple rules will help:

- the cross-section of the chimney pipe is indicated in the boiler passport;

- the chimney is made of sheet metal (galvanized or stainless steel). The chimney has a circular cross-section of the same diameter along its entire length and an inspection window for cleaning;

- the chimney should have no more than three turns or bends.

Chimney outlet of a heating device in a private house

Chimneys and their installation require a specialized approach and compliance with certain requirements. The walls of the chimney are usually made resistant to temperature changes, corrosion and chemical compounds.

The hood for boilers in a private house must meet building regulations:

- SNiP 41-01-2003 “Ventilation and heating of residential premises.”

- SNiP 42-01-2002, 42-101-2003 “Recommendations and requirements for gas distribution complexes”

Thus, while maintaining these legislations, it is necessary to ensure that smoke removal corresponds to the required air exchange and air safety. And to do this you need to calculate the height and cross-section of the chimney and air duct. During installation, the following conditions must be observed:

- the pipe must be positioned strictly vertically;

- rise above the roof ridge no more than 0.5 m;

- the total height of the vein channel is no more than 5 m;

- The joints in the channel are insulated with heat-resistant sealant.

If the above requirements are met, you can install the ventilation pipe for the heating device yourself.

Types of ventilation systems

The circulation of air masses in the room is natural or forced. The first is used for boiler units with a thermal power of up to 30 kW, if such a system is provided for this modification by the manufacturer.

The second scheme is installed in more powerful boilers with developed heating surfaces, several circulation circuits and a large length of smoke ventilation ducts. Such a heat supply system has large aerodynamic resistance along the path of the gas-air mixture, which the flue gases will need to overcome.

In this connection, their movement can only be ensured by force using a blower fan or smoke exhauster.

Natural

The least effective system, and at the same time simpler, is installed in one-story houses of a small area with low-power boilers. It is often used to organize air exchange in basements, attics, utility rooms and garages.

Natural exhaust in the boiler room

The intake of air masses in the furnace room is carried out through vents, window openings, ventilation grilles in the door panels, and exhaust ventilation is carried out through air ducts located at the top of the walls or in the ceilings with an outlet above the roof.

A professionally executed ventilation system changes the entire volume of air in the combustion chamber to fresh air. To do this, the inlet and outlet air holes are located opposite each other.

For example, the boiler unit is placed directly opposite the entrance, and the exhaust vent is located above the boiler. Air masses move from below, pass through the entire combustion chamber and go up to the hood. The window can be on any wall.

It is not recommended to place the air duct outlet near the boiler. In winter, a sharp drop in outside air temperatures can affect the operation of the boiler, which is why the hole is made at a distance of at least 1-1.5 m from the area where it is located.

Forced

Turbocharged heating devices or forced circulation boilers are installed only according to the recommendations of the equipment manufacturer. They are produced with closed combustion chambers, and the air is supplied by blowing centrifugal fans.

To increase the efficiency of boiler equipment and its repair, modern boilers are equipped with a combined air supply system using air filters, a heater, for air preheating and fans.

For gas boilers of higher power, smoke exhausters are additionally installed, which create a vacuum in the firebox, thereby forcing flue gases to move through the flues.

Innovative domestic boilers with a closed firebox, using gaseous fuel, are equipped with automation with a weather-dependent control and safety system.

It sets the mode depending on the outside temperature, and therefore regulates the supply of gas fuel volume. This function must be consistent with the amount of air entering the boiler to ensure complete gas combustion.

To ensure consistency between thermal engineering and aerodynamic processes, primary sensors for the temperature of the heating water and draft pressure in the combustion space are used.

Thus, the actuators in the fuel opening/closing mode will operate in proportion to the air flow entering the burner device.

How to choose material for the hood

To solve such problems, brick, stainless, galvanized steel or ceramic material is used. Let's analyze each of them in more detail.

Coaxial ventilation

This gas boiler hood in a private house consists of a short outer and a long inner pipe. In addition, it includes all sorts of accessories: clamps, elbows, gaskets, as well as a condensate receiver. This design is also called “pipe in pipe” and is used in gas heating appliances with a closed combustion chamber.

The design and principle of operation are the same for all boilers of this type:

- The pipe located inside is connected on one side to the boiler pipe, and its other side is led out to the street and combustion products exit through it. It is made of stainless steel and can withstand high temperature changes.

- The pipe, located outside, is connected at one end to the inlet, and the other end is taken outside the room. Fresh air enters through this channel.

- During operation of the unit, the exhaust combustion products are discharged outside due to draft through the internal channel, and at the same time fresh air is supplied to the combustion chamber through the external channel.

This coaxial device has the following advantages:

- The chimney is safe. This is possible because the escaping hot combustion products are immediately cooled by cold air coming from outside.

- Increased productivity. Fresh air heats up when supplied and increases the efficiency of the unit.

- Environmental friendliness of the system.

- Installation in the kitchen. Such a wall-mounted heating device does not spoil the overall interior of the room.

Another feature of installing such boilers with coaxial air circulation is that in a private home, the chimney can be installed both vertically and horizontally.

Brickwork

Nowadays brick is used less and less for ventilation shafts.

This is caused by two main reasons:

Firstly , due to its fragility, after 7-10 years the brick begins to crumble, and the masonry loses its tightness, which means it loses its purpose. It is destroyed due to the fact that the temperature in the channel changes and as a result condensation forms, which freezes in winter. It is more acceptable to make chimneys from this material when the walls are constantly in contact with hot waste.

Secondly , brickwork is a labor-intensive process; such a ventilation duct has a complex design and unjustified costs.

In this regard, a better option would be a brick shaft with a galvanized pipe inside for ventilation. It is assembled in parts from 2-meter contours, and the thickness of the walls is selected taking into account the temperature of the exhaust gases.

Steel hood

The exhaust gas during operation of a gas boiler has a temperature of about 430 degrees, and even more when operating solid fuel boilers. Therefore, the exhaust pipes for a gas boiler in a private house are made of stainless steel with a wall thickness of 0.7-1 mm. These products are quite stable to the action of condensation on the surface of the walls.

It should be noted that the service life of these ventilation pipes is significantly shorter than that of brick and ceramic ones. At the same time, standard steel hoods are easier to replace because they are lighter and do not require specialized foundations to provide strength.

Such channels are manufactured in different versions:

- Placement in a specially laid brick well;

- From factory circuits. In this case, each circuit is a sandwich pipe with two walls. Here one pipe is located inside another, and the gap is filled with heat-insulating material.

The use of such hoods simplifies installation, and they can be mounted both indoors and outdoors.

How to ventilate a furnace

A professional calculation of the supply ventilation system in a cottage with an autonomous heating source should be carried out as part of the overall project of a residential building in the ventilation section.

The project must include sections for calculating the size of veterinary ducts, determine the types of ventilation equipment and installation diagrams. The design task is to create a system that can provide threefold air exchange.

Scheme

Natural ventilation can be installed in rooms that are not located in lowlands and when the house is not covered by other buildings that impede normal air exchange. Such a diagram should determine the location of functional units.

Ventilation diagram with supply unit

So the air intake pipe should be located at the bottom of the wall, and the outlet pipe should be located at the top, on the opposite side. This is required to organize natural convection in the room. In addition, the air outlet from the combustion chamber should not be influenced by heat coming from the heating source and radiators.

Tools and materials

Various materials are used for the arrangement of air ducts: plastic, zinc-coated metal sheets, ordinary steel sheets or duralumin.

For individual houses with autonomous heating, it is possible to use PVC sewer pipes of the required diameter as air ducts. In addition to these pipes, adapters are purchased, and a protective grille is purchased for the air intake pipe.

Additional materials for arranging ventilation for a gas boiler in a private house:

- Protective sleeves for ceilings.

- Fastenings and installation clamps.

- Construction sealant that seals voids between sleeves and wall transitions.

- Set of construction tools.

- Hammer for making through wall holes

- Protective means.

Ventilation installation

It is recommended to carry out work on arranging gas ducts in the warm season. The workplace should have good lighting and there should be no strangers interfering with the activities.

Before starting to assemble the system, it is carried out in a trial version on a free site, thereby checking the completeness. Next, according to the diagram, mark the places where fastening holes are created in the walls and ceiling transition. The inlet pipe is installed at a level of 25 cm from the ground. Subsequent measures for organizing the ventilation system:

- Clean the mounting holes from dirt.

- Install sleeves for the passages of ventilation ducts.

- Installing pipes.

- Fix the vertical section, checking the quality of the fastener.

- Install the fan and connect it to the power supply.

- They check the functionality of the connected flue ducts and ventilation systems in the boiler room of a private house.

Coaxial pipe

This boiler hood is an innovative chimney design. It is carried out on the principle of pipes suddenly built into each other and simultaneously performs two functions: removing flue gases from the boiler into the atmosphere and taking in clean air necessary to ensure complete combustion of fuel in the boiler.

Such chimneys are divided into two types: horizontal and vertical placement. Horizontal ones go through the wall, and vertical ones go through the ceiling into the attic and then through the roof.

The second system, when installing a gas boiler, is the most complex, its price is more expensive, and in addition it requires the installation of a condensate drain.

This modification of the chimney has one significant drawback - there is a possibility of condensate liquid freezing on the outer part of the structure. This problem can be solved by insulating the chimney with heat-protective material.

Made of brick

Traditional brick has long been used to construct air ducts and smoke exhaust systems. Currently, it does not meet the required level of performance requirements and is significantly inferior to other modern materials.

This is also due to the fact that brick ventilation duct structures are very bulky, require the involvement of highly qualified specialists, but at the same time they are short-lived, and when in contact with acid-containing condensate, the rate of their destruction increases significantly.

Therefore, recently only the shaft is built from brick, and the chimney of the gas boiler itself is made of galvanized pipes with wall thickness that takes into account the temperature regime of the flue gases.

Steel chimney

Currently, this type of chimney is the most common due to its high-quality characteristics. Steel pipes in ventilation and chimney systems are easy to install compared to brick ones.

The thickness of the pipe walls is selected based on the temperature of the flue gases. At a maximum temperature of 400-450 C, the permissible wall thickness is 0.6, and at higher temperatures - 1.0 mm.

The disadvantage of such systems is that at high temperatures they quickly burn out, in addition, they have poor resistance to acid condensate released from flue gases at a dew point of approximately 55 C. To combat corrosion processes, stainless steel pipes are used, which placed in “sandwich” panels.

Ceramic chimney

This type of chimney exhaust system is particularly versatile, and therefore is considered an ideal solution for gas fuel boilers. They are easy to clean, do not collect soot on their surface due to the glossy internal coating, have high gas density and resistance to aggressive chemical compounds. An important advantage of ceramic material is its durability.

Ceramic pipe. Photo source: ekaterinburg.freeadsin.ru

However, like any building material, it has its drawback - high moisture permeability, so they need condensate drains.

In addition, such pipes are not used alone in chimneys, but are combined with mineral wool and stone. The best option for arranging such a system is when the ceramic pipe is covered with insulating material and then placed in an expanded clay concrete shell.

Air duct materials in gas boiler houses

Properly selected material for the air duct ensures longer operation of ventilation.

In accordance with current standards, the following can be used as a material for organizing the ventilation of rooms with gas equipment:

- brick;

- ceramics;

- asbestos;

- galvanized and stainless steel.

It is not advisable to use plastic for air ducts, because... this reduces the fire resistance of structures. Some regulations (for example, paragraph 7.11 of SNiP 41-01-2003) indicate that air ducts can be partially made of flammable materials.

When using plastic elements, you must remember that the presence of flammable elements in the structure will complicate the commissioning of boiler equipment and its acceptance by gas service employees

Regardless of what material is used, all ventilation ducts passing through cold areas must be insulated. In these places, draft may decrease, condensation may form, and the ventilation duct of a boiler room with a gas boiler may freeze and stop performing its functions. That is why it is better to stretch pipes along a warm circuit, eliminating the possibility of them freezing.

Brick exhaust ducts

Brick is not durable because... due to temperature changes, condensation forms on its surface, leading to the destruction of the material. If brickwork is taken as the material for the shaft, then the chimney is assembled from single-circuit galvanized metal pipes, the thickness of which depends on the temperature of the gases emitted.

Ceramic ventilation pipes

Air ducts made of ceramics are universal, easy to use and durable. The principle of their assembly is similar to the technology for constructing ceramic chimneys. Due to their high gas density, they are resistant to severe pollution of various types and aggressive chemical environments.

But in such hoods it is necessary to install condensate drains, because... ceramics absorb moisture well. Structurally, such a hood consists of 3 layers:

- ceramic inner layer;

- middle insulating layer of stone and mineral wool;

- outer expanded clay concrete shell.

This ventilation system cannot have more than three elbows. A drip and inspection are installed at the bottom of the ceramic chimney.

Steel air ducts

Steel exhaust ducts are convenient and practical.

A metal chimney in a gas boiler room can have a rectangular or round shape in cross-section, but in this case the width of one side should not exceed the width of the other by 2 times

When installing a steel ventilation system, you must adhere to the following recommendations:

- The collection of segments is carried out using the “pipe to pipe” method.

- Wall brackets are attached in increments of no more than 150 cm.

- The length of horizontal segments should be no more than 2 m, if the system does not provide forced draft.

According to standards, the thickness of steel walls should be at least 0.5-0.6 mm. The temperature of the gas produced by boilers is 400-450 0C, which is why thin-walled metal pipes can quickly burn out.

Ceramic hood

It should be appreciated that a ceramic channel is an ideal solution for all types of boilers in a private home. This material is resistant to high temperatures. It is also neutral towards toxic chemical compounds that can be formed during the combustion of various fuels. Ceramic hood channels are mainly arranged vertically in modules with one or two recesses.

In the latter version, the second channel is used to ventilate the boiler room or to supply air to the boiler burner. Typically, such sandwiches are insulated with mineral wool to protect them from cooling and condensation. In addition, natural draft increases in an insulated pipe. When installing such a ceramic hood, there must be a gap for free passage of air between the insulation and the surface of the well.

On the building materials market you can find sets of ceramic hoods in a metal casing. This model does not require ventilation gaps and is mounted on a heating device both inside and outside the house. They can be operated with exhaust gas temperatures up to 450 degrees.

At the same time, ceramics absorb moisture well, so they usually have a tray to collect condensed moisture. And the channel itself is provided with free access for airflow. Thanks to the smooth surface in the pipe, it is resistant to contamination and easy to clean during maintenance.

To operate solid fuel boilers in a private home, pipes are used that can withstand temperatures of 650 degrees. In addition, they must be neutral to soot combustion and operated in a dry condition.

Regulatory framework of the Russian Federation

Installation of ventilation systems is mandatory regardless of the type of heating equipment used (clause 9.38 of SNB 4.03.01-98). Installation of heating and ventilation equipment is carried out under the supervision of representatives of gas services.

If during commissioning tests defects in the ventilation system and technical inconsistencies with the design documentation are revealed, commissioning of the heating system will be refused.

The Gas Inspector's responsibilities include visual inspection of equipment, safety functions, controls, and carbon monoxide monitoring. If necessary, the owner of the premises may require the inspector to provide certificates-permits to work with an anemometer or SRO

Ventilation provides a constant intense flow of fresh air. The operation of exhaust systems is regulated by a number of regulations.

Legislative acts and GOSTs

The regulatory framework relating to ventilation and air conditioning of gas equipment is quite extensive. These legal acts include:

- Federal Law No. 384;

- Government Decree No. 1521 on ensuring mandatory compliance with 384-FZ;

- Government Decree No. 87;

- Government Decree No. 410 on safety measures for the maintenance of gas equipment;

- SNiP (II-35-76, 2.04-05);

- SanPiN 2.2.4.548-96. 2.2.4;

- ABOK standards and recommendations in the field of ventilation, etc.

But legislative acts may change, so when installing ventilation equipment for a gas boiler room, you should monitor their latest editions in official sources.

All standards and regulations that will be applied when checking ventilation equipment can be clarified with the gas service of your locality

Also, all ventilated systems in rooms with boiler equipment must comply with the following GOSTs and SP:

- GOST 30434-96;

- GOST 30528-97;

- GOST R EN 12238-2012;

- GOST R EN 13779-2007 on air conditioning and ventilation in non-residential buildings;

- GOST 30494-2011 on microclimate in residential and public buildings;

- SP 7.13130.2013 on requirements for ensuring fire safety;

- GOST 32548-2013 (interstate standard);

- SP 60.13330.2012 (refers to SNiP 41-01-2003), etc.

Project documentation must be drawn up on the basis of these regulations. To ensure that it does not contradict official requirements and standards, it is necessary to carry out thermal calculations and calculate the main parameters of the exhaust system at the project development stage.

Certification of ventilation equipment

When purchasing exhaust and fresh air supply devices, you should check their documents. A declaration of conformity must be issued for ventilation equipment sold in the Russian Federation.

This document confirms that the devices comply with all current requirements of the Customs Union set out in the following technical regulations:

- TR CU 004/2011 on the low-voltage equipment used and the safety of its operation;

- TR TS 020/2011 on electromagnetic compatibility of the equipment used;

- TR TS 010/2012 on the safety of machinery and equipment.

This product declaration is mandatory, but in addition to it, the manufacturer or importer of ventilation equipment can undergo an official voluntary certification procedure for compliance with GOST standards. The presence of such a certificate, obtained on a voluntary basis, indicates the high quality of the product and the reliability of the manufacturer.

A voluntary certificate of conformity for air ducts can be requested when purchasing ventilation equipment for a gas boiler room. It indicates all technical characteristics of the product

But voluntary certification requires additional capital investments, so they often save on it. In accordance with Federal Law No. 313 and Government Decrees No. 982 and No. 148, mandatory certification of ventilation equipment has been abolished.