Every housewife is familiar with the problem of reducing pressure in the water supply when several points are turned on simultaneously. Equipping the system with a distribution manifold will help solve the issue. In common parlance, the knot is called a water comb.

This wiring scheme is currently considered the most effective and in demand. The engineering design has a complex structure, but has advantageous qualities.

Advantages of a collector distribution system

— strong connection in the system;

— ensures convenient operation of household equipment connected to the water supply;

— installation on a pipe with hot water is allowed;

— eliminates temperature changes;

— makes it possible to install plumbing in a hidden way;

— nodal connections facilitate repairs in individual areas and do not require a complete shutdown.

The only disadvantages include the cost of the manifold and the individual parts required for its installation (fittings, risers, valves, etc.). In addition, a large number of connections makes the system cumbersome. But if you take into account the benefits and reliability of the device, then the costs are fully justified by the benefits received.

Purposes of installing a water comb

Regardless of the length of home heating, the temperature of the medium in any area must remain within the permitted range, without significant errors - this is the first task of installing a distribution manifold or comb, as it is otherwise called. Besides:

- The heating distribution unit makes the main line repairable without turning off the boiler and radiators - you just need to turn off the tap in the desired area.

- The collector allows you to save on fuel by optimizing the supply of the required amount of media to the radiators. If the room does not require high temperature, the supply is reduced and, conversely, increased to a comfortable level in children's rooms, bedrooms and other parts of the house.

The described reasons for the installation are undoubtedly important for the comfortable and economical use of heating and hot water generation. However, there is a minor drawback - water combs with taps are bulky and in small rooms are inappropriate due to their protruding position

It is important to think through “disguise” in advance, hiding the device in the walls or under the floor

Types of distribution combs

Collectors are mounted on hot and cold water supply. For convenience and to prevent confusion, manufacturers produce models in different colors (red and blue).

By type, combs differ in the number of taps, which varies from 2 to 4. For a larger number of connections, it is recommended to use combinations of several distribution devices. For example, the existing 6 points can be equipped with two combs for 3 outputs.

Equipping the heating system with a manifold will be no less useful. Heating will be carried out evenly, which will eliminate differences in the temperature of individual rooms.

The operation of any type of switchgear is safe. The absence of pressure drop will eliminate emergency situations with breakthroughs and flooding.

Purpose of a plumbing comb

A plumbing comb (collector) is a device for draining water from a common riser to consumer appliances. The comb is installed to equalize the pressure in the water pipes and uniformly distribute water from the riser (pipeline) to the existing plumbing fixtures in the house (faucets, toilet, washing machine, shower cabin and sink), each of which is connected to a separate outlet.

The device itself is a large diameter pipe with several outlets. The presence of a comb allows you to successfully supply water to all appliances in the house and, if necessary, block access to water for one of the plumbing fixtures (locally), without the need to turn off the entire water supply (all equipment operates independently of each other without loss of water pressure).

- Installation of a crest on ready-made communications

– 2000 rubles - Installation of the comb price per output

- 300 rubles - Repair of the comb with repair of supply pipes

- 3,500 rubles. - Dismantling the comb

– 150 rubles.

Installing a comb in the water supply system

When installing a comb (collector) yourself, you need special tools, as well as knowledge of the water supply system. You should come up with a diagram of the distribution pipes in advance, select the type of pipes used, and calculate the length of each fragment (as well as the type of connections). When choosing pipes connecting to the comb, polypropylene pipes are most preferable (they are the easiest to install into the system, which is an undoubted advantage when installing a collector system yourself).

Installation of a plumbing comb

The collector wiring diagram must take into account that each unit of equipment located in the room is separately connected through a comb. A tap should be installed at each branch from the central system: this system will eliminate the need to shut off the water supply to the entire system in the event of failure of one of the lines diverging from the comb. To be able to completely shut off the water supply system, a tap should also be installed at the base of the collector.

Comb installation

The comb is installed according to the following scheme:

- Polypropylene pipes are cut and soldered, as well as their fragments are connected using fittings (the ends of the segments are heated and quickly inserted into the fittings).

- The shut-off of collector and shut-off valves is checked and the water supply is subsequently started.

- Each wiring is checked separately. In the absence of leaks and problems with water supply, we can state the successful completion of installation work

In most cases, the comb is installed separately for hot and cold water. All combs are designed taking into account the upcoming installation: mounting clamps are provided for mounting on an installation cabinet or wall, and the possibility of connecting central heating heat meters is allowed. All devices have high hydraulic characteristics, are resistant to corrosion and allow installation work to be carried out without the use of additional sealing measures.

If you do not have the necessary knowledge and experience in plumbing work, you can turn to experienced professionals. Competent specialists will select equipment taking into account the type of existing pipes, quickly and efficiently perform all necessary installation work and test the system for faults.

“>

How to choose a water distribution manifold?

Before purchasing a comb, you should familiarize yourself with the technical characteristics of different types in order to choose the optimal model for your water supply.

Factors to consider when choosing:

• pressure in the water supply system;

• collector throughput;

• number of water intake points;

• installation on hot or cold water supply;

• possibility of connecting an additional point.

The material from which the switchgear is made deserves no less attention:

The distribution comb plays an important role in the water supply and heating system. This is a separate part that is designed to distribute water evenly throughout all parts of the water supply in the house. The comb can also be used for underfloor heating systems; thanks to its properties, thermal energy will be distributed evenly, which means that the warm air in the room will flow evenly. Let's take a closer look at the device and installation features of the distribution comb.

A Question of Choice

A high-quality distributor is capable of operating at high fluid pressure, has trouble-free shut-off valves, and a high degree of environmental safety when distributing water.

Before purchasing a collector, it is necessary to determine the number of water consumers to which an individual pipeline will be connected. Then you need to purchase a collector, the number of outlets of which is equal to the number of water consumers.

If the supply pipe is made of polypropylene, then the distributor should also be installed from this material. In the case where the supply pipe is metal, it is better to use a distributor made of copper alloy or stainless steel.

When choosing a distribution manifold, it is necessary to take into account such a design feature of these devices as the possibility of replacing the tap of each outlet. Otherwise, if one of them fails, the collector will need to be completely replaced.

Example of installing a comb in a bathroom

Why do you need a distribution comb?

During the construction of old-type houses and apartments, main pipe routing (sequential laying) was used, which is inconvenient for modern times. Many people faced the problem of uneven heating of apartments, and, unfortunately, no one could cope with the different pressures in the pipes. But today the problem has been solved; a solution called a distribution comb has arrived on the modern market. Unfortunately, in order to correct the situation in houses and apartments with a ready-made heating system, you will have to change the pipe layout to a collector system. If you are just planning to heat the room, this article will be useful for you.

What will change after installing the distribution comb:

- The pressure in the pipes will be equalized throughout the room.

- The problem of sudden cooling of water in the bathroom when you turn on the tap in another place will disappear

- The house will be heated evenly

This is only part of all the advantages of manifold pipe routing after installing the comb. To minimize uneven water supply, the comb should be installed for both cold and hot water. Special taps are installed on it; they allow you to shut off the flow of water in a separate unit ; this is convenient in the event of a leak in the toilet or a broken tap in the bathroom.

Why is this necessary?

Why and when do you need a water supply comb?

Collector water distribution is necessary in two cases:

- If you need to ensure the disconnection of several plumbing fixtures or their groups from one point (manifold cabinet). This feature is very useful in a mini-hotel or hostel;

All plumbing is disconnected from one manifold cabinet

- If you need to ensure constant water pressure on all devices at any ratio of water consumption between them.

The second point probably requires some clarification.

Remember the cute communal scene: one of your family members is taking a shower in the bathroom, the other is trying to wash up the dishes in the kitchen. As soon as he opens the cold water tap further, an angry roar from the scalded body can be heard from the bathroom.

Why is this happening?

Because an increase in cold water flow with a constant hydraulic resistance of the water supply leads to a drop in pressure at all water collection points.

Open the tap on one mixer and the pressure on another will drop sharply

This is a common problem with so-called tee (or series) connections.

Tee (sequential) water distribution

It is worth providing each plumbing fixture with its own supply connected to a common collector - and the problem of pressure drop will be solved: regardless of the water flow in the kitchen, the pressure in the bathroom will remain unchanged.

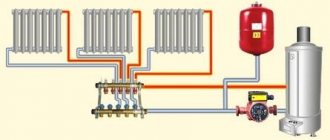

Scheme of collector wiring in a house with a boiler

Captain Obviousness suggests: in order for the distribution comb for water supply to provide constant pressure at all points of water collection, the throughput of the water supply section to the comb must be at least equal to the total water flow on all simultaneously used plumbing fixtures.

Installation of distribution comb

Installation of the comb does not bode well for easy work. As a rule, it takes a lot of time and requires the hands of a specialist who knows a lot about this matter. But, despite all the installation difficulties, they try to install this particular wiring in modern houses and apartments, since it is very effective and easy to use . New models of combs are produced taking into account the complexity of installation, this greatly facilitates the work of the master during installation. You can mount it not only in a mounting cabinet, but also to the wall; for this purpose, the kit includes mounting clamps for greater stability of the device, and its high resistance to corrosion allows the comb to serve for many years.

In order to clearly understand what a distribution comb is, you need to know about it all the information necessary for a person who does not understand anything about this matter. For a complete overview, it is worth presenting several types of different combs.

Manufacturing materials can be polymer, steel, brass or copper.

Configuration:

- Simple ones lack an important quality - control of coolant flows. Such combs divide the total flow of water by the number of nodes present in the house; they supply a uniform flow to the bathroom, kitchen, toilet and other places where water flows. The design of the comb is the simplest - a coupler with special connections on both sides and branches in the amount of 2, 3 or 4 pieces.

- Complex - have many useful additional elements: pipeline fittings; control and accounting sensor; automation _ Temperature sensors, or as they are also called, thermal sensors, are installed in combs with an electronic or mechanical system. They completely control the flow and supply of water through the pipes, especially convenient when the coolant is connected.

Selection of pipes for the heating system

When creating a manifold wiring diagram for heating a low-rise residential building or other private building, it is necessary to take into account the method of laying pipes throughout the house. If the piping will run under the floor, in a concrete screed, then it is recommended to buy heating pipes in coils so as not to make connections in the floor, as mentioned above.

Plastic pipes must have sufficient flexibility, the pipe material must not be subject to corrosion and the influence of aggressive environments, must not be destroyed at low or too high temperatures, and the service life of the pipes must be extremely high.

The requirements for temperature resistance and tensile strength of pipes are determined by the performance characteristics of the installed heating system in a house or apartment. For individual development, the pressure in the pipes should not exceed 1.5 atm, and the maximum temperature regime should be in the range of 500C -750C. If the house has a “warm floor” system, then the temperature of the coolant in the pipes should not rise above 300C -400C.

Manifold for combined heating

When installing a manifold heating circuit in an apartment building, the pressure in the pipes will always be high, and the pipe material must withstand ≥ 10-15 atm. at a coolant temperature of up to 110-1200C. Therefore, when laying heating pipes in an apartment building, it is recommended to use corrugated pipes made of stainless steel, rather than metal-plastic or PVC products. As a working example, we can cite the Kofulso brand of pipes, which can withstand pressures of more than 15 atm. at coolant temperature ≥ 1100C. The pressure force that causes the destruction of this material is 215 kgf/cm², which is an excellent indicator.

Collector wiring in the apartment

The bending radius of such stainless pipes is equal to their diameter, which allows them to be laid in almost any place and with any bend, without fear that the pipe will leak at the bend. Connections in such piping are made using special fittings, and the twist points are fixed with a lock nut, which ensures the tightness of the connection of corrugated pipes with silicone seals.

But stainless steel is not the cheapest material, and when installing manifold pipes in a two- or three-story building, such a project will be quite expensive. Therefore, it makes sense to use pipes made of cross-linked polyethylene, for example, PE-X brand. These pipes, like other PVC products, are sold in coils, the length of one pipe is 200 meters, the material is able to withstand pressure up to 10 kgf/cm² at a coolant temperature in the system up to 950C. A short-term increase in temperature up to 1100C is allowed.

Corrugated stainless steel pipes

Water pipes made of cross-linked polyethylene are also connected to each other using special fittings in the form of plastic or metal (bronze, brass, copper) fittings with a locking ring, which fits tightly onto the pipe and seals it tightly. The advantage of such pipes is that cross-linked polyethylene has a mechanical memory, that is, assembly is carried out according to the following scheme: the pipe is stretched with a special extender so that a fitting can be inserted, and after some time (up to a minute) the pipe takes on the original diameter and tightly presses the fitting. Additionally, tightness is ensured by a locking ring.

How not to make a mistake when choosing a distribution comb

Before purchasing a device, it is important to consider every little detail. Correlate all the functions that will need to be performed in the future comb. In this case, special attention should be paid not to the material, unfortunately many people look only at it, but also to other important factors.

What to pay attention to first:

- The throughput capacity of the purchased device - it is important that it copes with the flow of water to all nodes.

- What pressure in the system is the comb designed for?

- Energy consumption based on each connection point.

- Possibility of expansion when new water supply units appear in the house.

Choosing the right distribution comb is an important job that is difficult to do on your own, especially if a person understands nothing at all about this difficult matter.

Price

General Fittings Cold Water Manifold - The manifold is designed for use in a cold water system only. The material from which the device is made – nickel-plated brass – does not interact chemically with impurities in water, thereby allowing the device to be used for at least 10 years.

The comb is equipped with valves that are located on the main distributor pipe. The number of pins of this device is 4 pcs., but if necessary, a block of an unlimited number of pins can be assembled from separate sections.

The price of the comb is 1400 rubles.

Distribution manifold DM, Gidruss is a universal device that can be used for distribution of water supply and heating systems. The material from which the distributor is made is structural steel, capable of withstanding coolant temperatures up to + 120 degrees. The pressure in the water supply system when installing this device should be no more than 6 bar.

Number of comb leads – 4 pcs. Fastening to a horizontal plane is carried out using special brackets that securely fix the distributor, completely preventing its movement during operation.

Leaders of sells

For an even clearer understanding of what a distribution comb is and how to choose the best device for yourself, you need to look at the recent sales leaders. From this information, you can find out what requirements must be met and what new functions have been added by manufacturers.

You will be presented with 2 types of distribution comb and distribution manifold, common throughout the world, which have the most modern functions:

- distribution comb for 2 pipes. Combines low price and excellent quality. The manufacturer is the famous company Rehau. The average price in Russia is 700 rubles. Serves to regulate the coolant on several circuits. You can connect to the device both ordinary cold water passing through pipes and a heated floor system, as well as other heating devices. Installation of the comb is facilitated thanks to the sliding sleeves with which it is attached to the pipes. Made of brass, this material is characterized by long service life and high strength.

- distribution manifold for 11 groups. Collectors have the same functions as combs, the only difference is in the number of connections - the collector has many more of them, connections are made in groups, for cold and hot water separately. Rehau has proven the high quality of its devices. This is evidenced by the numerous purchases by Russians of collectors and combs from their company. The Rehau Rautitan HLV distribution manifold branches out the circuits of radiator distribution systems. All devices have passed mandatory quality checks and necessary tests, including pressure testing in emergency situations. Just like the comb, the manifold of this company is made of brass, which indicates high quality and durability. The average price in Russia for the Rehau Rautitan HLV distribution manifold is 11,000 rubles. The kit includes: eurocone, ball valves, connecting nipples and built-in air valve.

Famous brands

Valtec is an Italian manufacturer of a line of products for constructing water supply systems.

A full range of products for metal-plastic, polypropylene water supply and stainless steel systems is always on sale. In Russia, representative offices are located in 6 cities, including Moscow, St. Petersburg, and Krasnodar. Rehau is a German manufacturer with a history dating back to 1948. Products undergo multi-stage quality control.

Far (FAR) is another Italian company. In addition to shut-off and distribution valves, the line includes metal-plastic, polypropylene, copper and steel pipes.

What is a collector?

When installing a water supply system from scratch or replacing an old one, you need to think about the location of all consumers: toilet, washbasin, washing machine.

In a typical apartment, the number of plumbing fixtures varies from four to ten. Experienced plumbers recommend their customers to install a water collector.

A water collector is a kind of distributor, which is an important plumbing element of a cold and hot water supply and heating system. It is installed on the central riser and hidden in the plumbing closet. Access to the distribution comb should not be blocked by furniture or sewn tightly into the wall. However, professional repairmen will give the engineering unit an aesthetic appearance.

Selecting a location

First of all, the water distributor must be installed in such a way as to maximize the length of each pipeline to the consumer. If this rule is neglected, then over longer sections the fluid pressure will differ significantly.

If the water supply is installed in a multi-storey building, then the collector is installed on each floor.

There are two ways to install a water comb:

- In the wall of the building.

- In the distribution cabinet.

The first installation option is used when the usable area of the room is limited, or the open installation of pipes and distribution boxes will significantly change the design of the room. In this case, a niche is built in the wall, which is closed with a valve, and if necessary, it will be possible to gain access to the control of the device.

If it is possible to install the distribution device in a utility room, then in this case a special box is installed, inside which the comb and all the pipes leading to this device are fixed.

If the water supply is installed in a multi-storey building, then the collector is installed on each floor

Collector design and principle of operation

The direct function of a collector in a water supply system is to distribute one water flow into several flows of equal pressure.

Combs with two, three and four outlets are available. If more branches are needed, the distributors are connected to each other. In this way, a water supply collector is assembled for the required number of outlets.

The collector is connected directly to the riser. On two opposite sides of the device there is a threaded connection (internal thread on one side, external thread on the other) for connecting to the main line and connecting the combs to each other.

A plug or an additional plumbing device, for example, a membrane water hammer absorber, is installed at the free end of the collector.

The diameter of the inlet hole is 20-40% larger than the outlet hole. For example, on a standard manifold for installing water supply in an apartment, the diameter of the inlet hole is 3/4 inch, the outlet hole is 1/2 inch.

1. Manifold with valves. 2. Manifold with ball valves.

Both ball valves and valves can be installed at the outlet openings, allowing not only to open and close the water flow, but also to regulate the power of the flow in this area.

Making a comb with your own hands

elements for the comb

Although this is not very economically justified, with the necessary tools and a lot of patience, you can make a polypropylene comb yourself. To do this you will need the following materials:

- hacksaw and soldering iron for polypropylene;

- pieces of polypropylene pipe with a diameter of 25 and 32 mm;

- tees 32x25x32;

- plugs for 32nd diameter;

- couplings with internal threads 32:1 inch and 25:3\4;

- couplings with external thread 25:3\4;

- sealant;

- Ball Valves;

- air extractor.

You can do without an air extractor. But be sure to leave space at both ends to connect additional devices to the water supply comb in the future. During welding, it is important to “by eye” check the quality of the seams to prevent completely welded elements.

Video on how to make and install a cold water distribution comb yourself:

Why do you need a collector?

A water supply system with a separator and a separate pipe supply to each consumer will cost more than a classic wiring. Is it worth overpaying for a collector for water and heating?

- The device is used to regulate water pressure in the apartment. In standard wiring, the pressure in an open tap often decreases if someone opens another tap or flushes the toilet. This threatens not only discomfort, but also burns due to too hot water, which suddenly begins to flow. The well-thought-out diameter of the manifold eliminates pressure problems. No matter how many taps are open in the apartment, the water pressure remains the same.

- There are taps at each outlet that allow you to regulate the flow of water along the branch. If the mixer is being repaired, it is not necessary to completely turn off the supply of cold and hot water from the risers. It is enough to switch only a certain branch.

- The absence of joints and tees built into the wall minimizes the risk of leaks. If a faucet or fitting fails, it can be easily replaced by disassembling the manifold system in the cabinet. The lining in the bathroom will not be damaged.

- If you need to add another consumer to the water supply system, you will not have to redo the entire wiring. Connection will be inexpensive and will not require much time.

Grade

Let's try to evaluate the collector water supply against the background of the more familiar tee wiring.

pros

In general, we have already listed them: stable water pressure and turning off all water supply branches from the only manifold cabinet.

Minuses

Alas, the solution we are interested in has more than enough disadvantages:

- High material consumption. The total length of water supply connections will increase several times compared to tee wiring;

The photo allows you to appreciate the full scale of the disaster

By the way: combined wiring (for example, a manifold connection of faucets and a series connection of a toilet cistern with a washing machine) will somewhat reduce the cost of pipes.

- The lines will have to be laid hidden. Open wiring, typical of a tee circuit, is inappropriate here: several rows of pipes on the walls are a very dubious decoration of the house;

Collector water distribution involves hidden pipe laying

- Hence, another practical conclusion: collector wiring is carried out, willy-nilly, only at the stage of construction or finishing of housing. The water supply with serial connection of devices can be installed even after finishing finishing.

Reservoir classification

Separating combs for water supply differ in both their design and materials. Before choosing a collector, study the entire range on the market.

Separators are made from different materials:

- Stainless steel is resistant to corrosion, fire and high temperature. The weight of the stainless steel collector is light, which makes it easy to attach it to the wall. This is an absolutely harmless material that gives the product an attractive appearance.

- Brass is an incredibly durable metal that is not afraid of corrosion and high temperatures. Brass combs are expensive, but they guarantee maximum strength.

- Dividers made of polypropylene are not afraid of rust and are lightweight.

Manifold made of polypropylene.

Some craftsmen can make a collector with their own hands from polypropylene pipes, which is in no way inferior in quality to factory products.

Collectors differ in the way the pipes are attached. Depending on the material of the pipes used, the comb model is selected.

1. A comb for installing taps and any plumbing fixtures at your discretion. 2. With compression fittings - designed for installation of pipes made of metal-plastic or cross-linked polyethylene. 3. For installation of polypropylene pipes. 4. Under the Eurocone. Suitable for installing pipes from almost any material through an adapter (Eurocone).

Separating combs differ in the number of bends. Minimum – 2 outputs, maximum – 6. Bends that are not currently in use can be closed with plugs. If it is necessary to make more than 6 outputs, several collectors are connected to each other.

Device Description

Manifold for water heated floor

The design of a water distribution manifold is generally a piece of pipe with an inlet for connecting the main line and several outlets for flow points

When choosing a device, pay attention to the design and technical characteristics

Types of combs

Manufacturers produce a range of products in question, which is sufficient to organize the most complex water supply or heating system.

Combs are usually divided into several types depending on:

- body material;

- number of exits;

- center distance of fittings or bends;

- availability of additional options.

Construction material

The development of technology in industry makes it possible to produce combs for water supply from different materials. Manufacturing companies and marketers skillfully take advantage of this, offering products of any choice:

- bronze - an alloy of copper with tin and the addition of other elements to give the required properties;

- brass - an alloy of copper, zinc and additives;

- steel;

- polypropylene;

- silumin.

When comparing bronze and brass, preference should be given to the first material - it is much stronger, and accordingly, there is less likelihood of accidents and breakdowns

This is very important in apartment buildings, when a leak floods apartments located below the floor

Models can be distinguished by touch and weight. Bronze has a coarse grain structure, while brass products are smooth to the touch. The weight of similar structures made of bronze is much higher than that of brass.

Steel elements are susceptible to corrosion, so they last less than devices made of non-ferrous metals. Steel combs should be cheaper, but manufacturers use a trick by covering the body with nickel plating. This gives the product a presentable appearance, allowing sellers to inflate the price. Steel appliances are used in dry rooms where the risk of rust is low.

Water supply collectors made of polypropylene gained popularity with the beginning of the mass use of plastic pipes in construction. The comb body is thicker and can withstand a greater load than the connected pipes, so you should not be afraid of a breakthrough in this place - the supply pipes will be the first to collapse from water hammer.

An important advantage is that the polypropylene manifold is connected to the entire system using high-temperature welding, like other components of the water supply system. In this case, threaded products are not used, which simplifies installation, reduces the likelihood of leaks, and reduces cost

Silumin collectors are the cheapest of the products under consideration. They are produced mainly by companies from China. The equipment has one advantage - low price. Disadvantages include poor oxidation resistance

The material is fragile, be careful when installing - do not use excessive force

Types of collectors

Comb with two outlets

For small apartments or separate rooms, purchase a water collector with two outlets. Options with three or four exits are designed for two-story houses.

All metal combs have two threaded holes for connection to the main line, which allow you to connect several collectors in series. For example, by connecting 2 and 3 output collectors in series, a comb with 5 outputs is assembled. You can increase the number of leads by soldering polypropylene products.

The center distances of the bends have little effect on the technical characteristics. Most manufacturers produce products with such distances in the range from 36 to 110 mm.

The closer the fittings are located, the more difficult the installation and the more inconvenient it is to manipulate the taps. On the other hand, such switching equipment takes up less space during installation.

Products with large gaps are more expensive; it is used in cases where the equipment is installed in a separate room.

Collectors are distinguished by the ability to regulate the flow of water:

- without regulators - the outlet looks like a thread or fitting for connecting a metal-plastic pipe;

- with ball valves;

- with adjustable taps;

- with automatic shut-off equipment that regulates the flow;

- the choice depends on the complexity and tasks assigned to the plumbing.

Products on the market

The catalogs of accessories for collector water supply systems provide a wide variety of not only combs, but also their components.

- Dividers without taps are much cheaper. They allow you to assemble a device that will best suit the object. This option is preferable, as it allows you to easily replace only the failed faucet. While the one-piece design will require complete replacement.

- Devices with shut-off valves greatly simplify the installation of a water supply collector. They simplify the assembly of the unit - there is no need to install taps.

- Accessories allow you to adapt the system according to your wishes: valves, pump groups, plugs, valves, brackets, couplings, ends, servos, fittings.

- Manifold cabinets are sold separately, which are mounted into the wall and provide an aesthetic appearance, as well as access to the engineering unit.

What are air vents and what are they for?

Many owners of radiator systems have encountered a situation where, with hot pipes, some parts of the radiator do not heat well or are generally cold; similar problems arise with insulation with water floors. The main reason for this phenomenon is the presence of air in the pipes, which rises and impedes the movement of the coolant.

If in an open circuit air bubbles are sent to an unclosed expansion tank located on high floors of a building or attic, and bleeding is not so important, then in a closed system an air bleeder for the heating system is vital on all circuits and individual heat exchange devices.

When plugs interfere with the operation of the system, manual or automatic heating drain valves are used to remove accumulated air. One of the simplest devices is a regular valve installed at the top point of heating radiators. To bleed air from the batteries, open the valve and wait for the moment when the stream stops flowing jerkily along with the air - in radiators without air, the water flow will be uniform.

In individual heating lines of private houses, instead of ordinary valves, special locks are installed on the radiators, which function automatically or are manually adjusted. With their help, they remove not only air from devices in which gas formation occurs, but also, when necessary, oxygen from water, which causes accelerated corrosion of metal fittings.

Rice. 2 Air vent for venting air from the heating system - design

How to install?

Before installing a water distribution unit for cold and hot water supply, give an accurate answer to the following questions and consider the following points:

- How many water consumers are there on site? The number of collector outlets should be the same or slightly greater than the number of consumers. Excess branches are closed with plugs.

- What type of pipes will be used to install the water supply? It is necessary to purchase devices designed specifically for pipes made of the selected material.

- Estimate in advance the position of all engineering elements in the space of the plumbing cabinet (you can make markings on the wall). Please note that a water meter and a water filter are installed in front of the distribution comb. The convenient location of all devices facilitates maintenance and repair work.

- Get reliable fastening - a poorly secured distribution unit can lead to depressurization of connections and damage to the pipeline.

- Before installation, make sure that you have all the necessary consumables on hand: sealing material, gaskets, adapters.

Installation of the water distribution unit occurs in the following sequence:

- Install the inlet shut-off valves on the water supply riser.

- Install the meter, filter and check valve.

- Connect the manifold and securely fix it to the wall

- Install a water supply to each consumer. Secure the pipes with fasteners.

This operating algorithm will allow you to avoid errors. Regardless of whether the collector is needed for water supply or heating, its installation is the same. Such wiring requires more time, skill and money, but pays off quickly and provides comfort in further use. Collectors are appropriate not only in cottages and large houses, but also in apartments.

Project implementation

In order not to become a victim of the situation described earlier, you need to connect a manifold with the correctly selected pipe diameter. You can make a pipe from a half-inch product for the shower and tank. At the same time, the entrance to the collector should be several times larger.

But you shouldn’t be overzealous either. There is no need to install a doubled entrance. A slight increase in the input channel compared to smaller outputs will already give a positive result.

These materials are easy to work with. There is no point in repeating the benefits of using plastic.

It turns out that the work may be difficult, but the result is worth it. Manifold wiring allows you to save money on the purchase of tees. And if metal-plastic pipes are installed, then the tees for them are very expensive. But still, there are no special restrictions here. The owner himself makes the decision.

It should be noted that every owner can independently perform collector wiring. But before starting work, you need to draw up a diagram on paper, which can then be implemented in practice. The collector system for distributing water pipes requires careful operation.

As you might guess, the system will have many connections of pipes, adapters, shut-off valves and other elements

Therefore, it is very important to pay special attention to every detail, so that later you don’t have to redo all the work, which will add even more hassle.

Today you can buy metal-plastic pipes, copper pipes, stainless steel pipes and polypropylene pipes in any construction or specialized store. There are also all kinds of connections, adapters, taps.

That is why it is necessary to have a work plan in advance. It will allow you to purchase the required amount of building materials for the system.

Areas of application of heating combs

The main purpose of the heating comb is to optimize and rationally distribute the coolant. Without a correctly designed and installed distribution manifold, the heating may not operate correctly. The comb allows you to use all the useful power of the boiler, while obtaining maximum efficiency of the entire system.

Collectors also allow you to include several consumer points in the system and be sure that the temperature of the coolant in all sections of the main will be the same. If you do not use a distribution comb, it often turns out that the radiator near the boiler is very hot, and the radiator, for example, on the second floor, is lukewarm.

This happens because the coolant cools down while it reaches the last battery. This effect can be avoided and the path of the coolant to the end consumer can be reduced by dividing it into specific circuits.

Connection rules and installation features

Installation of the comb begins with attaching it with brackets to the wall, where it will be located openly or in a closet. Then you will need to attach the main pipes from the heat source to the ends and begin piping.

Option #1 – without additional pumps and hydraulic arrows

This simple option assumes that the comb will serve several circuits (say, 4-5 radiator batteries), the temperature is assumed to be the same, and its regulation is not provided. All circuits are connected directly to the comb, one pump is used.

The characteristics of pumping equipment must be correlated with the performance of the heating system and the pressure created in it. So that you can choose the best pump that is ideal in terms of characteristics and cost, we recommend that you familiarize yourself with the rating of circulation pumps.

A master with experience in manifold equipment knows how to correctly install a distribution comb and hide it in a cabinet so as to hide all the pipes

Since the resistance in the circuits is different (due to different lengths, etc.), it is necessary to ensure optimal consumption of the coolant by balancing.

To do this, balancing valves, rather than shut-off valves, are installed on the return comb nozzles. They can regulate (although not exactly, but by eye) the coolant flow in each circuit.

Option #2 - with pumps on each branch and a hydraulic arrow

This is a more complex option, which will be needed if necessary to power consumption points with different temperature conditions.

So, for example, in radiator heating, water heating ranges from 40 to 70 °C, a warm floor needs a range of 30-45 °C, hot water for domestic needs must be heated to 85 °C.

In the piping, the hydraulic arrow will now play a special role - a section of pipe that is blind at both ends and has two pairs of bends. The first pair is needed to connect the hydraulic needle to the boiler; the distribution combs are connected to the second pair. This is a hydraulic barrier that creates a zone of zero resistance.

For boilers with a power of 50 kW and above, it is recommended to use a distribution comb together with a hydraulic arrow. It is mounted vertically on the wall with separate brackets to avoid excessive horizontal overloadOn the comb itself there are mixing units equipped with three-way valves - temperature control devices. Each outlet pipe operates its own pump independently of the others, providing the specific circuit with the required amount of coolant.

Types and modifications of heating combs

Modern distribution manifolds can be of two main types. Due to differences in their structure, they are used in different cases.

- Radiator manifolds have found their application in small volume systems. They are well suited for heating systems of a two-story private house, which have several heating circuits and heated floors. Such collectors are available with various coolant supply options: bottom, top and side. Most often there are distribution combs with a lower coolant supply. This is due to the fact that pipes laid under the floor retain heat much better, and are also completely invisible and do not spoil the appearance of the rooms.

- Distributive hydraulic arrow. This heating device is designed for multi-storey buildings and large volumes of liquid. The fundamental difference in the structure of such a collector is the container, which is located between the distribution combs and combines them. This is necessary in order to equalize the pressure throughout the system, and also to prevent a sharp temperature change in the pipes. The efficiency of a hydraulic arrow can be maximized if there is a circulation pump for each individual circuit.

The nuances of homemade work

The main condition for correct heating operation is the creation of hydraulic balance in the system. The ring collector for heating must have the same throughput capacity of the incoming pipe (the cross-section of the main pipe connected to the supply line) as the sum of the same indicators in all circuits. For example, for a system with 4 circuits, it looks like this:

D = D1 + D2 +D3 +D4

When making a heating manifold with your own hands, remember that the distance between the supply and return sections of the pipe should be a value equal to at least six comb diameters.

When installing the device, take into account the following nuances:

- an electric boiler or gas boiler is connected to the upper or lower pipes

- the circulation pump only fits into the end side of the comb

- heating circuits are connected to the top or bottom of the collector.

To heat a house with a large area, circulation pumps are installed on each circuit. In addition, to select the optimal volume of coolant, additional equipment is installed on each inlet and outlet pipe - balancing flow meters and adjustment valves. These devices limit the flow of hot liquid to a single pipe.

In order for the boiler distribution manifold to perform its functions in full, it is necessary that the length of all circuits connected to it be approximately the same length.

It is possible (but not necessary) to additionally equip a mixing unit when manufacturing heating collectors. It consists of pipes that connect the inlet and return combs. In this case, to regulate the amount of cold and hot water as a percentage, install a two or three-way valve. It is controlled by a closed-type servo drive, which receives a signal from a temperature sensor installed in the heating circuit.

This entire design allows you to regulate the heating temperature of a particular room or a separate circuit. If too hot water enters the collector in the boiler room, the flow of cold liquid into the system increases.

For a complex heating system in which several collectors are installed, a hydraulic arrow is installed. It improves the performance of distribution combs.

A manifold for a boiler room, which you make yourself, will ensure normal heating operation only if you accurately select the parameters of the system piping. Therefore, you first need to entrust the calculations to a professional, and then get to work.

Remember that a comfortable temperature in your home depends on many factors. Only a fully balanced system will ensure correct heating operation.