Private housing stock occupies more than 56% of the total area of all housing. Their gasification level is about 75%. The Zhitomir gas boiler is designed to work in heating systems as a heat generator for heating the coolant and producing hot water. This is a relatively inexpensive boiler. It is equipped with modern automatic control and regulating devices of both domestic and foreign production. It is produced under the ATEM brand.

Gas boiler Zhytomyr (ATEM - Ukraine)

About the manufacturer and its products

The Atem brand and its Zhytomyr gas boilers have been known and available to customers for more than 27 years. Of course, from the beginning of production to the present time, the products have changed a lot. The company's developers are constantly improving units to satisfy all the needs and wishes of consumers. That is why Atem is a leader in the field of heating equipment in the domestic market.

Good quality and reliability are the main parameters related to boilers of this brand.

Atem products have received various awards more than once. For example, “European quality”, “Golden Mark”. The units are marked with the “Highest Standard” quality mark.

Gas boilers Atem Zhytomyr are designed for houses equipped with chimneys. The product range is quite wide, and this gives the potential buyer the opportunity to choose the optimal model.

Boiler features

Looking at the reviews of owners on gas boilers in Zhitomir, it becomes clear why this manufacturer’s equipment stands out so much, why it is so popular and relevant.

The equipment is characterized by many distinctive positive features in comparison with competitors' analogues. Yes, like any other devices, boilers of this brand also have disadvantages, but in comparison with the many advantages, any inaccuracies are insignificant.

Let us highlight the main advantages that Atem gas boilers have:

- A steel heat exchanger that allows you to transfer maximum heat energy to water, which is generated when burning fuel.

- Full compliance with all international standards.

- High-quality and reliable design of the burner device. Thanks to it, the heating unit is considered highly efficient and emits a minimum of harmful substances during gas combustion.

- Use of high-quality automation from a foreign manufacturer. This allows you to achieve better technical parameters.

- Simple and comfortable control and operation.

- Attractive design.

- Small design dimensions.

The unit has various settings that make it possible to adjust the desired temperature level. There are built-in sensors that monitor the stable operation of the heating structure.

Specifications

The Atem-Frank private enterprise, located in Zhitomir, produces two types of gas heating systems:

- in floor version;

- in a suspended version (so-called parapet boilers).

Floor-standing units are produced as single- and double-circuit, the latter can supply hot water to 2-3 consumers at low costs. General technical characteristics of the Zhytomyr gas boiler for the entire range of floor heaters are presented in Table 1.

The DHW capacity of double-circuit floor-mounted installations is from 175 to 1400 l/h with a heated water temperature difference of 35 ºС. The product can be equipped with a circulation pump, installed as an option. The characteristics of the model range of parapet units can be seen in Table 2.

Double-circuit parapet boilers provide hot water consumption from 160 to 345 l/h with a water temperature difference of 35 ºС.

As can be seen from the tables, the suspended and floor-mounted single-circuit boilers Zhitomir are adapted to the conditions of low gas pressure in main pipelines, which is their advantage. A significant drawback is that the maximum permissible coolant pressure in the heat exchanger of the unit is quite low, for floor-standing versions - up to 2 kgf/m2, and for suspended ones - up to 0.7 kgf/m2. At the same time, foreign analogues can operate with system pressure up to 3 kgf/m2. This suggests that ATEM gas installations are more adapted to gravity systems and small houses with 1-2 floors. It is not recommended to purchase suspended models for two-story cottages, since there is simply not enough pressure for normal operation of the system.

General information

The modern gas heating boiler ATEM Zhytomyr has high performance and compact dimensions. The use of foreign automation allows us to achieve optimal performance.

The user has access to many settings, which allows him to maintain the desired temperature in the room. Sensors will ensure that everything works without interruption. Consumers love Zhytomyr boilers, and reviews emphasize the optimal price-quality ratio.

Advice! The cost of a Zhitomir boiler today is 12-45 thousand rubles. Moreover, products at the upper price range have high performance and are capable of heating large areas of premises, suitable for heating multi-storey private houses. For heating a small house or apartment, a modification in the middle price range, up to 20,000 rubles, is suitable.

Varieties

Today, several types are involved in the production of Zhytomyr boilers - parapet (wall-mounted) and floor-mounted. In turn, floor products also have divisions into single-circuit and double-circuit.

Floor-standing

If a gas boiler is needed only for heating purposes, attention should be paid to single-circuit models. They are unpretentious, practical and economical. The equipment of the single-circuit boiler “Zhitomir” primarily involves imported components. Thanks to them, the device can be turned on and off if necessary. And if there is a need, in addition to heating, to have hot water in direct access, you will need to choose from dual-circuit options.

Due to price demand, double-circuit boilers are a little more expensive, but they also provide double pleasure to the consumer in their operation.

In terms of their technical characteristics, floor-standing boilers mostly have the following similarities:

- the maximum temperature limit is +90 degrees;

- efficiency is 92%;

- gas pressure – 635 Pa.

But when choosing a model you definitely like, you need to consider its specific characteristics and capabilities.

Wall mounted

The same separation as in floor-standing boilers is also present in wall-mounted boiler models. They can also be single-circuit or double-circuit. The efficiency of all devices is the same. The same applies to gas pressure.

But it’s still worth considering their characteristics in more detail:

- the power of parapet boilers must be no less than 5 kW and no more than 20 kW;

- the coolant in the device is no more than 17.5 liters;

- depending on the chosen model, natural gas consumption is considered; according to the standard - 0.56–1.67 cubic meters per hour;

- profitability due to imported automation.

For its part, the manufacturer provides a wide range of boilers to choose from, but the Zhitomir-3 KS-G-020 SN model is still in great demand. This device differs from its counterparts not only in terms of availability in terms of price, but also has clear technical data. The design of the device is designed in a minimalist style; the appearance of the boiler looks like a cabinet. It should only be placed on the floor. On the front of the model there is a small door behind which hides a button for turning on and adjusting the device settings. In the same part there is a control window, with the help of which you need to monitor the performance indicators of the boiler.

The basic package includes a housing, which also includes heat exchanger elements. On the outside, it is covered with heat-insulating material and a casing made of steel. The burners are presented in two pieces: one is the main one, and the second is the ignition one. The package includes a gas duct and an automatic gas valve, which is responsible for safety during operation.

If the temperature rises above +95 degrees, the shutdown sensor breaks the circuit to the valve, and the valve itself automatically closes the gas supply.

Why Zhytomyr boilers?

The Zhytomyr boiler has been known among consumers for more than twenty years. The choice of these products is often due to several reasons

:

- the design of the products uses EUROSIT automation devices made in Italy, which has long been known as a supplier of the most reliable equipment for boiler houses;

- these devices for automatic combustion mode control can turn the gas supply on and off at a certain coolant temperature within 0.08 s;

- when the enhanced gas supply is turned off, the control equipment leaves the pilot burner on, its combustion is always stable, which is a guarantee of successful operation;

- POLIDORO burners are of high quality, they almost never break down;

- The stable flame never breaks away from the edges, which does not lead to malfunction of the combustion process of gaseous fuel.

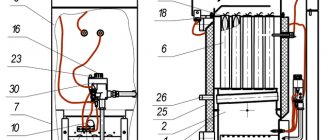

The boiler is in an open state.

The company has service centers that always have spare parts and components for heating equipment produced there. Representatives ensure that point-of-sale sales managers can provide clear product information.

The media conducts regular surveys of the population about the quality of operation of equipment produced by Atem-Frank. Constant modernization of manufactured products is carried out in order to improve their quality and attractiveness for the population.

Video on the topic:

Range of gas parapet boilers

The parapet-type gas boiler “Zhytomyr” is an inexpensive device for organizing water heating of a small country house with an area of up to 150 m². It successfully combines elements of turbocharged and atmospheric boilers - a closed combustion chamber and a coaxial chimney in the absence of a blower fan.

The movement of gases through the coaxial chimney of a parapet heat generator occurs naturally, without a fan or smoke exhauster

Principle of operation. The heat generator, suspended from the wall near the floor, burns natural or liquefied gas without pressurization. Combustion products are thrown out through an internal short pipe passing through the wall. Air enters the firebox through the external channel (outer pipe) naturally. New versions are equipped with 2 separate pipes - smoke and air.

The line of parapet models "Zhitomir-M" includes 5 single-circuit and 4 double-circuit boilers, designated by the abbreviation AOGV-SN and ADGV-SN, respectively. Thermal power of the devices is 5, 7, 10 and 15 kW. Let's reveal the design features of heaters:

- the material of the main heat exchanger is steel, the secondary heat exchanger for hot water supply is copper;

- combustion chamber – completely closed;

- burner - tubular type, safety automatic - gas valve SIT 630 made in Italy;

- ignition – piezoelectric, from a button on the valve;

- 4 fittings DN40 for connecting the heating system - two on each side of the housing.

The boiler comes complete with a gas-air unit (otherwise known as a coaxial pipe), a flexible pipe for connecting to the gas main, fasteners and an asbestos sealing cord. The cost of a single-circuit unit with a power of 5 kW (heated area - 50 m²) is 270 USD. e., double-circuit 15 kW - 475 USD. e.

New version of wall heat generator with separate pipes for air and flue gases

Reference. Up-to-date information on the pricing policy and offered models of heat generators can be found on the official resource at: shop.atem.ua.

Specifications

The Zhitomir-M parapet boiler has the following operational parameters:

- fuel efficiency (EF) – 90%;

- minimum inlet gas pressure – 6.4 mbar, maximum – 17.6 mbar;

- operating pressure in the heating system – 1.5 Bar, maximum permissible – 2 Bar;

- coolant temperature at the outlet of the heat exchanger – no more than 90 degrees;

- the amount of water in the boiler jacket is from 5 to 19 liters;

- maximum pressure from the cold water supply – 6 Bar;

- The dimensions of the largest device in the line are 360 x 495 x 825 mm (LxWxH).

Natural gas consumption, hot water output and the size of the chimney duct depend on the power of the heater. The specified characteristics are presented in the table, in more detail on the manufacturer’s website.

Advantages and disadvantages

The most important advantage of Zhytomyr parapet boilers is the price that is affordable for people with average and low incomes. Heating installations can be freely purchased in Ukraine and the CIS countries.

Let us list the other advantages of chimneyless heat generators:

- Energy independence. The boiler does not require electricity, although it can work in conjunction with an external circulation pump.

- Small size and simple design.

- Reliability and safety provided by proven gas automatics from the EuroSIT brand.

- A full-fledged smoke channel is not required.

- The double-sided arrangement of the fittings expands the possibilities for connecting heating network pipes.

Important point. You should not perceive the listed nuances only in relation to Zhytomyr devices. The market is saturated with parapet clone boilers with similar pros/cons.

Design diagram of a double-circuit version of the heater

Despite the low threshold of permissible coolant pressure (2 Bar), wall-mounted boilers can operate as part of closed systems with a membrane expansion tank. The main thing is to maintain the specified threshold when filling with water and adjust the pressure inside the air chamber of the tank according to the instructions.

Since we profess the completeness and reliability of the published information, we will reveal the shortcomings of the Zhitomir-M heaters:

- The degree of automation of the boiler is minimal and includes only a set of safety functions - protection against attenuation, overheating and a critical decrease in pressure in the gas pipe.

- If the wall faces a windy passage, the burner may periodically go out. The problem is solved by installing an additional screen on the windward side of the chimney.

- The performance of the hot water heat exchanger is enough to serve 2 consumers with low consumption. If you turn on the shower and the kitchen faucet at the same time, the water temperature will become uncomfortable for washing.

- A constantly burning pilot light wastes fuel. This fact is critical for residents of Ukraine and other countries with high prices for main gas.

- Manual ignition mechanism.

All safety, heating and gas control functions are concentrated in the 630 SIT valve

The disadvantages of heat generators are not critical and are a consequence of the maximum simplification of the design and reduction in cost. At the same time, the service life of inexpensive Zhytomyr boilers reaches 15 years, taking into account minimal maintenance.

Solid fuel boiler Zhitomir-9 KS-G-016SN/AOTV-12

| Type of fuel | Natural gas according to GOST 5542-87/Solid fuel - anthracite JSC DSTU 3472-96 |

| Fuel combustion efficiency (COP), not less than % (gas/solid fuel) | 92/78 |

| Gas pressure, Pa (mm water column), nom./min./max. | 1274/635/1764 |

| Coolant | Water pH7 |

| Maximum water temperature at the boiler outlet, no more than °C | 90 |

| Recommended coolant temperature, °C | 60-80 |

| Coolant operating pressure, no more than, MPa (kg/cm2) | 0,1 (1) |

| Maximum pressure in the hot water supply system, MPa (kg/cm2) | 0,6 (6) |

| Vacuum behind the boiler, Pa, no less - no more (gas/solid fuel) | 2/25 — 8/10 |

| Temperature of combustion products at the boiler outlet, not less, °C (gas/solid fuel) | 110/140 |

| Rated thermal power, kW (gas/solid fuel) | 16/12 |

| Heated area, m2, up to (gas/solid fuel) | 160/120 |

| Volume of water in the boiler, l | 44 |

| Water consumption for hot water supply with a temperature difference Δ t 35°С, not less than kg/year (at a coolant temperature in the boiler of 90°С) | — |

| Nominal gas consumption, normalized. conditions, m3/hour | 1,58 |

| Anthracite consumption, kg/hour | 1,8 |

| Overall dimensions of the firebox, mm | 300x315x500 |

| Conditional diameter of connecting pipes to the heating system, mm | 50 |

| to the gas supply system, mm | 15 |

| to the water supply system, mm | — |

| Overall dimensions, mm, no more (height/width/depth) | 1135x595x580 |

| Boiler weight, no more, kg, net/gross | 131/134 |

kotly.zhitomir.ua

Design features

The general structure of the Zhytomyr floor-mounted gas boiler is shown below:

The design of the water heating installation is simple and ensures energy independence for all models of the manufacturer. The gas burner is an atmospheric, single-stage type from the Italian brand POLIDORO, of simple design, whose reliability has been tested by time. The automation systems for gas boilers Zhitomir, made in Italy, are equally reliable in operation. The automatic non-volatile gas valve of the EURO SIT brand is the most popular among all manufacturers of boiler equipment; leading foreign and domestic brands install it in their products.

To transfer thermal energy to the heating system, the installation uses a fire-tube-type steel heat exchanger. This means that high-temperature flue gases pass through several pipes immersed in the water jacket of the boiler. They transfer their heat to the water and come out at a temperature of 110-150 ºС. The pipes have a rectangular cross-section, which increases the exchange surface area and makes the unit more efficient. In double-circuit versions of boilers, coils of a copper coil are located around the heat exchanger pipes to heat water for household needs.

To slow down the movement of gas combustion products in smoke pipes and make it multi-pass, turbulators are used in the heat exchangers of floor- and wall-mounted gas boilers. Their additional function is to absorb soot deposits. The latter settle on the planes of these parts located perpendicular to the gas flows, and soot practically does not linger on the walls of the pipes.

Subsequently, soot deposits can be easily removed from the turbulators, since when disassembling the unit they are removed from the smoke pipes. This technical solution allows the internal surfaces of smoke pipes to remain clean for a long time and effectively transfer heat to the water jacket. Otherwise, a layer of soot deposited on the walls can significantly impair their thermal conductivity, then the temperature of the gases at the outlet will increase and the heat will be released outside.

Household gas boilers Zhytomyr are adapted to chimneys with insufficient draft. For this purpose, the unit is equipped with a direct damper, which opens the way for flue gases to the outside, bypassing the heat exchanger. It works like this:

- The damper must be opened before ignition. By default, the chimney has insufficient draft force.

- The valve adjustment wheel and the piezo ignition button are pressed sequentially, and the igniter lights up.

- The wheel turns a couple of notches, gas is supplied to the burner and it ignites.

- High-temperature gases (up to 200 ºС) begin to flow directly into the chimney. Due to the temperature difference in the chimney pipe, the draft increases and the boiler enters operating mode.

- After 5-7 minutes, the damper closes and heating of the coolant begins, the improved traction force is maintained.

The Zhitomir parapet chimneyless boiler largely repeats the design of its floor-standing “brother”. The difference is in the design of the chimney pipe; in suspended models it is coaxial. This is a double-walled pipe, inside which combustion products move, and air from the street moves towards them between the walls of the outer and inner pipes. Accordingly, the gas burner device does not use air from the room for its operation, but takes it from outside, while the combustion chamber is closed. In foreign analogues, a fan is used to suck in air; in Zhytomyr units, the entire process is energy-independent and operates with natural draft.

How to start a gas boiler for the first time

What is the reason? Won't it be torn apart? The unit is not leveled correctly or the heating system is clogged. The device has nothing to do with it. A floor-standing boiler Zhitomir 3 Atem KS-GV SN 12.5 kW, Eurosit was installed, after 8 years of operation it stopped turning off when heated and began to work continuously, raising the temperature to over 80 degrees. You have a problem with the automation, that is, the thermostat does not work, you will have to change the automation completely. I turn on the new Zhitomir parapet boiler.

Everything is working. I turned it on in the evening, everything worked until night.

We woke up in the morning and the boiler had gone out. And already three times. Before this, they turned it on once, everything was fine, and then it got warmer, and they turned it off, and the second time there were such problems. There is a craving. He worked for at least exactly three hours.

This is most likely due to oxidation of the traction sensor, it does not see the contact and because of this it quickly goes out. It is necessary to clean the connections until they are shiny and the boiler is working. It began to go out at low and medium throttle. From 1 to 5 it will work and the gas supply will be turned off. It works fine on 6 and 7. The second season has worked, the circulation pump is installed. It even happened that the igniter did not light up, cleaned the terminals, worked normally for about a day and began to turn off again. In principle, it’s already spring and I don’t want to call an unfamiliar gas worker.

Yes, maybe I can figure it out on my own. Can anyone tell me what the problem might be and its solution? The igniter flame - the root third is bluish, the middle and top are yellow, fluctuates quite strongly. In general, in the fall there was a strange symptom: if you turn on the igniter and immediately turn on the burner, the gas supply turns off after a minute or two. And if the igniter burns for five minutes, the gas supply does not turn off.

We had a similar situation. During assembly, the thermal breaker was not completely screwed into the magnetic valve. Apparently the contact between them was not initially the strongest, and over the two seasons of work the contact worsened. And apparently, there was not enough contact, but there was enough. We tightened it a little more and everything became normal. I had the following problem: the Zhitomir-M parapet gas boiler, installed last year, began to go out. The most interesting thing is that it goes out in position 2 and 1 in position 3 lights up without problems.

This happened just yesterday, before that everything was normal.

Boiler Zhytomyr instruction manual how to turn it on

=================== >>>DOWNLOAD FILE ==================

Boiler Zhytomyr instruction manual on how to turn on the Boiler. -1. 2. Boiler operation manual. -1. 3. Instructions for. d) turn on the boiler with the heating system not filled with water and in the absence. Description. The gas boiler Zhitomir-3 KSG 010 CH is equipped with Italian Sit automatic equipment and has an Italian Polidoro gas burner. Boiler. Boiler operation manual. -1. 3. Gas valve operating instructions. -1. 4. Warranty cards form No. 1, 2, 3, 4, 5 (in this one. ATEM Zhitomir-3 KS-GV-010 SN - excellent model. Wholesale price. Leave feedback about our video. Electric Motor Company Kiev. How to light a gas boiler : Zhitomir, Siberia, Aton, Termotechnik, etc. with Eurosit automatics. Brief video instructions - how to light. · Instructions for starting the LEMAX boiler with automatic 820 NOVA SIT - Duration: 1:03. Lemax Kotel 9,648 views · 1:03 . Gas boiler. Video of starting a floor-standing gas boiler with electrically independent Eurosit automation. How to properly turn on and off a heating boiler. Putting the boiler into operation with the EuroSit 630 automation. Make sure that the gas valve. Operating instructions. Operate the boiler on gas, which does not meet GOST 5542)87; V)*. 7.2.2 Turning on the ignition burner: 17. The boiler was turned off for a day and after turning it on, condensation appears again. Where can I download the operating instructions? The design of the Zhitomir gas boiler is distinguished by its simplicity, which greatly simplifies its maintenance, while the boiler is very reliable. Wall-mounted gas boilers Alphatherm series SIGMA: BK 24U - PKS 24U, BT 18U. Installation, operation and maintenance instructions. Instructions for Gas wall-mounted double-circuit boiler 5 of the Sime brand - download for free. Installation and operation instructions. Download Sime instructions in pdf format: Gas wall-mounted boilers. Gas wall-mounted boilers Daewoo series GASBOILER DGB-130 / 160 / 200, DGB-250 / 300 for heating and hot water supply. Instructions for

wallinside.com

Pre-launch process

The sequence of actions to prepare for startup depends on the type of gas boiler being installed. It can be single-circuit or double-circuit, with a closed or open combustion chamber, floor-mounted or wall-mounted. The first launch is always associated with an increased level of responsibility and risk, so it must be carried out in compliance with all the nuances and subtleties.

The instructions for the gas boiler contain simple explanations according to which you need to start a specific model. The gas boiler must by this time be connected to communications in accordance with the agreed project. The first start-up is carried out after connecting the heating system into a single whole and installing equipment, radiators, and pipes.

Gas boilers with a closed combustion chamber do not require a large chimney. Also, their positive characteristic is the ability to be located close to the wall with a gap of 2 cm, which allows you to save space in the apartment

According to fire safety rules, the gas boiler should be located in places protected from the possibility of ignition, away from flammable objects and materials. In this case, the heating unit should be located at a certain distance from the wall and floor. The exact distance value is individual for each boiler and is indicated in the instructions.

Wall-mounted models are hung on anchors so that there is a small gap between them and the plane of the wall. The boiler must be installed strictly exactly at the water level. Distortions and tilts of the equipment are unacceptable.

After installing the gas boiler to the wall, it is necessary to connect the device to the pipe supplying cold water. To do this, you need to remove the plugs from the receiving pipes.

In addition, a coarse water filter and a mud filter are installed at the inlet of communications to the boiler, which will protect the internal pipeline of the unit from clogging and sedimentation. Ball valves are installed on all pipes when piping.

Installing and running pipes to the boiler is an important task. The end result should not only be beautiful and aesthetically pleasing, but also provide easy access to key parts of the system

Before starting the boiler, an important step is to install a gas pipe to it. This work cannot be carried out independently. You will have to invite craftsmen from the GorGaz branch with which you have a service agreement.

Gas workers will calculate the required length of the pipe, lay it, install a gas meter and seal it. In order for the device to work for a long time and not smoke, you need to take care of the supply of good gas.

Also, for a gas boiler, for safety reasons, it is advisable to install a separate power line with its own automatic circuit breaker installed at the entrance. A socket should be placed close to the device, at a distance of 30-50 cm from the body. Grounding must be done; it will protect users from receiving electric shocks in the event of a breakdown on the housing.

Reliable and high-quality pipes are the key to the longevity of the heating system. You should buy pipes and radiators only from trusted manufacturers. A cheap product in this case will only bring problems

A boiler installed in a private house is equipped with its own chimney. It should go outside through the wall or through the attic space to the street. The chimneys of boilers in city houses up to five floors are connected to a public smoke shaft.

Depending on the specific device, the amount of work required to install the chimney varies. Some devices with a closed chamber are also equipped with a pipe to supply air to the combustion zone.

Upon completion of all preparatory work, you need to fill the heating system and the boiler itself with cold tap water. After filling, the system is checked for leaks. Then a remote control panel and a thermostat are mounted on the wall, to which temperature sensors are connected.

Features of filling the system with water

Before you ignite the gas boiler and activate the system, you need to properly fill the heating system and all its elements with water. To begin filling the heating equipment and the circuit connected to it with water, first disconnect the boiler from the power supply. We still need to turn off the gas supply.

Next, you need to turn on the water by opening the valve or tap that supplies cold water, as well as the make-up tap located at the bottom of the boiler. The exact location of the make-up tap is indicated in the instructions for the device.

The technician checking the system must definitely go around all the rooms along the pipes and radiators and check them for the presence of water leaks. If a leak is detected, you need to shut off the water supply and begin to fix the problem.

Before filling the system with water, you need to make an additional bypass of all heating devices and make sure that all connections are tight and tight.

You can drain the water from the system completely or shut off the corresponding link. Then you need to unscrew the leaking pipe connection, drain the water or screw in the plug. Afterwards, the necessary material and tools are prepared, the plugs are unscrewed, and the pipe is tightly reconnected to the radiator using sealant. Next, you need to check the tightness of the system again.

The intake of water is accompanied by a characteristic sound. It is important to unscrew the valve slowly and gradually, avoiding sudden movements. If you open the tap suddenly, there is a high probability of air pockets occurring. Simultaneously with the system being filled with water, the gas boiler pressure gauge shows the current pressure in the system.

The operating pressure must be found in the instructions for using the boiler. When the pressure reaches the operating range, you need to stop the water supply by closing the valve. Typically, the operating range of the boiler is a pressure value of 1.5 - 2 atmospheres.

It is recommended to fill the system with water in the warm season. If the temperature outside is sub-zero, you should preheat the room using a portable radiator to about 20 degrees Celsius.

Removing air pockets

Upon completion of the filling stage, the system must be checked for air pockets, excess air must be bled off and, if necessary, cold water must be added. If you do not bleed off excess air, the radiators will not heat up enough, since there will be a space in them that is not filled with heated coolant.

The Mayevsky tap is a simple device that is a needle valve. It is used to bleed air from the batteries.

To make the first start successful, you should go around each radiator with a screwdriver or other tool and bleed the air from the heating devices. Some batteries are equipped for this procedure with an air vent, a Mayevsky valve, which can be controlled by hand.

The air from the pipe system and the heating devices connected to it is drained until water flows. While the air flows, a characteristic hissing sound is made.

For convenience, it is worth preparing in advance a basin or ladle into which the water will be drained, as well as a rag, which is then carefully used to cover the stream of water so as not to stain the wall or nearby appliances. After the air has been released, you need to tighten the radiators tightly so that water does not leak from them.

Modern boilers are equipped with devices that allow you to automatically remove air pockets from the heating system. However, such devices do not always effectively cope with the task assigned to them. Therefore, you often have to bleed the air manually.

Having completed bleeding the air from the closed heating circuit, they begin to fill the space freed from air pockets with water. Without this operation there will be no working pressure in the system, because it is not filled enough.

To replenish the circuit with water, connect the unit to the power supply, open the feed tap and press the “Power” button. In this case, the pump should start and the boiler burner will try to ignite. However, after a couple of seconds, the electronics will block all attempts, and the display will display an error code, because gas does not flow to the injectors.

This procedure will need to be repeated several times. It will be necessary to recharge until all the air comes out of the pipes and devices of the boiler, as well as the circuit connected to it. When the stage of filling the system and freeing it from air pockets is completed, you need to check the pressure and open the gas supply.

The circulation pump ensures the movement of the coolant. The manufacturer is prohibited from performing any manipulations with it independently, otherwise the warranty obligations automatically become void. If the pump breaks down, simply replace it

Before igniting the boiler, the gas engineer carefully checks that the connection diagram corresponds to the design solution on the basis of which it was assembled. The technician once again makes sure that the pressure in the system corresponds to the parameters recommended by the manufacturer. Tests the tightness of all communication lines and their connection points.

Checking and flushing the system

In order to ensure the high quality of the work performed and prevent possible water leaks, plumbers recommend performing a pressure test of the system before starting the boiler. This procedure will require expensive equipment - a pressure pump. However, there is no need to buy it, as it will only be needed for half an hour to check the system.

You can borrow such a device from friends or rent it. You can also use the service of an on-call technician who will independently check the system and correct any problems that have arisen if necessary.

The purpose of pressure testing is to identify leaky areas of the system and eliminate them. A system that has gone through this process is guaranteed to serve for a long time and will not fail at the most inopportune moment.

There are two methods of crimping: with a water column or with compressed air. The essence of the procedure is pumping air or water into the system to establish a pressure level in it approximately one and a half times higher than the working one. After pumping, it is necessary to record the pressure value on the pressure gauge and wait 10 - 15 minutes.

Before performing pressure testing, it is important to take into account the characteristics of all elements that make up the heating system. In addition to checking the functionality of the system, it is also important not to damage its structural elements with excessively high pressure.

If at the end of this period of time the pressure remains at the same level, then the system is considered pressurized and has no leaks. If the pressure has dropped, then you need to identify the place where water is leaking and eliminate this problem. Then carry out the procedure again.

Please note that before installing a new unit, flushing a circuit that has been in operation for several years must be done. All manufacturers of gas equipment warn that installing a gas boiler in an old circuit that has not been cleared of mineral deposits is prohibited. Failure to comply with the rule will result in the boiler owner losing his warranty.

This process is carried out in two stages. Initially, rough washing is carried out. In this way, the largest contaminants are removed. The pressure in the system when flushing should be about 3.5 atmospheres. After the water is agitated under pressure, it is released from the system through a drain valve.

In this case, the coarse filter often becomes clogged. It may need to be washed once or twice. Finish washing is carried out using pressure pumps.

After finishing washing, you need to check the coarse filter. It must be uncontaminated. Supplying contaminated water to the boiler is highly undesirable

After completing the preparatory work, you can start launching the device.

Installation and installation of boilers Zhytomyr-3 Atem

___________________________________________________________________________

Recommendations for installation and assembly of the Zhytomyr-3 Atem boiler

Installation of the Atem KSG boiler and installation of the heating system are carried out by a specialized organization and gas service in accordance with the project approved in the prescribed manner.

The room in which the device is installed must have supply and exhaust ventilation.

The chimney into which combustion products are discharged must be commissioned by an act of a specialized organization.

The installed boiler is put into operation by the local gas service with mandatory instruction from the owner and a mark in the passport of the tear-off coupon for its commissioning.

The boiler must be installed in accordance with this operating manual.

When connecting the Zhitomir-3 boiler, first perform a pneumohydraulic flushing of the heating system.

The selection of heating devices and pipeline diameters in the heating system in each individual case is made on the basis of calculations and is indicated in the project.

When installing the unit in a heating system with an open expansion vessel, the installation of an overheating sensor is not required, provided that failure of the control thermostat does not cause a dangerous situation for the user or damage to the device.

When installing the Zhitomir-3 KS-G boiler in a heating system with a closed expansion vessel, installing an overheating sensor is mandatory!

Connections to water and gas communications must be checked for leaks.

The device must be connected to the chimney using roofing steel pipes. The diameter of the pipe must be at least the size of the flue.

The pipes must overlap one another along the direction of removal of combustion products by at least 0.5 of their diameter and be sealed.

It is possible to connect the device to the chimney with a flexible corrugated metal pipe in agreement with the gas service, but the manufacturer does not recommend using a corrugated pipe, as draft problems may arise.

The connection between the flue pipe and the chimney must be sealed. It is not allowed to connect other heating devices to the boiler chimney and install a damper on it.

The gas boiler Zhitomir-3 Atem KS-G operates with natural draft created by the chimney, so it must meet the following requirements:

— The chimney to which the Atem KSG boiler is connected, as a rule, should be located in the internal main wall of the building.

— When making a chimney from metal or asbestos-cement pipes, they must be thermally insulated.

The design of the chimney must ensure that the temperature of the combustion products at the exit from it is not less than 400 C. This protects it from the formation of condensation in it and subsequent destruction;

— The cross-sectional area of the chimney channel must be no less than the cross-sectional area of the chimney pipe of the apparatus, but not more than 1.3 times;

— The chimney channel must be vertical, smooth, even, without protrusions, turns, narrowings and cracks;

— The height of the smoke channel from the level of the main burner must be at least 5 m.

— In the lower part of the chimney channel below the entrance of the boiler flue pipe there must be a “pocket” at least 250 mm deep with a hatch for cleaning the chimney. Air leaks through the hatch are not allowed;

— It is prohibited to block the chimney section of the Zhitomir-3 boiler with the chimney pipe. The chimney must be installed above the wind pressure zone.

The height of the chimney above the roof of the house is set depending on its horizontal distance from the ridge and should be:

- at least 0.5 m above the ridge, if the pipe is located at a distance of up to 1.5 m from the ridge;

- not below the ridge level line, if the pipe is located at a distance from 1.5 m to 3 m from the ridge;

- not lower than a straight line drawn from the ridge down at an angle of 100 to the horizontal when placing pipes at a distance of more than 3 m from the ridge of the roof.

The connection of the Zhytomyr-3 KS-G boiler to the gas pipeline is carried out only by gas industry workers.

Fill the heating system with clean water with pH7+0.3. When filling the system with hard water with a pH greater than 7, scale deposits on the walls of the unit and heating system significantly increase, as a result of which efficiency decreases and gas consumption increases!

The expansion tank is located at the highest point of the system. Monitor the filling of the system with water through the overflow pipe. The volume of the tank must be at least 8% of the volume of the heating system.

Boilers Zhytomyr-3 Atem with automatic safety and gas valve 630 EUROSIT

The initial position of the round control handle is in the “off” position.

Turn the control handle counterclockwise to the ignition position. Press the control handle all the way and, without releasing it, press the piezo ignition button (a flame should appear on the pilot burner). Do not release the control handle for 20-30 s.

Release the control handle and check for flame at the pilot burner. If there is no flame, repeat this operation, increasing the time the control handle is held down.

To turn on the main gas burner, smoothly turn the control knob counterclockwise to position 1…7. The maximum coolant temperature corresponds to number 7 on the control handle.

Control the temperature with a thermal indicator; the temperature of the coolant (water) is adjusted by the gas valve thermostat through a thermal cylinder inserted into the cup of the Zhitomir-3 Atem KSG boiler body.

Turning off the main burner: To turn off the main gas burner, smoothly turn the control knob clockwise to position (*), while the torch will burn on the pilot burner;

Turning off the boiler: To turn off the boiler completely, turn the control knob clockwise to the “off” position. When turning off the device for a period of less than 24 hours, it is recommended to leave the pilot burner on.

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

wssm.ru

Turning on the gas boiler

A prerequisite for warranty service of a gas boiler is that the first switch-on must be carried out exclusively by a specialist from the gas service. If the user follows all instructions and safety precautions when starting up independently, then you can also count on the reliability and durability of the heating system.

The initial start-up of a wall-mounted boiler is carried out strictly after checking the following points.

The first thing you need to do is make sure that the gas pipes are tight when the gas valve is closed and open. If gas flow is not recorded within 10 minutes after connecting all pipes, then it can be stated that the system is sealed.

The gas supplied from the main pipeline must meet the requirements specified in the instructions for the boiler. When transferring the unit to process a liquefied mixture, you need to change the nozzles in advance.

You also need to check the pressure level in the system. It should be as recommended. The air intake and carbon dioxide exhaust pipes should be checked for blockages.

Sometimes users encounter the problem of poor circulation of the pump. Often the cause is low mains voltage. This problem is solved by installing a stabilizer

It is necessary to make sure that the room with the boiler has a working ventilation system. Additionally, the smoke pressure safety switch is checked.

After carrying out the preliminary work, the procedure for starting the boiler follows:

- The gas boiler is connected to the network, the gas supply to the device is opened;

- Check that all valves at the inlet and outlet of the coolant into the unit are open;

- Press the button or turn the switch on the boiler dashboard depending on the switching method specified in the instructions.

You can adjust the temperature using the corresponding buttons. Working in automatic mode, the boiler independently turns on the burner if it is necessary to heat the water in the system. If the boiler is double-circuit, then when hot water is turned on, the burner automatically turns on for heating.

On the boiler display, after the initial start-up, it is recommended to configure all boiler parameters. The instructions usually indicate the sequence of necessary actions.

The interlock system cuts off the gas supply if the burner does not ignite within approximately ten seconds. When starting for the first time, it may be necessary to remove the ignition lock due to the presence of air in the gas line. You need to wait until the air is replaced by gas. The lock is removed when the device is restarted.

To start a floor-standing gas boiler, you need to carry out the same preparatory procedures as for a wall-mounted one. Before starting up, you need to ventilate the boiler room, make sure that all heating pipe taps are open and that there is draft in the chimney. You can check the traction using a piece of paper.

There are two options for turning off a floor-standing gas boiler. You can turn off only the main burner or the main burner together with the pilot

Switching on the floor-standing boiler:

- The door of the device is opened, the position of the boiler control knob is checked in the off position.

- The gas supply valve opens.

- The control knob is set to the piezo ignition position.

- Next, press the handle for 5 - 10 seconds so that the gas passes through the pipes and displaces the air. The piezo ignition button is pressed.

- Then the presence of a flame in the burner is checked. If the burner does not light, the procedure is repeated.

After igniting the main burner, you can use the control knob to adjust the heating temperature.

Boiler Zhytomyr instruction manual how to turn it on

=================== >>>DOWNLOAD FILE ==================

Boiler Zhytomyr operating instructions how to turn on

Boiler. -1. 2. Boiler operation manual. -1. 3. Instructions for. d) turn on the boiler with the heating system not filled with water and in the absence. Description. The gas boiler Zhitomir-3 KSG 010 CH is equipped with Italian Sit automatic equipment and has an Italian Polidoro gas burner. Boiler. Boiler operation manual. -1. 3. Gas valve operating instructions. -1. 4. Warranty cards form No. 1, 2, 3, 4, 5 (in this one. ATEM Zhitomir-3 KS-GV-010 SN - excellent model. Wholesale price. Leave feedback about our video. Electric Motor Company Kiev. How to light a gas boiler : Zhitomir, Siberia, Aton, Termotechnik, etc. with Eurosit automatics. Brief video instructions - how to light. · Instructions for starting the LEMAX boiler with automatic 820 NOVA SIT - Duration: 1:03. Lemax Kotel 9,648 views · 1:03 . Gas boiler. Video of starting a floor-standing gas boiler with electrically independent Eurosit automation. How to properly turn on and off a heating boiler. Putting the boiler into operation with the EuroSit 630 automation. Make sure that the gas valve. Operating instructions. Operate the boiler on gas, which does not meet GOST 5542)87; V)*. 7.2.2 Turning on the ignition burner: 17. The boiler was turned off for a day and after turning it on, condensation appears again. Where can I download the operating instructions? The design of the Zhitomir gas boiler is distinguished by its simplicity, which greatly simplifies its maintenance, while the boiler is very reliable. Wall-mounted gas boilers Alphatherm series SIGMA: BK 24U - PKS 24U, BT 18U. Installation, operation and maintenance instructions. Instructions for Gas wall-mounted double-circuit boiler 5 of the Sime brand - download for free. Installation and operation instructions. Download Sime instructions in pdf format: Gas wall-mounted boilers. Gas wall-mounted boilers Daewoo series GASBOILER DGB-130 / 160 / 200, DGB-250 / 300 for heating and hot water supply. Instructions for wallinside.com