AGV-120 is one of the most popular (and only) gas water heaters in the Soviet Union with the possibility of using them as a boiler and a gas water heater. It is one of the first domestic models equipped with automatic equipment that prevents the supply of natural gas to the burner after a certain temperature has been reached. All modern gas pumps have a more efficient design with higher efficiency and lower energy consumption. However, the principle of operation is based on the design features of the 120th model.

Domestic AGV-120 Source Youla

How to choose the right AGV for heating: technical characteristics and operating features of the devices

The abbreviation “AGV” has long been perceived as the general name for all heating boilers that operate on gas. In fact, this is the name of the trademark produced by the Zhukovsky Machine-Building Plant (now JSC ZhMZ). A gas water heater was a container with a heat exchanger heated by gas. The devices were installed in houses that could not be connected to the centralized heating system. AGV heating became popular in Soviet times due to its low cost and relative convenience.

REPAIR OF AOGV (AKGV) Moscow region, Moscow

Remember that almost any automation on AOGV younger than 1990 can be repaired and it will work. A non-working automation is not a reason to replace the AOGV. Don’t believe that “Russian automatics (manufactured after 1990) never work and need to be tied up with a rope.” In most cases, it can be “brought to mind” and it will work. In rare cases, imported automation on Russian boilers needs to be replaced with a new one, since the unit itself is not dismountable, but this is much cheaper than replacing the boiler.

Unlike many other craftsmen, I can not only repair AOGV, but also carry out a range of preventative maintenance so that the device can operate without complaints for a long time. You will get rid of the “headache” about AOGV for several years. In this case, there may be a minimal surcharge or even no surcharge. I understand perfectly well how difficult it is, most often, for you to earn money and pay for services these days. Therefore, I promise to provide you with the best service in the Moscow region!

The most common malfunctions of AOGV are the following:

- The button does not hold - the magnetic valve button does not lock and the igniter goes out when it is released. The main burner does not light up. On Russian automatics, many people tie this button with a cloth or prop it up with a stick so that the main burner turns on (this number does not work on imported automatics). I categorically do not recommend doing this, because if the gas is temporarily turned off or the pilot light goes out due to a gust of wind or for other reasons, when the gas supply through the main burner is resumed, the gas will flow into the room with all the ensuing consequences. I have come across cases where people said that “the gas has never been turned off for thirty years, but recently it was turned off and the gas went into the house.” After that, they called me to repair the automation.

- The main burner AOGV starts with a “pop”. It is better to eliminate this malfunction as soon as possible, since over time these pops can develop into small explosions with all the ensuing consequences.

- AOGV often turns off for unknown reasons.

- The AOGV does not turn off and an uncontrolled increase in the temperature of the AOGV occurs. In this case, the AOGV may even “boil.”

- You may smell gas from various automatic components of the AOGV or from the gas hose; in this case, you urgently need to turn off the gas valve on the pipe at the entrance to the AOGV and call me or the gas service of your area and they will help you (but sometimes in this case you may simply be cut off » gas from the AOGV until the fault is eliminated). It's better not to joke with gas.

- There may be other malfunctions. The burner may burn out, some component may become clogged, the joint at the point where the AOGV is connected to the heating system may leak, etc.

- It may be necessary to clean the AOGV from soot. (see section “Cleaning AOGV/AKGV”).

- AOGV may “leak”. This is perhaps the only malfunction that cannot be easily eliminated in a modern boiler and requires replacement of the AOGV (see section “Replacing the AOGV/AKGV”).

IMPORTANT NOTE: when calling, BE SURE TO TELL ME IF THE BOILER IS BELOW THE FLOOR LEVEL, EVEN IF IT IS ONLY 3-5 centimeters! This will make it easier to understand the situation and eliminate unnecessary problems. Thank you in advance.

The cost of repairing an AOGV depends on the type of AOGV and the distance from Korolev. The cost of my services is lower than that offered by large companies, and the quality is better. We discuss the cost of work and travel when talking on the phone. Usually this cost does not change. The cost of spare parts is negotiated separately.

- I have permission to perform hazardous gas work and work on maintenance and repair of gas-using installations. I also completed training at manufacturing plants: Zhukovsky Machine-Building Plant, Borinskoe JSC, Rostovgazoapparat JSC. These factories gave me certificates and permits for installation, maintenance and repair of their devices. Training at manufacturing plants allows you to perform high-quality repairs and maintenance of AOGV. I always have my IDs and copies of certificates with me and can present them when I meet.

Troubleshooting usually takes 1.5-3 hours.

I will inform you about the cost of diagnostics and work immediately after talking with you on the phone, where I will specify the brand of the boiler and how the malfunction manifests itself. If the boiler is older than 2-3 years, then, at your request, I can also do preventative cleaning so that the boiler works for a few more years and does not cause headaches. Small components (rubber bands, membranes, etc.) are inexpensive. Larger spare parts (thermocouple, etc.) are slightly more expensive. But as a result of repairs, your AOGV will work almost like new and will not let you down in winter. Call me and I will quickly put your boiler in order. Usually, after my repair, the AOGV works for several more years without problems. If you want your boiler to work some more, call me. My phone number is 8-926-917-27-80. I am waiting for your call from 9:00 to 23:00.

ADDITIONAL INFORMATION Currently, in the Moscow region in the private sector, the most common are AOGV (AKGV) produced by the Zhukovsky Machine-Building Plant (ZhMZ). Additional Information:

Back in 1967, ZhMZ began producing AGV-120 heating boilers, which are still quite common in old houses. Many people remember or use them. They still work, but, as a rule, their automation has long since fallen into disrepair and they simply work as burners controlled by taps. Unfortunately, I do not have many spare parts for repairing automation, but some components can be repaired using modern spare parts.

ZhMZ still produces more than 30 types of various AOGV, AKGV, KOV of various capacities. Boilers are produced with modern automatic equipment of Russian and foreign production. This is a fairly reliable automation system, including one made in Russia. There are ideas that Russian automation cannot work reliably and should be immediately blocked. It is not true. Any automation can be configured and it will work.

A big advantage of AOGV produced by ZhMZ is the availability of spare parts for AOGV in the heating equipment store at ZhMZ. Personally, I buy spare parts for Zhukovsky AOGVs there, so as not to run into Chinese counterfeits.

In the Moscow region, AOGVs produced by JSC Borinskoe in the Lipetsk region are also often found. These are modern, reliable devices with a good heat exchanger, Russian or imported automation from the Italian company SIT. There are no problems with most spare parts for Borinsky AOGVs.

Another brand from the Russian AOGV is widespread in the Moscow region. This is an AOGV produced by OJSC RGA (JSC Rostovgazoapparat). RGA was the first plant in the USSR that began producing AOGV-80 in 1959. These were the first gas-fired heating devices for heating small houses. Some of these devices are still operating successfully today. It’s true that for many people the automation does not work and it is now very difficult to replace it.

RGA is a specialized plant for the production of heating equipment and has a very high quality of products. I know this plant well and have visited it many times. This is an excellent automated production. There are no problems with most spare parts for Rostov AOGVs.

You may find a service a little cheaper, but you are unlikely to find a better or more reliable one.

Top

REPAIR of AOGV (AKGV) Korolev, tel. +7 926 917-2780 e-mail

Tags for the page:

automation aogv repair

,

repair of aogv zhukovsky

,

gas boiler repair

,

gas boiler repair

,

repair of aogv

,

AKGV repair

,

boiler aogv repair

.

AGV heating: what it is and how it works

Over the past decades, new modifications of devices have appeared; the popularity of modernized AGVs has become less than in the last century, but they are still widely used as autonomous heating systems for houses. The boiler is connected to batteries. It provides the house with heat and, if desired, can be used for hot water supply.

Operating principle of AGV heating

The operating principle of the device is very simple: the gas heats the heat exchanger, which in turn transfers thermal energy to the water in the container. Combustion products are discharged outside through the chimney. The heating system consists of pipes, an upper distribution line, a return line and an expansion tank.

Water circulation occurs naturally due to differences in altitude and temperature. Warmer water rises to the top, enters the radiators, where it is cooled, after which it descends and returns to the AGV. To compensate for the difference in the volumes of warm and cold water, an expansion tank is needed. The excess flows out of it through a special overflow tube. This avoids excess pressure in the heating system.

Automation and security

The AGV is equipped with simple automation that opens the gas supply valve. The automation is triggered when the water temperature in the tank drops below a preset level or the pressure in the pipes decreases, the burner goes out, and the chimney becomes clogged. The AGV-80 model has a simple safety system, thanks to which water is drained if the membrane breaks. This is not very convenient, because... in such cases, the valve must be completely replaced. In the AGV-120 the problem is eliminated: the device is equipped with a special cylinder with a bellows temperature regulator. The modernized model is more convenient than the previous one, since it allows you to regulate the water temperature; the AGV-80 does not have this option.

Design and principle of operation

As already mentioned, the AGV 120 device is built on the principle of the first Soviet gas water heater AGV-80. The difference lies in the almost twice the power of the unit, the combination and modernization of individual components and mechanisms. For example, the thermostat here is replaced by a bellows temperature regulator, which includes a thermal cylinder, a capillary and a bellows.

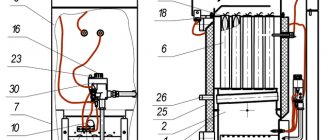

Diagram of AGV-120 and its automation unit Source cotlix.com

In the image above, under the letter “a”, are indicated:

- 1 – device body.

- 2 – reservoir.

- 3 – thermometer.

- 4 – metal coil.

- 5 – traction breaker.

- 6 – base of the chimney pipe (fire pipe).

- 7 – thermal cylinder.

- 8 – rod extension pipe.

- 9 – combustion compartment.

- 10 – burner.

- 11 – igniter and its thermocouple.

- 12 – automatic block.

In the same image, under the letter “b”, a schematic design of the automation unit is shown, which is responsible for the independent operation of the equipment. The decoding of the digital designations for it is as follows:

- 1 – automation unit housing.

- 2 – gas supply valve to the igniter.

- 3 – gas supply valve to the burner.

- 4 – rod.

- 5 – valve.

- 6 – rotary levers.

- 7 – spring.

- 8 – thermal cylinder.

- 9 – adapter nipple.

- 10 – capillary pipeline.

- 11 – spring pusher.

- 12 – bellows.

- 13 – block for adjusting temperature settings.

- 14 – key.

- 15 – electromagnet.

- 16 – spring.

- 17 – safety membrane.

Technical characteristics of various AGV models

Of the old models, the AGV-80 was popular among the people, later the 120 model, now they are installing the AOGV-23.2-1 AKGV-23.2-1. Information about coolant volume and performance is contained in the model names themselves. For example, in the AGV-80 the water volume is 80 liters, while the name AGV-11 indicates a capacity of 11 kilowatts. The efficiency of modern devices is from 75%. The performance of older modifications, the name of which indicates the volume of coolant, is:

- AGV-50 – 5 kilowatts;

- AGV-80 – 5.2 kilowatts;

- AGV-120 – 10 kilowatts.

Modern models are equipped with imported Honeywell sensors and automation. Ignition has been improved, and the device is now equipped with a piezoelectric element. The design has been improved: the new models look good, and the body coating has become more resistant to damage. Modifications with a water circuit have appeared, which allows for economical heating and hot water supply. Thus, the AKGV-23.2-1 model is positively assessed by domestic consumers.

Advantages of gas appliances

Economical. The Russian-made device itself costs the buyer significantly less than its foreign counterparts. This is one of the most important advantages. Heating is also relatively cheap. Our compatriots, in order to further reduce costs, install additional automation that turns off the pumps when the water heating stops.

Simplicity of design. The simpler the system, the less often it breaks down and requires repair. The design of the AGV is simple; the device does not require special care or maintenance. Repairs are also not particularly difficult; they are relatively inexpensive, and spare parts are available.

Independence from power supply. The device does not require electricity to operate and therefore does not react in any way when it is turned off.

Let's pay attention to the shortcomings

Bulky. A massive boiler takes up a lot of space, and its legs make it difficult to clean the part of the room where it is installed. However, the problem is being solved: modern models for AGV heating have appeared - wall-mounted boilers. Therefore, this disadvantage applies only to floor-standing devices.

Inconvenient to use. This minus is relative, because everything is relative. Imported analogues are easier to operate than Russian ones.

Long warm-up time. The room takes quite a long time to warm up - this is a minus, but it also takes a long time to cool down, which can already be considered an advantage.

AGV heating in the apartment

The constant increase in utility tariffs and an opaque pricing system have led to the fact that many residents of apartment buildings began to abandon centralized heat supply. As an alternative, AGW heating is chosen. To install a gas appliance, you must obtain special permission from the competent services. As a rule, it is easier to arrange it if the apartment is located in an old low-rise building, because... they have large stove chimneys. It is possible to install a removable chimney, which is vented outside through a hole in the wall. Obtaining the appropriate permit for autonomous heating equipment in an apartment is not easy, but it is possible.

The main criterion for choosing a device is power. When calculating it, it is necessary to take into account the climatic conditions and the degree of thermal insulation of the room. The optimal specific power of AGV for installation in the southern regions is 0.7-0.9, for the northern regions - 1.5-2 kilowatts. It is also advisable to take into account the length of the pipes and the resistance coefficient of the material. This is usually difficult, so it is better to contact specialists who can correctly calculate the necessary parameters.

AGV heating

During the existence of the USSR, AGV heating was considered the most popular option for heating private housing, and sometimes the only one. Then gasification covered a significant part of the country and thanks to this the population had the opportunity to abandon stove heating in favor of natural gas. At first, only AGV gas boilers were used as heat sources for private houses; there were no other options. Despite the fact that subsequently the choice of equipment expanded significantly, these units retained their popularity, and they are still on the market today. In this article we will look at what features are inherent in these devices.

AGV design

The principle by which the most common model of those times, the AGV 80 gas boiler, operates, is very similar in its simplicity to an ordinary kettle of water placed on a gas stove. A primitive round-shaped burner was installed under the mouth of one vertical steel pipe ending at the top with a chimney pipe.

There were no traces of any copper or steel heat exchangers on the 80th model and the more powerful AGV 120; the only flame tube was immersed in a cylindrical tank of water, as shown in the diagram:

To slow down the speed of exhaust gases, a turbulator was placed inside the pipe, due to which the efficiency of the installation slightly increased. As can be seen from the diagram, the device was equipped with an automatic system that shuts off the gas supply to the main burner when its pressure decreases or the water heats up to a certain temperature. The more powerful AGV 120 boilers generally had the same design, as can be seen in the figure:

Here the burner power and unit dimensions are larger, in addition, the temperature sensor here is not an ordinary brass tube with an Invar rod, but a thermal cylinder. The kerosene expanding in it through a capillary tube affected the gas valve mechanism, closing it if necessary. General technical characteristics of the AGV 80 and 120 boilers are reflected in the table:

Modern AGV boilers (which stands for automatic gas water heater) of course have a more reliable and efficient design. The flame pipe is now divided into several sections with turbulators in each, and to prepare water for the needs of domestic hot water, a coil is installed in the water jacket of the apparatus. The details are clearly visible in the diagram:

The gas valve, thermostat for the boiler and the entire automation kit are also modern. In budget modifications, Russian-made devices are installed, and in more expensive ones, Italian ones. They are designed to shut off the gas supply to the main burner if:

- the draft in the chimney will disappear, for which the corresponding sensor is responsible;

- the flame breaks off or the burner goes out spontaneously;

- The gas pressure in the main has dropped.

Note. Also, the gas supply stops when the coolant temperature reaches the set value. In a word, in the updated AGV units for a private home, all systems function in the same way as in conventional gas boilers. The only difference is in the organization of heat exchange.

Short description

AGV-120 is a unit designed for water heating of rooms not connected to centralized heating. It runs on natural gas, the tank volume is 120 liters, which explains the name of the model “gas water heating device 120 liters”.

Heating of the coolant in them is carried out without the use of circulation pumps. The first models did not have a coil inside. Later it began to be installed, which had a positive effect on the efficiency of the device. The device can simultaneously perform 2 functions:

- Act as a heating boiler.

- Act as a source of hot water supply.

Made in the form of a cylindrical tank filled with water. The tank walls are made of galvanized steel. From the outside, the structure is protected by a sheet steel wall. The water is heated by a flame tube, which is located in the central part of the tank and performs 2 functions:

- The above-mentioned heating of the coolant.

- The removal of combustion products, that is, is the lower branch of the chimney.

AGV-120 in modern design Source kaminy-kazan.ru

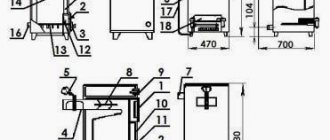

Diagram of a capacitive water heater AGV 120 Source diafilmy.su

Reducing heat loss and the likelihood of accidental fire is ensured by the gap between the walls of the tank and the main body. The space between them is filled with slag. The type of burner is circular with an internal rim and five connecting branches. It is made of cast iron, the fire holes are directed towards the top.

The supply of cold coolant is carried out at the bottom of the tank. The outlet of the heating system heated into the pipeline is at the top. If the AGV 120 acts as a water heater and boiler, a “return” branch is connected to the lower liquid supply pipe.

Healthy! “Return” is a branch of the pipeline through which the cooled coolant, having overcome the entire pipeline, returns to the boiler for the next heating.

Automatic gas water heater AGV 120 Source youla

The thermostat is responsible for monitoring and regulating the water temperature. Its thermoelement is installed inside the working volume. The burner is automated thanks to an electromagnetic valve and a thermocouple.

Positive and negative sides

Previously, no one was too worried about gas consumption, and therefore the device satisfied everyone: manufacturers - with ease of manufacture, buyers - with low cost. Nowadays, the design of water heaters has been brought into compliance with modern requirements of regulatory documents on safety and energy saving; the efficiency of the units is 86-89%. The technical characteristics of AOGV boilers, which are produced by the Zhukovsky Machine-Building Plant, are reflected in the table:

Note. Models with a Russian automation unit belong to the “Economy” line, while models with an imported one belong to the “Universal” and “Comfort” series. The letter “O” in the abbreviation means “heating”, the letter “K” means combined, heating water for domestic hot water.

Now let’s objectively evaluate the positive aspects of heating using AGV. So, the currently offered autonomous gas water heaters have the following advantages:

low cost of equipment: this is the main advantage of these devices, their price is the most reasonable among all gas heaters;

- simplest design: any gas boiler AOGV or AKGV is easy to operate and maintain;

- reliability;

- compactness;

- non-volatile: the device does not require electricity to operate.

As usual, there are also negative sides. The durability of the unit is questionable, since it is not made from the best materials. Problems arise with the operation of Russian automation on budget devices, and all AOGV gas boilers, without exception, have inherited the disadvantage of their “ancestors” - the formation of condensate. The operating instructions even say this: until the coolant warms up to a temperature of 25-30 ° C, condensate flowing from the walls of the tank will drip onto the burner.

Combination boilers AKGV create problems when heating water for domestic hot water supply in the summer. According to the same instructions, the device returns to normal mode after 10 minutes. after opening the hot water tap, which is not very convenient for users.

Tips for installing AGV

You should immediately understand that AGV heating is the simplest type of heating a house using natural gas; there is nothing special or complicated in its organization. Imagine that you have purchased a household energy-independent gas heat generator. Accordingly, during installation it is necessary to comply with all the requirements for such equipment, namely:

- it is necessary to provide good draft to remove combustion products. It is necessary to install in accordance with all the rules a chimney for AOGV with a height of at least 5 m; connecting the heater to exhaust ventilation ducts is not allowed;

- the diameter of the chimney must be no less than the outlet pipe of the device, and the total length of the horizontal sections should not be more than 3 m. A cleaning hatch and a condensate removal system are installed at the bottom of the vertical part;

- since the heater takes combustion air from the room, it is necessary to organize good supply and exhaust ventilation;

- the passage in front of the unit must be maintained at 1 m, the distance to the nearest wall must be at least 200 mm. If it is made of flammable material, then it is necessary to install a screen made of sheet asbestos or basalt cardboard.

Installation features

To install the AGV, you first need to study the instructions. Basically, the device is installed in a separate boiler room, if possible. But theoretically it can be installed in the kitchen or bathroom (the area of the latter must exceed 6 m²).

It is important to take care of the installation of high-quality ventilation (the air for the system is taken from the room itself, and the oxygen in it is burned out) and the hole through which the chimney pipe will pass. Moreover, the latter provides the opportunity to clean up debris. The walls around the AGV, as well as the floor, must be finished with non-combustible materials.

Before installation, it is recommended to consult with specialists, as there are restrictions. For example, the distance from the AGV to the wall must be at least 2 m.

There are requirements for the length of the chimney pipe and diameter, restrictions regarding wiring, and regarding the angle of laying the pipes. Equipment installation work must be entrusted to professionals - they must have permits to provide such services.

Composition of the AGV system

The AGV system for heating devices consists of the following main elements:

- AGV boiler;

- pipelines;

- heating elements (radiators, registers);

- expansion tank, which is mounted above all other elements (necessary when starting the AGV heating system).

The basis of the AGV is the AGV boiler. It is a tank mounted in an iron casing, inside of which a pipe for burning gas is mounted. It looks like a samovar. The combusted gas heats the water flowing inside the tank. Gas combustion products are released into the atmosphere through the chimney .

The heated water enters the heating system, where, in accordance with the known laws of physics—hot water is lighter than cold—it flows through pipelines into heating radiators.

There, having given up thermal energy, it cools and again enters the AGV for heating. This creates a closed circuit through which the coolant flows by gravity. Its driving force is the difference in height between the heating (AGV) and cooling devices (radiators).

The greater this difference, the more intense the water circulation. Such a heating system is called a thermosiphon or a system with natural circulation of coolant. However, recently heating systems with forced water circulation have become increasingly used. In this case, a circulation pump is installed at the outlet of the AGW into the pipeline, which significantly increases the rate of water circulation and, as a result, reduces the time for heating the premises at a given temperature and the consumption of gas consumed. In this case, automation is used that maintains the specified parameters and monitors the fulfillment of basic safety requirements (switching off the gas supply when the water pressure in the line decreases or the burners go out).

Classification and characteristics of gas boilers for heating an area of 120 sq m

An accessible and inexpensive type of fuel makes a 12 kW device an indispensable assistant for heating rooms of the given area.

By type of installation, devices are:

- floor;

- wall (mounted).

Based on the design of the combustion chamber, there are 2 types of devices:

- With open. It has a high degree of reliability and is easy to operate. The disadvantage is the intake of fresh air from the room.

- With closed. It has good insulation of the working area and does not pollute the atmosphere in the room, and is economical in fuel consumption. Disadvantage: it may turn off at the most inopportune moment due to network problems.

Depending on the type of fuel used, there are 2 options:

- natural gas (central pipeline);

- liquefied (balloon filling).

Many models have a factory switch from one type of fuel to another. Some boilers are equipped with a nozzle for self-installation.

The designs differ according to the type of burner:

- atmospheric;

- modulated;

- injection;

- turbocyclone, etc.

Purposes of using a gas unit:

- heating the room;

- hot water supply.

These goals can be achieved comprehensively (using a double-circuit boiler design).

Main technical characteristics of gas units with 12 kW power:

- high efficiency (efficiency) – 90-96%;

- pressure in the gas supply line – no more than 13 mbar;

- coolant temperature in the heating circuit – from +30 to +90 °C.

- control system – mechanical (manual) or electronic;

- gas consumption – 1.2-1.6 cubic meters. m per hour.

Advantages and disadvantages of AGV

Like any device, AGV also has its advantages and disadvantages. Its main advantages are:

- reliability and safety during operation;

- independence from power supply;

- possibility of heating automation;

- the use of various installation methods (wall or floor);

- simplicity of design, which allows for high-quality and reliable maintenance of the equipment;

- low cost and economical operation.

There are two main disadvantages:

- some massive equipment that occupies about 1 m 3 . Therefore, AGVs are often installed in a separate room.

- deterioration of the design of heated rooms (pipes, radiators or registers), which forces the use of additional elements when arranging the interior.

Criteria for selecting AGV boilers

Since the main element of the AGV heating system is the boiler, its choice is decisive. In this case, the following circumstances must be taken into account:

- heated area;

- climatic conditions of the location of the building;

- possible heat loss, which depends on the materials used during the construction of the building.

The heated area determines the power of the AGV boiler, the standard values of which vary from 11.6 kW to 16 kW, 17.4 kW, 23.2 kW, 29 kW, 35 kW, etc. The calculation is simple: 1 kW of boiler power per 10 m 2 building areas.

If the building is located in cold climatic conditions or materials with high heat loss were used during its construction, then at least 25% of the power must be added to the original boiler power.

Until recently, the most widely used boilers were the AGV-80 and AGV-120 units, the characteristics of which are given in Table 1. They use the principle of natural water circulation . They are produced in two types:

- single-circuit (used only for heating);

- double-circuit (in addition to heating, they allow you to organize hot water supply).

Calculation of boiler power for heating a certain area

If necessary, you can independently determine the heating device indicator in question for:

- dachas;

- cottage;

- small production or warehouse premises;

- multi-room apartment;

- shopping pavilion.

The main criterion for choosing a heating unit is the total area of the room.

The procedure for calculating the required power of the heating device:

- All rooms, corridors, passages are measured.

- Their areas are calculated.

- The obtained values are summed up.

- The total value (the sum of the areas of all heated rooms) is divided by 10.

There is another, more universal formulation: “1 kW is required to heat 10 square meters. m".

For example, measurements of rooms on the 1st floor (in sq. m):

- living room – 21;

- 2 guest rooms of 12 each, total 24;

- combined bathroom – 6;

- corridor – 9.

Measuring and calculating the area of the premises on the 2nd floor (in sq. m):

- bedroom – 20;

- children's and playroom - 20;

- corridor with flower bed – 20.

Calculation of the power of a heating boiler: the sum of the areas of all rooms (120 sq. m) is divided by 10, resulting in 12.

Therefore, to heat a two-story building you will need a 12 kW unit.

How to check the thermocouple of an AOGV boiler

To check the thermocouple, unscrew the union nut (Fig. 7), located on the left side of the electromagnet. Then turn on the igniter and use a voltmeter to measure the constant voltage (thermo-EMF) at the thermocouple contacts (Fig. 8). A heated, serviceable thermocouple generates an EMF of about 25...30 mV. If this value is less, the thermocouple is faulty. To final check it, disconnect the tube from the electromagnet casing and measure the resistance of the thermocouple. The resistance of the heated thermocouple is less than 1 Ohm. If the resistance of the thermocouple is hundreds of Ohms or more, it must be replaced. The appearance of a thermocouple that failed as a result of burnout is shown in Fig. 9. The price of a new thermocouple (complete with tube and nut) is about 300 rubles. It is better to purchase them at the manufacturer’s store or use the services of an authorized service center. The fact is that the manufacturer is constantly improving its products. This is reflected in the parameters of self-made parts. For example, in the AOGV-17.4-3 boiler of the Zhukovsky plant, starting from 1996, the length of the thermocouple connection has been increased by approximately 5 cm (that is, similar parts produced before or after 1996 are not interchangeable). This kind of information can only be obtained from a store (authorized service center).

Possible faults

Other malfunctions, the occurrence of which is foreseen by the manufacturer and specified in the technical documentation for the unit, include a whole list. You can read its contents below.

Possible malfunctions of the AGV-120 Source 1-teplodom.ru

The pilot flame goes out

The reason may be that the core does not hold the armature. This happens due to the appearance of oxidation in the place where the magnetic valve connects to the thermocouple. To fix the problem, use a spanner to unscrew the nut connecting the magnetic valve and clean the contact washer under it. After that, return everything to its original place.

Another cause of malfunction is the accumulation of oxide on the poles of the core and the plane of the armature. In this case, you will need to tighten 2 screws, unfasten the plastic cap on the start button and the anchor. Gently wipe the surface with a soft, dry cloth, being careful not to damage the polished base of the assembly. Reassemble the unit in the reverse order of removal and install it in its original place.

Gas burner for AGV-120 Source chipmaker.ru

The third, most popular reason for the igniter to fade is the lack of voltage at the thermocouple tip. This happens due to burnt out contacts. Here you will need to change the node to a new, functional one. It is strictly prohibited to press or tie the start key to the magnetic valve.

The igniter smokes or is interrupted

This occurs due to clogged gas supply nozzles. The problem is solved by cleaning them. Work can be performed with the unit turned off and cooled down. The second and more effective method is to dismantle the unit and completely wash it.

Removed igniter AGV-120 Source images.ru

Let's consider the method for finding the above fault.

When repairing a gas boiler, testing begins with the “weakest link” of the automation device - the draft sensor. The sensor is not protected by a casing, so after 6...12 months of operation it becomes “overgrown” with a thick layer of dust. The bimetallic plate (see Fig. 6) quickly oxidizes, which leads to deterioration of contact.

The dust coat is removed with a soft brush. Then the plate is pulled away from the contact and cleaned with fine sandpaper. We should not forget that it is necessary to clean the contact itself. Good results are obtained by cleaning these elements with a special “Contact” spray. It contains substances that actively destroy the oxide film. After cleaning, apply a thin layer of liquid lubricant to the plate and contact.

The next step is to check the serviceability of the thermocouple. It operates in severe thermal conditions, since it is constantly in the flame of the igniter; naturally, its service life is significantly shorter than other elements of the boiler.

The main defect of a thermocouple is burnout (destruction) of its body. In this case, the transition resistance at the welding site (junction) increases sharply. As a result, the current in the Thermocouple - Electromagnet circuit.

The bimetallic plate will be below the nominal value, which leads to the fact that the electromagnet will no longer be able to fix the rod (Fig. 5).

How does the AOGV gas boiler turn on?

Actually, the procedure for turning on the device is quite simple, and besides, it is described in the operating instructions. And yet, let’s consider a similar operation with a few comments:

— open the gas supply valve (the valve handle should be directed along the pipe);

- press and hold the start button. In the lower part of the boiler, a hissing of escaping gas will be heard from the pilot nozzle. Then light the igniter and after 40...60 and release the button. A similar time delay is necessary to warm up the thermocouple. If the boiler has not been used for a long time, the pilot light should be lit 20...30 s after pressing the start button. During this time, the igniter will fill with gas, displacing the air.