Mains gas is the cheapest type of fuel for an autonomous heating system. Manufacturers offer a wide selection of equipment that runs on this fuel. Heating equipment has an affordable price, has a good level of automation, and is equipped with security systems. You can install this equipment in a wooden house, just like in a cottage made of any other building material. It is necessary to fulfill a number of standard requirements and comply with specific conditions associated with the increased flammability of wood.

Main characteristics

This combination - gas and wood - should be given careful attention, because gas has high explosive characteristics, moreover, during the combustion process itself, the parts of the heating structure heat up, which also adds a certain level of risk.

Important elements of the house that need to be taken into account when choosing such heating are:

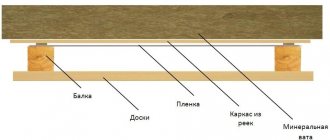

- Floor material. As a rule, the floor is made of boards, plywood or OSB, which are laid over the foundation beams. Such a base is quite movable, which eliminates the possibility of installing a water-based underfloor heating system, because it must be mounted with a screed.

- Insulation of walls and windows. Basically, such surfaces are made of logs or beams, which have a high level of thermal insulation. The coldest place is considered to be the opening, both window and door. That is why heating of a wooden house should be centralized in such places.

It is also important to note that a large amount of heat is also lost through the roofing areas, so the surface of the floor and attic should also be carefully insulated.

Moreover, a material such as wood has good flexibility, which allows the entire system of pipes and air vents to be installed without much interference.

Digging methods and tools

Ground work is carried out in two ways:

Mechanical .

The simplest, but more expensive. The digging is carried out by hired equipment; a single-bucket excavator or mini-excavator is used for the trench for communications. This method gives results faster and is less labor intensive. Disadvantages: the width of the ditch may be greater than expected by the project for gasification of the facility, which is adjusted manually. Suitable for the construction of apartment buildings or for private households, if the source of the resource is located far from the site.- Manual . Requires physical effort, inexpensive, can be done independently. Digging is done using a shovel, according to the parameters provided for in the project plan.

The choice is made depending on the location of the object to which the gas pipeline is extended. For small areas, country houses, when a branch is made from the central system, it is enough to dig a trench by hand. A shovel is also used to form slopes and remove uneven surfaces after excavator work.

If work is carried out in an area where there are other active communications, digging with an excavator is not performed. There is a high risk of damage to adjacent pipes. This applies to urban areas, residential areas of gardening associations, etc.

Gas boiler

This design consists of a centralized boiler that heats the heating compartment. In this case, the gas is liquefied and distributed through the pipes, thereby releasing thermal energy. The radiators themselves, being heated to a safe temperature level of 80 degrees, heat the room. The safest solution in this case would be to use main gas, since it is located in a special room - the boiler room - and does not need to be carried through all rooms of the house. However, heating a wooden house with gas using a gas boiler has some features that must be taken into account:

- It is necessary to choose a boiler that operates on the convection principle, since condensing boilers, although they are less expensive, require a low temperature of the pipeline system, which cannot be done while maintaining the optimal level of heat. The heated floor system can operate at low temperatures, but it is difficult to install it in wooden houses (for more details: “Warm floors in a wooden house are the key to comfort”).

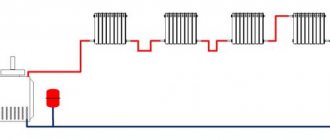

- The heating system should, as a rule, be single-pipe, barrack-type. The main pipe runs along the entire perimeter of the house, and heating radiators are cut in the direction of this pipe. All this is suitable for a convection boiler, with heating of 60 degrees and above.

- You can purchase boilers with electronic ignition. That is, they do not need to constantly maintain the combustion mode of the main burning part, which in turn increases the level of safety. In case of frequent power outages, you can simply install an uninterruptible power supply system

Laying a gas pipeline

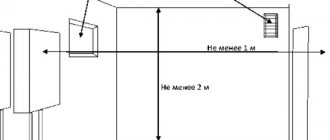

Let's look at the permitted minimum distances from the gas pipeline to other communications.

- From the surface of the gas pipe to the open wiring there should be 25 cm when laying parallel and 10 cm when intersecting;

- For hidden wiring, these distances are reduced to 5 cm and 1 cm, respectively. The same rule applies to wiring in pipes;

- Distribution and input panels with gas pipes should not intersect;

- There must be a distance of at least 1000 mm to the “bare” electrical wiring busbars;

- Utilities (water, sewerage) intersect with the gas pipeline no closer than 2 cm. Parallel installation is selected locally and is not standardized.

Convector with gas

Such gas heating in a wooden house is suitable if gas is only available in cylinders. This system does not need to be installed around the entire perimeter of the house, since the convector itself is installed under the window, and the cylinder itself is located in another or this room (for more details: “Heating a house with gas cylinders is a simple old-fashioned solution”).

The main disadvantage of such a heating system is that it only heats the room in which it is located. So, if there is more than one room in the house, then a gas convector will have to be present in each room, which in turn increases the number of gas cylinders that supply the gas itself. At the same time, a significant advantage of such a system is its low cost, especially compared to a bimetallic radiator. Moreover, the gas convector does not require the location of additional boilers and pipes. It can even be installed in non-insulated rooms; the heating itself will depend on the power of the convector.

What is required to connect to the gas pipeline

The owner of a wooden house must fulfill the following requirements to connect to the main gas pipeline:

- obtain technical specifications;

- prepare a home gasification project;

- carry out installation work.

Before installing the equipment, it is recommended to check with the gas supply organization for the list of documents required to obtain permission to connect. The lists vary in different regions, but most often include a grounding test report in the house, a boiler operating permit, and a gasification project.

Basic fire safety rules

Gas heating in a wooden house must be installed in accordance with all fire safety rules, since the lives of the inhabitants of the house directly depend on it. The instructions themselves, as a rule, are attached to the boiler; you can also find photos of the main structural elements there. There are few main points, however, you should pay attention to them.

- Firstly, it is necessary to carefully protect the surface on which the boiler will be installed from fire. The best option is galvanized steel and asbestos substrate. It is also important to take into account that the dimensions of the substrate and stand should be 10 centimeters larger than the heating system itself around the entire perimeter.

- Secondly, all other electrical appliances must be located at a distance of at least 30 centimeters from the boiler itself. All electrical wiring should not be carried out above or below the boiler, since such an insulation system will quickly fail under the influence of hot air.

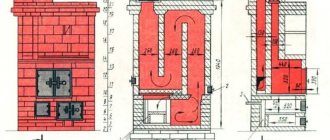

- Thirdly, the diameter of the chimney must correspond to the pipe on the gas boiler, and also have three bends, but no more. The section type should be round, stainless steel is selected as the material.

- Fourthly, the chimney opening must be larger than the chimney itself. This will make it possible to lay an additional layer of insulation using asbestos or a piece of cement-asbestos pipe, which will reduce the level of heating of gas combustion products.

- Fifthly, the gas boiler must be located in a separate room with an area of 4 m2, and it must also have a door, the width of which must be 80 centimeters, and a window.

- And finally, sixthly, the height of the chimney should exceed the height of the roof by 50 centimeters.

Boiler room in a wooden house

To heat the cottage, a gas boiler of 30-40 kW is sufficient. To install this heating equipment, a separate boiler room building is not required. The boiler is installed in a house; the room for heating equipment must meet the following requirements:

- the boiler room is located on the ground floor;

- the boiler is not installed in living rooms, bathrooms, bathrooms;

- boiler room volume is at least 15 cubic meters;

- the room has a window with an area of 0.03 sq.m. for each cubic meter of volume;

- The supporting structures of the mansion must be treated with fire retardant compounds.

The room is equipped with fire extinguishing equipment and personal protective equipment. The door to the room is no narrower than 80 cm and should have a small gap for ventilation. The room is equipped with a forced ventilation system.

Do it yourself or order it?

If you are unsure of your own abilities or lack minimal construction skills, it is better to prefer the services of professionals. The work of installing a chimney is not particularly difficult: the cost of work in Moscow is calculated based on the height of the house and is about 2,000 rubles. per 1 m. The total cost of installation also depends on the choice of material (diameter, type, additional structures, etc.).

Modern building materials allow you to do all the work yourself: the outer part is assembled from separate modules. Sandwich products do not require additional thermal insulation. Before making a pipe in a bathhouse through a wall, you need to calculate its height, take into account the purchase of related materials and the requirements for the safe installation of a hot structure.

Mistakes when choosing a chimney

Mistakes in the design, selection of materials and installation of the chimney pipe have a negative impact on the operation of the chimney.

The most common manifestations are:

- fire of building materials;

- destruction of chimney walls;

- drop in traction indicators.

The most common mistakes when selecting and creating a chimney:

- incorrectly selected pipe;

- using the wrong materials;

- violation of fire safety regulations.

Wrong choice of pipes usually causes poor-quality traction. Its strength is influenced by external aspects: precipitation, wind characteristics, and so on.

That is, it is important to ensure the influx of fresh air masses from the outside, for which you can install a separate air channel from the street, which can be regulated

Inaccuracies in pipe construction may include the following aspects:

- incorrect choice of section;

- low chimney height;

- there are deviations from a straight vertical line - the angle of the inclined parts is not allowed greater than forty-five degrees.

If we talk about the incorrect selection of materials, then in the case of mediocre characteristics of the brick for the chimney, it begins to collapse quite quickly, which causes the structure to freeze.

Not all stainless steel models are suitable for creating a chimney. It is better to use AISI 321 steel, which is most resistant to fire and acids, as well as physical impact. When using enameled pipes, you should select the appropriate models based on thermal characteristics, since often such pipes simply burn out for many.

Another common mistake is violating fire safety regulations.

The main mistakes in this case are:

- lack of fireproof cutting and filling with high-quality fireproof materials between pipes;

- poor-quality pipe lining, which causes it to overheat.

As you can see, creating a chimney for boilers of various types is not difficult even for an uninitiated person. But it will function efficiently only if a large number of different factors are taken into account.

In the next video you will find diagrams of chimneys for the boiler.

Pros and cons of underground installation

Advantages of the underground installation method:

design safety, safety from damage, human factors, climatic phenomena;- aesthetic appearance;

- possibility of using plastic pipes;

- long service life;

- difficulty of unauthorized connection.

Flaws:

- the event is costly;

- it is necessary to clear the area of plants and trees, often the asphalt is opened at the site of communications;

- abundance of documentation for approval.