In home heating, there is one of the most popular sources, characterized by efficiency and functionality - heated floors. This system was very expensive for quite a long time and available only to wealthy owners of private houses in the suburbs of Moscow or other Russian cities, but now the price has dropped to the middle price segment.

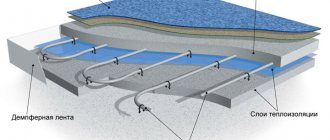

To create a heating circuit inside the floor covering, it is important to secure the pipeline or cable to the base. For this purpose, many fasteners are used: harpoons, mounting tapes and other devices.

One of the effective elements is considered to be an anchor bracket for heated floors. Let's consider the features of using these fasteners, the types of materials used and the rules for choosing brackets.

Mounting options and fixation methods

The system will function efficiently provided it is properly installed and connected to central heating. In order for the floor covering to heat up evenly, you need to correctly position the linear footage of the pipeline. There are several ways to lay pipes:

- spiral;

- snail;

- snake

Snake laying is most often used. The pipes are laid relative to each other at a distance of 30 cm. First, they are laid straight, then turned 180° and laid in the opposite direction. This arrangement will allow you to effectively distribute heat over the entire surface of the floor. The distance between pipe sections varies depending on the thickness and flexibility of the material.

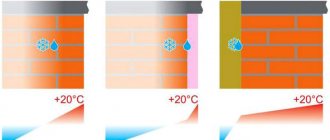

The system is installed on a rough surface with film waterproofing. You can use a backing made of mounting rails, metal reinforcing mesh or polystyrene foam boards. Features of materials:

- Reinforcement mesh. The material is sold in uniform lengths or in coils. The mesh is laid on a concrete surface, pipes are mounted on top and secured with clamps. Due to the availability of the material and low price, this method of fixing the floor is the most popular. With such installation there is a possibility of damaging plastic products, so the work is done carefully, spending a lot of time on it.

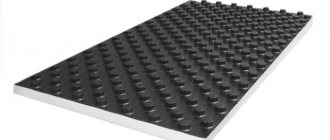

- Expanded polystyrene board. The material has uniform protrusions (bogs) that are intended for laying pipes. They come in different shapes and locations. Thanks to the projections, the pipeline is protected from damage and can be laid in any way. The slab is an expensive material, the use of which requires additional fasteners.

- Mounting bars. The products have an elongated shape and are equipped with special clamps. Pipes installed in clamps have good protection from damage. Unlike reinforcing mesh, this material is easier to install. Mounting bars are expensive and rarely appear on sale.

The fixing substrate protects the pipes from displacement while pouring them with cement mortar. Therefore, the substrate requires mandatory installation.

Which option is better

In the first time after the appearance of heated floors in our country, exclusively the method of fastening to a reinforcing mesh was used for their arrangement. This was explained by its cheapness. In addition, in those days there were simply no other options, and ordering components abroad was very expensive. Currently, the option of fastening using anchor brackets and tackers has become very widespread.

Thanks to the use of new installation technologies, installing heated floors in a home takes much less time. The most difficult to implement are those schemes in which the pipe circuits are located almost right next to each other. In such situations, the tucker does not fit into the small gap between adjacent turns, which leads to its frequent false positives.

Is it possible to connect underfloor heating pipes or not?

When laying a pipeline for a heated floor, often the length of the circuit is not enough to make a solid loop. In this case, the question arises: is it possible to connect the pipes to each other, and how to do this? There are several methods for connecting contours, which depend on the type of material.

Let's take a closer look at the methods of how to connect underfloor heating pipes.

Connection of cross-linked polyethylene and metal-plastic pipes

Contours made of polyethylene or metal-plastic can be sewn together using fittings (brass, bronze and plastic); they can withstand high temperatures. Fittings are:

- Electric welding ones are effective, but their installation requires special equipment, so they are rarely used. The process looks like this:

- An electric welding fitting is placed on the pipe cut;

- welding equipment is connected to the terminals, it will supply voltage to the element, which will lead to heating and fusion of the joints;

- the device turns off, the resulting connection can withstand pressure up to 12 Amp.

- Pressing - the main advantage is that when pressing, the entire space is filled with polymer, thereby creating a high-strength connection.

Sequencing:

- A nut is placed on the edge of the crimp tube, with the thread facing the connection;

- the split ring is put on with an indentation of 1 cm from the cut and fixed;

- the hose with the fitting device is stretched;

- The crimp nut is tightened tightly using two wrenches.

- Crimp fittings - these fittings are the easiest to install at home:

- a clamping sleeve is placed on the polymer hose;

- the end of the contour is stretched in diameter using an expander;

- with the stretched edge, the tube is pulled all the way onto the fitting fitting;

- the connection point is fixed in this position for several minutes, this is enough for the fitting to be tightly spliced.

Copper pipe stitching

Just as when installing a plastic circuit, copper can be joined using press or push fittings. This method is recommended in open areas, so that in case of leakage the part can be easily changed.

But the most reliable and practical way is to solder copper pipes. This is a more labor-intensive process, but the connection is durable and reliable. Sequencing:

- contour sections are cleaned from the outside and inside;

- a special connector for soldering copper floor heating pipes is used to lubricate the edges of the parts - only from the top;

- the products are joined, and the excess mixture is removed;

- the joint is heated with a gas burner and solder fills the gaps.

How to connect underfloor heating pipes (press fitting)

As mentioned above, the pipeline can be joined using press fittings. This part consists of:

- housings - come in different shapes (angle, tee, coupling);

- sleeves are the basis of the fitting, the raw material for its production is stainless steel;

- clips - an elastic ring (gasket) that connects the body and the sleeve.

Pressing is carried out using special press jaws. The essence of the procedure is to compress the handles of the tool. The process is quick and easy, and no special skills are required to carry out this work.

The advantage of using such a connection is strength, long service life and the design does not require maintenance.

Types of electric floor

There are three types of electric floors - rod, cable and in the form of infrared films. Only the first two can be considered really popular, partly because the third stands out for its rather high price.

With water heating everything would be much more complicated, because the placement of all the tubes plays an important role there.

- Extension of radiators - step-by-step description and tips on how to add a section quickly and easily (145 photos + video)

- How to make heating with your own hands - diagrams, projects and features of using current heating systems (115 photos)

- Connecting a temperature sensor - automation connection diagram and nuances of use in a heating control system (130 photos, diagrams and video installation)

In the latter case, full-fledged radiators are sometimes very difficult to install, especially depending on the layout of the attic floor and the roof itself, but laying a heated floor that will turn on only when someone uses this room is a great idea.

Mounting options and fixation methods

Effective operation of underfloor heating is possible provided that the pipes are correctly installed and connected to the central heating system. The key task of the contractor is to correctly distribute the linear footage of the pipeline on the surface of the subfloor to ensure uniform heating of the floor covering.

As a rule, pipes are installed in a “snake” pattern, i.e. First, the pipe goes in one direction, then makes a 180-degree turn and is laid in the opposite direction so that the two sections are located relatively close to each other (up to 30 cm).

This way, the coolant energy is effectively distributed over the entire floor area in the room. The pitch between pipe branches depends on its thickness, material, flexibility and intended heating mode. Thin plastic pipes made of polypropylene or polyethylene are laid in frequent increments.

Before installing a heated floor, prepare a rough surface - a concrete screed or a wooden plank floor, on which film waterproofing is laid. One of three types of underlay is placed on the subfloor:

- reinforcing metal mesh;

- polystyrene boards;

- mounting rails.

A special fixing substrate is a mandatory requirement for the correct installation of underfloor heating pipes, otherwise the pipes may move during the process of pouring the cement screed, and the system will not work correctly.

Reinforcement mesh - advantages and disadvantages

Metal reinforcing mesh is the most popular way to fix underfloor heating pipes. It is sold in the form of identical lengths or in coils, and is laid on a concrete floor. Pipes are distributed along it and fixed using various fasteners.

The advantage of this method is the availability of reinforcing mesh and its low cost in construction stores. The disadvantage is the labor-intensive installation process and the high risk of damage to plastic pipes.

We recommend that you familiarize yourself with: Metal hose in a sheath with PVC insulation to protect the cable

Pros and cons of polystyrene backing

Polystyrene boards are shaped products with protrusions equidistant from each other - bosses, between which pipes are laid. There are various shapes and configurations of bosses.

The main advantage of this installation method is the speed and ease of installation of pipes, which can be arranged in any way: “snail”, “snake” and other patterns. Thanks to the protruding elements of the polystyrene plates, the pipes are protected from mechanical damage. Disadvantages include the high cost of materials and the need to use additional fasteners.

Mounting rails for laying heated floors

Tires are long products with special clamps with which pipes are secured. With their help, you can easily and quickly install flexible plastic pipes that will be protected from damage.

Compared to reinforcing mesh, mounting bars are less labor-intensive in terms of installation, but their disadvantage is that they are rarely available for sale and can be quite expensive.

In addition to the substrate, various fasteners are used to firmly fix underfloor heating pipes:

- Plastic clamps or cable ties are simple products that form a loop covering the pipe and the bars of the metal reinforcing mesh. This is the simplest and most affordable method of fixation, but it is only suitable for reinforcement substrate.

- Plastic clamps with notches are products designed for fastening pipes to a polystyrene backing. They are installed on top of the pipes and pressed into soft polystyrene, held in place by spacers included in the sharp tips.

- Plastic clips are products in the form of a small horseshoe with a flat, level base on which they are installed. The pipe is laid and held motionless.

- Metal clamps in the form of a loop that matches the diameter of the pipe. Such products have a hole for a fastening element - a nail, self-tapping screw or bolt - for fixing on the rough surface.

We recommend reading: Why heating pipes in an apartment make noise or hum, and how to fix it

Foam insulation

In cases where the insulation is made of polystyrene boards, special brackets are used for the water circuit. The bracket is made of plastic, at the end there are teeth in the form of hooks with pointed edges.

Outwardly, its appearance resembles an anchor. The use of staples during installation must be accompanied by accuracy and special care.

The distance between the laid pipes on the foam sheet is calculated, markings are made, after which fastening can be done.

Experts do not recommend removing the bracket and changing its installation location, since the thermal insulation sheet crumbles and becomes of poor quality.

Construction of polyethylene pipe

Reinforcement. Almost all cross-linked polyethylene pipes have a complex multilayer structure.

It could be:

- polypropylene;

- fiberglass;

- aluminium foil;

- perforated aluminum;

- solid aluminum sheet.

The reinforced layer is able to neutralize sudden pressure changes inside the PE-S pipe when used in a hot water or heating system.

The design of cross-linked polyethylene products provides for the presence of a reinforced layer both on the surface of the product and at various depths. If it is necessary to solder two or more pipes, the reinforcing layer is stripped to 1 cm.

Pipes made of cross-linked polyethylene for underfloor heating are practically not reinforced. This material is also called “pure”.

Oxygen barrier. The manufacturer also calls it a “diffusion barrier” or “anti-diffusion protection.” This layer is mandatory for all types of cross-linked polyethylene products.

The reason for its appearance in HDPE pipes is the ability of oxygen molecules to penetrate into the material through a three-dimensional lattice, as a result of which cross-linked polyethylene is slowly but surely destroyed.

The diffusion barrier can also be either inside or outside the pipe.

Fasteners for heated floors

Let's start with easier-to-install roll-on electric floor heaters. These are cable or carbon mats and film heaters (also carbon or bimetallic). They are rolled out over a layer of insulation. They are usually secured with tape. Only for film floors they often use double-sided tape, and for mats - regular tape. In some cases, the cable mat mesh is shot with a staple gun or a construction stapler.

Scotch tape is a universal material used to attach some materials for heated floors.

Fastening underfloor heating pipes

Laying pipes or heating cables requires special clamps. They may be different. The design and installation method differ, which largely affects the installation speed. So, what and how can you secure the pipes or cables of a heated floor:

- Lay a metal mesh with a step between the rods of 5 cm. The step is not important, it’s just more convenient to calculate the step of laying a pipe or cable. With this method, the pipes are attached to the cells with plastic clamps or pieces of wire.

- Single clips (pictured below right). They are used together with a heat insulator on which markings are applied. The same grid with a side of 5 cm, but drawn. Each fastener is fixed in the subfloor according to the installation diagram. Even more painstaking and lengthy work. Such fasteners work well only when using high-density polystyrene. Then the fastener is inserted by hand or with a special machine, grabbing the pipe or cable.

- Mounting tapes (pictured top left). They can be metal or polymer. In metal ones, the petals are bent and cover the cable or pipe. The plastic ones have grips located quite often. The pipe or cable is simply pressed into them. These planks are attached in increments of 40-50 cm. Not a bad option: they are inexpensive, installation proceeds quickly.

- Expanded polystyrene boards with molded fixing elements (pictured below). These are the most expensive retainers. But two layers of the “pie” are combined at once: thermal insulation (plates are available in thicknesses of 30 mm or more) and fasteners. The shape of the fastening element depends on the manufacturer, but in any case, pipes and cables are fastened quickly and easily.

It’s up to you to decide which fasteners to use for heated floors. The fastest way is polystyrene plates, the cheapest is mesh. But a word of warning: when choosing fasteners for a water floor, keep in mind that you will need to fill the water heated floor system before pouring the screed. When using plastic mounting tape, there is a possibility that the pipe will break out of its sockets without a tie. There is such a possibility in polystyrene plates, but this happens extremely rarely. From this point of view, a grid is better.

Installation technique

Heated floor pipes are mounted on insulation - polystyrene foam

The most common option for using anchor brackets is the fastening of heated floors with elements having a standard size of 16 mm. Laying the structure with their help is organized according to the instructions, which prescribe the following sequence of operations on polystyrene plates:

At the final stage of arranging a water heated floor, they proceed to fixing polypropylene-based pipelines on a previously prepared base. For this purpose, anchor brackets already selected to size are used. Upon completion of this stage of installation work, the entire structure is covered on top with two layers of gypsum fiber blanks.

Expanded polystyrene boards with fixation

Option 1

A very creative way to install pipes. Since with the help of volumetric protrusions on the coating, pipes can be laid in any pattern as you wish. Despite the small distance between the protrusions, many people think that this is what will fix the pipe, but this is far from the case. For fixation, special clips are also used, which guarantee the reliability of a strong fastening of the pipe.

Advantages: The pipe is protected by special bosses from mechanical damage. Such a system can be freely purchased both on the market and in a specialized store.

Disadvantages: Quite a high price for all components. To fix the pipe, additional elements must be used.

Option 2

This installation method is very similar to the previous one, but there are significant differences. There are special protrusions on the coating that firmly fix the pipe without any additional equipment. You can fix the pipe in a very simple way: by carefully pressing the pipe between these protrusions.

Advantages: This method of attaching a pipe is considered very convenient and reliable. The slab is not damaged when moving across the floor. An excellent combination of functionality, quality and price.

Disadvantages: The cost is much higher than the earlier examples. Such a specimen is quite difficult to find in markets and specialized stores.

Insulation on wooden joists

The heating system for floor coverings made of wood requires installation on wooden modules. Each module is placed on logs, so the water circuit is always on top of the insulation.

The pipes are fastened into special grooves, so the installer does not have to think about how to form a heating circuit - the distance between adjacent grooves has already been adjusted. Fixation and type of fastening are selected based on the base, which is located under the pipeline. It is important to take into account all the features so as not to complicate the installation processes.

Anchor bracket for heated floors. Buy in Moscow

In the world of modern technology, heated floors are not a luxury, but additional heating and comfort for your home. Therefore, it is necessary to carefully select component materials for its installation. And in this process every small detail is important. All components can be purchased from, which has established itself in the construction markets of Russia and the CIS as one of the most successful and promising.

The anchor bracket kl 10016 for heated floors is one of the most important and indispensable installation elements. It is a blue clip that has impact-resistant plastic teeth. For its production, stamped polymer is used.

Method of fastening the harpoon bracket

The anchor bracket for a heated floor is attached to the pipes of the floor heating system, deeply “anchored” into the mats of the thermal insulating material of polystyrene foam with special grooves (notches), while reliably fixing the contours of the floor on the mounting grid.

This is achieved by the fact that the pipe is clamped in a special clip spacer, which is almost impossible to straighten after installation.

When calculating the number of fasteners, you should remember that for one meter of pipe you will need two or three brackets. Accordingly, for 200 meters you need to take about 500 pieces. For installation in bends, it is recommended to use 10 cm increments for more reliable fixation of pipes.

Install staples with a special fastening gun-tacker or stapler on all horizontal sections of heating pipes, especially on bends and turns. Often, a rod is used to attach clips - a special tool with a long handle and a lock at the bottom, which facilitates the work process.

How to purchase clamps?

The anchor shackle, which you can buy in the office in Moscow or on the website, is of high quality. The price will also pleasantly surprise you with its availability. Call the numbers provided or request a call back to receive advice from a qualified specialist. In addition, you can leave a request on the company’s website, and operators will contact you to discuss details and confirm the order.

Despite their small size, staples play a big role in installing heated floors. Reliable fastening of pipes is the key to long-term and safe operation of the underfloor heating system, which means your real pleasure, unique coziness and comfort.

To create a contour of a warm water floor, it is necessary to securely fix the pipes to the base. The method of fastening water pipes is different. To do this, use a harpoon or mounting tape, or lay pipes in special mats with bosses.

Installation features

As a rule, the length of the pipeline does not exceed 100 meters, which is necessary to create normal pressure in the system and circulate the coolant. In this case, the number of staples required will be about 250 pieces.

It is allowed to install two brackets per meter of water circuit. In this case, it will be possible to ensure reliable fastening of the pipes without damaging the concrete screed.

By securely securing the pipeline, it will be possible to make it as resistant as possible to any mechanical stress that could lead to depressurization of the system and its failure.

In addition, durable clips can protect pipes from deformation during high pressure in the system, which can also lead to coolant leakage and, as a result, expensive repairs.

Without taking care to securely fix the pipes and encountering their damage, you will have to completely or partially dismantle the floor covering and concrete screed, which will always be accompanied by large financial costs and loss of time.

Warm floor. REFLECTOR in the screed or How we are being scammed out of money.

What does the consumer actually pay for when buying a REFLECTOR for a heated floor?

count in dollars, who needs hryvnias anyway)))) just like our Belarusian rubles))))) How many hryvnias were given for a dollar in March 2017?

Happy New Year! How would you “for yourself” attach pipes to polystyrene? The method of using ties to masonry mesh is vehemently criticized on the Internet, and there is logic in it. In this case, all other fastening methods will damage the film (which is between the EPS and the screed). The anchor brackets pierce the film, and the fastening strips are also attached right through. How then to attach it if the film is still pierced by fasteners during the installation process?

My underfloor heating cake is a shiny film - a penpoplex plate - a black film, then a metal-plastic pipe.

Hello Bogdan. The comment is rather belated (2019 is just around the corner), but better late than never. I respect your experience and work very much, but in this case you are not quite correctly interpreting the manufacturer’s recommendations. That is, there is indeed a divorce, but it’s not about the price, but about the material itself. The store actually sells silver-colored film, but in reality there should be aluminum foil on the film. The film has a reinforcing function (for foil) and a protective function for polystyrene, while aluminum is designed not to reflect. (as erroneously interpreted), but to increase the heat transfer area, to make a heat spot out of the thread. Otherwise, we risk getting a zebra effect (depending on the thickness of the screed above the pipe.). I repeat once again, do not take it as a lecture, just a small adjustment. By the way, as I suspected, we are practically fellow countrymen (I’m from Novaya Ushitsa).

Let's chat. My viber is +380982526377

It’s nice to know adequate fellow countrymen. You’re right. But. Show me this film.

The screed was opened; the film was present, but the transparent reflector had already eaten up the cement.

Great, I’ll say more, cement screed does not have any harmful effects on polystyrene. for example. polystyrene concrete blocks. The film is needed only to prevent the solution from flowing and lifting the insulation. so just insulation and screed and that’s it!

let the experts tell you about everything else, but I have a question for you: why the hell hide it. styrene from the screed (black film), if all adhesives for screed are made on a cement base (the same puddle environment)

+Bogdan Khmelnitsky Film only to cover the seams of the insulation. If the seams are foamed, I think the film is superfluous.

+Vitaly Sadovyi I think that if a polystyrene polymer is exposed to aggressive puddle conditions for 28 days, then its molecules will certainly begin to change their structure, not for the better!

unconvincing, even in 45 days nothing will happen to polystyrene, not to mention the fact that classic concrete stands for 28 days, and modern modified screeds even less.

+Vitaly Sadovy Possibly because of time! The time for complete completion of reactions in a cement screed is 45 days. The indicators in adhesive solutions are many times less!

Mounting methods

There are quite a lot of ways to attach underfloor heating pipelines. Over time, new technologies appear, both means and methods of fastening are improved.

Let's consider the most common of them, which have received the approval of professionals who have been tested by time of operation.

Attaching to reinforcement mesh

In laying a warm pipeline, the reinforcing mesh does not play the role of a reinforcing element, but rather the basis for fastening heating pipes. It is laid on various layers of hydro- and thermal insulation made of expanded polystyrene or polystyrene, and plastic bends are mounted on top, attaching them to the welded mesh using various means.

The following fasteners are used:

Nylon ties, clamps of different lengths. Price from 1 ruble per piece.

Wire fastening connectors made of steel. They tie the pipes to the mesh with a special hook at a distance of 75 cm between the fastening points. The price per piece is approximately 2 rubles.

Plastic swivel clips installed on the mesh. Raise the mesh above the insulation by 0.5-0.8 mm, which better connects the mesh to the screed. The pipe is inserted into the clamp and snaps into place. Price from 5.5 rubles per unit of goods.

Any home craftsman can carry out these methods with his own hands, having made the necessary calculations.

Mounting on mounting rails

Special fixing tires are produced in the form of a plastic track 50 cm long with clip clamps on top. The planks can be connected to each other into a single strip of the required dimensions. They are convenient for laying pipes made of cross-linked polyethylene PEX.

They are attached to the insulation with anchor brackets, and to the concrete floor using dowels. Price from 48 rubles per piece.

Securing the pipe with clamps

In the absence of reinforcing mesh, fastening with staples or metal clamps is used. These mounting parts are attached to the screed with dowels and nails, and to the wooden floor with self-tapping screws.

Fastening with a tucker

The use of a tacker, a device that resembles the principle of operation of a stapler, is becoming increasingly popular among professionals. In sales it is often called that. The tool is designed for fixing pipes to polystyrene foam with anchor clamps. The device is equipped with a magazine bar that can accommodate 100 or more harpoon staples. Design features allow the operator to work without bending over, without putting much effort on his arms and back, significantly increasing the speed of operations.

Previously, the price of the instrument was at least 17-18 thousand rubles; now devices costing from 4 thousand have appeared on sale.

Advantages and disadvantages

Using a special device, you can quickly secure pipes.

The advantages of anchor brackets include:

- high speed and ease of installation of products in comparison with other methods;

- reliability of fastening of pipe blanks;

- durability;

- relatively low cost.

The fastening element can be used to fix other types of pipelines that are not related to heated floors. Due to the presence of protective plastic teeth, the products in question are highly resistant to impact loads. The disadvantages of fasteners of this class include the complexity of installation on some types of water and electric heated floors.