Autonomous heating systems demonstrate the greatest efficiency if they are based on gas boilers.

It is customary to classify the products of European companies as the highest quality and most reliable units, although there are serious complaints about them regarding the excessive sensitivity and fragility of some important components.

Recently, significant competition for these models has come from gas boilers from domestic manufacturers who have managed to find their own approach to creating heating equipment.

The driving idea was the exclusion of unreliable elements from the design, the rejection of all components without which the unit is capable of operating.

Let's consider the floor-standing gas boilers of the Russian] Siberia [/anchor], which have managed to provide a serious alternative to imported models.

Floor-standing gas boilers Siberia

Siberia gas floor-standing boilers are produced by Rostovgazoapparat CJSC. The brand was created on the basis of previously produced gas heating boilers, the design of which was modified, improved and optimized to the maximum.

The main idea professed by the developers was to create a maximally independent unit capable of operating in difficult conditions and not requiring electricity.

For our country, this approach turned out to be the most correct, and the low cost of boilers immediately created stable demand.

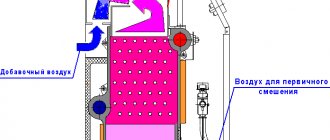

The units all have an atmospheric (open) burner, which places increased demands on the organization of air exchange in the room where it is installed. Smoke removal occurs naturally, so drafts or sudden changes in air flow are unacceptable - they create a danger of flame failure or smoke in the room.

A heat exchanger made of cast iron or stainless steel allows heating of the coolant with high efficiency - efficiency is up to 90%.

Siberia or Lemax: which is better

Floor-standing gas boilers have a similar, slightly more complex design, but similar automation and burners. The efficiency of almost the entire Lemax model range is also 90%, but gas consumption is on average 10% higher. For example, Lemax Premium-16 kW has a maximum gas consumption of 1.9 m3/hour. Lemax boilers are quieter, and even steel models are designed to operate in a circuit with a pressure of up to 3 bar. However, their cost is 10-20% more expensive.

Siberia is more reliable, more economical, simpler and cheaper. But it is deprived of the above-described advantages inherent in the Lemax model range. In general, both manufacturers are worthy of attention and it is not for nothing that they are sales leaders among domestic manufacturers of gas boilers.

Review of Lemax gas boilers The most famous and widespread among domestic models

Types

According to the set of functions, Siberia boilers are divided into two large groups:

- Single-circuit . They provide only the preparation of coolant for the heating system.

- Dual-circuit . Capable of simultaneously heating coolant and hot water.

The first group has the simplest design, and the second has an additional heat exchanger.

The issue of heating hot water is solved simply - the hot coolant that has just left the heat exchanger enters the secondary one and transfers some of the thermal energy to the water.

This method does not require significant design complexity, which allows you not to increase the price and get maximum benefit from the operation of the unit.

Advantages and disadvantages

The advantages of Siberia floor-standing boilers are:

- Simplicity of design, reliability and reliability.

- Lack of expensive electronics.

- Complete energy independence of the units.

- Compact, small size and weight.

- Low gas consumption.

- The prices of Siberia boilers are approximately half that of their European counterparts.

Flaws:

- The complexity of ignition, requiring a certain sequence of actions.

- For maximum efficiency, an external circulation pump is often needed.

- Natural draft is unstable and highly susceptible to external influences - drafts, gusts of wind, weather changes negatively affect the smoke removal system.

- The need to obtain permission from gas workers for installation.

IMPORTANT!

The disadvantages can be considered design features, since they are present not only in Siberia (Siberia) boilers, but also in all non-volatile units without exception.

What series and models of the company exist?

There are three model lines:

- AOGV. Single-circuit floor models used only for space heating. They have 5 models with power from 11 to 35 kW. They are simply marked Siberia 11, Siberia 17, etc.

- AKGV. Double-circuit units providing heating and hot water supply. They have the same power models, the marking contains the letter “K” (combined) - Siberia 17K, Siberia 23K, etc.

NOTE!

Both groups (AOGV and AKGV) are equipped with a primary heat exchanger made of stainless steel. Double-circuit ones have a secondary plate heat exchanger for heating hot water.

- KCHGO. Increased power models with cast iron heat exchanger. The power range is between 16-50 kW.

The power of the boiler determines the area that it is capable of heating: 11 kW - 110 m2, 35 kW - 350 m2, etc.

Floor-standing gas boiler Siberia 11K

Rostov-on-Don, Lenochnaya, 3

+7+7

Purpose: home water heating and hot water supply. Siberia boilers are resistant to significant changes in gas pressure, are completely energy independent, and have increased efficiency. The design uses basalt fiber - a key element of thermal insulation for spacecraft.

Technical equipment:

- Heat exchanger made of carbon structural steel;

- Automation unit (SIT): magnetic valve, modulating thermostat with active instant on/off function, thermoelectric flame control device with re-ignition lock, pressure stabilizer, piezo ignition, gas filter;

- Atmospheric burner made of heat-resistant stainless steel (Polidoro);

- Capillary thermometer with increased capillary volume;

- Thermal insulation foil using basalt fiber;

- Powder enamel coating of the body.

| Model | power, kWt | Peculiarities | Chimney diameter, mm | Dimensions, mm (HxWxD) | More details |

| 11 | 11,6 | heating only | 130 | 850x280x560 | |

| 17 | 17,4 | heating only | 130 | 850x280x560 | |

| 23 | 23,2 | heating only | 140 | 850x380x560 | |

| 29 | 29 | heating only | 140 | 850x380x560 | |

| 35 | 35 | heating only | 140 | 850x380x560 | |

| 11K | 11,6 | heating + hot water | 130 | 850x280x560 | |

| 17K | 17,4 | heating + hot water | 130 | 850x280x560 | |

| 23K | 23,2 | heating + hot water | 140 | 850x380x560 | |

| 29K | 29 | heating + hot water | 140 | 850x380x560 |

| Model | 11 | 11K | 17 | 17K | 23 | 23K | 29 | 29K | 35 |

| Rated thermal power, kW | 11,6 | 11,6 | 17,4 | 17,4 | 23,2 | 23,2 | 29 | 29 | 35 |

| Reduced gas consumption | |||||||||

| natural, m3/h | 1,18 | 1,18 | 1,76 | 1,76 | 2,3 | 2,3 | 2,94 | 2,94 | 3,75 |

| liquefied, kg/h | 1 | 1 | 1,21 | 1,21 | |||||

| Approximate heating area, m2 | up to 125 | up to 125 | 100–200 | 100–200 | 100–250 | 100–250 | 150–300 | 150–300 | 150–400 |

| Flue gas efficiency, % | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Water temperature setting limit, °C | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 |

| DHW at Δt=35°C, l/min | 3,8 | 5,5 | 7 | 8 | |||||

| Connecting thread of fittings, inch | |||||||||

| for gas supply | G½ | G½ | G¾ | G¾ | G¾ | G¾ | G¾ | G¾ | G¾ |

| Inlet/outlet | |||||||||

| to the heating part | G1½ | G1½ | G2 | G2 | G2 | G2 | G2 | G2 | G2 |

| to the water heater parts | G½ | G½ | G½ | G½ | |||||

| internal diameter of the chimney, dm, not less | 1,25 | 1,25 | 1,25 | 1,25 | 1,38 | 1,38 | 1,38 | 1,38 | 1,38 |

| Overall dimensions, mm | |||||||||

| height | 850 | 850 | 850 | 850 | 850 | 850 | 850 | 850 | 850 |

| width | 280 | 280 | 280 | 280 | 380 | 380 | 380 | 380 | 380 |

| depth | 560 | 560 | 560 | 560 | 560 | 560 | 560 | 560 | 560 |

| Weight, kg | 52 | 56 | 56 | 59 | 65 | 70 | 70 | 76 | 90 |

terma.su

Specifications

Let's look at the parameters of Siberia floor-standing boilers:

| Options | Values |

| Boiler type | Gas convection |

| Installation type | Floor |

| Fuel type | Natural or liquefied gas |

| Functionality | Preparation of coolant for heating systems, heating of hot water for the DHW circuit |

| Efficiency | 90 % |

| Serviced area (maximum) | Up to 500 m2 |

| Boiler power | 11-35 and 16-50 kW kW |

| Power supply | Absent |

| Burner type | Atmospheric (open type) |

| Burner material | Stainless steel |

| Heat exchanger material | Stainless steel or cast iron |

| Ignition type | Piezo |

| Chimney diameter | 125 mm |

| Weight | 56-200 kg |

| Dimensions | 850×280×560 mm, 850×380×560 mm |

| Guarantee period | 24 months |

| Service life with proper maintenance, maximum | 25 years |

Floor-standing gas boiler Siberia 11

Rostov-on-Don, Lenochnaya, 3

+7+7

Purpose: home water heating and hot water supply. Siberia boilers are resistant to significant changes in gas pressure, are completely energy independent, and have increased efficiency. The design uses basalt fiber - a key element of thermal insulation for spacecraft.

Technical equipment:

- Heat exchanger made of carbon structural steel;

- Automation unit (SIT): magnetic valve, modulating thermostat with active instant on/off function, thermoelectric flame control device with re-ignition lock, pressure stabilizer, piezo ignition, gas filter;

- Atmospheric burner made of heat-resistant stainless steel (Polidoro);

- Capillary thermometer with increased capillary volume;

- Thermal insulation foil using basalt fiber;

- Powder enamel coating of the body.

| Model | power, kWt | Peculiarities | Chimney diameter, mm | Dimensions, mm (HxWxD) | More details |

| 11 | 11,6 | heating only | 130 | 850x280x560 | look |

| 17 | 17,4 | heating only | 130 | 850x280x560 | |

| 23 | 23,2 | heating only | 140 | 850x380x560 | |

| 29 | 29 | heating only | 140 | 850x380x560 | |

| 35 | 35 | heating only | 140 | 850x380x560 | |

| 11K | 11,6 | heating + hot water | 130 | 850x280x560 | |

| 17K | 17,4 | heating + hot water | 130 | 850x280x560 | |

| 23K | 23,2 | heating + hot water | 140 | 850x380x560 | |

| 29K | 29 | heating + hot water | 140 | 850x380x560 |

| Model | 11 | 11K | 17 | 17K | 23 | 23K | 29 | 29K | 35 |

| Rated thermal power, kW | 11,6 | 11,6 | 17,4 | 17,4 | 23,2 | 23,2 | 29 | 29 | 35 |

| Reduced gas consumption | |||||||||

| natural, m3/h | 1,18 | 1,18 | 1,76 | 1,76 | 2,3 | 2,3 | 2,94 | 2,94 | 3,75 |

| liquefied, kg/h | 1 | 1 | 1,21 | 1,21 | |||||

| Approximate heating area, m2 | up to 125 | up to 125 | 100–200 | 100–200 | 100–250 | 100–250 | 150–300 | 150–300 | 150–400 |

| Flue gas efficiency, % | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Water temperature setting limit, °C | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 |

| DHW at Δt=35°C, l/min | 3,8 | 5,5 | 7 | 8 | |||||

| Connecting thread of fittings, inch | |||||||||

| for gas supply | G½ | G½ | G¾ | G¾ | G¾ | G¾ | G¾ | G¾ | G¾ |

| Inlet/outlet | |||||||||

| to the heating part | G1½ | G1½ | G2 | G2 | G2 | G2 | G2 | G2 | G2 |

| to the water heater parts | G½ | G½ | G½ | G½ | |||||

| internal diameter of the chimney, dm, not less | 1,25 | 1,25 | 1,25 | 1,25 | 1,38 | 1,38 | 1,38 | 1,38 | 1,38 |

| Overall dimensions, mm | |||||||||

| height | 850 | 850 | 850 | 850 | 850 | 850 | 850 | 850 | 850 |

| width | 280 | 280 | 280 | 280 | 380 | 380 | 380 | 380 | 380 |

| depth | 560 | 560 | 560 | 560 | 560 | 560 | 560 | 560 | 560 |

| Weight, kg | 52 | 56 | 56 | 59 | 65 | 70 | 70 | 76 | 90 |

terma.su

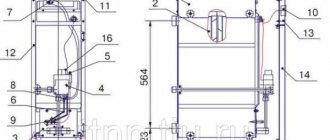

Device

The design of Siberia floor-standing boilers consists of:

- Primary heat exchanger.

- Secondary heat exchanger (for dual-circuit units).

- Three way valve.

- Gas equipment (valve, stabilizer, filter, etc.).

- Piezo ignition unit.

- Gas burner (pilot and main).

- Gas pressure stabilizer.

- Control devices - thermometer and pressure gauge.

The main functions are performed by the burner and the heat exchanger, where the coolant is heated.

Then it is either immediately discharged to a three-way tap (single-circuit models), or it first passes through a secondary heat exchanger and heats the hot water.

After this, the liquid in the mixing unit receives the set temperature and is discharged into the heating circuit.

The movement of flows is carried out by gravity, under the influence of thermal movement of layers of liquid.

Smoke and combustion products are removed using the same method..

Gas boiler Siberia 11

- home

- Boilers

- FLOORING gas

- AOGV SIBERIA

- Steel

- Single-circuit

- Reliability and durability.

- Affordable price.

- Double savings: during purchase and during operation.

- Modern design and optimal dimensions.

- Fully automatic control system and safe operation.

- Ease of control and quiet operation.

- Wide service network.

- A prestigious brand that dominates its class.

- A wide range of.

- Resistance to the “quality” of utility networks.

Gas boiler Siberia 11

Floor standing boilers Siberia

Siberia - floor-standing gas heating devices of the latest generation. Purpose: home water heating and hot water supply. Siberia boilers are resistant to significant changes in gas pressure, are completely energy independent, and have increased efficiency. The design uses basalt fiber - a key element of thermal insulation for spacecraft.

- Heat exchanger made of high-quality carbon structural steel with a developed heat exchange area;

- Automation unit (SIT): magnetic valve resistant to household pollution, modulating thermostat with an active instant on/off function, thermoelectric flame control device with re-ignition lock, gas pressure stabilizer, piezo ignition, gas filter;

- Atmospheric burner made of high-alloy heat-resistant stainless steel (Polidoro);

- Capillary thermometer with increased capillary volume;

- Thermal insulation foil using basalt fiber;

- Powder enamel coating of the body.

| Model | 11 | 11K | 17 | 17K | 23 | 23K | 29 | 29K | 35 |

| Rated thermal power, kW | 11,6 | 11,6 | 17,4 | 17,4 | 23,2 | 23,2 | 29 | 29 | 35 |

| Reduced gas consumption | |||||||||

| natural, m3/h | 1,18 | 1,18 | 1,76 | 1,76 | 2,3 | 2,3 | 2,94 | 2,94 | 3,75 |

| liquefied, kg/h | 1 | 1 | 1,21 | 1,21 | |||||

| Approximate heating area, m2 | up to 125 | up to 125 | 100–200 | 100–200 | 100–250 | 100–250 | 150–300 | 150–300 | 150–400 |

| Exhaust gas efficiency,%, not less | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Water temperature setting limit, °C | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 |

| Water consumption in hot water supply mode. when heated at ?t=35°C, l/min | 3,8 | 5,5 | 7 | 8 | |||||

| Connecting thread of fittings, inch | |||||||||

| for gas supply | G? | G? | G? | G? | G? | G? | G? | G? | G? |

| Inlet/outlet | |||||||||

| to the heating part | G1? | G1? | G2 | G2 | G2 | G2 | G2 | G2 | G2 |

| to the water heater parts | G? | G? | G? | G? | |||||

| Internal diameter of the gas outlet pipe, dm, not less | 1,25 | 1,25 | 1,25 | 1,25 | 1,38 | 1,38 | 1,38 | 1,38 | 1,38 |

| Overall dimensions, mm | |||||||||

| height | 850 | 850 | 850 | 850 | 850 | 850 | 850 | 850 | 850 |

| width | 280 | 280 | 280 | 280 | 380 | 380 | 380 | 380 | 380 |

| depth | 560 | 560 | 560 | 560 | 560 | 560 | 560 | 560 | 560 |

| Weight, kg | 52 | 56 | 56 | 59 | 65 | 70 | 70 | 76 | 90 |

www.climat1.ru

User manual

Operating Siberia boilers is not difficult at all . The owner’s only task is to maintain the cleanliness of the unit and the absence of soot, soot or ash inside the unit. Changing the mode is done by turning the knob to the desired position.

In order to light the boiler, you need to press the handle, pushing it all the way, while simultaneously pressing the piezo ignition button.

Hold in this position for some time (up to 1 minute) until a flame appears on the pilot burner.

Then the control knob is switched to the desired operating mode, which will cause the flame on the main burner to light up and heating of the coolant will begin.

The system is filled with water with the make-up tap open. The process lasts until water flows from the signal pipe, after which the tap is closed.

Download instructions

Download instructions for the Siberia floor-standing gas boiler.

Price range

The cost of Siberia floor-standing models depends on the power and set of functions of this unit.

The general range is between 20-65 thousand rubles. At the same time, the delivery set includes only the boiler, gasket, instructions and packaging. The chimney and other additional accessories (if needed) will have to be purchased separately .

IMPORTANT!

It is not recommended to save on concluding a warranty agreement. It’s not that expensive, but it will allow you to quickly and freely solve a lot of problems.

Characteristics

* Check with the seller for exact specifications.

General characteristics

| Boiler type | gas |

| Number of circuits | single-circuit |

| Maximum heating power | 11.6 kW |

| Heated area | 125 sq. m. |

| Efficiency | 90 % |

| Installation method | floor |

| Burner type | gas |

| The combustion chamber | open |

| Non-volatile | Eat |

| Auto-ignition | No |

| Flame modulation | No |

| Bunker included | No |

| Built-in boiler | No |

| Connecting a heated floor | No |

| Blower fan | No |

| Exhaust fan | No |