A pyrolysis or so-called gas generator boiler is heating equipment that runs on solid fuels. A solid fuel pyrolysis boiler is characterized by high efficiency and efficiency; the operating time of the heating unit on one load of fuel can reach from 10 hours to two days. Gas generating units can be used for heating both residential buildings and industrial buildings.

Design Features

- loading chamber or pyrolysis chamber;

- the combustion chamber;

- throttle valve (gate);

- grate;

- air supply channels (primary and secondary);

- water heat exchanger;

- chimney.

As mentioned above, the firebox of a gas generating unit consists of two chambers, located one above the other and separated from each other by a grate. The firebox of a pyrolysis boiler is usually made of alloyed heat-resistant steel. Grate bars are made of cast iron, steel or refractory ceramics. Through the primary oxygen supply channel, outside air is transported into the pyrolysis chamber, the second channel supplies air to the combustion chamber. The water heat exchanger of a pyrolysis boiler or the so-called “water jacket” is designed to heat the heating fluid of the heating system. Pyroboiler designs use tubular or plate heat exchangers. The exhaust combustion products are discharged into the atmosphere through the chimney.

The design of the gas generator boiler provides the ability to adjust the power of the heating unit in the range from 30 to 100%. The control element is a damper located at the rear of the heating unit. Depending on the set temperature of the coolant at the outlet, the regulator automatically opens or closes the damper.

Operating rules

To get good heat transfer from a gas generator heater with minimal fuel consumption, manufacturers recommend adhering to the following rules:

- use only dry firewood, permissible humidity 12...20%;

- when installing and piping the boiler, be sure to use a three-way mixing valve or the Laddomat-21 complex device to maintain the temperature in the return line at 65 °C;

- operating coolant temperature at the supply – 80…90 °C;

- the heat generator must operate at a power close to maximum; the unit cannot be operated for a long time in low productivity mode (less than 50%);

- It is very advisable to burn with large logs, but not with round logs;

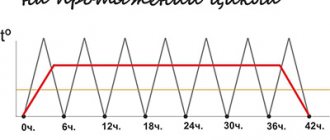

- Together with pyrolysis boilers, it is strongly recommended to use a buffer tank, which will accumulate excess thermal energy;

- The requirement for the minimum volume of the heat accumulator is 25 liters for each kilowatt of heater power.

Explanation. If cold coolant with a temperature below 65 degrees enters the boiler tank, then during the gasification of the fuel, condensation and tar will form in the primary chamber. Read more about correct piping in a separate guide on connecting TT boilers.

The supply of coolant to the boiler must be regulated by a three-way valve.

After the buffer tank, another mixing unit is installed to lower the water temperature. The use of a buffer tank is due to the efficient operating mode of the boiler - intense combustion, outlet temperature 80...90 degrees. It is under these conditions that a high efficiency of 86–87% is achieved. You cannot “choke” a heat generator with air; the combustion efficiency will drop to 40–50%, like a homemade potbelly stove.

Types of pyrolysis boilers

Depending on the design, pyroboilers are divided into units with natural draft and forced inflating. The main advantage of a pyrolysis boiler with natural draft is the independence of the unit from electricity. Disadvantages include increased requirements for smoke ducts. Pyroboilers with natural draft are equipped with chimneys with a height of at least 5 m. The draft of the chimney should ensure a vacuum of air in the firebox in the range from 16 to 20 Pa, the draft should be sufficient to overcome the resistance force of the gas-air path of the boiler and the smoke channel.

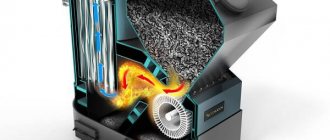

The design of the forced-air pyroboiler involves the use of a fan. Air supply to the gasification and combustion chamber can be provided in three ways:

- the blower fan is mounted on the front wall of the boiler;

- a fan (smoke exhauster) is installed on the chimney;

- the equipment is mounted both at the outlet and at the entrance to the gas-air path.

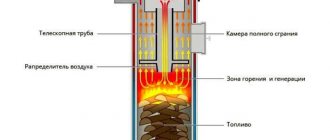

The location of the gasification and combustion chambers also depends on the type of design of the pyrolysis boiler. In units with natural chimney draft, the afterburning chamber is located above the gasification chamber, so the air flow occurs in the direction from bottom to top. In devices with artificial draft, on the contrary, the combustion chamber is located above the combustion chamber, the air moves from top to bottom.

Real advantages of pyrolysis heaters

Let's list the advantages of gasifying boilers declared by sellers, and then weed out outright stories:

- pyrolysis heat sources are full-fledged gas generators that produce flammable synthesis gas;

- the units are very economical and environmentally friendly due to their high efficiency;

- boilers completely burn coal and wood, with virtually no residue;

- burning duration is over 10 hours (the most modest indicator is 8 hours).

Note. Advertisers and not very conscientious manufacturers always compare gas generating units with conventional direct combustion boilers, “forgetting” about equally efficient pellet heaters. But even this comparison is not very advantageous.

The first statement is too bold. Let's remember: intense pyrolysis begins from strong heating and lack of oxygen, but what happens in the boiler? The fan pumps air into the firebox in excess, there is no smoldering. Synthesis gas, of course, is released, but direct combustion of fuel is also present.

On the left is the flame torch in the afterburning compartment during boiler operation, on the right is the fire tube heat exchanger (top view)

Let's look at the other advantages:

- Statements about efficiency and environmental friendliness are not fairy tales. Due to decent efficiency, the boiler better utilizes fuel energy and emits much less toxic compounds into the atmosphere - nitrogen oxide and carbon monoxide. Under 1 condition: recommendations for operating mode and moisture content of firewood are fully observed.

- The reasons for more complete combustion are dry wood and forced air injection. If you put sawdust briquettes or dry acacia into a traditional turbocharged boiler, the ash residue will also be zero. A lot of light ash is simply blown by a fan into the chimney. This means that this fact is not an advantage.

- The duration of combustion depends on 2 factors: efficiency and capacity of the fuel compartment. In terms of efficiency, solid fuel boilers are inferior to pyrolysis boilers by 10%, which is a small increase in operating time. The main factor is the volume of the combustion chamber; if it reaches 80 liters or more, the firewood burns out in 6–8 hours.

Reference. The Czech manufacturer Atmos describes the advantages of its heat generators (literally): large fuel bunker – long burning time. Hence the conclusion: the statement about the duration of work is true, only the reason is different - the capacity of the firebox, and not the fact of generating wood gas.

There are also many tales told about the economical smoldering mode, which is simply absent in pyrolysis units. The Atmos DC15E operating instructions say so - a decrease in flame intensity leads to a decrease in efficiency and an increase in fuel consumption.

The newest heat generator “Atmos” of pyrolysis type at the exhibition “Aquatherm-2019”

Advantages and disadvantages

The advantages of a pyrolysis thermal unit include:

- Efficiency up to 90%;

- fuel economy;

- environmental friendliness;

- ease of maintenance;

- minimal amount of ash, no soot.

Another significant advantage of gas generator boilers is their compatibility with any heating system.

The disadvantages are:

- high price;

- complex design;

- bulkiness;

- increased requirements for fuel relative to humidity;

- the need to connect to electricity (applies to boiler models with forced air supply).

Conclusions and recommendations for selection

It makes sense to choose a pyrolysis boiler from all existing boilers in this situation:

- you are willing to pay for efficiency and environmental protection;

- the budget allows you to purchase a heater and heat accumulator of the required volume;

- there is enough space in the boiler room for equipment;

- It is possible to prepare high-quality firewood, buy briquettes or dry freshly cut wood.

The heat generator model is selected according to power and functionality. How to choose the right wood-burning heat source for your home, read our instructions.

Initially, pyrolysis domestic boilers are designed to install a storage tank and use good fuel. This is a Western European practice, where solid fuel units cannot be operated without a buffer tank.

Our incomes are not so high, which is why homeowners save on everything - equipment, fuel, combustion method. Hence the conclusion: at the moment, gas generator installations are incompatible with the needs and expenses of most homeowners, because they cannot be operated correctly.

Operation of a boiler with pyrolysis combustion

The operating principle of a pyrolysis boiler is based on the thermal decomposition of solid fuel into chemical components:

- carbon;

- pyrolysis gas.

The process of generating flammable pyrolysis gas from wood and other types of solid fuel is possible at high temperatures in the range of 200-8000, under conditions of oxygen deficiency and subsequent afterburning of the released gas, which mixes with secondary heated air in the afterburner chamber. During the pyrolysis combustion process, the flue gases leaving the boiler mainly contain carbon dioxide and water vapor, and the amount of harmful impurities is reduced to a minimum.

Significant disadvantages of boilers

If you visit any online store of heating units and ask how much pyrolysis heat generators cost, you will immediately see their main drawback. Not the most expensive Russian boiler “Suvorov M” K-20 (20 kW) will cost 1320 USD. e., and identical in power ATMOS DC 20 GS – 2950 cu. e. For comparison: the price of the expensive traditional heater Buderus Logano S131-22 H is 1010 USD. e.

Let us outline other disadvantages of gasifying heat sources:

- 2 chambers, a brick or ceramic lining plus a water jacket in the lower part of the body - the listed design solutions significantly increase the weight and size of the units;

- high requirements for fuel quality;

- coolant with a temperature of 80 °C is rarely used when heating private houses, which means that you cannot do without an expensive heat accumulator + piping elements;

- Ceramic lining parts do not last forever - the nozzle may crack due to overheating and will have to be replaced.

It must be said that pyrolysis boilers attract home craftsmen. But making such a unit with your own hands is very difficult; you need experience and investment in purchasing materials. It is not possible to make a heater for free. It is much easier to weld a regular or mine boiler.

Note. Judging by the reviews of boiler owners on thematic forums, it is still possible to use raw firewood. The algorithm is as follows: the unit is melted and warmed up with dry logs, then wet wood is added. But the share of such fuel should not exceed 30%, otherwise soot and soot will form. Let's listen to the expert's opinion in the video:

Operating modes of a gas generator boiler

All pyrolysis boilers operate in three modes:

- ignition mode. In this operating mode of the pyroboiler, the throttle valve is maximally open, and the flue gases are discharged directly into the smoke vent duct;

- operating mode – the gate is completely closed, the pyrolysis process takes place in the chamber. Air supply, depending on the boiler model, is provided either naturally or forcedly;

- additional loading mode – the process of decomposition of solid fuel under the influence of temperatures continues, the throttle valve is open, additional fuel is being loaded.

Additional fuel loading should be carried out quickly to avoid filling the air with carbon monoxide and heat losses.

Device

The huge chamber is designed for storing solid fuel: coal, firewood and other flammable substances. Firewood or other fuel flares up, then the air is automatically shut off. For the flame to be intense, air is needed. There is not enough oxygen for intense combustion, and the wood begins to smolder. Wood gas and a lot of carbon are released - ash particles. Air and ash particles are mixed in another chamber and the afterburning process occurs. Both chambers are separated by a special grid on which fuel is stored. The peculiarity of fire in such a device is that it has a reddish tint due to the reaction with carbon.

Scheme of operation of the pyroboiler

The pyrolysis boiler circuit consists of the sequence of the following processes:

- loading fuel into the boiler furnace, ignition;

- after the fuel has ignited, the damper is closed, the combustion process gradually enters the smoldering stage;

- through the primary channel, outside air is supplied to the loading chamber, part of which is used to maintain the smoldering process and achieve the required gasification temperature;

- pyrolysis gases enter the combustion chamber through the grate;

- to ensure the combustion process of pyrolysis gases, air is supplied to the afterburning chamber through a secondary channel;

- volatile products burn, releasing a certain amount of heat, part of which is directed under the grate and used to maintain pyrolysis, the second goes directly to heating the boiler;

- waste combustion products pass through a water heat exchanger and are discharged into the chimney;

- maintaining the optimal combustion temperature is supported by a thermal control system.

Additional information about the operation of a pyrolysis boiler can be found in the video

What is pyrolysis?

Pyrolysis refers to the process of producing and subsequently burning combustible gas. Pyrolysis is a characteristic process for solid fuel boilers. The fuel is placed in a closed chamber and the amount of air in it is gradually reduced. Firewood or coal begins to smolder. Carbon dioxide released during fuel combustion enters another compartment and is mixed with air heated to a certain temperature. Re-combustion occurs. The main advantage of pyrolysis: it increases the amount of burning time and, accordingly, the amount of heat. In the open air, any fuel burns quickly and produces a minimal amount of heat. In the 50s of the last century, engineers invented a circuit for the latest equipment suitable for pyrolysis. Due to the high cost and lack of justification, development did not begin.

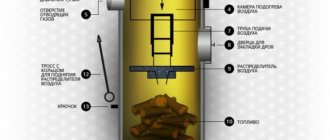

What does a gas generator set consist of?

The main difference from a classic wood-burning boiler is the presence of an additional combustion chamber in which the gas released is burned , and in the primary firebox it is generated from wood with an insufficient amount of oxygen. The layout of the chambers and the design of the pyrolysis boiler can be different, the firebox can be located either below or above, this does not change the principle of operation. Traditionally, it is located below, above the ash pan, into which a drawer is placed for ease of cleaning. The ash pan lid tilts up and in operating mode serves to regulate the amount of air entering the firebox. This is realized using a chain drive, which is tensioned or released by a thermostat. The latter is installed at the top of the boiler.

Operating principle of a pyrolysis boiler

All the main elements and details of the installation can be seen by studying the detailed drawing of the pyrolysis boiler. The main firebox is equipped with a door for loading firewood and is tightly closed during operation. Above it there is a secondary combustion chamber in which air supply devices are located. They may have different configurations in devices from different manufacturers, but their task is the same: to supply heated air into the afterburning chamber through many holes of a certain diameter. The air is heated along the path from the ash pan door to the distributors.

The design of the pyrolysis boiler provides for the possibility of cleaning the upper afterburning chamber; for this purpose it is equipped with a special door. The spaces of both chambers are connected to each other by a channel through which gases rise for combustion. The outer shell of the housing is a water jacket, heated by both fireboxes. To supply coolant to the heating system, threaded pipes are cut into it. Water temperature and pressure are controlled using instruments installed on the front panel.

The chimney for a pyrolysis boiler is no different in its design from the pipes for the emission of combustion products of classical units. One of the requirements is sufficient draft for the boiler to operate. The simplest design of the unit does not provide for the installation of a blower fan, so combustion occurs due to natural draft. The second requirement is that the part of the pipe located outside be insulated. The reason is the low temperature of the flue gases (up to 150 ⁰C), so there is a very high probability of condensation forming on it and rapid destruction of the pipe material.

A little chemistry and physics

The physical and chemical processes occurring in pyrolysis boilers are also interesting. The operating principle of traditional units is direct combustion, when the flame plays directly on the surface of the firewood. Here everything happens differently. Combustion in the main firebox occurs at approximately +400-500 degrees, which is an order of magnitude less than in traditional units. Going to the afterburning chamber, the pyrolysis products burn at temperatures up to +1100-1200 degrees.

The maximum temperature is observed at the very end of the torch, the minimum temperature is at its base.

A blower fan allows you to inflate the flame of pyrolysis gases to very high temperatures. Instead, a blower is sometimes used, but the effectiveness of such a solution leaves much to be desired.

Another interesting difference in operating principles is the temperature of the exhaust gases. In traditional heating units it is +300-400 degrees. In pyrolysis units it is +140-160 degrees - slightly higher than in gas units. This means that the overwhelming majority of the heat went into the heating system and did not go into the atmosphere.

Pyrolysis products in pyrolysis boilers are created in an oxygen-poor environment - just like in that glass tube in physics class. The draft can be artificial, as in the example above, or natural, as is implemented in non-volatile pyrolysis boilers. Otherwise the principle of operation is the same. Once in the afterburning chamber, the gases burn to form a high-temperature flame. Moreover, the combustion is quite deep, with minimal release of harmful carbon and nitrogen oxides.

There are a huge number of pyrolysis boilers on sale, differing in their design. But their operating principle is the same.

Advantages and disadvantages

The main advantages of a pyrolysis boiler include the fact that thanks to its use you can significantly reduce the cost of firewood. The consumer has the opportunity to ensure maximum long-term combustion due to the operating principle of the boiler. The house is heated, and there is no need to worry about adding firewood. The average burning time of one batch of fuel is as much as 12 hours; you will have to approach the device no more than twice a day. An ideal boiler for burning duration. An environmentally friendly choice, the fuel is burned completely and the emission of harmful substances into the atmosphere is minimal.

Such a device has its disadvantages, the most common include:

- During the cold off-season, firewood consumption increases;

- The ash evaporates into the chimney, simultaneously polluting it and everything around it;

- In the event of a breakdown or incorrect operation, it is quite possible that there will be an overconsumption of firewood, the ash will not evaporate;

- Wet firewood is absolutely not suitable. A lot of energy is spent drying them. They don't smolder.

- Quite a high price;

With your own hands

Below is a 25-minute video of designing and making your own pyrolysis boiler. The author describes the assembly process step by step and also talks about the difficulties encountered.

Possible mistakes:

- Wrong alloy. The most common mistake, which, by the way, is typical not only for home-made models, is the use of the cheapest materials from ferrous metals. They do not belong to the category of heat-resistant materials, which ultimately leads to burnout of the structure and difficult, or even simply impossible, repairs. It is necessary to carefully select the steel grade and use special heat-resistant alloys. For example, 20Х23Н18 and the like.

- Small thickness of steel. Another mistake is the incorrectly selected thickness of the steel sheet. This parameter is determined based on the temperature distribution throughout the boiler, but the minimum value is about 5 mm. The thicker it is, the more expensive it is, but then the boiler will work longer.

Blueprints

An attraction of unheard of generosity – there’s no other way to describe it! From us you can download drawings of pyrolysis boilers completely free of charge. This will allow you to assemble the heart of the heating system in your backyard or garage if you wish.

We present long-burning boilers, which you can find under the Bourgeois K brand. Drawings of a 20 kW boiler can be downloaded for free from the link below.

- .

- ;

See examples of graphic materials in the images below.

You also have a unique opportunity to order a set of drawings for one of the models at a very attractive price. Of course, this is an option for those who are going to make a boiler with their own hands, not only for themselves, but also to order. To contact, use the form below.

Range

The products are widely represented, since the extraction of pyrolysis gas has been known for quite a long time and the technology has been tested in the chemical industry.

As a rule, most large manufacturers of boiler equipment also have a line of long-burning boilers. In the table below we have indicated the most popular heating equipment from Russian, Ukrainian and German manufacturers. Before considering a specific model, it is strongly recommended to calculate the boiler power using our small online calculator. Popular models of pyrolysis boilers for private homes

| Boiler name | Short description | Model | Power / approximate heated area, kW/m2 | Approximate price, rub. |

| Atom, Motor Sich | Ukrainian, for firewood with dimensions (380–1000)×(100–410) mm and humidity up to 50%. Walls made of steel 6–10 mm, protected with ceramic concrete | MS-16 | 8–19/80–190 | 120 000 |

| MS-25 | 13–30/130–300 | 138 000 | ||

| MS-32 | 16–38/160–380 | 162 000 | ||

| Teplogarant, Burzhuy K | Russian single-circuit boilers are low cost | Standard T-10 | 10/100 | 40 000 |

| Standard T-20 | 20/200 | 56 000 | ||

| Standard T-30 | 30/300 | 69 000 | ||

| Atmos | Czech equipment made of steel 3–8 mm thick, individual elements of which are protected by ceramic blocks | DC 15E | 10–15/100–150 | 72 000 |

| DC 18S | 14–20/140–200 | 81 000 | ||

| DC 22S | 15–22/150–220 | 94 000 | ||

| DC 25S | 17–25/170–250 | 96 000 | ||

| Vulcan | Ukrainian single-circuit steel 5 mm thick. The nozzle and ash pan are made of high-strength heat-resistant concrete | ECO 15 | 15/80–100 | 81 000 |

| ECO 20 | 20/150–200 | 85 000 | ||

| ECO 25 | 25/200–250 | 87 000 | ||

| ECO 30 | 30/250–300 | 91 000 | ||

| Miracle | Russian pyrolysis boilers can be equipped with an electric heating element, automatic or manual draft regulator | 10 | 8–12/100 | With a manual draft regulator: with a heating element – 55,000, without a heating element – 49,000. With an automatic draft regulator: with a heating element – 66,000, without a heating element – 59,000 |

| 18 | 12–18/185 | With a manual draft regulator: with a heating element – 65,000, without a heating element – 59,000. With an automatic draft regulator: with a heating element – 76,000, without a heating element – 69,000 | ||

| 30 | 18–30/300 | With a manual draft regulator: with a heating element – 82,000, without a heating element – 75,000. With an automatic draft regulator: with a heating element – 91,000, without a heating element – 84,000 | ||

| Trajan (some write Trojan) | Russian long-burning boilers with the ability to connect an electric heating element | T10 | 10/90 | 47 000 |

| T15 | 15/120 | 51 000 | ||

| T20 | 20/120–220 | 56 000 | ||

| T30 | 30/240–330 | 70 000 | ||

| Buderus (Buderus) | German single-circuit boilers | Logano S121-2 21 | 21/210 | 163 000 |

| Logano S121-2 26 | 26/260 | 166 000 | ||

| gano S121-2 32 | 32/320 | 177 000 | ||

| Viessmann | Another award-winning German manufacturer of boilers made of steel with a thickness of at least 8 mm | Vitoligno 100-S VL1A024 | 25/250 | 170 000 |

| Vitoligno 100-S VL1A025 | 30/300 | 220 000 | ||

| Geyser | Russian single-circuit (PK) or double-circuit (PK2) long-burning boilers | PK-10 (PK2-10) | 10/100 | 48 000 (51 000) |

| PK-15 (PK2-15) | 15/150 | 53 000 (56 000) | ||

| PK-20 (PK2-20) | 20/200 | 59 000 (61 000) | ||

| PK-30 (PK2-30) | 30/300 | 72 000 (76 000) | ||

| BTS | Ukrainian boilers made of steel with a thickness of 5 mm (standard class) and 6 mm (premium class). Ceramic lining | BTS-15 | 15/180 | 117 000 |

| BTS-20 | 20/230 | 121 000 | ||

| BTS-25 | 25/280 | 139 000 |

We invite you to watch a short video about the operation of Trajan boilers.

A little visualization of the work of Buderus pyrolysis boilers is in the video below.

And also about the rather popular boilers from TeploGarant - Bourgeois K.

Yes, by the way, there are models that are designed to work with different fuels. This can be coal, peat and even pellets. The use of pellet boilers allows you to largely automate the fuel supply process.

Reviews

Among the sea of custom reviews, it is very difficult to find opinions that are truly unbiased and based on real impressions. What users usually complain about:

- excessive formation of tar due to the fact that the required high temperature is not maintained in the combustion chamber;

- the need to install an additional buffer tank with water, which will accumulate excess heat;

- small steel thickness, which leads to changes in the geometry of the body and burnout of its individual parts.

How much will materials and spare parts cost?

Exactly how much a home-made pyrolysis boiler will cost depends on the required power and the chosen design. However, if you buy heat-resistant steel, grates, make lining, install automation (albeit inexpensive), the amount runs up to $850-1200. These are the costs of materials and components, but with independent welding. They are voiced by those who have already welded and used a pyrolysis machine. If you have to pay for welding, then the costs must be doubled.

As you can see, in the case of mastering welding, there are savings, but they are far from the greatest. You can find ready-made options for solid fuel pyrolysis boilers for $1,500. Although, as you know, a cheap product has a low price for a reason. They saved on something there. And we can even guess on what: on the lining. It is the secrets of protecting the walls of the furnace from burning out that manufacturers protect most of all, and spend a lot of money on research in this area. That’s why high-quality equipment costs a lot of money.

Review of popular models

It should be understood that any pyrolysis boiler is a fairly heavy unit that is not intended for hanging on the wall. Such devices can be used both for heating a small house and spacious cottages. Like other heating units, long-burning boilers vary in power.

When choosing a pyrolysis combustion boiler, you should focus on such indicators as the thermal power of the device, the size of the loading chamber, the presence of a secondary circuit, etc.

Buyers usually focus on this indicator.

Among the popular models of such equipment we should mention:

- Atmos (Ukraine) - presented by devices that can operate on both wood and coal, power varies from 14 to 75 kilowatts.

- Attack (Slovakia) - capable of heating areas up to 950 sq. m, some models are able to continue working even during power outages.

- Bosch (Germany) - high-quality products from a well-known brand, power varies between 21-38 kilowatts.

- Buderus (Germany) is represented by the Elektromet and Logano , the first is well known in Europe as a classic version of a pyrolysis boiler, the second is more modern versions intended for private homes.

- Gefest (Ukraine) - high-power devices with efficiency up to 95%.

- KT-2E (Russia) is specially designed for large residential premises, the unit power is 95 kilowatts.

- Opop (Czech Republic) - relatively inexpensive boilers, reliable and durable, power 25-45 kilowatts.

- Stropuva (made in Lithuania or Ukraine) with a power of seven kilowatts or more are quite suitable for a small home, but the model range also includes more powerful devices.

- Viessmann (Germany) is an ideal choice for private households, power starts from 12 kilowatts, the use of modern technologies allows you to save fuel.

- “Buran” (Ukraine) with a power of up to 40 kilowatts is another popular option for owners of large cottages.

- “Logika” (Poland) high-power devices of 20 kilowatts easily heat rooms up to 2 thousand square meters. m, it is more of a boiler for industrial needs: heating workshops, offices, greenhouses, etc.

When choosing a pyrolysis boiler for a private home, you should pay attention to models with two circuits, in order not only to heat the home, but also to provide it with an autonomous hot water supply.

The heat exchanger for hot water supply can be storage or flow type. For the latter option, boiler models with increased thermal power are used.

If you want to save money, you can try making a pyrolysis boiler with your own hands. The technology for its assembly is described in this article.