Sawdust is an excellent material for heating houses and greenhouses.

They are made of wood, which means that when used correctly, they are only slightly inferior in heat capacity to firewood.

You can get them cheaply , and in some cases even for free .

Next we will tell you about different methods of heating different rooms with sawdust:

- houses;

- makeshift;

- greenhouses

We will also consider in detail all types of heating stoves and long-burning boilers that can use sawdust as fuel.

How sawdust burns

Before talking about the features of sawdust boiler houses, it is necessary to understand the combustion mechanism of this fuel itself, because it is very different from the combustion mechanism of wood.

No matter how tightly the firewood is stacked, air always passes , and in sufficient quantity to support combustion.

Even loose sawdust allows much less air , so smoldering quickly dies out without supplying additional air to the combustion zone.

Sawdust burners only work effectively when the fire moves from top to bottom . Therefore, only a layer of sawdust 2–5 cm thick constantly burns.

Due to the fact that only a small amount of fuel is involved in combustion, the power of sawdust boilers and stoves operating on them, while being the same as wood and coal heating appliances, is 2–3 times less .

Another factor that reduces the power of a boiler or furnace is the low combustion temperature of sawdust.

If wood burns with the correct air supply, the flame temperature exceeds 1000 degrees, often reaching 2000 degrees in the tongues of fire. Moreover, this is a powerful fire , because the entire mass of firewood emits pyrolysis gases.

The fire temperature of burning sawdust, even with proper air supply, does not always reach 1000 degrees due to the weak flow of pyrolysis gases .

Pyrolysis gases effectively exit only from the top layer 5–15 mm .

Gas comes out with difficulty from burning or heated sawdust located below, because the sawdust located above interferes with it.

Despite such disadvantages, sawdust is ideal for long-burning boilers and furnaces.

After all, well-compacted sawdust burns for a very long time .

Often, a homemade iron stove burns for 5–8 days with one load of sawdust, providing heating for the entire house.

Automation tools

Automation requires a special control unit - the automation of a solid fuel boiler does not have the appropriate capabilities. The auger and blower motors, as well as temperature sensors, are connected to the controller. Receiving a signal from the sensors, the controller will control the operation of the engines, regulating the fuel supply and traction.

The homemade product can also be equipped with a device for automatic ignition and flame control with a photosensor, which are also controlled by the controller. The filling sensor in the fuel pipe will allow you to control the supply of bulk energy.

The use of automation equipment significantly increases the cost of the unit, but makes it as convenient to use as possible.

Automation of boiler operation using a pellet burner

Suitable heating systems

For heating private houses and any buildings with sawdust, the following systems :

- heating stoves;

- heating stoves with a water heating register or heater;

- water heating with radiators;

- water heated floor;

- air heating;

- air heated floor.

Heating stoves heat the space around them , so they are suitable only for small houses . At a distance of 10 meters from the stove, the temperature drops by 10–15 degrees, so in large houses the stove can only act as an additional heater.

Heating stoves with a water heating register or heater combine the advantages of stoves and boilers. They provide the same heat as a conventional heating furnace and heat the coolant, which is supplied through pipes or ducts to remote rooms.

The large mass of the stove turns it into a heat accumulator , thanks to which you do not have to re-light the boiler every 2 hours or add firewood to it every hour. The stove will maintain the coolant temperature for up to 6–10 hours , so you can heat it 2–3 times a day.

Water heating with radiators in each room can be used with either a water boiler or a sawdust stove if it has a water register . Like any other water heating, it can operate on natural or forced circulation of coolant.

natural circulation systems, hot water first rises to the ceiling, then descends into each room and flows either to the radiators or to the heated floor. In systems with forced circulation, water is driven by a pump, so all pipes can be laid under the floor.

Water and air heated floors not only heat the room, but also improve its microclimate. In winter, it is very pleasant to walk barefoot on the floor, feeling its warmth with your feet. The main disadvantage of a heated floor is the high cost of materials and work, because it is necessary not only to lay air ducts or a water pipe, but also to properly insulate the space between the floor and the ground or foundation.

Air heating is just as expensive as underfloor heating, because it is necessary to lay air ducts throughout the house, as well as install automatic humidifiers due to the strong drying of the air. Ovens with heaters can be used as a heat source.

The only difference between furnaces and boilers is that the boiler has

a water jacket , that is, the space between the hot body and the outer casing is filled with water.

Here are the distinctive features of each heating device:

- stove - direct heating of the air and surrounding space;

- heater - heating air for delivery to other rooms without heating the surrounding space;

- stove-heater - heating the surrounding space and heating air for delivery to other rooms;

- stove with register - heating the surrounding space and water for delivery to other rooms;

- boiler - heating water for delivery to other rooms.

Therefore, air heaters and boilers are installed in utility rooms and are often insulated from the outside. After all, it makes no sense to waste thermal energy on strong heating of the utility room, and the less heat spent on this, the more will go to other rooms.

Two in one - smokehouse with stove

An interesting option for making a smokehouse with your own hands is when a stove is built directly in the body of the washing machine, which heats the sawdust. That is, not only the tank is involved here, but also the metal body itself.

The sequence of actions is as follows:

We remove the engine from the car, take out the tank, and cut a rectangular hole in the body.

Cutting a hole for the firebox

We seal the tank: to seal the holes without welding, you can use self-tapping screws with metal plates on them, they will close all the holes.

A grill from a refrigerator, oven, or some other mesh is suitable as a shelf for food. We weld it inside the tank.

We seal the lid - also using a plate and self-tapping screws. We install the tank in its original place. We put about 100 grams of sawdust on the bottom and place food on the grate.

If you don't have a washing machine, you can replace it with a barrel!

We make a fire through a sawn hole under the tank. If it is undesirable to do this on the surface where the smokehouse stands, then it is good to weld a metal sheet inside and place firewood on it. When the smoke starts, you need to note the time required to smoke a particular product. During the process, it is advisable to check the condition of the meat or fish and ensure that the wood chips do not overheat.

To prevent sawdust from burning, it is recommended to slightly moisten it. Another option is to use fresh, not dried wood chips. Under no circumstances should you use coniferous wood for smoking; alder and fruit trees and shrubs are ideal.

Requirements for heating devices

For heating with sawdust, it is necessary to use long-burning boilers and stoves that meet the following conditions :

- fuel combustion from top to bottom ;

- large outer surface area (important for stoves);

- large area of the heat exchanger or water jacket;

- large volume of firebox ;

- possibility of supplying air to the combustion zone.

Due to the small size of sawdust, they can be fed into the stove or boiler automatically, which further increases the battery life of the heating device. Most often, an auger feed is used for this - a rotating auger lifts or lowers sawdust from the hopper and scatters it in the combustion zone.

When there is too much ash, the heater is stopped and cooled to clear the ash and reload it with fuel.

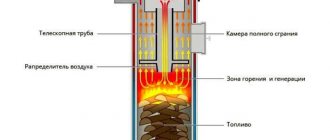

Boilers and long-burning stoves of the Stropuva type (Russian analogue of Bubafonya) are well suited for heating with sawdust. These devices implement the principle of top combustion of wood , and air enters directly into the combustion zone.

Long-burning stoves and boilers running on sawdust can not only be bought, but also made with your own hands. Homemade devices also implement the requirements for heating devices described above.

Popular models

- Svetlobor is a domestic manufacturer that offers fully autonomous installations. They can operate without human intervention for months, limited only by the amount of stored fuel. However, you will have to pay a lot for automatic operation. So, a 25 kW boiler costs about 400,000 rubles.

- "Froling" - an Austrian company offers boilers that operate on wood chips, pellets and shavings. Control over the work can be exercised while in another city, via SMS or the Internet. The cost of a 15 kW T4 boiler will be more than 800,000 rubles.

- "FACI FSS" is an Italian-Russian production. You can order installation with a selected set of automation functions. For example, a boiler with a power of up to 115 kW without additional automation costs 400,000 rubles. If there is automatic cleaning of the heat exchanger, ash removal, GSM-Module (remote control) - 600,000 rubles.

- "TERMAL" (Macedonia). Series “SF” - indicates the presence of a mechanism for automatic fuel supply. A household unit with a power of up to 28 kW costs just over 200,000 rubles. The device can be equipped with a burner for burning waste or diesel fuel.

Furnaces and boilers for working on sawdust

There are 2 types of fireboxes, which differ in the method of air supply :

- from above , through a descending air duct;

- from below , through a pre-made channel in the sawdust.

The most famous furnaces and boilers of the first type are devices under the Stropuva brand. They are produced both in the form of stoves and boilers.

As we already said in the article (Fuel from sawdust), the difference between stoves and boilers is that the former heat the air directly , and the latter heat the coolant . Then the coolant, which can be either water or air, flows through pipes into the rooms and heats them.

With drop-down duct

Long-burning furnaces and boilers in Stropuv are designed as follows :

- the body is made of pipe with a diameter of 50–70 cm ;

- two doors cut into this housing - a loading door on top and a cleaning door on the bottom;

- a telescopic pipe passes through the lid (in homemade devices it is replaced by a regular long-length pipe) - an air duct;

- a steel circle with a thickness of 10 and a width slightly less than the internal diameter of the housing is welded to the bottom of the air duct

- a chain or steel cable is attached to the upper side of the disk to lift the air duct;

- corners or channels are welded to the bottom side of the disk , creating an optimal gap between the disk and the fuel;

- The smoke exit hole is made slightly above the cleaning door.

The following boilers and furnaces operate on sawdust:

- by lifting the air duct using a cable or chain, the stove or boiler is loaded with sawdust, compacting it as much as possible;

- Having loaded sawdust, kindling is placed - paper and various wood chips;

- after waiting for the kindling to flare up, lower the air duct and close the loading door;

- the air supply is set to maximum , due to which the top layer of sawdust flares up and the stove/boiler goes into operating mode;

- fire and smoke rise through the space between the disc and the housing and heat both the duct and the housing ;

- the furnace begins to radiate heat , and the boiler heats the water jacket ;

- As the sawdust burns, its level becomes lower and the air duct descends after it, this system ensures a constant flow of air into the combustion zone and an optimal fuel combustion mode .

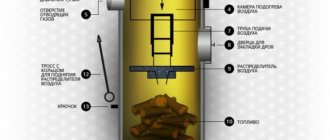

With bottom air supply

Boilers and furnaces without a lowering duct are designed and operate slightly differently. Their air duct approaches the firebox from below .

Such heating devices are loaded through a hinged lid . The chimney is connected just below the hinged cover.

The hinged lid is sealed with asbestos cord or tape.

During loading, a long cone-shaped wooden plug is inserted into the air duct (the upper diameter is 1.5–3 times larger than the lower one).

The sawdust is compacted tightly and after loading is completed, the plug is pulled out - air flows through the resulting channel to the upper burning layer of sawdust.

Kindling is placed on the sawdust and set on fire. When the kindling has flared up, close the hinged lid, setting the chimney damper and the air supply regulator to maximum draft mode.

After the sawdust has flared up, the air supply is reduced and the stove or boiler goes into a prolonged burning (smoldering) mode.

Fuel supply mechanism

Solid fuel heating boilers operate autonomously and can be done with virtually no maintenance. Sawdust is supplied using several means.

The receiver has open access to the outside of the building. It is equipped with a screw drive connected to the storage. When the bunker is fully loaded with fuel, the conveyor starts working - it supplies fuel to the mechanized compartment.

There are two types of storage, they differ in the technique of feeding sawdust into the boiler:

- a hopper with an inclined base, cone-shaped, with a screw mechanism in the lower part;

- agitator with blades, sawdust is loaded by rotation.

Not all fuel from the storage goes directly into the firebox. Wood chip boilers of the pyrolysis type are equipped with a drum and a screw transmission, which supply fuel in parts.

Stoves, boilers and heaters: which is better

When choosing sawdust heating, you must consider the following:

- the volume of water in the water jacket of the boiler should be 10–15% of the total volume of water in the heating system, therefore it is advisable to use forced movement of water through thin tubes;

- Stropuva water boiler 65 thousand rubles , and the price of sawdust boilers made by yourself is 30–50 thousand rubles , including the cost of material;

- air heating not only heats, but also dries the air ;

- water heating pipes can be hidden under the finishing, but air heating pipes will have to be laid in plain sight due to their large cross-section (pipe diameter in cm is equal to half the area of the room in m²);

- it is very difficult to find long-burning industrial heaters (boilers and furnaces that heat air, which is then supplied through pipes through pipes) using sawdust , and their cost often exceeds the price of the Stropuva boiler;

- the cost of manufacturing air heaters is comparable to the cost of manufacturing a boiler;

- the costs of material and installation of water and air heating are approximately the same and amount to 15–20 thousand rubles for one room measuring 15–20 m2;

- the cost of manufacturing a stove is 20–50 thousand rubles , depending on the size.

Heaters and boilers are well suited for heating large houses , because they heat the coolant, which then flows through pipes or ducts to remote rooms. For small houses, it is preferable to have a stove installed at the junction of all rooms.

If someone is not satisfied with the appearance of an iron stove , it can be covered with a brick grate - it will improve the appearance of the stove and will not interfere with air movement.

Sawdust and wood chips: their effectiveness as solid fuel

Shredded wood obtained from processing logs or specially prepared from industrial waste is called sawdust and can be used as fuel. The raw materials for boilers are wood waste such as:

- slabs of various species, ash boards, wood chips of various shapes and sizes;

- fresh sawdust or outdoor storage, different humidity and age;

- shavings are dry, small and long, stale, in varying degrees of preservation;

- furniture that has fallen into disrepair, remains of building structures, doors, pallets.

Raw materials that are preparing to become fuel must comply with the requirements of GOST 33103.1 - 2014:

- do not have toxic chemical compounds released during combustion and metal inclusions (nails, hinges in the remains of fiberboard, chipboard);

- contain no more than 0.5% mineral impurities, 5% rot and 8% tree bark.

The resulting biomass is sifted to obtain sawdust fractions up to 30 mm in size . This parameter is critical for the operation of the feed mechanisms of automatic boilers and affects the combustion process. Smaller sawdust requires more air injection for complete combustion than those specified by GOST requirements.

This is what bulk fuel looks like in the photo. On the left is sawdust, on the right is wood chips.

Ash content is a parameter that determines the amount of resulting fuel combustion waste. The higher the ash content, the more often the boiler is cleaned, the lower the calorific value of the fuel. The presence of formaldehyde and other toxic chemicals in sawdust used as fuel in household boilers is unacceptable and requires other disposal. The most important parameter that determines the amount of heat produced from sawdust is humidity. It can significantly change the ability of an automatic boiler to perform its functions. It is advisable to control this parameter before loading and be able to bring sawdust in accordance with the requirements of the boiler manufacturer.

When concluding contracts for the supply of sawdust to fuel an automatic boiler, not only the price, but also the quality of the supplied products is important. Based on the requirements of GOST 33103.1 - 2014, we recommend that the sawdust parameters be clearly stated in the contract. Compliance with these points will allow you to operate the unit for a long time and with full heat transfer. Having a supplier nearby with a good price and decent quality of fuel is the main point when choosing a solid fuel boiler for heating your home.

Sawdust as a fuel for automatic boilers has the following advantages:

- The efficiency of even budget automatic boilers using sawdust is up to 90%;

- availability of high-quality raw materials for fuel;

- low cost of raw material from wood processing industries;

- a correctly selected and configured boiler burns environmentally friendly fuel with a minimum of smoke, soot and ash;

- interruptions in quality sawdust are easily covered by any solid fuel (chips, firewood, coal, raw sawdust) with loss of efficiency, but without catastrophe.

But the disadvantages of sawdust are also significant:

- transportation from wood processing industries requires appropriate packaging since this wood waste material is free-flowing and bulky, especially in dry form;

- equipment for a seasonal sawdust warehouse requires a separate building with good ventilation and compliance with fire safety standards SNIP and PPB;

- periodic maintenance of the sawdust conveyor to the boiler, cleaning the chimney, monitoring the humidity of raw materials.

To determine how effective sawdust and wood chips are as fuel for heating boilers, we compared the characteristics of the most common types of fuel in one table:

| Type of fuel (W – humidity) | Calorific value kW/kg | Efficiency,% | Fuel price, rub./ton (m3) | Cost of kW of energy, rub. |

| Brown coal (w up to 40%) | 3,6 | 70 | 3 200 | 1,27 |

| Hard coal (w from 7 to 15%) | 7,5 | 70 | 7 000 | 1,34 |

| Anthracite (w from 1% to 3%) | 8,7 | 70 | 8 500 | 1,40 |

| Natural gas | 10,3 | 90 | 5 700 | 0,65 |

| Firewood (w 60-50%) | 2,2 | 60 | 1 500 | 1,05 |

| Firewood (w 30-20%) | 3,1 | 60 | 1 800 | 0,83 |

| Granules (pellets) | 4,7 | 85 | 9000 | 2,25 |

| Crushed chips (w up to 20%) | 2,0 | 95 | 200 | 1,33 |

| Sawdust (w up to 20%) | 0,81 | 95 | 120 | 1,33 |

| Briquettes (eurowood) | 4,3 | 85% | 8500 | 1,65 – 2,32 |

Installing a coolant register

Now you can think about connecting the boiler to the heating system. To do this, you will need to install a register at the chimney outlet of the boiler.

The figure clearly shows the installed register with the connected supply and return connected to the central heating system. This is one option, you can use a completely different one. The main thing is that it corresponds to the thermal parameters of the boiler you have manufactured and fully satisfies the volume of the installed radiator heating system.

We will not dwell in detail on the structure of the register. Let's say one thing: the closer to the boiler it is installed, the more efficiently it works.

Pipelines connected to the register