Operational and adjustment tests (RNT) of boilers:

1) Drawing up and agreeing with the Customer on a program for operational testing of boilers; 2) Adjustment of boilers in accordance with the test program under technological load: 30%, 55%, 75%, 95%; 3) Detection of air suction into the furnace and flue ducts of boilers; 4) Determination of technical and economic parameters (gross efficiency, heat losses, specific fuel consumption per 1 Gcal of generated heat), environmental (O2 concentration; CO; NO; SO2 in flue gases) and operational indicators of boilers; 5) Determination of the actual aerodynamic resistance of the air and gas path of boilers; 6) Determination of the optimal fuel-air ratio for setting up automation systems; 7) Issuing recommendations and measures to improve the reliability and efficiency of the main and auxiliary equipment; Processing of test materials, preparation and issuance of technical reports valid until the next equipment adjustment; 9) Registration of regime maps, in accordance with the Guidelines for drawing up regime maps of boiler installations and optimization of their management (RD 34.25.514-96) for maintenance personnel, indicating optimal operating modes, valid for 5 (five) years until the next equipment adjustment .

2) Adjustment of boilers in accordance with the test program under technological load: 30%, 55%, 75%, 95%; 3) Detection of air suction into the furnace and flue ducts of boilers; 4) Determination of technical and economic parameters (gross efficiency, heat losses, specific fuel consumption per 1 Gcal of generated heat), environmental (O2 concentration; CO; NO; SO2 in flue gases) and operational indicators of boilers; 5) Determination of the actual aerodynamic resistance of the air and gas path of boilers; 6) Determination of the optimal fuel-air ratio for setting up automation systems; 7) Issuing recommendations and measures to improve the reliability and efficiency of the main and auxiliary equipment; Processing of test materials, preparation and issuance of technical reports valid until the next equipment adjustment; 9) Registration of regime maps, in accordance with the Guidelines for drawing up regime maps of boiler installations and optimization of their management (RD 34.25.514-96) for maintenance personnel, indicating optimal operating modes, valid for 5 (five) years until the next equipment adjustment .

What does the boiler operating map display?

Almost all indicators, which, as a rule, consist of this document, are indicated in percentages.

These indicators provide us with the following data:

- gases in percentage: carbon, oxygen, carbon monoxide;

- the volume of gas that is located outside the boiler structure;

- efficiency factor of the unit (gross, net);

- the amount of heat losses that accompany the process of burning fuel (including gas);

- amount of heat loss due to chemical underburning;

- the percentage of heat that is lost when the heaters operate.

These are only the main indicators in the boiler operation chart; there are several additional ones:

- the volume of steam that is formed over a certain time period;

- steam temperature at outlet;

- air pressure in burners;

- gas pressure.

All indicators have their own units of measurement - degrees, for example, pascals, etc. All boilers must have regime maps.

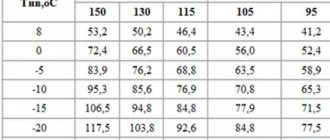

Example of a boiler operating map

Such cards are needed for the competent operation of gas and steam devices, as well as water heaters.

The main advantage of this document, which allows you to monitor the performance of the unit, is that when using it, you can independently observe all functional changes. Let’s say you can understand the degree of air pressure required for a certain load on the equipment. In addition, the fuel must burn completely and the equipment must be safe.

You can find out what the service life of a gas boiler depends on in this article

Operational and adjustment tests of the chemical water treatment plant (hereinafter referred to as the WTP):

1) Drawing up and coordination with the Customer of a program for operational and commissioning tests of the ToVP; 2) Adjustment of the boiler room HVP system is carried out in accordance with the load test program within the boiler operation limits (30%-95% of the boiler load); 3) Calculation of operating standards: quantity, productivity of devices, temperature, dose of reagents, water consumption during purging, rinsing, regeneration, under various operating conditions of the HVP installation; 4) Identification of the main values of excess consumption of water, acid and salt for regeneration; 5) Selection of favorable operating modes of the water vapor treatment plant with the preparation of regime maps, in accordance with the Methodological guidelines for the development of instructions and regime maps for the operation of pre-boiler water treatment plants and for maintaining the water chemistry regime of steam and hot water boilers (RD-10-179-98), for maintenance personnel indicating the optimal operating modes, valid until the next adjustment of the equipment; 6) Processing of test materials, preparation and issuance of technical reports, valid until the next adjustment of equipment, indicating the maximum permissible indicators of water quality: mineralization (salinity), total hardness, total alkalinity, content of suspended impurities (transparency), oxidability, iron content, value pH and other indicators that affect the operation of cold water heaters, as well as condensate returned from production, and condensate after water heaters (mains, DHW).

Water treatment plants

The main identified shortcomings in the operation of water treatment plants of most thermal power plants (in addition to unsatisfactory technical condition) are:

- technologically unregulated (for various reasons) operating mode of the water pre-treatment plant (clarifiers) with frequent systematic violations leading to deterioration in the quality of coagulated water;

- also, for various reasons (including due to disruptions in the operation of the pre-treatment unit), the operating mode of the ion exchange part of the VPU is not adjusted;

- Due to certain reasons, the operation of the VPU is not always correct.

These shortcomings lead to the fact that water treatment plants produce water of worse quality and are operated with much less efficiency than they could even with their current technical condition.

The operating mode of water treatment plants not in accordance with the requirements of industry regulations leads to increased (often several times) specific consumption of chemical reagents (sulfuric acid, sodium hydroxide), to increased water consumption for the own needs of the water treatment plant and, thus, to increased operating costs. Some of the identified problems can be solved with relatively low financial investments in the repair, replacement or modernization of equipment, ensuring in the future optimal operation modes of the equipment and, accordingly, saving resources.

Let us give two examples of deficiencies identified during technological inspections that have an extremely negative impact on the efficiency and reliability of the operation of the water pumping unit.

Example 1. As a result of the failure (natural wear) of two control valves on the process flows of the water supply unit of one of the thermal power plants, the water consumption of these flows was 70% higher than calculated for more than two years at the time of the survey. With the technologically provided irreversible discharge of these flows in an increased quantity by the same 70%, the “extra” unnecessary losses of heated partially treated water amounted to about 30 thousand m3 per year, which in monetary terms amounted to about 700-800 thousand rubles. At the same time, the cost of replacing worn-out control valves at that time was about 150 thousand rubles with a further service life of about 10 years.

Example 2. At one thermal power plant, due to the lack of general station tanks for the supply of make-up demineralized water with the required capacity of several thousand cubic meters, the operating mode of the water pump can be simply called catastrophic. The demineralized water and condensate storage tanks available at the station with a total capacity of only about 400 m3 in no way provided the necessary damping of the consumption of demineralized water to feed the TPP cycle. During one shift, the load of the water treatment plant changed from 4 to 10 times (and always sharply) in the range of 30...120 t/h, depending on the amount of demineralized water consumption in the boiler-turbine shop. At the same time, the systematically extremely unsatisfactory quality of coagulated water after actually non-functioning clarifiers negatively affected the technical and economic indicators of the next purification stage - mechanical filtration and subsequent stages of ion exchange desalting. Thus, the entire water treatment plant was operated for many years in off-design modes, in which it is, in principle, impossible to adjust the equipment and talk about any operating efficiency. In this example, to correct the situation, much more significant investments are required compared to the previous one. But the magnitude of real losses from operational inefficiency is corresponding.

Drawing up a regime map for the water chemical regime (hereinafter referred to as the water chemistry regime) of boilers:

1) Checking the operation of boilers in continuous and periodic blowdown modes with calculation of operating standards; 2) Listing of all necessary modes of corrective treatment of feed and boiler water; 3) Indication of the recommended doses of corrective reagents, the location of their introduction and an indication of the method of monitoring the relevant processes; 4) Indication of boiler water quality standards, both recommended by the boiler manufacturer and established in accordance with the test program; 5) Carrying out sampling in accordance with GOST R51592-2000 “Water. General requirements for sampling" and GOST R51593-2000 "Drinking water. Sampling" (steam, source water, condensate, pre-boiler water, feed water - before and after the installation of the hot water vaporizer, return condensate), inspection of the cold air vaporizer installation; 6) Making the necessary adjustments to the instructions for conducting water chemistry; 7) Processing of test materials, preparation and issuance of technical reports valid until the next adjustment of the equipment; Preparation of instructions and regime cards, in accordance with the Guidelines for the development of instructions and regime cards for the operation of pre-boiler water treatment plants and for maintaining the water-chemical regime of steam and hot water boilers (RD-10-179-98), for operating personnel, with instructions various operating modes valid until the next equipment adjustment.

2) Listing of all necessary modes of corrective treatment of feed and boiler water; 3) Indication of the recommended doses of corrective reagents, the location of their introduction and an indication of the method of monitoring the relevant processes; 4) Indication of boiler water quality standards, both recommended by the boiler manufacturer and established in accordance with the test program; 5) Carrying out sampling in accordance with GOST R51592-2000 “Water. General requirements for sampling" and GOST R51593-2000 "Drinking water. Sampling" (steam, source water, condensate, pre-boiler water, feed water - before and after the installation of the hot water vaporizer, return condensate), inspection of the cold air vaporizer installation; 6) Making the necessary adjustments to the instructions for conducting water chemistry; 7) Processing of test materials, preparation and issuance of technical reports valid until the next adjustment of the equipment; Preparation of instructions and regime cards, in accordance with the Guidelines for the development of instructions and regime cards for the operation of pre-boiler water treatment plants and for maintaining the water-chemical regime of steam and hot water boilers (RD-10-179-98), for operating personnel, with instructions various operating modes valid until the next equipment adjustment.

Chemical control

Chemical control is an integral part of the operation of thermal power plants, all types of adjustment work and technological inspections.

Properly performed chemical control of the coolant allows you to correctly maintain the operating mode, timely and with high accuracy identify emerging violations in the operation of thermal power plant equipment and heating networks.

An audit of chemical control carried out at thermal power plants allows us to identify various shortcomings and bottlenecks. Based on the results of the audit, knowing the level and features of chemical control, it is possible to perform an analysis of the water-chemical regime of the power plant for previous periods based on operational documentation, as they say, with “open eyes”: with a full understanding of the history of the development of possible violations identified, the current situation and forecasting further developments of events.

At various thermal power plants, such shortcomings as incorrect performance of certain types of chemical analyzes have been repeatedly revealed. This is especially true for ultra-pure coolant flows, such as feed water and steam. To the point that at some thermal power plants, individual standardized indicators simply ceased to be fulfilled as “unachievable”. It is unnecessary to explain what the actual lack of control over the quality of feed water and saturated and superheated vapors leads to.

Example 6. At one of the largest power plants in the territory of the former USSR, due to incorrect performance of a chemical analysis of one of the standardized quality indicators of demineralized water, the issue of fundamentally changing the water chemistry regime of the thermal power plant was considered, which, by the way, did not create any problems. The results of chemical analyzes of one indicator were systematically unintentionally distorted for the worse during the determination process.

A change in the water chemistry of thermal power plants would entail a significant increase in the consumption of demineralized water for own needs, and a 2-3 times increase in the amount of chemical reagents consumed for the regeneration of filter materials. As a result, this would have resulted in a significant increase in financial costs for operation, but it would not have solved the virtually non-existent “problem” of the quality of demineralized water, due to which the issue of changing water chemistry was raised. By coincidence, the true picture of determining the quality of demineralized water by the specialists of the commissioning organization was established, the situation was corrected, and the issue of changing the water chemistry system of the power plant was removed.

Operational and adjustment tests of the deaerator:

1) Drawing up and coordination with the Customer of a program for operational testing of the deaeration unit; 2) Adjustment of the deaeration installation of the boiler room is carried out in accordance with the load test program within the limits of boiler operation (30%-95% of the boiler load); 3) During the process of operational adjustment, clarify the parameters of the heating steam, incoming water and condensate, determine the amount of vapor, set the operating mode of the deaerator and the degree of removal of carbon dioxide and oxygen at various loads. Test the deaeration installation with the automation switched on; 4) Based on the test results, develop and issue to the customer a technical report and a regime map for the operation of the deaerator; 5) Processing of test materials, preparation and issuance of technical reports valid until the next adjustment of the equipment; 6) Processing of test materials, preparation and issuance of technical reports, valid until the next adjustment of equipment, indicating productivity; heating steam pressure; pressure in the deaerator; temperature of chemically purified water entering the deaerator; condensate temperature; temperature of deaerated water; residual oxygen content in feed water; carbon dioxide content in feed water; feed water hardness; feed water alkalinity; condensate hardness; 7) Preparation of instructions and regime cards, in accordance with the Methodological Guidelines for the development of instructions and regime cards for the operation of pre-boiler water treatment plants and for maintaining the water chemistry regime of steam and hot water boilers (RD-10-179-98), for maintenance personnel, indicating the various operating modes valid until the next adjustment of the equipment.

What should be displayed on the regime map?

Almost all the indicators that actually make up the boiler operating map are shown as percentages. The following data shows us such indicators.

- The ratio of the following gases in percentage: oxygen, carbon monoxide, carbon.

- The volume of gas located outside the boiler device.

- Efficiency of the heating device (gross, net).

- What are the heat losses that accompany the process of burning fuel (in particular, gas).

- What are the heat losses caused by chemical deficiencies?

- Finally, what percentage of heat is lost during the operation of heaters.

These are just the main indicators in the map, but there are a number of additional ones.

- The volume of steam produced over a certain period of time.

- What is the temperature of this steam when it leaves?

- What is the air pressure in the burners?

- What is the gas pressure?

Operational and adjustment tests of the vapor cooler:

1) Drawing up and coordination with the Customer of a program for operational testing of the vapor cooler; 2) Adjustment of the boiler room vapor cooler is carried out in accordance with the load test program within the limits of boiler operation (30%-95% of the boiler load); 3) In the process of operational adjustment, clarify the parameters of incoming steam and water, determine the amount of condensate, set the operating mode of the vapor cooler and the degree of removal of carbon dioxide and oxygen at various loads. Test the vapor cooler with the automation switched on; 4) Based on the test results, develop and issue to the customer a technical report and a performance map for the operation of the vapor cooler; 5) Processing of test materials, preparation and issuance of technical reports valid until the next adjustment of the equipment; 6) Processing of test materials, preparation and issuance of technical reports, valid until the next adjustment of equipment, indicating productivity; incoming steam pressure; pressure in the vapor cooler; temperature of chemically purified water entering the vapor cooler; condensate temperature; residual oxygen content in the condensate; carbon dioxide content in condensate; condensate hardness; condensate alkalinity; condensate hardness; 7) Preparation of instructions and regime maps, in accordance with the Guidelines for the development of instructions and regime maps for the operation of pre-boiler water treatment plants and for maintaining the water chemistry regime of steam and hot water boilers (RD-10-179-98), for maintenance personnel, indicating the various operating modes valid until the next adjustment of the equipment.

Introduction

Fundamentally dividing operational and adjustment work at long-running thermal power plants and commissioning work at power plants under construction and commissioning (and individual power units), the following should be said.

Everything seems to be clear with commissioning work: there are a number of enterprises and organizations that specialize in performing commissioning and commissioning of energy facilities under construction, both on a turnkey basis and in individual units and areas.

The direction of operational and adjustment work in the water-chemical part at existing power plants has gradually and imperceptibly come to naught in recent years. The reasons for this are:

- firstly, the mandatory requirement, not established by regulatory documents of the industry, to carry out routine and adjustment work on the water chemical part at thermal power plants by specialized organizations at a certain frequency;

- secondly, banal savings of money combined with the deeply erroneous opinion of some managers that this type of work is completely unnecessary at their power plants (justification, again, for saving money).

It is clear that saving money directly follows from the first point.

At many power plants, operational and adjustment work at water treatment units (WPU) and water chemical regime (WCR), technological surveys in this direction have not been carried out for 20-25 years or more. The range of organizations that can carry out work for power plants at a high engineering level has narrowed significantly.

In addition, and unfortunately, a whole generation of operators has grown up who, for objective reasons, do not know what power adjustment is, who have not seen the positive results of professionally performed adjustment work. This, in turn, has led to the fact that thermal power plants in the Russian Federation have accumulated an impressive baggage of neglected, unresolved problems relating to the operating technology of the water treatment plant and the main equipment in terms of water chemistry, and affecting the reliability and efficiency of operation. These problems at existing thermal power plants need to be solved, because Their decommissioning is not expected in the coming decades.

This article was prepared by the author on the basis of more than twenty years of experience in commissioning, operational and adjustment work, surveys, consultations at two dozen large power plants owned by various energy companies in the Russian Federation and abroad.

Operational and adjustment tests of a water softening installation:

1) Drawing up and coordination with the Customer of a program for operational testing of a water softening installation; 2) Adjustment of the boiler room water softening installation is carried out in accordance with the load test program within the limits of boiler operation (30%-95% of the boiler load); 3) Calculation of operating standards: quantity, productivity of devices, temperature, dose of reagents, water consumption during purging, rinsing, regeneration, under various operating conditions of a water softening installation; 4) Identification of the main values of excess consumption of water, acid and salt for regeneration; 5) Selection of favorable operating modes for a water softening installation with the preparation of regime maps, in accordance with the Guidelines for the development of instructions and regime maps for the operation of pre-boiler water treatment plants and for maintaining the water chemistry regime of steam and hot water boilers (RD-10-179-98), for maintenance personnel, indicating optimal operating modes, valid until the next adjustment of the equipment; 6) Processing of test materials, preparation and issuance of technical reports, valid until the next adjustment of equipment, indicating the maximum permissible indicators of water quality: mineralization (salinity), total hardness, total alkalinity, content of suspended impurities (transparency), oxidability, iron content, value pH and other indicators that affect the operation of cold water heaters, as well as condensate returned from production, and condensate after water heaters (mains, DHW).

⇒

Operational documentation

Operational documentation, namely: instructions for operating the water treatment plant and conducting water chemistry, operating schedules for a significant part of thermal power plants were prepared not by specialized commissioning organizations, but by the personnel of the chemical shops of power plants, who do not always have the appropriate qualifications for this type of work.

The content of the instructions for the operation of the water treatment plant and for the conduct of water chemistry is often such that newly hired operational, engineering and technical personnel cannot be qualifiedly trained in these instructions. In fact, training of new employees is carried out only verbally, by transferring practical experience of working with equipment to them by long-time employees. And, unfortunately, the available and transferred practical experience is not always correct from a technological point of view. And this, of course, leads in the future to improper operation of the equipment and, as a consequence, a decrease in the efficiency and reliability of the operation of the water treatment plant and main equipment, deterioration in the quality of the water produced by the water treatment plant, and ineffective management of water chemistry at thermal power plants.

In this case, the basis of training should be operating instructions that fully reflect both the theoretical and practical aspects of working with the entrusted thermal power plant equipment.

Without in any way detracting from the qualifications of the operating personnel of chemical shops specifically as equipment operators, and without searching for those to blame for the current situation, it can be characterized as follows: “this is how it happened historically.”

Summarizing the above examples, I believe that the situation in this direction is serious and requires immediate correction.