Long-burning furnace design diagram is an option that allows you to use solid fuels, one load of which is enough for several days. Simple designs require two bookmarks per day, and complex ones require one bookmark every few days.

In any case, long-burning solid fuel stoves are an economical option that operate for a very long time without human intervention. There are several models that are common in many regions of Russia - these are Bubafonya and Stropuva. One of their distinguishing features is their simplicity of design. Is it possible to make a Stropuv boiler with your own hands?

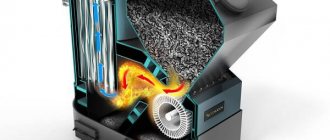

The main difference between Stropuv and other types of long-burning furnaces is the fuel combustion zone. In this design, combustion occurs from above, as in a regular fire. In other types, the combustion zone is located below on the grate.

What are the advantages of the first option? The zone will gradually decrease from the highest point to the grate. In this case, there is no specific effect of high temperatures on any boiler height level. This allows the use of material with a smaller thickness for the manufacture of the furnace, which not only saves money, but also ensures convenience during work.

Story

The creator of the Stropuva boiler is Lithuanian engineer Edmundas Strupaitis, who in 2000 developed a design in which fuel combustion occurs from top to bottom.

In 2005, the stove received a CE certificate, which confirmed the high quality of the product.

In 2008, in Lithuania, the unit received the title of “Best Product of the Year”, after which the products began to be supplied to Russia and a number of other European countries. To date, Stropuva stoves are sold in most countries of the European Union and the CIS.

The official representative of the Lithuanian company in the countries of the Customs Union is. In 2012, construction began on the production of boilers in Russia. Currently, about 100 dealers in various regions are engaged in selling the plant’s products.

Design and principle of operation

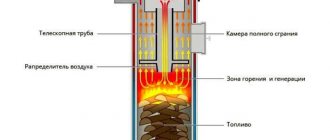

The body of the Stropuva boiler consists of two main parts: a cylindrical container placed in another container of the same shape, which are “clad” in thermal insulation. The coolant circulates in the space between the containers. The firebox is located inside a small container.

Boiler design

The bi-thermal draft regulator allows the stove to independently, without human intervention, regulate the volume of air supplied to the firebox. The principle of its operation is based on the fact that when heated, the boiler body expands and the bithermal regulator automatically closes the damper. If the combustion in the firebox slows down, the reverse process occurs, the housing cools and contracts and the regulator opens the damper.

Just like with the Bubafonya stove, the combustion process occurs only in the upper part of the stack, into which a controlled amount of oxygen enters through the air distributor pipe (also often called a piston or heel), this has a positive effect on the burning duration of the unit. Before entering the furnace, the air is preheated in the air heating chamber, which is located in the upper part of the boiler.

The air distributor is always located on the bookmark and as the fuel burns, it moves down.

Note! The efficiency of the boiler can be increased or decreased by changing the volume of air supplied.

Depending on the boiler model, the fuel used is wood, coal and pellets. To operate on coal and pellets, universal Stropuva boilers with a U attachment are used, which are equipped with a grate and a damper.

DIY Stropuva boiler drawing

The boiler design provides two doors:

- for loading fuel (top door);

- for removing ash (lower door).

At the back there is a hole for the chimney pipe. The coolant inlet and outlet are also located there. All boiler models use a 32 mm pipe for supply and return.

Collapsible stove Stropuva

Let us consider in more detail the manufacturing technology of various furnace options. The first has a trimmed barrel as a body, which has a fairly large wall thickness.

Thin-walled containers are not recommended for use for such devices due to the fact that under the influence of high temperatures and constant heating, the metal of the walls quickly burns out and it becomes necessary to select a new housing.

To limit the volume of the fuel combustion chamber, a disk is made from a steel sheet 1-1.5 millimeters thick, the diameter of which is two centimeters less than the internal diameter of the barrel. A hole is cut in the center of the disk into which an air duct is inserted and connected to the disk. Due to the operation of the limiter in the immediate vicinity of burning fuel, it is strictly forbidden to use soldered seams to connect it to the oxygen supply pipe. It is better to step back 3-4 centimeters from the end of the pipe on the walls to make a thrust roller, and insert the remaining part of the pipe into the hole in the stopper and flare it on the reverse side with a hammer.

The furnace lid has two holes of approximately equal diameter. The central one is designed to freely lower the air duct through it as a portion of the fuel burns out, and the side one is used to install a smoke exhaust pipe.

The process of operation of this device consists in laying a sufficient amount of fuel, the role of which can be played by either chopped or round logs with a diameter of up to two hundred millimeters, or brushwood and wood chips. The burning rate of small fuel elements is much higher, which requires more frequent loading of the furnace.

After laying the firewood, a limiter is installed and the stove is closed with a lid. The fuel can be ignited with direct access to it before installing all the necessary parts, or after assembling the stove through the air supply pipe using a burning rag previously moistened with gasoline or other flammable liquid.

Advantages

- High efficiency (up to 86%). Efficiency can be adjusted by increasing or decreasing the volume of incoming air.

- Autonomy. Stropuva long-burning wood-burning solid fuel boilers do not have electronics, therefore there is no dependence on electricity, and the combination with heating systems with natural coolant circulation makes them completely autonomous. Universal boilers operating on different types of fuel do not differ in such autonomy, because they are equipped with an automatic air supply system to the firebox, which consumes about 15-20 W/h.

- Beautiful appearance.

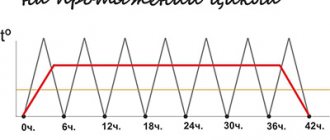

- Long-term work on one tab. At the minimum air supply mode, the wood-burning boiler on one tab works up to 31 hours, and at the maximum mode up to 6 hours. Universal models are distinguished by the highest “performance” among the entire model range of Stropuva boilers: when using coal, the combustion duration at the minimum mode is up to 130 hours, at the maximum - up to 32 hours; when using pellets, the burning duration is up to 72 hours.

There must be air flow into the room where the heating unit is installed.

Required amount of fuel for one 10 kW load of universal model S10U:

- firewood - 25 kg;

- coal - 50 kg;

- pellets – 90 kg.

Advice! For optimal functioning, it is recommended to select the boiler power with a 30% margin relative to the area of the heated room.

Do-it-yourself Stropuva boiler

Stropuva are modern, highly efficient and very popular solid fuel boilers. The main difference between such boilers and other common equipment is the method of fuel combustion - in Stropuv boilers it is upper. This allows for the longest possible operation of the heating unit on one load of fuel. Industrial designs can operate for up to 1-1.5 days on one load of firewood and up to 3-5 days on coal. You will be surprised, but you can assemble a sling boiler with your own hands without any problems. Moreover, for this you do not need to have special knowledge or be able to work with complex tools.

Do-it-yourself Stropuva boiler

Features and advantages of Stropuva boilers

The main difference between the boiler in question is the innovative top combustion. In addition, the Stropuva heat exchanger has a round shape. These factors made it possible to achieve maximum battery life of the equipment, significantly increasing its energy independence and efficiency.

Confirmation of the effectiveness and profitability of Stropuv boilers are all kinds of certificates, numerous awards and, of course, many positive user reviews. However, factory-assembled equipment is quite expensive. And why spend money if you can quickly assemble the boiler yourself.

You can verify the effectiveness of top combustion of fuel using a simple experiment. To do this, you just need to take two matches and light them. Hold one with the flame up, the other with the flame down. The match that you turn upside down will burn much faster.

Long-burning solid fuel boilers STROPUVA

In the boiler, the fuel burns in layers. First, the surface part burns, and only after that the flame moves to the underlying layers. This allows you to ensure the most rational fuel consumption and achieve a high efficiency even when operating the boiler at minimum power.

Design

Design

Boilers of this type have an extremely simple design, but their efficiency does not suffer from this. As the fuel burns out, a special telescopic distributor will move down, providing air supply directly to the combustion site, and not to all the fuel, which will also contribute to the most economical fuel consumption.

The boiler heat exchanger has a rounded cylindrical shape. This eliminates the risk of the unit exploding from excessive internal coolant pressure.

Despite the fact that the finished unit has relatively large dimensions, its design remains very ergonomic and original. Aesthetic cylindrical shape, minimal number of protruding elements, compact placement, almost complete absence of contamination in the boiler room - all this is also the undeniable advantages of the unit in question.

Advantages

Solid fuel boilers STROPUVA

Stropuva boilers have many advantages, including:

- very high efficiency. It reaches 90% or more, which is a very impressive figure, especially when compared with other solid fuel boilers;

- maximum battery life for its class on one load of fuel;

- independence from power grids and automation equipment (for wood-burning models);

- ease of use and maintenance;

- operational safety;

- reliability and long service life.

Stropuva S

Stropuva solid fuel boilers do not need to be connected to various types of automation systems. The mechanism of action of the equipment is based on the thermostatic characteristics of the metal, which provides a number of advantages. Among the main advantages, it is necessary to highlight the absolute independence from electricity. This advantage becomes especially noticeable when it is necessary to install a heating system in places with problematic electrical networks or where there is no electricity at all.

That is, a homemade Stropuva boiler can be successfully used where there is no access to any other heat sources except solid fuel. Moreover, such a boiler is capable of not only efficiently heating rooms, but also heating water.

In the homeland of this equipment, in Lithuania, due to the relatively high cost of other energy resources, many people install low-power Stropuva boilers even in ordinary apartments.

Guide to self-assembly of a Stropuva boiler

Before starting work, prepare the necessary equipment for this.

You won’t need any extremely difficult to use tools or hard-to-find materials. However, it is better to collect everything in advance so as not to be distracted by searching for missing elements in the future.

Stropuva boiler assembly kit

- Metal barrel. Use a large container with a capacity of 200 liters or more.

- Welding machine.

- Thick-walled metal pipe.

- Fiberglass.

- Metal channels.

- Asbestos.

- Chisel.

The function of the body of the heating unit in question will be performed by a large metal barrel. You can use either new or old container. The main thing is that the barrel does not have through holes and signs of severe corrosion damage.

The function of the body of the heating unit in question will be performed by a large metal barrel

If possible, it is best to use a Soviet-made barrel. Such products are much more durable and high quality compared to their modern counterparts.

If you have access to a rolling machine, you can purchase a large sheet of metal and use it to assemble the boiler body. The recommended sheet thickness is 2.5-3 mm. The optimal dimensions are 125*250 cm. At the end you should get 2 cylinders with a diameter of 50 and 45 cm.

Furnace assembly

The work of making a sling boiler is carried out in a few simple steps.

First step. Clean the barrel from all sorts of contaminants, and then cut a hole in its top. That is, you simply need to “knock out” the top of the container to gain free access to its interior.

Sheet metal housing

Second step. Cut a small piece from a metal pipe with a diameter of about 15 cm. From it you will make a pipe for connecting the chimney.

Third step. Cut a hole in the side wall of the barrel to install the previously prepared pipe, and then weld a section of the smoke exhaust pipe to the finished hole.

Hatch for cleaning ash

Fourth step. Take the previously cut top of the barrel and make a hole in it with a diameter of about 100 mm.

Double fuel loading hatch with asbestos gasket

Fifth step. Prepare a pipe with a diameter of 10 cm and weld it to the hole prepared in the previous step. The length of the pipe should slightly exceed the height of the barrel.

Double wall boiler with asbestos lining

The holes in the inner cylinder are pre-cut

The external hole was cut and the exhaust pipe was welded in

Sixth step. Take 4 metal channels and weld them along the radius of the boiler lid. You need to weld at every 45 degrees of the circle.

A pancake with an air supply pipe was made

A pancake with an air supply pipe was made

Seventh step. Weld a pre-prepared pipe to the back of the cover. Place the lid on the barrel.

Eighth step. Make a damper for the blower pipe. By changing the position of this damper, you can set the desired intensity of traction.

Checking the boiler after assembly

Checking the boiler after assembly

Before accepting a homemade Stropuv boiler for permanent use, be sure to ensure that it is in good working order and reliable. Don't ignore this step. The safety of further operation of the heating unit directly depends on a correctly performed check.

Fill the barrel with wood to about a third of the height. Add some kerosene and throw a lit match into the container. Ideally, the wood will ignite almost immediately. At the same time, you should not notice the presence of smoke, or any draft, or any kind of uncharacteristic odors.

STROPUVA

If any of the above symptoms are present, do not use the boiler. Such equipment is very likely to soon fail and harm its owners. But if you assembled the unit in strict accordance with the instructions above, there will be no problems.

The amount of firewood given earlier will be enough for approximately daily heating of a small room. If the room is medium sized, double the loading volume.

Thus, you can assemble an excellent sling boiler for heating a variety of small and medium-sized rooms with your own hands. Now you don’t have to spend a lot of money on buying expensive equipment. You just need to follow the instructions in everything and your home will always be warm and cozy.

Good luck!

Video - Do-it-yourself sling boiler

tolkostroyka.ru

Chimney

To a large extent, the efficiency of the boiler depends on the draft in the chimney pipe. If the draft is poor, the combustion products do not have time to be removed through the chimney and, as a result, the boiler begins to smoke and the room is gradually filled with smoke, and the combustion process in the firebox slows down.

As a rule, lack of traction occurs for several reasons:

Stropuva boiler chimney design

- Insufficiently wide chimney diameter;

- Insufficient chimney height. Should rise 50 cm above the ridge;

- The chimney is filled with combustion products (tar, soot, etc.);

- Incorrect dimensions of the horizontal part of the chimney (length should be at least 20 cm, but not more than 150 cm).

Increased cravings lead to:

- excessive fuel consumption;

- increased combustion temperature;

- increased noise level of the boiler.

When installing a chimney, special attention should be paid to fire safety. The chimney connection to the boiler must be made of metal. It is necessary to regularly clean the chimney itself, as well as its horizontal part, because Accumulations of tar and soot can ignite and cause a fire.

The joints must be well sealed.

Stationary version of a barrel stove

The second version of the stove, made by hand, has certain similarities and some differences with respect to the stove described above.

It is also made on the basis of a steel barrel, which, if desired, can be found quite often in the vastness of city or industrial landfills. At the same time, the limiter is made of a thicker steel sheet.

In addition, its distinctive feature in this device is the presence of four unique blades welded at the bottom, made from pieces of 50x50 steel angle.

The shape of the chimney also attracts special attention. Unlike the previous design, this Stropuva stove has a chimney extending from the side wall and forming a 90-degree angle with it. Such a bend can lead to clogging of the pipe at the bend with solid combustion products - soot and ash, carried away by smoke. In addition, the pipe also has a lower outlet, in which liquid accumulates, coming from incompletely dried firewood and entering the smoke in the form of steam. Passing through the less heated part of the pipe, the liquid condenses and flows down, from where it must be periodically removed in order to avoid corrosive destruction of the latter.

Long chopped logs, laid either across the stove body or installed vertically, are successfully used as fuel for this stove. Theoretically, it is quite possible to use round logs, the length of which is only 15-20 centimeters less than the height of the furnace body. To kindle large-sized firewood, you just need to lay a layer of wood chips on top and set it on fire.

After intense combustion is achieved and the limiter and lid are installed, the flame will spread downward.

It is worth noting another advantage of the Stropuva stove. If all the rules are followed, one load of fuel may well be enough to operate the device for up to two days or more.

Dear readers, comment on the article, ask questions, subscribe to new publications - we are interested in your opinion

Recommendations for operating a long-burning solid fuel boiler in Stropuva

- When filling the firebox with firewood, it is recommended to place larger logs in the upper part of the stack along the edges, and smaller ones (no more than 0.5 kg) in the central part. This is necessary to prevent the formation of a large amount of smoke during kindling.

- It is necessary to fill the firebox completely, this will allow the boiler to operate longer on one fill.

- When using firewood, the ash should be cleaned out once a month. When using coal, the ash is removed each time before adding a new batch of fuel.

- Air penetration into the firebox through the ash cleaning door is not allowed. The lower door must be closed while the unit is operating.

- The humidity of the firewood should not exceed 30%, otherwise, most likely the fuel will not burn at all, or will not burn enough, which will not allow the required coolant temperature to be reached.

- The air distributor should not be lifted during combustion, as Most likely, after lowering, it will take an incorrect position and sink deep into the combustion zone, this in turn will affect the service life of the boiler.