Articles

All photos from the article

If in summer few people worry about heating in the house, then in winter the problem of heat comes to the fore, otherwise it is simply impossible to live in such a room. Thanks to a variety of systems, it is possible to maintain comfort not only in the main rooms, but also in the hallway or even the basement.

In this article we will not touch upon electric and solid fuel (liquid fuel) heating systems; today our main character is a gas boiler for a wooden house.

In the photo there is a wall-mounted gas boiler

With its help, you can easily maintain the desired temperature anywhere in the building. At the same time, the efficiency of the device is higher than the rest of the above equipment. The disadvantage is that permission to install it is required from various departmental organizations (see also the article “Inputting electricity into a wooden house: overhead and underground methods. Cable protection”).

Advice: in order to get the most out of a gas boiler and not waste a lot of fuel, you need to insulate the room as best as possible. One option involves replacing old windows with new plastic ones.

Installation of a gas boiler in a wooden house must be carried out in accordance with safety requirements

Installation on different walls

The rules for installing a boiler on the walls of a wooden house require strict compliance with all fire safety regulations and factory instructions. The unit must be firmly fixed to the wall, ensuring a vertical/horizontal level.

At the same time, there are differences in installation and fastening requirements for partitions made of different wall materials, and similarly for hollow walls.

Installation on a reinforced concrete wall

Reinforced concrete is the ideal building material for the walls of buildings intended to house a gas unit. Such building structures are distinguished by excellent strength characteristics, belonging to the class of fire-resistant materials.

Installing the unit on such wall material does not require any special measures. The installation is carried out using steel anchors, on which, according to the level, the prefabricated strip is strengthened and then the unit is hung.

Such a wall is perfect for placing a heating device of any design and power, including large models with a built-in hot water storage tank.

Installation on a brick wall

In existing regulatory directives for installing heating units on a brick wall, the conditions for installing a gas boiler are specified separately. Brick, like reinforced concrete, is a fire-resistant building material, so it is possible to install the boiler directly on the wall.

However, sometimes representatives of the gas service, who are responsible for issuing permission to operate the unit, require plastering of the unit’s site. During the process of plastering the areas, a mounting plate for the mounted unit is installed. After the plastering is completed, two bolts come out of the wall, on which you need to install a gas boiler in a wooden house.

Is it possible to hang a boiler on a wooden wall?

Despite the fact that such walls are flammable materials, fire safety rules allow the installation of a gas boiler on a wooden wall, provided that a heat-resistant substrate is first placed.

To thermally insulate the unit from wooden walls, it is recommended to install a base of the following thermal insulators:

- Basalt wool with a rigid base made of steel sheet, on which a layer of material over 50 mm is placed.

- Basalt refractory sheet material.

In the event of an emergency with an open flame, they are fully capable of protecting the surface of timber walls from fire.

Advice from professionals

Proper operation of gas equipment is not only reliable and durable, but also, above all, the safety of everyone living in a private wooden house. According to existing legislation, the user is responsible for the safe operation of boilers.

Therefore, experts advise boiler owners to adhere to a number of simple rules:

- Carry out periodic maintenance of the unit within the time frame and in the amounts established by the equipment manufacturer, as a rule, at least once a year.

- There is no need to save money on filters. Both the gas pipeline and the heating circuit must be provided with similar protective devices.

- It is unacceptable to use rubber hoses to connect gas.

- During the operation of the boiler, the quality of combustion, draft in the furnace and ventilation in the furnace room are monitored.

If there were previously doubts about installing gas boilers in houses made of timber, then they are a thing of the past. Innovative gas heating today is most suitable for such a facility, since it has reliable automatic protection and a thermal process control system.

All this allows you to completely prevent the creation of emergency and fire hazardous situations in the house.

What kind of doors should there be in the boiler room?

If this is a separate room in a residential building, then the doors leading from the furnace room must be fireproof. This means that they must hold the fire for 15 minutes. Only those made of metal meet these requirements.

Factory or homemade - it doesn’t matter so much, as long as it fits the parameters

If the furnace room has an exit to the street, there should be unsecured doors. Moreover, SNiP says “weakly fortified.” This is necessary so that during an explosion the box is simply squeezed out by the blast wave. Then the energy of the explosion will be directed to the street, and not to the walls of the house. The second advantage of easily “removable” doors is that gas can escape freely.

Doors to the boiler room are sold with a grille at the bottom

Often the project sets an additional requirement - the presence of a grated hole in the lower part of the door. It is necessary to ensure air flow into the room.

Features of operation

After familiarizing yourself with the issues of preparing a boiler room, installing a foundation, installing supply and exhaust ventilation and installing a chimney, it is important to understand the features of installing a solid fuel boiler.

At the initial stage of work, remove the packaging from the unit and assemble it according to the attached instructions. The boiler is fixed to the base so that its outlet coincides with the inlet of the chimney. The model is fixed to the foundation in a strictly horizontal position; a building level is used for this.

Connect the heat generator to the chimney and heating system according to the selected diagram. At the final stage of work, the automation is set up, the fan is secured and a circulation pump is installed.

How do heating radiators work in private homes: operating principle

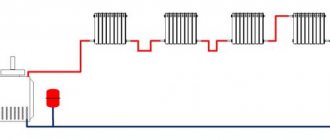

Heating radiators in a private home are devices that transfer heat into the room from the coolant. The degree of its heat transfer ability depends on the area of the heating surface of the device. The open pipeline serves as an additional heating surface.

In European countries, the most common is the so-called gentle heating, since conventional heating systems dry the air in the room and also electrify it. As the heating radiator operates, dust settles on it, which then rises with the warm air. It begins to decompose into substances, some of which are quite harmful to human health.

By using gentle heating, this problem can be solved. In this case, the temperature of the heated surface should not exceed 45 °C. Taking into account the operating principle of heating radiators, additional fins are installed on them, which make it possible to increase the area of heating devices.

Typically, heating devices are installed in wall niches under windows, placed along the walls in 1-2 rows; sometimes they are covered from above using decorative panels. However, in the vast majority of cases, devices are placed directly on the walls under the windows. The length of heating devices is no more than 75% of the length of the window opening, and they are not mounted on internal walls.

Depending on the method of heat transfer, type of heating surface, material, and the magnitude of thermal inertia, several types of heating devices are distinguished: convective, radiation, convective-radiation. All devices can be either with a smooth or ribbed heating surface.

Heating devices include finned tubes. Many narrow fins allow you to increase the heating surface area. Install the pipes, forming several rows. These heating devices are low cost and compact. They are easy to install.

The operating principle of a heating radiator is based on combining the operating principles of convector and radiant heating devices. According to its design, it can be sectional or panel, made of metal.

In Russia, sectional cast iron radiators are most widespread. They consist of single- or multi-channel sections and have channels of ellipsoidal or round cross-section. The sections are connected to each other using nipples with rubber, paronite or cardboard gaskets.

In order to prevent an increase in hydraulic pressure, an expansion tank (damper) is used. It not only serves as a container for excess water that occurs after it is heated, but also replenishes the lack of liquid when cooling the water. Expansion tanks can be either open or closed. In private homes, the latter are mainly used.

A heat pipe is used to supply and remove coolant from heating devices. It consists of liners, risers, mains and horizontal branches. The water heating boiler and the riser are connected to each other using a main line, and the connections act as connecting elements between the risers and heating devices. The riser is a pipe connecting the connections to the main line.

Preparation for installation

Figure 4. Installation diagram of a parapet boiler: 1 - air duct pipe; 2 — air duct section; 3 - boiler; 4 - seal; 5 — M6 bolt; 6 — clamp; 8 - chimney pipe; 10 — M8 nut; 11 — washer 8; 12 - chimney protection; 13 - eye; 14 — M10 pin; 15 — M10 nut; 16 - washer 10.

The very first thing you should start preparing for installation is to read the detailed instructions for installing the device and purchase everything that is necessary to install the boiler and connect it to the heating system: fittings, fittings, fasteners, etc.

The next stage of preparation is the selection of tools. To make a hole in a stone wall, you will need at least a hammer drill, or better yet, a hammer drill with a diamond bit that matches the diameter of the air duct pipe (for Aton boilers, the air duct diameter is 240 or 270 mm). If there is no crown, you can get by with a small-diameter drill, the length of which is sufficient to pass through the wall. If you work without a crown, then you will need a spatula, and if you have to work high, where you cannot get to it from the street, then you will need a spatula as long as the thickness of the wall. You will need drills for stone with a diameter corresponding to the fastening elements of the boiler being installed.

You will also need keys (in particular, an adjustable wrench) and screwdrivers in accordance with the fasteners supplied to the boiler and connections to the pipelines.

To remove the coating from the wall, you will need a knife, a spatula, a sponge and a basin if the wall is covered with wallpaper, or another appropriate tool.

The measuring tool you will need is a level and a ruler, most likely you will need a square. You will, of course, need a pencil or marker for marking.

Personal protective equipment: glasses, mask, vibration-proof gloves, possibly knee pads.

Types of heating of wooden houses

To keep a log house cool in summer and warm and cozy in winter, it is important to choose the right heating options based on modern heating systems

Electric heating

Heating a wooden house using electric heating guarantees residents ease of control of appliances and the absence of harmful emissions. In addition, there is no need to build a separate boiler room and chimney.

The electrical system has virtually no shortcomings, but it can be affected by external factors in the form of constantly increasing resource costs and imperfect operation of electrical networks with frequent voltage drops. To protect yourself from such problems, you can stock up on a generator, but in this case the issue of saving becomes moot.

If electric water heating is used, the risk lies in the coolant, which can leak or freeze if the equipment is not used correctly.

Electric heating is provided by:

- heaters (mounted, floor, built-in - such as underfloor heating);

- radiators equipped with individual heating elements;

- radiator heating circuit, the “heart” of which is considered to be a heating electric boiler.

Gas heating

Gas heating in a wooden house is an easy-to-maintain and fairly effective method that provides high efficiency, but at the same time requires increased attention to safety precautions. This is especially true for wooden structures in which it is planned to install a gas boiler.

In addition, not all suburban settlements are supplied with gas, which is also a problem that can be solved by installing a special container on the site for storing imported gas - a gas holder or purchasing cylinders, but this will significantly increase costs.

Solid fuel

Solid fuel equipment is considered the best option for heating those houses that do not have access to a gas pipeline and where there is questionable operation of electrical networks.

Such heating is effective and less expensive than an electric unit, and is also attractive due to the low price of the equipment and the ability to install all the elements yourself. Modern models of solid fuel boilers include components and parts that improve their efficiency: for example, an automatic machine for dosed supply of coal into the boiler.

For normal operation of the unit, it must be installed on the ground floor or in a specially built boiler room.

The raw materials for heating this type of boiler are coal, peat, firewood, sawdust or pellets. The device becomes very hot during operation, which increases the risk of fire.

To ensure safety, it is important that the boiler room is lined with non-combustible material. In addition, it is necessary to take care of the premises intended for storing raw materials

Pechnoe

Stove heating in a wooden house provides warmth and comfort. The most commonly used stoves are the Swedish type, which combine not only heat transfer functions, but are also equipped with a hob and oven. If desired, such a stove is complemented with a fireplace and sleeping places are arranged against its wall.

The disadvantage of stove heating is the likelihood of poisoning by combustion or ignition products. In addition, the stove can heat a house with an area of no more than 100 square meters using wood or coal. m.

Liquid fuel

Oil boilers are also particularly popular in areas where other heating options are not possible.

Diesel fuel (diesel fuel) is used as the main raw material. The advantage of this type of heating is considered to be the low cost of raw materials, and the main disadvantage is the possibility of carbon monoxide poisoning, the occurrence of fires if safety precautions are not followed, and the need to equip special premises.

Infrared

Considering the difficulties with popular heating systems, an innovative and efficient heating scheme based on infrared radiation was developed.

The principle of operation of this equipment is the operation of heating elements that radiate thermal energy on the surface of a wooden house (furniture, walls, ceilings, floors), which, when heated, release heat into the air. At the same time, warm air rises and mixes with cold air, which avoids overheating and saves up to 70% of energy.

Sometimes combined types of heating are used, when several types are used simultaneously. This can be heating with an electric boiler, the functions of which, in the event of a power outage, begin to be performed by a solid fuel unit.

Installation of a wall-mounted gas boiler with your own hands - stages of work

When purchasing a gas boiler, many people want to save money and install it themselves. Is it possible to do this? In some cases, yes, but it still won’t be possible to do without specialists. After all, gas is an explosive fuel, and its connection by persons without a special license is illegal. The remaining work on installing a wall-mounted gas boiler can be carried out without the involvement of specialists, but all the requirements of the relevant SNIPs should be taken into account.

Please note that not all manufacturers allow self-installation. For example, the companies Ariston, Viessmann, Bosch recommend using the services of specialists only from their service centers.

BAXI, Ferroli, Electrolux are more loyal to the issue of installation and allow installation of a gas wall-mounted heating boiler with your own hands.

Therefore, before purchasing a particular model, read the documentation and find out whether you can install this unit yourself.

Note! The first step, before starting installation work, is to develop a project and approve it with the relevant supervisory authorities.

Stove heating device in a private house: design of modern stoves

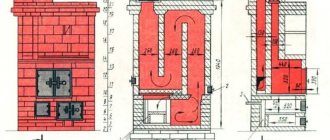

The main structural elements in a stove heating device for a private house are: foundation, trenches, ash chamber, firebox, smoke channels (smoke circuits), chimneys.

The foundation is the base of the stove, which takes on the loads from the stove and chimneys. This structural element must be reliable, since the safety of the structure in use depends on its strength. Correct placement of the stove foundation requires its location to be separate from the foundation of the house. The minimum gap between them is 3 cm, which is filled with sand.

First of all, they dig a well, which is then filled with small fragments of stone or baked brick, after which everything is carefully compacted. In this way, a pillow is prepared for the foundation. Then liquid cement mortar is poured into the pit. Laying a brick or stone foundation is done with bandaging of the seams. The last layer of cement mortar is carefully leveled.

After erecting the foundation, they begin to construct such a structural element of the furnace as shale. They are rows of brickwork that raise the oven on top of the foundation. To install the slates, two or three rows of brickwork are made. The bottom of the furnace is thus also involved in heat transfer.

An element of the design of heating furnaces, such as a blower, or ash chamber, serves to supply air to the firebox and to accumulate the ash coming from it. A special grate in the form of cast iron or steel rods is installed between the firebox and the ash chamber. While the stove is operating, the chamber door should be open, and at the end of the fire it should be closed to avoid rapid cooling of the air inside the stove.

The firebox in heating stoves is a furnace chamber in which fuel is burned - wood and coal. A special hole is installed in the upper part of the firebox to remove flue gas. The dimensions of the chamber are selected in such a way that it is possible to load into the furnace the amount of fuel necessary to heat the furnace.

At the bottom of the firebox, slopes to the grate are arranged, ensuring the free movement of ash into the ash pit. To prevent coals and ash from falling out of the combustion chamber, its door is installed above the grate by one row of brickwork. You can extend the life of the firebox by lining it with refractory bricks.

The operating principle of a stove heating system in a private home is based on heat intake through smoke channels, or smoke circulations. They can be positioned both vertically and horizontally, as well as rise and fall. How efficiently a stove operates depends on the size of the smoke ducts and their location.

The flue gas, passing through the channel, gives off energy in the form of heat to the walls, which heat the furnace. In order to increase heat transfer, smoke channels are designed in such a way that they are long and often change direction.

The smoke ducts of a modern stove heating of a private house can have a cross-section of 13 x 13, 13 x 26, 26 x 26 cm, their walls are made smooth (they are not plastered, since if the plaster is destroyed, the channels may become clogged). Access to the smoke circuits for cleaning them from soot is provided through special doors.

To obtain draft that helps remove gases from burned fuel, a chimney is installed, which is placed outside the house - on the roof. Most often it is made with a round cross-section, since gas movement in pipes with corners is somewhat difficult. In addition, round pipes are easier to clean. Ceramic or asbestos-cement pipes are used as the material for their manufacture.

Types of parapet units

Parapet gas boilers have some features that distinguish them from conventional units:

- A closed combustion chamber, in which the installation of a coaxial pipe is sufficient to remove flue gases. It simultaneously ensures the supply of combustion air to the burner from the street and the removal of flue gases.

- The devices do not depend on electricity and can work autonomously.

- They can be used to heat rooms as an independent device without radiators.

Parapet-type units may differ in other characteristics. They are:

- single-circuit and double-circuit;

- power from 4 to 40 kW;

- on the outlet side of the pipe: left-handed, right-handed;

- floor and wall.

Such units can be equipped with burner devices of different types: single-stage, two-stage and modulating. Also, different models differ in the automation equipment.

Main characteristics

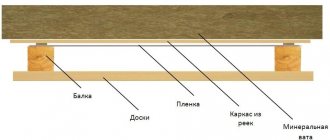

Important elements of the house that need to be taken into account when choosing such heating are:

- Floor material. As a rule, the floor is made of boards, plywood or OSB, which are laid over the foundation beams. Such a base is quite movable, which eliminates the possibility of installing a water-based underfloor heating system, because it must be mounted with a screed.

- Insulation of walls and windows. Basically, such surfaces are made of logs or beams, which have a high level of thermal insulation. The coldest place is considered to be the opening, both window and door. That is why heating of a wooden house should be centralized in such places.

Article on the topic: Is it possible to insulate a wooden house with foam plastic from the inside?

It is also important to note that a large amount of heat is also lost through the roofing areas, so the surface of the floor and attic should also be carefully insulated.

Moreover, a material such as wood has good flexibility, which allows the entire system of pipes and air vents to be installed without much interference.

Flue gas removal

Channels and pipes designed to remove gas combustion products must ensure normal combustion in the boiler furnace. Due to this:

- the cross-section of the smoke exhaust duct should not be less than the dimensions of the boiler connecting pipe;

- it is allowed to reduce the cross-sectional area of the chimney if the design of the heating unit provides for the forced removal of combustion products and air supply;

- channels can be located inside capital walls and partitions of appropriate thickness or be attached to them;

- the material for the manufacture of chimneys must be fireproof and not subject to active corrosion;

- the design of the chimney must include a special hatch for cleaning the channel from soot and a device for draining the resulting condensate;

- the height of the chimney is higher than the ridge of the roof or a line at an angle of 15° when moving away from it.

All butt connections of elements are made airtight and exclude not only the release of combustion products into the premises, but also the possibility of air leaks and a decrease in draft.

Basic fire safety rules

- Firstly, it is necessary to carefully protect the surface on which the boiler will be installed from fire. The best option is galvanized steel and asbestos substrate. It is also important to take into account that the dimensions of the substrate and stand should be 10 centimeters larger than the heating system itself around the entire perimeter.

- Secondly, all other electrical appliances must be located at a distance of at least 30 centimeters from the boiler itself. All electrical wiring should not be carried out above or below the boiler, since such an insulation system will quickly fail under the influence of hot air.

- Thirdly, the diameter of the chimney must correspond to the pipe on the gas boiler, and also have three bends, but no more. The section type should be round, stainless steel is selected as the material.

- Fourthly, the chimney opening must be larger than the chimney itself. This will make it possible to lay an additional layer of insulation using asbestos or a piece of cement-asbestos pipe, which will reduce the level of heating of gas combustion products.

- Fifthly, the gas boiler must be located in a separate room with an area of 4 m2, and it must also have a door, the width of which must be 80 centimeters, and a window.

- And finally, sixthly, the height of the chimney should exceed the height of the roof by 50 centimeters.