The most effective method of insulating walls is external insulation.

Thanks to it, you can retain heat without reducing the area of the room.

An extremely important advantage of this thermal insulation method is that the external walls will retain heat .

Insulation of the external walls of a brick house is the optimal method of thermal insulation of a building.

The following materials are suitable for insulation:

- mineral wool;

- Styrofoam;

- extruded polystyrene foam;

- penoplex;

- penofol;

- penoizol;

- polyurethane foam.

We will look at some of them in this article.

Internal and external insulation - features and nuances

A wall that is insulated from the outside will cool several times slower. The undoubted advantages are:

- Heat losses are minimal;

- The dew point is located either in the insulation itself, or at the edge of the outer wall (it all depends on the parameters);

- Condensation will never form on the wall;

- The wall warms up completely, there are no significant temperature jumps .

Differences in insulation

Internal wall insulation is not considered so popular, all due to a number of significant disadvantages:

- Heat is lost by 10%.

- Dew point location . It is located in the space between the inside of the wall and the insulation or in the insulation itself. This causes condensation to accumulate, and after a while dampness appears in the room.

- The wall does not retain or accumulate heat.

Despite a number of disadvantages, internal insulation is also characterized by positive qualities:

- Work can be carried out at any time of the year, regardless of weather conditions.

- It is easy to carry out insulation yourself; for this you only need basic knowledge and the necessary materials.

What mistakes can be made during the work process and how to avoid them?

Some people violate the technology of installing the material and insulating a brick wall with it, and then complain that they spent so much money, but it is of little use. To prevent this from happening and to avoid blaming the consequences of mistakes on bad luck, you need to immediately take into account several points :

- Before starting work, identify “cold bridges”, that is, areas through which high heat transfer will occur. You can use the service of a special company that, using a thermal imager, will quickly and with a 100% guarantee identify such places. Often, “cold bridges” appear at the junctions of materials or structural elements.

- Select the correct material thickness. If the thickness is too small, then it will not be enough for high-quality insulation of the walls, as a result of which they will freeze. If it’s too big, you’ll end up with an overconsumption of material, and that’s all extra money.

Follow the work technology.

For example, reinforcing mesh should be fixed to the wall with a small amount of mortar, and not to a dry surface and then applied with glue. The reason is that this way the mesh will better adhere to the pores of the material and will not fall off during use.It is better to additionally dowel the polystyrene foam instead of just placing it on glue. This makes it more likely that the material will last on the wall for many years.

- Do not use low-quality, too cheap or expired materials and solutions, otherwise they may not have the required parameters, for example, in terms of fire safety and toxicity.

- Correctly lay individual insulation elements. After completion of the work, the house should become like a thermos, not letting out heat from the inside and not letting in the cold from the outside. If you do not properly seal the seams between the floors and the joints between the elements, then cold and moisture will seep through them, and then dampness and destructive processes will appear.

- Clean the brick wall thoroughly - remove dirt and prime it, otherwise air bubbles will form, the material will not adhere tightly to the wall and may fall off in the future.

If you are interested in how and with what you can insulate brick walls from the inside and outside, take a look at this section.

Main types of insulation and their brief description

Organic heat insulators on the market are represented by a wide range of products.

They are based on materials of natural origin:

- Arbolite insulation is considered the newest material, which is based on sawdust, shavings, uncut straw and reeds. Also, the insulation is made of cement and organic additives. These are CaCl2, H2SO4, as well as the product obtained after processing ordinary clay, kaolin or nepheline, and Na2O.

- Foam-polyvinyl chloride insulation . It consists of polyvinyl chloride resin, which, after exposure to light or electromagnetic vibrations, acquires a characteristic foam structure. At the same time, it is considered a universal heat insulator.

- Chipboard insulation . Components - shavings, resin obtained as a result of controlled chemical processes, antiseptics, fire retardant.

- Insulation with a fiberboard base . It resembles chipboard in its own way. The base is wood waste, or trimmed corn and straw stalks. The material may well also consist of compressed old paper.

- Polyurethane foam is based on polyester , it includes H2O, an emulsifier and isocyanates. When catalysts begin to act, all elements interact as a result of a chemical reaction, in which a new type of insulation appears.

Inorganic heat insulators

Mineral wool comes in two types: slag and stone . To produce the first, companies use slag. Stone wool is distinguished by: CaCO3, rocks that are used for paving streets, minerals containing calcium and magnesia, volcanic rocks and others.

Possible insulation option

Many future homeowners, at the stage of building a stone house, immediately think about a durable option for wall insulation. Load-bearing walls are built from porous material, and the outer part is lined with brick. A gap is left between them, which will be empty (vent gap) or filled with expanded clay. It was used back in the USSR and was considered an “eternal material.”

Such a “fur coat,” although labor-intensive, requires additional costs and time, but it does not need to be repaired every 3-5 years. A significant disadvantage is low strength, high cost and impracticality.

A cheaper option is walls made of double hollow silicate bricks. This is an analogue of a “double wall” (made of 2 bricks), it retains heat well inside the house, is cheaper and more durable than a heterogeneous “fur coat” made from a bunch of “pie” materials.

Brick and concrete are heat-intensive materials; you need to try hard to keep them cold with good heating equipment even at minus 40 C.

With normal heating and operating conditions of the house, the payment costs are no higher than in a similar stone house, wrapped in a “multi-layer fur coat” of expensive and short-lived materials. The money for their construction, repair or reconstruction every 5-10 years can be used to pay housing and communal services, and there will still be some left over.

On a note! A house made of aerated concrete blocks with a thickness of at least 45 cm does not need insulation, provided there are no gaps in the walls and roof and a good heating system.

External insulation of brick walls - how to choose optimal thermal insulation?

Minvata

This concept includes the following varieties:

- glass wool, as well as stone wool;

- slag wool

All these materials are characterized by corresponding fibers, which are based on glass, rocks, and slag.

Averages:

- thermal conductivity – 0.041-0.044 W/(mK);

- impermeability – 20-200 kg/m3.

IMPORTANT!

Before deciding whether to insulate a brick facade with this material, it is necessary to take into account that it is prone to excessive absorption of moisture . Therefore, it is additionally treated with special chemical materials.

Mineral wool

Styrofoam

An oversized material, which, due to its characteristics and affordable price, has become the most popular material for thermal insulation . In the construction market you can always find a copy whose average indicators are:

- thermal conductivity – 0.033-0.037 W/(mK);

- impermeability – 11-35 kg/m3.

Foam plastic is practically free from moisture, plus it is vapor-proof. In addition, the material is quite fragile, easily flammable, and during smoldering it releases many dangerous chemical elements. This material has many disadvantages, but it is ideal as an economical option.

Styrofoam

Extruded polystyrene foam

In terms of its characteristics, the material resembles the foam plastic described above, only there is one difference - exclusively the latest developments are used in its production.

Averages:

- thermal conductivity – 0.028-0.032 W/(mK);

- impermeability – 25-38 kg/m3.

It is often used for external insulation; it is quite strong and retains heat well. Naturally, its cost is several times higher than that of the two options discussed above.

Warm plaster

It is distinguished by sound insulation and vapor permeability.

Characteristics:

- thermal conductivity – 0.065 W/(mK);

- impermeability – 200-340 kg/m3.

This is an ideal insulation material for cladding the external wall of a brick house, but requires special conditions due to its characteristics:

- layer of plaster no more than 50 mm;

- the foundation must be further strengthened.

Plaster

Features of heat insulators for insulating brick houses

The first thing that needs to be taken into account for high-quality insulation of a structure is the characteristics of heat insulators. There are dozens of insulation materials in stores that differ from each other and may be suitable in one case or another. Since the task is to keep the heat inside, protect the brick walls and make the house presentable, you need to choose a suitable material that will not be afraid of wind, precipitation, freezing and heating. List of criteria:

- Heat conductivity indicators. This is the first thing you should pay attention to. The lower this indicator, the better the insulation for brick walls on the outside of a house will retain heat inside. The number indicates how much warm air will be lost in 1 hour per m2, with a thickness of 1 m.

- Moisture absorption - it indicates how much moisture the insulation material can absorb. The more moisture in the structure, the worse the thermal insulation characteristics. Many insulation materials are afraid of moisture and require ideal protection from precipitation. It is better to insulate the facade of a brick house with materials that have low moisture absorption.

- Flammability indicates whether the insulation is protected from fire, whether it supports combustion or not. All materials are divided into 4 groups based on flammability: G1, G2, G3, G4. When choosing insulation for brick walls, group G1 is most often used. Such insulation can go out without an open flame.

- Density. The higher it is, the stronger and heavier the material, but its thermal insulation characteristics weaken. The lower the density, the lower the load on the foundation and the better the insulation, however, the strength of the product decreases.

- Soundproofing. An important parameter that will make the room more comfortable and quieter. Penetrating noise will be dampened, which is important for those who live in busy areas, near train stations, airports, playgrounds, factories and similar noisy enterprises. Typically, all wall insulation materials have this indicator at a high level.

- Ecological cleanliness. Since the heat insulator will be located outside, this is not the main criterion. This is more of a requirement for those who carry out internal insulation of brick walls.

Among other things, pay attention to weight. A brick house is heavy and puts a lot of stress on the foundation. Heavy insulation should not be used, especially if during the construction of the building no reserve was made for the strength of the foundation.

So that the work can be done with your own hands, pay attention to the complexity of installation. For beginners, a material that has a clear and simple installation technology that does not require additional equipment is suitable. Taking into account all these recommendations, you can choose a suitable thermal insulator for insulating your home.

Thermal panels

This material is distinguished by both thermal insulation and the ability to cover the surface of walls..

Characteristics:

- thermal conductivity – 0.025 W/(mK);

- impermeability – 45-55 kg/m3.

NOTE!

Today on the market you can find panels that are produced as imitation siding or lining. They are covered with a special quartz coating.

Thermal panels

Glazing

Windows are not only the eyes of a house, but also one of the ways it loses heat. Even with ideally warm walls, up to 50% of heat can be lost through window structures. Installing high-quality windows is the first step in insulating the entire house. At the same time, properly selected glazing will allow you to warm the room in winter and cool it in summer.

Despite the large selection of models and profiles, PVC windows are popular among homeowners. They are distinguished by high heat and sound insulation properties, durability, functionality, attractive appearance, accessibility and the ability to decorate them in accordance with the wishes of the customer.

Double-glazed windows play an important role in window construction, on which the performance characteristics of the windows depend. We recommend that you learn in detail about double-glazed windows, the principles of their operation and even the rules of selection from the video:

All about double-glazed windows.

Source https://oknanovgoroda.ru/steklopakety

Such interesting and accessible information will help you make your home as comfortable and cozy as possible. We recommend!

Pie wall - what elements does a brick wall consist of?

- Plaster - from 10 to 35 mm depending on the chosen option for the brick wall;

- Hollow or solid brick;

- Foam plastic PSB 25 (from 70 to 120 mm);

- Steel lathing;

- Vapor barrier and wind barrier multifunctional membrane.

- Plaster or mortar known;

- External finishing - facing brick or decorative plaster.

wall pie

Waterproofing walls before installation

Brick does not need to be specially protected from water. A reliable barrier is a heat insulator and plaster applied on top of it (in the case of mineral wool, a superdiffusion membrane).

Waterproofing material covers the foundation.

The foundation and basement are covered with waterproofing material, if it is also decided to insulate them. Use bitumen-polymer mastic or rolled material such as rubemast.

A few words about waterproofing and vapor barrier

At the stage of thermal insulation of the wall, it is necessary to pay special attention to the vapor barrier, otherwise the insulating material will become unusable after some time. The classic material for vapor barrier is polyethylene.

When installing, you must handle it extremely carefully and do not pull it too hard, otherwise the film may become deformed, especially during seasonal changes in climatic conditions.

Waterproofing

A frequently used vapor barrier material is considered to be mastics specially created for this purpose. If they are applied to the wall, they will allow air to pass through while retaining moisture. Waterproofing protects various building structures from moisture penetration. It is easy to apply, does not require special qualifications from workers, and does not form seams.

For brick walls, plaster is often used instead of vapor barrier, which is not very true in the case of mineral wool, because the insulation will begin to dampen.

Vapor barrier and waterproofing

How to apply warm plaster to walls?

Working with insulating plaster will take time, especially if you lack painting skills. To properly prepare the solution, the mixture is diluted according to the instructions.

- Brick walls are cleaned and protruding parts are removed. The surface is primed with a penetrating compound.

- A plaster mesh and beacons are attached to create a common plane.

- The prepared solution is applied to the walls. The thickness of the layer depends on climatic conditions, but it should not exceed 5 cm.

- You can create various decorative textures on the finished surface.

The insulation materials considered can be used in any region; the thickness of effective thermal insulation is calculated according to local climatic characteristics.

Sealing cracks and preparing sheathing

It is better to replace damaged walls or carry out major repairs. Gaps in joints are sealed with natural materials or synthetic stone sealants .

Before insulating the wall, you need to take care of preparing the sheathing. The distance between its bars should be determined based on the width of the insulation slab . It is important to use a building level to check the vertical and horizontal surface for finishing. The sheathing bars should be directed perpendicular to the direction of the facing panel.

Brick wall sheathing

Do not forget about installing transverse sheathing to ensure high-quality ventilation.

For the convenience of installing intermediate elements of the sheathing, a rope is pulled from the corner beam from below and above the facade . Some people mark future elements with chalk.

Preparing the brick surface

Before insulating a building, carry out the following actions:

- Decorative elements, lamps, canopy over the door, spotlights, antenna, and external air conditioner unit are dismantled. Remove window sills and frames.

- Knock down the old facing material in places where it does not hold firmly or has crumbled.

- Eliminate defects: seal cracks and potholes with mortar, knock down bumps.

- They clean the walls from dirt and sweep away dust.

- Cover the façade with primer.

If foam plastic is intended to be used, the enclosing structures are sheathed on the inside with a vapor-proof film.

Insulation of a brick wall from the outside using mineral wool as an example

- On the outside, the brick base must be sheathed with OSB boards ; gaps must be maintained between them, the size of which is indicated by the manufacturer. After installation, the gaps are filled with foam.

- Then, on the outside, a membrane with waterproofing is stretched, which protects the mineral wool from moisture , on top of which all exterior finishing will be carried out. Many companies produce waterproofing materials with strips on which connecting elements are applied for a tighter joint. If such strips are missing, the joints should be glued with double-sided tape.

- Then sheets of mineral wool are tightly installed . Often a material is used whose density starts at 35-50 kg/m3. A material with a lower density will certainly settle or roll off, which will cause cold to pass through the formed voids.

- Mineral wool slabs are installed so that the previous mine connections are covered. by 150-200 mm. The overall insulation thickness is based on climate and temperature indicators, but the average is 150 mm.

- After laying the sealant into the walls, all voids that appear are filled with film for installation.

Insulation with mineral wool

Insulation under siding

Technology for insulating the walls of a house

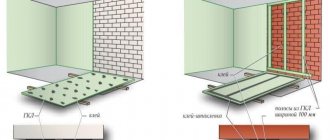

There are two most commonly used types of insulation :

- Wet facade . The thermal insulation layer is installed using a special glue, covered with a mesh and treated with a decorative finishing coating. They use mineral wool, polystyrene foam, expanded polystyrene, and siding and decorative plaster as finishing.

- Sandwich panels . Insulation of brick walls is designed at the stage of their construction. They are covered with a casing made of metal or wood treated with an antiseptic, where the thermal insulation material is subsequently installed. And the frame is sheathed on top with decorative material. This technology is suitable for houses with a strong and durable foundation.

The first stage of insulation is always cleaning the wall from dirt and various debris.

You also need to treat the walls with a primer Source rmnt.ru

The further procedure for carrying out work depends on the selected material.

So, to insulate the walls of a house with polystyrene foam, they are first plastered. The surface is primed and panels of heat-insulating material are installed using special glue or dowels.

Cut-up heat insulator slabs are attached to a pre-moistened wall with an adhesive mixture. After installation, the material is allowed to dry for two days. They are additionally fixed with dowels and the first layer of glue is applied to level the surface. Additionally, it seals cracks and cracks. Then the mesh is glued onto the polystyrene foam and covered with glue again.

After the surface has dried, it is plastered with ready-made ceresite solutions, rubbed, primed and facade paint is applied.

Mineral wool is installed in two ways:

- method of installing a ventilated facade;

- by gluing the insulation directly to the wall.

The first option is more common. It involves the installation of sheathing and a layer of waterproofing. Wooden or metal sheathing is attached directly to the wall surface. The mineral wool is placed tightly between the guide bars and covered with a waterproofing sheet. The slats are again stuffed on top, providing ventilation between the insulation and the facing material.

Then siding is mounted on the slats or reinforced mesh is laid with further plastering of the surface.

Thermal insulation with polystyrene foam and polyurethane foam - basic principles

Today, many builders insulate their facades with extruded polystyrene foam. The slabs are laid taking into account the degree of horizontality . Sags will ideally cope with the task. When installing the slab, it is extremely necessary to pay attention to maintaining the uniformity of the profile strip; for this, a building level is used.

The joining of the slabs is carried out according to the principle of brickwork, in other words, you need to mount half the slab through each row . The cracks are sealed with liquid polystyrene and pieces of polystyrene foam, but it is better not to use polyurethane foam. If the slabs are poorly joined, this can be easily corrected with a float.

Foam boards are attached with glue, but do not forget about special dowels with caps. Otherwise, due to strong gusts of wind, the slabs will fall off.

As for polyurethane foam, this is a new generation material that:

- Is non-toxic and environmentally friendly;

- Does not lose its characteristics for a long time and lasts for more than half a century;

- It hardens in a short period of time, thanks to this the installation time is significantly reduced;

- Insulation materials based on Polyurethane are completely safe for health. After hardening, this material becomes environmentally friendly;

- Thermal insulation with polyurethane foam is characterized by the lowest possible flammability when compared with other types of insulation;

- Polyurethane foam is not capable of transmitting or absorbing moisture. Thanks to excellent thermal insulation, home owners are free from problems associated with the formation of condensation, mold and mildew.

Thermal insulation with polystyrene foam

Thermal insulation PPU

Insulating a brick house from the outside has a number of advantages. The main thing is to choose the right material and use it rationally, taking into account all the subtleties.

Carrying out the necessary calculations before choosing insulation

To insulate the facade of a brick house, the first thing that needs to be considered is the thermal conductivity of the structures. You need to start with a table that shows data for regions. For example, in Moscow it is 3.14 sq.m*/W. Next, the value for the existing design is determined. For example, for hollow ceramic bricks it is 0.41 W/m*.

In order for the brickwork to comply with the standard, a wall with a thickness of 3.14 * 0.41 = 1.29 m will have to be erected. In order to save money, if in practice a structure of 0.5 m is laid out, then it is necessary to compensate 0.5 / 0.41 = 1.2 sq.m*/W. For cladding, for example, clinker bricks account for 0.012/0.8=0.015 sq.m*/W, which practically does not affect the total lack of conductivity of the walls, even with a thin layer of adhesive mortar.

If you use mineral wool with a coefficient of 0.044 W/m* as insulation, then the thickness of the insulator should be at least 1.2*0.044=53 cm. For polyurethane foam it will be 1.2*0.035=42 cm, and for extruded polystyrene foam 1.2*2 ,8=34 cm.

After determining the thickness of a particular heat insulator, the issue of the total weight of the material on the supporting structures is considered. Only after this can you decide what methods will be used for installation and decorative finishing.

Preparing a brick wall for insulation

Any finishing work can be carried out provided there is a strong, dry, clean and “healthy” base. It is necessary to check the strength of the masonry mortar and the old wall covering, if any (paint, tiles, plaster, etc.). The latter is recommended to be completely dismantled.

If oily stains are present, they are treated with a degreaser. Areas affected by rust, fungus, mold or bacteria must be “cured” with exterminators and protected with preventative compounds. Cracks are fixed, faulty bricks are replaced, large chips are filled with leveling agent or tile adhesive. Finally, the surface is impregnated with a primer with antifungal additives for outdoor use.

- Waterproofing walls . When insulating a brick, the dew point shifts towards the heat insulator. Since decorative finishing follows, the risk of condensation is high, which will negatively affect the brick. To reduce it to a minimum, special films and membranes with one-sided vapor permeability and waterproofing properties are used. They are mounted with an overlap to prevent leaks.

- Relevance of the sheathing device . The lathing is assembled in the case of a ventilated structure. Attach it to the wall so that the insulation is recessed throughout its entire thickness, flush with the outer edges of the planks. The pitch between the timber or profile is calculated based on the physical parameters of the slabs or insulator sheets (for soft ones it is reduced by 1-3 cm on each side). The structure is assembled horizontally and vertically to prevent the appearance of cold bridges.

Which to choose?

To correctly select a thermal insulation system, it is necessary to calculate all the basic parameters that affect the thermal efficiency of the object.

Experts recommend paying attention to the following properties of heat-protective materials:

- The density should be maximum; the thickness of the layer and the total weight of the structure will depend on this indicator.

- The thermal conductivity coefficient is chosen to be the smallest in order to reduce the process of heat transfer from a warm source to a cold one;

- Resistance to all negative factors, both mechanical and natural.

- Biostability, no mold formation processes.

- Moisture absorption is selected as low as possible; in this case, it can be guaranteed that freezing of the walls will not occur, or additional vapor and moisture insulating layers can be installed.

- The flammability class can be taken equal to class 4, when the insulation stops burning in the absence of open fire.

- Durability of at least 25 years.

- The material must have good vapor permeability, especially for internal thermal insulation of a house.

- High level of sound insulation.

Is it better to insulate from the inside than to insulate from the outside?

In order to accurately determine the effectiveness of thermal protection, laboratory measurements of the building's heat loss are carried out . Before choosing an insulation scheme, it is better to choose a method that will be available in the real conditions of existing housing construction.

In the retail chain there are many materials that can be laid for both external and internal insulation. Many experts believe that insulating brick houses inside is not entirely correct.

However, this option is resorted to if:

- the house is recognized as an architectural monument;

- the buildings are located very close to each other, so it is not possible to carry out installation work on thermal protection;

- The external cladding of the building is made of expensive finishing bricks and it is not economically feasible to cover it.

According to customer reviews, it is best to use mineral wool for the exterior decoration of a brick house; it has the best protective properties. If you need budget material, buy polystyrene foam.

Penoplex is also a good choice for external protection of bricks; in addition to thermal protection, it also has waterproofing, so it is well suited for insulating facades. But penoizol is a universal material that protects a brick house well when installed outside and inside.

Internal thermal insulation must be treated with care, being careful not to create a dew point.

To protect freezing brick walls from contact with condensate vapor, one of the following options is used:

A polymer insulator that does not allow vapor to pass through is installed. This can be extruded polystyrene foam, high-density foam, or spray polyurethane foam.- Install hydro and thermal insulation.

- Heat-insulating plaster is applied to brick walls.