Where to buy a Don 16 boiler ↑

When building a country house, owners are faced with the natural need to organize and equip autonomous heating.

When it is not possible to connect the house to gas supply, you have to choose something alternative. One of such heating system options is the Don solid fuel boiler. It is worth recognizing that this is a convenient and reliable unit to use, which has many excellent reviews. Let's start not with the question of where to buy Don, but with who produces it. The device is manufactured by the Conord Plant, located in Rostov-on-Don. The instructions, uniform for current versions, allow them to be fueled with wood, peat and coal, and if the necessary substances are not available, the boiler can be freely switched to gas. This remarkable flexibility of application is the result of the introduction of strict standards specifically created for the production of equipment with special consumer parameters. Don solid fuel boilers are produced with a power from 11 to 40 kW.

We provide installation and commissioning services for the products we sell.

The KST 16 boiler Mozyrselmash is one of the most popular products in its line. This model can also be slightly modified, namely, have a . This boiler has a rated thermal power of 16 kW. Very high efficiency guarantees economical solid fuel consumption and high productivity. Depending on the area of the heated premises, a boiler of the required power is selected. Solid fuel heating boilers are perfect for remote houses and cottages where there is no gas supply

Typically, such boilers are installed in private homes and industrial premises, where it is very important to maintain the room temperature regardless of utilities. Unlike gas boilers, KST does not depend on gas pipes and electricity, which makes it as reliable as possible

The operational life of the KST boiler is at least 10-15 years, according to the manufacturer. The reliability and practicality of this boiler is confirmed by numerous reviews from satisfied customers. Purchase equipment only from official representatives of the Mozyrselmash manufacturer to protect yourself from low-quality products.

Specifications ↑

These products of the Rostov association are presented in five varieties. Without a pre-installed gas burner, only Don KS-T-16 boilers are available, which take only firewood. The remaining solutions (T-R, TG, TVm, TGVm) are equipped with the circuits necessary for the transition. General properties:

- power (kW): 16;

- Efficiency on solid fuel/gas (%): 75/82;

- gas consumption (m3/h): 2;

- weight (kg): 139-154;

- length/width/height (mm): 700/470/1030;

- heated area (m2): 160.

Only one unit in the line is equipped with a traction regulator, which makes operation easier. In improved solutions, the shortcomings associated with its absence are compensated by the decent adaptability of gas burner systems and the good performance of the DHW circuit. The modest design of the classic version is explained by the desire to ensure ease of use.

Model overview

Let's describe the best models.

KS 16

Of all the models presented by domestic manufacturers, one of the most popular is the “Don” KS 16. Its main advantages: excellent technical characteristics, convenient operation and economical consumption of energy resources.

Having domestic assembly and components, it is ready to work in the most difficult climatic conditions. It is the Russian climate that does not allow many European analogues to compete with domestic developments. This line includes modifications that differ in the number of circuits and a number of smaller differences.

Key technical parameters:

| Heating area, m² | 160 |

| Natural gas consumption, m³/h | 2,0 |

| Thermal power, kW | 16 |

| Efficiency,% | 90 |

| Weight, kg | 139 |

| Dimensions (HxWxD), mm | 1030x470x700 |

| Cost, rub. | 22 000 |

KS-T-11

Steel. Non-volatile. For small objects. Operates on gas or solid fuel - the burner is changed.

Automation installed. Thanks to the Honeywell regulator, energy consumption is reduced by 30%. The firebox material is carbon steel, resistant to corrosion. Adapted to hard water.

| Heating area, m² | 110 |

| Natural gas consumption, m³/h | 2,0 |

| Thermal power, kW | 11 |

| Efficiency,% | 80 |

| Weight, kg | 65 |

| Dimensions (HxWxD), mm | 680x470x580 |

| Cost, rub. | 12 500 |

- Floor installation.

- Steel heat exchanger.

- The exhaust of combustion products is a chimney.

"Don Eco"

An economical version, the main difference of which is its compactness. The small device contains reliable Italian automation and an efficient heat exchanger. It features stable burner operation and high heat transfer.

The boilers are designed for heating small areas; they can be used with a flow-type water heater (“DON” or “CONORD”). In tandem with a water heater, this model will provide a small home with heat and hot water.

As an example, here are the technical characteristics and design features of the Don Eco KS-G-12S:

| Heating area, m² | 120 |

| Natural gas consumption, m³/h | 1,32 |

| Thermal power, kW | 12 |

| Efficiency,% | 90 |

| Weight, kg | 34,3 |

| Dimensions (HxWxD), mm | 650x230x573 |

| Cost, rub. | 13 500 |

- Heating system pressure (min/max) - 0.1/1.2 bar.

- The coolant is water.

- One circuit.

- Floor-standing version.

- Open firebox.

- Steel heat exchanger.

- Gas removal is through a vertical chimney.

- Body color: white.

- Warranty - 2 years.

DonStail

New gas equipment from DonStail models with increased performance. Powerful heaters with a strict and stylish design. The white color and decorative perforations on the body create a feeling of lightness; the device fits harmoniously into a modern interior.

Thanks to the special design of the heat exchanger and Sit automation and Polidoro burner, these modifications have high efficiency, low energy consumption and are completely safe.

Characteristics of the single-circuit version of DonStail KS-G-12 S:

| Heating area, m² | 120 |

| Natural gas consumption, m³/h | 1,32 |

| Thermal power, kW | 12 |

| Efficiency,% | 92 |

| Weight, kg | 73 |

| Dimensions (HxWxD), mm | 835x343x515 |

| Cost, rub. | 18 000 |

- Floor-standing version.

- Open firebox.

- Steel heat exchanger.

- White color.

- Warranty - 3 years.

- Piezo ignition.

Powerful boilers "Don"

For heating large cottages, industrial and warehouse buildings, high-power devices are used:

- At 40 kW. Efficiency - 76%. Heats a room up to 400 m². Weight - 290 kg. The dimensions are small - 700x850x1430 mm.

- At 50 kW. Consumption 3 m³/h. Provides heat for cottages up to 50 m². Efficiency - 85%. Dimensions - 850x700x1430 mm.

- At 100 kW. The most powerful option is for 1000 m². Efficiency - 87%. Weight - 560 kg. Dimensions - 1280x900x1090 mm. An ideal solution for large country houses and non-residential premises.

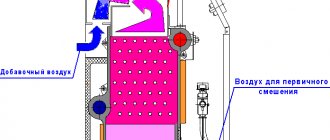

Operating principle ↑

The functioning scheme is simple. The elements that make up a regular Don 16 boiler are few, they are simple: a firebox with a water jacket, temperature sensors, a pipe system supplemented with turbulators. When burning fuel, the water cavity heats the injected water, convection amplifiers send the liquid into the general circuit through the upper pipe, and it is replaced by cold flows supplied to the lower one. The meter monitors and corrects the temperature. Although the devices are manufactured on the same base, they have slightly different structures. The difference is in the details. The letters that make up the brand name will help you figure out what advantages they offer in each case. There are nine letter designations: 1). "K" - boiler. 2). "T" - solid fuel. 3). "G" - gas. 4). "M" - modified. 5). “C” - with a steel heat exchanger. 6). “C” - with cast iron. 7). “B” - with a water coil. 8). “P” - with draft regulator. 9). "TG" - universal.

Gas boilers Conord: review, design, automation

It's no secret that imported floor-standing gas boilers are of higher quality compared to domestic boilers. This applies to the material used to make the elements, the reliability of the automation, and the assembly of the device. However, the price of imported analogues differs noticeably upward. Our task is to find a Russian-assembled gas boiler with an optimal price-quality ratio.

I propose to disassemble Conord floor-standing gas boilers, reviews of which can increasingly be found on various thematic forums. Let's consider the model range, technical characteristics, device, types of automation (gas burner devices), using the instructions for use.

Model range and description of Conord boilers

Conord floor-standing gas boilers are available with capacities from 8 to 30 kW. They come as single-circuit: KSts-G-8, KSts-G-10, KSts-G-12, KSts-G-16, KSts-G-20, KSts-G-25, KSts-G-30; and double-circuit: KSts-GV-10, KSts-GV-12, KSts-GV-16, KSts-GV-20, KSts-GV-25, KSts-GV-30.

Single-circuit ones can only be used for heating from 30 to 300 m2. Conord double-circuit gas boilers can be used for both water heating and hot water supply (DHW).

Floor-standing gas boilers Conord

There is no point in buying, for example, a double-circuit boiler KSts-GV-12 with a power of 12 kW. It will not give us a good volume of hot water.

Boilers can be used in both open and closed heating systems.

Installation of floor-standing gas boilers Conord

The boiler consists of a steel firebox 3 mm thick, a casing, a water jacket, smoke pipes with turbulators built into them to increase the efficiency of the boiler, a gas burner device (automation), a layer of thermal insulation made of basalt cardboard, and a thermometer to monitor the temperature of the coolant. In double-circuit models, a special coil for the water circuit is installed around the smoke pipes.

The coolant inlet and outlet, as well as the DHW coil, are located on the rear side of the boiler body. The thread diameter of the heating connection pipes for all models of this brand is 2 inches or 50 mm. For DHW circuit 1/2 or 15 mm. The chimney diameter for models with power from 8 to 12 kW is 115 mm, for 16 kW and above - 150 mm.

Conord boiler design

Automation for gas boilers Conord

Three types of automation can be installed on floor-standing boilers of this brand:

— domestic type AGU-T-M

- Italian Euro SIT

In general, the automation, although not particularly sophisticated, is unpretentious. In the event of a breakdown, it is not difficult to find spare parts for it. For example, a bimetallic strip that often fails costs about 50 rubles.

Automation type AGU-T-M

Ignition occurs by pressing the piezoelectric element button or using a match. The coolant temperature is provided by the gas valve and set by the thermostat knob.

Automation Euro SIT

Ignition is carried out by pressing the handle to the right of the thermostat and then turning it to the stop position to operate the boiler in economical mode.

— wide model range — three types of automation — cost-effectiveness — high efficiency — in case of boiler malfunction it’s easy to find spare parts — good thermal insulation

Disadvantages of Conord boilers

— build quality — steel thickness no more than 3 mm — price

The price of Conord boilers starts from 13,000 rubles for the most budget and low-power model. Still, it's a little expensive. For similar money you can already buy, for example, an imported floor-standing gas boiler “Protherm Wolf”, assembled in Slovakia. But it's up to you. Let's watch the video.

The first start-up of the heating system is a crucial moment on which the serviceability of its elements, coherence and uninterrupted operation depend.

How to turn on a gas boiler, fill the radiators with coolant, bleed the air, check everything and not forget anything.

Consider the procedure and rules for putting the heating system into operation.

If the boiler is new and you do not want to lose the possibility of warranty service, you will have to invite service employees. They will make a corresponding note in the passport stating that the first launch was carried out according to all the rules.

Advantages and disadvantages ↑

Steel heating boilers "DON" are designed for heating premises with an area of up to 400-500 sq.m.

Consumers appreciate the compliance of the equipment with domestic conditions of use (severe and long frosts, hard water), and the energy independence of its mechanisms. Previously, consumer interest was aroused by the good technical characteristics of the lines; now the stability of demand is supported by such qualities as:

- excellent thermal insulation and high safety (provided by an 8 mm casing);

- an impressive period of independent combustion with low fuel consumption (the presence of a lined chamber makes the Don 16 boiler capable of operating on one load for up to 8 hours);

- durability (due to the case being made of 3 mm steel);

- maintainability (parts can be replaced).

Lining critical bunkers prolongs thermal processes, increases efficiency, thereby guaranteeing decent efficiency. It also, as reviews indicate, leads to a decrease in ease of use. Additional processing of sections increases:

- heaviness (the Don 16 boiler is prohibited from being hung or placed on thin supports; it should be placed on thick floors or platforms);

- demands on fuel (humidity up to 15%; if the standards are neglected, smoke and soot will appear);

- uncontrollability (difficult to accurately calculate the operating speed and set the heating temperature);

- capriciousness in installation, which is what owners most often complain about.

How to choose

Thermal power. When choosing it, you need to know not only the area that is supposed to be heated. If a device is selected for heating a private home, you must also take into account what material it is made of and how insulated it is.

In apartments, the location is important - central or corner. In the latter it is always colder, so the power must be chosen with a reserve. The approximate power of the device is determined by the ratio - 1000 W for every 10 square meters of area

And for every cubic meter - 40–60 W. But it is recommended for cold houses and apartments to take boilers with a heating capacity reserve of 30%. Firstly, there will be no problems with heating in the most severe frosts, and secondly, the equipment will not wear out and will last longer

The approximate power of the device is determined by the ratio - 1000 W for every 10 square meters of area. And for every cubic meter - 40–60 W. But it is recommended for cold houses and apartments to take boilers with a heating capacity reserve of 30%. Firstly, there will be no problems with heating in the most severe frosts, and secondly, the equipment will not wear out and will last longer.

Dependence on power grids. This parameter is more important for reliability and stability than for efficiency. If boilers require electricity consumption, for example for ignition, it is insignificant.

Number of circuits. The capabilities and cost of the heater depend on the choice of this parameter. Single-circuit ones are chosen for heating; double-circuit ones, in addition to heating rooms, can heat water for domestic use.

Installation method. Wall or floor. The choice depends on the area of the room. Wall-mounted versions are more compact.

Heat exchanger material - steel or cast iron. Cast iron ones are more reliable, they are not afraid of corrosion.

Type of combustion chamber. It is more convenient with a closed firebox: they are safer, do not waste the internal air of the premises, they are preferred today by owners of houses and apartments that are not equipped with traditional chimneys.

How much do they cost

Equipment from domestic brands is a priori cheaper than imported ones, and products are no exception.

The price of Don boilers depends on the model and its power. An inexpensive single-circuit device KS-T-16, designed to heat 160 m², costs about 17,000 rubles. The cost of a powerful double-circuit device designed to heat 300 m² is 37,000 rubles.

Reviews ↑

On a professional forum, the installer Melky writes that in the villages of his region they order only such solid fuel boilers, everyone is happy. In response, Lis criticizes the KS-T-16R model. He is angry that in winter he is on duty at the stove, adding firewood every 3 hours, struggling with the tricks of the traction regulator, suffering from the cold. Nikola SD gives him a hint: the problems are created by the ill-conceived operating principle, which requires igniting all the loaded fuel at once. The combustion is uneven; adjusting the damper does not help. It is especially difficult to achieve the required performance in the off-season. Serge Ch. says: having found himself in the described situation, he asked a specialist to find out its cause; It turned out that the problem was the short length (less than 3 m) and small (less than 150 mm) diameter of the smoke pipes. I ordered a rework, the price of the service seemed a bit high. In the discussion section of the website on energy saving, NVB praises the KS-TGVm-16 version for its ability to provide powerful coolant circulation, allowing one to avoid purchasing a pump. Master Hottabych assures: the devices will delight your grandchildren if you set the emergency valve to 1.5 atmospheres, add foreign automation, and spend money on decent fuel.

Methods for adjusting temperature conditions

Let's consider this case - you purchased a gas boiler, the technicians installed it and adjusted the settings, setting a certain operating mode. But one fine day it became colder outside, and the previously established heating indicators no longer met the new realities. Then the owners have a question about how to increase the temperature on a gas boiler. This can be done in different ways, which depend on the model of the unit. Conventionally, methods for increasing temperature can be divided into:

- mechanical;

- electronic.

Which method is suitable in a particular case can be seen in the operating instructions for the gas boiler.

Read here about the choice of voltage stabilizers for gas boilers

Mechanical methods involve manual adjustment of the gas boiler settings. This addition of temperature is carried out with simple models of units, for example, AOGV or those produced by the Zhukovsky plant. Electronic regulation is provided automatically by a built-in or connected thermostat. This function is available on many modern models of gas equipment.

Price ↑

Multi-fuel water heating systems are considered universal products. The cost of the units is: 4-7 thousand rubles. (budget options), 10-35 thousand rubles. (affordable), 35-70 thousand rubles. (premium). According to the specified gradation, Don 16 boilers belong to middle class products, which is confirmed by the following figures:

- models KS-T-16: 12-14.5 thousand rubles;

- version KS-T-16R: 15-16 thousand rubles;

- systems KS-TG-16: 16.5-17 thousand rubles.

- variations KS-TVm-16: 17.5-20.5 thousand rubles;

- TGVm-16 schemes: 21-23 thousand rubles.

Firewood quality

The best firewood for a solid fuel boiler has always been oak firewood. Due to its high quality, these raw materials belong to the elite class. The cost of oak firewood is high, so it is not affordable for everyone. But such firewood is often indispensable when it comes to the taste of baked bread, pizza or other pastries. Here oak logs are simply irreplaceable.

Let's look at the characteristics of firewood from different types of wood:

- Oak: an elite, expensive variety. Burns powerfully, giving off a huge amount of heat;

- Birch: Best quality/cost ratio;

- Alder: excellent firewood, the house warms up quickly. In addition, the ancestors considered alder firewood to be “medicinal”, since in a house heated with its help, people were less likely to get colds;

- Pine: hot and aromatic firewood that burns well due to its resin content.

Brief operating instructions ↑

1). Fill the system with fresh water in small portions (maximum 8 l/min) until liquid is released from the overflow tube of the expansion tank. 2). Proceed with kindling, focusing on the nature of the fuel: I. Ignition of the CT: a). open the primary air plug, bring a rolled newspaper to the gap between it and the screw valve, make sure there is traction (the pages will be pressed); b). Fill the receiving chamber evenly halfway with firewood, set it on fire, and when ignited, pour small (up to 25-30 cm) pieces of coal on top; V). put no more than 5-6 kg of fuel at one time, spend about an hour loading the bunker; then set the gate so that the thrust is stable. II. Starting the gas burner: a). ventilate for 5-10 minutes. combustion unit by closing the main valve; b). check the traction force by bringing a sheet of paper closer to the viewing window; V). open the air supply valve, light the fire. 3). Close the doors; later adjust the temperature with a mixer or coil valve.

Brief technical specifications

| Technical characteristics of DON boilers | DON KS-T-16 | DON KS-TG-16 | DON KS-TVm-16 | DON KS-TGVm-16 | |

| Heating output kW | on gas | — | 16 | — | 16 |

| solid fuel | 16 | 16 | 16 | 16 | |

| Maximum heated area, m 2 h ceilings 2.7 m | on gas | — | 160 | — | 160 |

| solid fuel | 160 | 160 | 160 | 160 | |

| Weight kg | 139 | 139 | 154 | 154 | |

| Length | 700 | 700 | 700 | 700 | |

| Width | 470 | 470 | 470 | 470 | |

| Height | 1 030 | 1 030 | 1 180 | 1 180 | |

| Efficiency, % not less | on gas | 82 | — | 82 | |

| solid fuel | 75 | 75 | 75 | 75 | |

| Nominal gas flow, m3/h | — | 2 | — | 2 | |

| Hot water circuit capacity l/h* | on gas | — | — | — | 390 |

| solid fuel | — | — | 390 | 390 | |

Legend

- K - boiler

- C - steel heat exchanger

- G - gas boiler

- T - solid fuel boiler

- TG - universal boiler

- B - presence of a hot water circuit

- m - modernized

- * - the performance of the hot water supply circuit is indicated at a temperature difference between the outlet and inlet of 35 ° C

Distinctive features of Don boilers

Electrically independent All Don boilers do not require electrical energy to operate. Unique water jacket The water jacket of DON boilers is designed in a unique way. Water, which is the coolant, is distributed almost throughout the entire boiler body. But a special layer of thermal insulation (8mm) allows you to retain valuable heat and keeps the surface of the boiler cool. Safe A special layer of thermal insulation (8 mm) allows maximum preservation of valuable heat and prevents heating of the surface of the Don boiler. Reliable and durable DON boilers are reliable and durable, since the entire boiler body and combustion chamber are made of 3mm thick steel. Guarantees your peace of mind The large combustion chamber allows the Don boiler, when operating on solid fuel, to operate for up to 8 hours without refueling Single-circuit Don boilers (heating) KS-T-16, KS-TG-16 Double-circuit Don boilers (heating + hot water supply) KS-TGVm- 16, KS-TVm-16 Solid fuel boilers DON KS-T-16; KS-TVm-16 Universal (solid fuel and gas) boilers Don KS-TG-16; KSTGVm-16 Provides the ability to use both natural gas and solid fuel (wood, coal, solid fuel) as fuel. If you have purchased a DON universal boiler, you can easily convert a solid fuel boiler into a gas one without replacing the burner. Included with the DON universal boiler, we already offer you a gas burner device. Adapted to operating conditions on hard water, DON is a unique solid fuel boiler that, if there is a hot water supply circuit, has a replaceable coil. When working on hard water, which is especially typical for our country, the coil quickly becomes clogged. The ability to replace the coil significantly increases the service life of DON boilers. Provides comfort and stable temperature in the house Combines the best traditions of domestic heating equipment manufacturers Tested and certified in accordance with Russian standards

FULL TECHNICAL DATA

| Name | Boiler model DON | ||||||

| KS-T/TG-16/20 | KS-TGV-16/20 | KS-TV / TGV-31.5 | KS-TGV-31.5/40 | KS-GV-40 | KS-GV-50 | KS-TG/GV-16.5/25 | |

| Heating capacity, kW | 16 / 20 | 16 / 20 | 31,5 | 31,5/40 | 40 | 50 | 16/ 25 |

| Area of heated premises, with a ceiling height of up to 2.7 m, m² | 160 / 200 | 160 / 200 | 315 | 310 / 400 | 400 | 500 | 160 / 250 |

| Efficiency factor, % not less than: | |||||||

| - on solid fuel | 75 | 75 | 76 | 76 | 76 | 76 | 92 |

| - on gas fuel | 82 | 82 | 90 | 85 | 85 | 85 | 92 |

| Operating water pressure in the boiler, mPa (ng/cm2), no more | |||||||

| - in the coil | 0,6 (6,0) | 0,6 (6,0) | 0,6 (6,0) | 0,6 (6,0) | 0,6 (6,0) | 0,6 (6,0) | |

| - in the boiler | 0,12 (1,2) | 0,12 (1,2) | 0,12 (1,2) | 0,12 (1,2) | 0,12 (1,2) | 0,12 (1,2) | 0,12 (1,2) |

| Water temperature in the boiler 0 C, no more | 95 | 95 | 95 | 95 | 95 | 95 | 95 |

| Connecting thread of fittings for water supply and drainage: | |||||||

| - for heating | 2″ | 2″ | 2″ | 2″ | 2″ | 2″ | 2″ |

| - for hot water supply | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1 1/2″ |

| Connecting thread of the gas supply fitting | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1 1/2″ |

| Internal dimensions of the chimney, mm | 202x96 | 202x96 | 252x97 | 252x97 | 252x97 | 252x97 | f 150 |

| Boiler dimensions, mm: | |||||||

| - length | 700 | 700 | 850 | 850 | 850 | 850 | 700 |

| - width | 470 | 470 | 740 | 740 | 740 | 740 | 540 |

| - height | 1030 | 1180 | 1430 | 1430 | 1430 | 1430 | 1000 |

| Boiler weight, kg, no more | 139 | 154 | 282 | 282 | 237 | 237 | 78 |

| Vacuum behind the boiler, Pa: | |||||||

| - least | 10 | 10 | 10 | 15 | 15 | 15 | 10 |

| - greatest | 25 | 25 | 25 | 40 | 40 | 40 | 25 |

| Water heater water consumption with temperature difference at inlet and outlet 35 0, l/h, not less | -/- | 390/420 | 740 | 740/800 | 800 | 800 | 390/420 |

| Gas consumption at rated heating capacity, m 3 / h | 2,0/2,5 | 2.0/2,5 | 4 | 5 | 5 | 6 | 2,8 |

| Gas connecting pressure, kPa (mm water column): | |||||||

| — nominal | 1.3 (130) or 2.0 | 1.3 (130) or 2.0 | 1.3 (130) or 2.0 | 1.3 (130) or 2.0 | 1.3 (130) or 2.0 | 1.3 (130) or 2.0 | 1.3 (130) or 2.0 |

| - least | 0,6 (60) | 0,6 (60) | 0,6 (60) | 0,6 (60) | 0,6 (60) | 0,6 (60) | 0,6 (60) |

| - greatest | 1.8 (180) or 2.8 | 1.8 (180) or 2.8 | 1.8 (180) or 2.8 | 1.8 (180) or 2.8 | 1.8 (180) or 2.8 | 1.8 (180) or 2.8 | 1.8 (180) or 2.8 |

| Exhaust gas composition: | |||||||

| — carbon monoxide CO, mg/m 3, no more | 119 | 119 | 119 | 119 | 119 | 119 | 119 |

| — nitrogen oxides NO, mg/m 3, no more | 240 | 240 | 240 | 240 | 240 | 240 | 240 |

*The numerator contains the heating capacity and area of heated premises using solid fuel, the denominator - using gas fuel. The power calculation does not include the calculation of the power consumed by the hot water supply circuit. All parameters indicated in the table correspond to the operation of the boiler at rated heating output and established thermal equilibrium.

Transportation of Don boilers is permitted by all types of transport, provided that the product and packaging are protected from mechanical damage and exposure to precipitation, in accordance with the rules for the transportation of goods applicable to each type of transport. The method of loading and fastening of loading points must ensure complete safety of the boilers from mechanical damage. Don boilers are installed on vehicles in a vertical position.

DELIVERY SET OF DON BOILERS

| Name | Quantity per boiler model | ||||||

| DON | |||||||

| KS-T/TG-16/20 | KS-TGV-16/20 | KS-TV/TGV-31.5… | KS-TGV-31.5/40… | KS-GV-40… | KS-GV-50… | KS-TG/GV-16.5/25 | |

| Boiler assembly | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Lever | 3 | 3 | 2 | 2 | 1 | ||

| Axis | 1 | ||||||

| Damper | 1 | ||||||

| Spring | 1 | ||||||

| Operating manual for the boiler | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Operating manual for the burner | -/1 | 1 | -/1 | 1 | 1 | 1 | 1 |

| Primary air damper | 1 | 1 | 1 | 1 | |||

| Furnace sheet 16/31.5 | 1/- | 1/- | -/2 | -/2 | -/2 | -/2 | |

| Grate 22 | 2 | 2 | 5 | 5 | 3 | ||

| Grate 23/21 | 1/- | 1/- | -/1 | -/1 | |||

| Shield | 1 | 1 | 1 | 1 | |||

| Pin 26 | 1 | 1 | 1 | 1 | |||

| Turbulizer | 3 | 3 | 3 | 3 | 3 | 3 | |

| Scraper* | 1 | 1 | 1 | 1 | |||

| Poker* | 1 | 1 | 1 | 1 | |||

| Beam 14 | 1 | 1 | |||||

| Coal scoop* | 1 | 1 | 1 | 1 | |||

| Chimney in package | 1 | 1 | 1 | 1 | |||

| Gas burner device (packed) | -/1 | 1 | -/1 | 1 | 1 | 1 | 1 |

*Available upon separate order. Note: Accessories are located under the top removable cover.

4. SAFETY MEASURES 4.1 The heating boiler meets all requirements that ensure the safety of life and health of the consumer and, provided that all requirements for the installation and operation of the boiler are met, ensures the prevention of damage to the consumer’s property. 4.2 To avoid fires, the boiler must not be installed on combustible parts of the premises; steel sheets must be laid under asbestos cardboard or felt soaked in a clay solution under the boiler and 0.5 m in front of its front. 4.3 Persons familiar with the structure and operating rules of the boiler are allowed to perform maintenance. 4.4 Before igniting the boiler, it is necessary to ventilate the firebox for 10-15 minutes. 4.5 Check the presence of draft in the chimney by holding a strip of paper to the inspection window. 4.6 When the boiler is not working, the gas valve in front of the boiler must be closed. 4.7 PROHIBITED: 4.7.1 Install the boiler and heating system in deviations from this Manual. 4.7.2 Install shut-off devices on the supply line and on the pipe connecting the heating system to the expansion tank, as well as on the overflow line, except for the radiator inlets. 4.7.3 Adjust the automation for water temperatures in the heating system (boiler water jacket) above 95 0C 4.7.4 Operate the boiler when the heating system is not completely filled with water 4.7.5 Conduct pipelines with a diameter of less than 11/4 to the expansion tank, and also use expansion tank that does not correspond to the design for the heating system carried out by a specialized organization. 4.7.6 Excess water pressure: a) in the hot water supply system (tap water in the coil) over 0.6 MPa (6 kg/cm2) b) in the heating system over 0.12 MPa (1.2 kg/cm2) or height 12 m, (2.0 kg/cm2 for KSts boilers) 4.7.7 Quick filling of a hot boiler with cold water, no more than 8 l/min. 4.7.8 Install a circulation pump without developing a heating system design. 4.8 If you detect a gas smell in the room, immediately turn off the boiler, open the windows and doors, and call the emergency gas service by phone. Before she arrives and until the gas leak is eliminated, do not perform any work involving fire or sparking (do not turn on electric lighting, do not use gas or electric appliances). 5. DEVICE AND PRINCIPLE OF OPERATION 5.1 The main indicators of the boiler are given in Table No. 1. 5.2 Design and principle of operation of the boiler. 5.2.1 Boilers KS-G...; KS-GV...; KSts-G...; KSts-GV... are equipped with a gas burner device (depending on the configuration). 5.2.2 Boilers KS-T...; KS-TG...; KS-TGV..., KCh-TG, KCh-TGV... are universal and can operate on both solid fuel and gas. 5.2.3 Boilers KS-…V..; KSts-...V..., KCh-...V are equipped with a coil for hot water supply. 5.2.4 Boilers KS-G-..; KS-GV-..; KSts-G/m-…, KSts-GV/m-… (Fig. 1; Fig. 2; Fig. 3) consist of a firebox 1 with smoke pipes 2. There is a water jacket around the firebox 4. Smoke pipes coming out of the firebox , pass through the water cavity of the boiler. Turbulizers 5 are located in the smoke pipes for additional heat extraction and increased efficiency. The temperature of the water in the boiler is controlled by a thermal sensor 15. The heated water, as a result of the convection currents formed in the boiler, enters the heating system through the upper pipe 10. Return water from the heating system enters the boiler through the lower pipe 9. In the hot water environment, around the smoke pipes, there is a coil 3. Adjustment of the flow rate of the required water temperature is achieved with a mixer, or using a valve, increasing or decreasing the speed of water passing through the coil. The boiler draft is adjusted by turning the damper handle. The procedure and principle of operation of the gas burner device is described in the attached operating manual.

Boiler KS-GV-12N; KS-G-12N

1. Firebox 2. Smoke pipe 3. Coil 4. Water jacket 5. Turbulizer 6. Chimney 7. Damper 8. Insulation 9. Bottom pipe 10. Top pipe 11. Casing 12. Cover 13. Guard 14. Burner 15. Temperature sensor 16.Thermometer

Boilers KSts-G/GV-12…, KSts-G/GVm-20/25/31.5

1. Firebox 2. Smoke pipe 3. Coil 4. Water jacket 5. Turbulizer 6. Chimney 7. Damper 8. Insulation 9. Bottom pipe 10. Top pipe 11. Casing 12. Cover 13. Guard 14. Burner 15. Temperature sensor 16. Thermometer Boiler KSts-GV-31.5…KSts-G-20N with burner AGU-T-M-35ts(28)(23)ts 1. Firebox 2. Smoke pipe 3. Coil 4. Water jacket 5. Turbulizer 6. Chimney 7. Damper 8. Insulation 9. Bottom pipe 10. Top pipe 11. Casing 12. Cover 13. Guard 14. Burner 15. Temperature sensor 16. Thermometer 5.2.5 Boilers KS-T-...; KS-TG-…; KS-TGV-... (Fig. 4,5,6) consist of a furnace 16(14), equipped for burning solid fuel and gas and a convective flue 17(15). In the lower part of the firebox, grates 13 and a beam are installed, forming the grate web. To ensure complete washing of the heating surface with flue gases and improve the operation of the boiler, the rear wall of the upper part of the firebox is made in the form of a cooled canopy. On the front surface of the boiler, loading doors 1 and screwing doors 2 are attached, through which fuel is loaded, the grate is cleaned, as well as the surface of the firebox and convective chimney are cleaned. Boiler KS-TVm-16

1.Loading door 2.Loading door 3.Primary air damper 4.Pipe for connection to the smoke channel 5.Draft control damper 6.Casing 7.Pipe for connection to the supply pipeline of the heating system 8.Turbulizer 9.Thermometer 10.Insulation 11 .Water jacket 12.Shield 13.Grate 14.Water heater 15.Coil 16.Boiler furnace 17.Convective gases exit zone 18.Pipe for connection to the return pipeline of the heating system Boiler KS-T-16 1.Loading door 2.Loading door 3 .Primary air damper 4.Pipe for connection to the smoke channel 5.Pipe for draft control 6.Casing 7.Pipe for connection to the supply pipeline of the heating system 8.Turbulizer 9.Thermometer 10.Insulation 11.Water jacket 12.Shield 13.Grate 14. Boiler furnace 15. Exit zone for convective gases 16. Branch pipe for connection to the return pipeline of the heating system Boiler KS-TV-31.5; KS-TGV-31.5N; KS=TGV-31.5/40N 1.Loading door 2.Loading door 3.Primary air damper 4.Pipe for connection to the smoke channel 5.Valve for draft control 6.Casing 7.Pipe for connection to the supply pipeline of the heating system 8 Turbulizer 9. Thermometer 10. Insulation 11. Water jacket 12. Shield 13. Grate 14. Water heater 15. Coil 16. Boiler furnace 17. Convective gases exit zone 18. Pipe for connecting to the return pipeline of the heating system 19. Hatch for soot cleaning To provide hot water, the boiler has a coil 3 (Fig. 1, 2, 3), which is located in a hot water environment. When water from the plumbing system passes through it, the water in the coil heats up. Adjustment of the required water temperature is achieved with a mixer. In the absence of a mixer, adjusting the water temperature is achieved by increasing or decreasing the speed of water passing through the coil using a valve. 5.2.5.1 Construction of a natural gas boiler In a boiler for burning natural gas, instead of grates, a scramble door and a cast iron frame, a gas burner device with automation is mounted. On all boilers operating on natural gas, a combustion plate is installed in the upper part of the firebox close to the front wall. 5.2.5.2 The procedure and principle of operation of the gas burner device is described in the attached operating manual for the gas burner device. 6. INSTALLATION OF BOILER AND HEATING SYSTEM ATTENTION! Installation of a heating boiler should only be carried out by gas service specialists with a mark in the passport! 6.1 The gas burner device is stored in a separate package. To avoid damage, boilers must be transported in containers directly to the installation site. 6.2 When installing on combustible building structures, 0.5 m below the boiler and in front of its front, it is necessary to install a steel sheet gasket over asbestos cardboard or felt soaked in clay mortar. 6.3 In order to improve the conditions of water circulation in the heating system, the boiler must be installed in such a way that its lower pipe (see Fig. 1,3, item 9) is lower than the radiators of the heating system of the building (structure). 6.4 Pipelines are made from water pipes. Pipe connections can be made by threading and welding. 6.5 When installing pipelines by welding, threaded connections should be left to ensure disassembly of the system during repairs. 6.6 Recommended installation dimensions for radiators when installing residential heating: a) from the wall to the radiator no less than 3 cm; b) from the floor to the bottom of the radiator – 10 cm; c) from the top of the radiator to the window sill - at least 10 cm. d) When installing the radiator in a niche, the distance from the radiator to the side wall of the niche is at least 10 cm on each side. 6.7 When bending pipes, the radius must be at least 2 outer diameters of the pipe. 6.8 When laying pipes, risers must be installed plumb. The permissible deviation should not exceed 3 mm over 3 meters of pipe length. 6.9 Horizontal pipelines must be laid with a slope to allow air to escape from the system. The slope must be at least 10 mm per 1 linear line. meter of pipeline. In this case, the slopes of the branches to the heating device must be at least 10 mm over the entire length of the line towards the heating device. 6.10 If there are more than one boilers in the system, a plug valve or valve is installed on the return line to each boiler. 6.11 The boiler installation diagram is shown in the figures. Installation diagram of the boiler KS-G...-12.. Connection of the boiler with a brick chimney and cleaning device. Installation diagram of the boiler KS-G...-.. Connection of the boiler with a brick chimney and cleaning device. Installation diagram of the boiler KS-T...-16.. Boiler connection with a brick chimney and a cleaning device Installation diagram of the boiler KS-T...-31.5..; KS-GV-50.. Connection of the boiler with a brick chimney and cleaning device Installation diagram of the KSts-G...-.. boiler. Connection of the boiler with an asbestos-cement pipe Du-200 Installation diagram of the KS-TV-31.5...-.. boiler; KS-GV-50N Connection of the boiler with an asbestos-cement pipe Du-200 6.12 The chimney structure must meet the following requirements: the chimney to which the boiler is connected must be located in the internal main wall of the building. Smoke exhaust pipes laid through unheated rooms must, if necessary, be covered with thermal insulation. It is allowed to connect heating boilers to chimneys made of asbestos-cement pipes. The chimney installation must be agreed upon with the fire authorities. To ensure fire safety and avoid gas contamination in the room, the chimney must be installed above the roof level in accordance with the requirements of SNIP 2.04.08-87. 6.13 The cross-sectional area of the chimney should not be less than the area of the boiler pipe connected to the chimney (see Table No. 1). 6.14 Chimneys must be vertical, without ledges. 6.15 The diameters of the heating system pipelines are selected using a special calculation. The most common diameters are: - main boiler riser - 1¾-2ıı - distribution and collection lines - 1¼ - 1½ıı - connections to devices - ¾ - 1ıı 6.16 Heating boilers can be installed in a closed heating system with a membrane-type expansion tank. 6.17 When connecting the boiler coil to the hot water supply system, connect the cold water to the lower pipe, and the hot water outlet to the upper pipe. The pressure in the heating system in operating condition, at a water temperature in the heating system of 60º-80ºС, should not exceed the operating water pressure indicated in the table. 1 point 4 of the manual, that is, 0.12 MPa (1.2 kgf/cm2) or 0.2 MPa (2.0 kgf/cm2) for KSts boilers…. A safety valve should be installed on the riser, adjusted to a pressure of 0.15 MPa (1.5 ± kgf/cm2) or 0.18 MPa (1.8 kgf/cm2) for KSts boilers…. To control the pressure in the heating system, a pressure gauge with a measurement limit of 0-4 kgf/cm2 must be installed. ATTENTION: The design of a heating system with forced or natural circulation must be developed by a specialized organization that has the right to carry out this work. If the heating system involves filling and feeding the boiler from the water supply network, it is necessary to install a check valve in front of the tap. Fill the system with a pressure not exceeding the operating pressure of the boiler. Fill the heating system with tap water. Testing (pressure testing) of the heating system (pipes, radiators) should be carried out with the heating boiler disconnected, because the pressure in the boiler should not exceed the operating pressure specified in the passport. The volume of the expansion tank depends on the volume of the heating system and is calculated when developing a heating project. To prevent freezing of the expansion tank and drain pipe in winter, they must be installed in rooms with a temperature not lower than +5°C. There should be shut-off valves at the inlet and outlet of the coil. Installation of the boiler and heating system must be carried out taking into account the technical data (Table 1) 7. REQUIREMENTS FOR INSTALLATION OF A NATURAL GAS BOILER 7.1 When operating on natural gas, the boiler is installed according to a design agreed with the city gas authority. The installation and installation of the boiler is carried out only by a specialized organization that has the right to carry out such work. 7.2 Installation and adjustment of the gas burner device is permitted to be carried out by employees of specialized organizations licensed by Gosgortekhnadzor, in accordance with the requirements of the gas burner device operating manual. 7.3 The Gorgaz representative, when accepting the heating installation, must instruct the consumer on the rules for using gas appliances. 7.4 Install the gas burner device in accordance with the burner operating instructions. 8. BOILER MAINTENANCE. Before starting to light the boiler, you MUST slowly, no more than 8 l/min, fill the system with water until it appears from the overflow tube 3 of the expansion tank 4, and then begin igniting the burner according to the operating instructions for the gas burner device. Scheme of an open heating and hot water supply system 1. Boiler 2. Heating devices 3. Overflow 4. Expansion tank 5. Supply pipeline 6. Return pipeline 7. Heating system tap 8. Water drain 9. Check valve 10. System filling tap 11. Tap hot water supply (input) 12. Hot water supply tap (output) 13. Safety valve 14. Pressure gauge 8.1 Before igniting gas burner devices, it is necessary to ventilate the firebox for 5-10 minutes. The tap in front of the boiler must be closed. 8.2 Check the presence of draft in the chimney by holding thin paper to the inspection window of the burner shield. If there is traction, then the paper strip will be attracted. If there is no draft, ignition of the gas burner device is PROHIBITED. 8.3 When igniting the gas burner device, open the air supply to ensure normal draft; the draft is regulated by a damper on the boiler and a damper on the burner. ATTENTION: When starting the boiler, condensation may be released, which disappears during subsequent operation of the boiler, after the return has warmed up to 45°C. Scheme of a closed heating and hot water supply system 1. Boiler 2. Heating devices 3. Expansion membrane tank 4. Supply pipeline 5. Return pipeline 6. Heating system valve 7. Water drain 8. Non-return valve 9. System filling valve 10. Hot water supply valve (input) 11. Hot water supply tap (output) 12. Safety valve 13. Pressure gauge 9. MAINTENANCE OF THE HEATING SYSTEM 9.1 When operating the system, the water level in the expansion tank should not fall to the bottom and it must be maintained by periodically adding water, reducing the temperature of the water in the water boiler jacket up to 70ºС. 9.2 ATTENTION! If there is a knock in the system (hydraulic shock due to steam formation), immediately stop burning in the furnace and allow the water to cool to a temperature of 70-750C, then replenish the system with water and light the boiler again. 9.3 In winter, if it is necessary to stop heating for more than a day, it is necessary, in order to avoid freezing, to completely empty the heating and hot water supply system of water. The heating system is released through water drain 8 (Fig. 13) and water drain 7 (Fig. 14). To drain the hot water system, it is necessary to disconnect the water supply pipe and blow air through the water heater coil. 9.4 During operation, keep the temperature of hot water in the boiler no higher than 95 0C. 9.5 Using hot water from the heating system for domestic purposes is PROHIBITED. 9.6 For a gas-fired boiler, it is allowed to use a water heater in the summer when the heating system is closed. The water temperature, when flowing from the water heater, is regulated by a mixer or valve 12, increasing or decreasing the speed of water passing through the coil. When the water temperature in the boiler reaches 800C, the temperature sensor should stop supplying gas to the main burner. If there is no water flow for a long time (more than 2 hours) through the water heater coil, in order to avoid boiler boiling, any combustion in the boiler, including the ignition burner, is PROHIBITED. 9.7 For a boiler operating on solid fuel, the use of a water heater with the heating system turned off is not allowed. Burner AGU-T-M-13-55 kW 1. Valve 2. Block tap 3. Button 4. Igniter 5. Thermal plate 6. Nozzle 7. Thermal sensor 8. Lever 9. Nozzle 10. Pressure strip 11. Front shield 12. Gas distributor 13. Air regulator 14. Adjustment screw 10. POSSIBLE MALFUNCTIONS AND METHODS OF THEIR ELIMINATION Table No. 3

| Name of possible faults | Cause of malfunctions | Elimination method | Note |

| 1 | 2 | 3 | 4 |

| 1. The thermometer shows low water temperature | The thermometer sensor is dirty. | Drain the water from the system, unscrew the sensor, clean it and screw it back on. Pour water into the system. | Produced by the owner. |

| 2. The water temperature in the boiler is 95 0 C, and the heating radiators are cold. | Water leak in the system. Air in the heating system. The heating system is not designed correctly. The heating system was installed incorrectly. | Top up the system with water. Check that the slopes in the heating system are maintained. It is possible to install a circulation pump. Rework the heating system design. Install the heating system in accordance with the requirements of the section project. | See section 6 Boiler owner Boiler owner. |

| 3. Boiler leak | 3.1.The temperature sensor nut has come loose. 3.2. Condensate release. 3.3.The water heater nut has come loose 3.4.The water heater coil nipple nut has come loose | Tighten the temperature sensor nut, tighten the water heater nut. Disappears during subsequent operation of the boiler when the return temperature reaches 45 0 C. | Boiler owner. |

| 4. Spontaneous burner shutdown | 4.1.Insufficient vacuum in the chimney, the chimney is clogged. 4.2. The pilot burner went out and the nozzle became clogged. | Clean the chimney Clean the nozzle | Boiler owner. Boiler owner. |

| 5. Gas leakage at connections. | Gaskets are worn out, threaded connections are loose, and lubrication is impaired. | Replace gaskets. Repack connections. | Boiler owner. |

| 6. When the boiler is operating, the water does not reach the required temperature. | The gas valve setting is incorrect. Setting up a block crane | Adjust the operation of the gas valve and burner block tap. | See section 8. Master adjuster. |

| 7. Flame separation is observed | Great traction. Gas pressure is higher than permissible. | Adjust the damper draft and gas pressure. | Master adjuster. |

| 8. The water temperature in the boiler has reached 95 0 C, the main burner continues to operate. | The seal of the thermoblock is broken, the “projectile” of the block valve has burst, the lower ring of the “projectile” has burst | Fill the temperature sensor with a thermal cylinder hermetically with antifreeze A-40, or replace it. Replace the projectile, replace the projectile ring. | Master adjuster. |

| 9. The burner burns with a smoky flame. | Lack of primary air | Adjust the air supply using the primary air regulator. | Boiler owner. |

| 10. Flame penetration into the burner | Gas pressure below acceptable | Adjust | Master adjuster. |

11. SETTING UP AUTOMATIC CONTROL 11.1 This work is performed by gas service workers, only for boilers operating on gas. 11.2 Setting up an automatic gas burner device, as well as its technical data and operating procedure are described in the attached operating manual. 12. REGULATORY, PREVENTIVE WORK, METHODOLOGY FOR CONTROL TESTING OF SAFETY AUTOMATION. 12.1 The heating boiler and gas burner must undergo a preventive inspection at least once a year, including before the start of the heating season. 12.2 Preventive work is carried out only by employees of specialized organizations certified to carry out such work. 12.3 Maintenance work includes: 12.3.1 Checking the operation of the boiler and gas burner device: 12.3.2 Setting the burner according to the instructions in the passport. 12.3.3 Checking the operation of the safety valve, setting the lever with a temperature sensor according to the instructions in the burner passport; 12.3.4 Checking the tightness of the threaded connections of the gas pipeline, the tightness of the gaskets in the safety valve, by saponification; 12.3.5 Cleaning soot deposits on the burner, as well as internal surfaces in the boiler. 12.3.6 Technical condition (diagnosis) is carried out in order to establish the suitability of the boiler for further use for its intended purpose after the end of its service life. To determine the technical condition of the boiler, it is necessary to perform a minimal but sufficient amount of work: 12.3.6.1 Checking the condition of the turbulators, damper, thermometer. — the gate must be adjusted in such a way that there is no spontaneous rotation around its axis. 12.3.6.2. Triggering of the automatic safety system when the gas is turned off and the pilot burner goes out. 12.3.6.3. Triggering of the automatic safety system in the absence of draft in the chimney. 12.4 The results of preventive inspections and work must be entered into the boiler passport with the signature and stamp of a specialized organization (see Table 4.5). 12.5 Failure to complete the above work, as well as failure to fill out the table. 4.5 is a violation of the operating rules. In case of these violations, warranty service issues are not considered.

Chimney connection

When connecting equipment to a chimney, it must be taken into account that the cross-section of the pipe should not be smaller than the connecting pipe. There should not be any leaks at the connection point, since carbon monoxide entering the room leads to poisoning. The pipe located on the street must be insulated and a canopy must be installed in the upper part.

Conclusion

I would like to note that the technical characteristics of the heat supply equipment in question, produced by the Condor Plant, have good performance, price and quality indicators. But, like all other equipment, even from foreign manufacturers, it has positive and negative sides. In the end, the decision is yours.

Recommendations for installation

Installation of solid fuel units does not require special permits. At the same time, this does not mean that the owner should not monitor the quality of construction work and comply with fire safety standards.

Expert advice:

- The boiler should be installed on a flat concrete base, with a distance of at least 0.5 meters from the wall.

- When installing the boiler on a wooden floor, under it and half a meter in front of its front wall, a sheet of asbestos cardboard or felt soaked in a clay solution is laid on the floor, and steel sheets are laid on top of it.

- For normal fluid circulation in the system, the boiler must be installed in such a way that its lower pipe is at a lower level compared to the outlets from the heating batteries.

- Connections to pipes can be made using both threads and welds.

Don’t forget about the features of installing chimney ducts:

- chimney pipes are double-circuit, with thermal insulation between the structures. Thus, no water vapor is formed;

- for the construction of a chimney, asbestos-cement pipes are often used;

- the diameter of the chimney pipe must be similar to the diameter of the outlet pipe of the boiler equipment;

- the chimney must be installed above the roof level, read the SNiP rules;

- the chimney pipe must be level, without ledges.

Switching from solid fuel to gas

To convert a Don solid fuel boiler into a gas boiler, you need to purchase a special burner. It is connected to the electrical network and has an automatic system that regulates the degree of gas supply. In order to install the burner, you first need:

- remove the security door;

- dismantle the grates.

There are many benefits to switching to gas. There is no need to constantly add firewood. There is also no need for storage space for solid fuel. Those who use coal have another problem - where to put the sludge? With gas everything is much simpler. Even if you do not have a central gas pipeline, you can connect a cylinder or gas holder to the boiler.

In addition, there is no soot from the gas; it practically does not pollute the heat exchanger and chimney (see How to clean a chimney with your own hands). The temperature of the exhaust gases is also lower, which leads to the formation of condensation. Therefore, the chimney must be properly insulated. On the Internet you can find both positive and negative reviews about Don boilers. Below in the video you can see a review from a person whose boiler leaked after a year of operation.

When planning a heating system in a private home, owners often try to find a universal solution that allows them to easily switch from solid fuel to gas. On the Russian market there are models of heating devices capable of solving this problem. One of such devices is the Don 16 solid fuel boiler. In this material we will talk about the features of its design, advantages and disadvantages, and also provide user opinions.

So what is this model? The Don 16 boiler is a steel household solid fuel boiler with a water circuit, designed for heating houses or other small premises and for organizing hot water supply. Wood or coal can be used as fuel, and with minor modifications, pellets or gas. Let's take a closer look at its design and find out what allows it to achieve such versatility.