The German company Viessmann is a recognized world leader among manufacturers of heating equipment.

The company's products are supplied to many countries; the quality and efficiency of the equipment is highly appreciated by specialists and ordinary users.

Gas boilers make up a significant part of the company’s product range, since this type of heating is considered the most economical and efficient.

The Viessmann [/anchor] product range includes a large number of models, differing in various parameters and capabilities.

Let's consider a group of the most powerful and reliable devices - floor-standing gas boilers.

Advantages and disadvantages

Viessmann “Vitopend 100-W” boilers have a number of positive aspects:

- heat exchangers in the boiler are made of copper and stainless steel, which increases their service life, and the strong body of the boiler reliably protects it from mechanical damage;

- These boilers are equipped with high-power circulation pumps;

- during operation, the boiler makes minimal noise, which is positively noted by many users;

- the heating device has compact dimensions and a very stylish appearance;

- clear control system;

- installation work does not require much effort;

- the boiler has an automated security system that monitors all indicators.

Among the negative aspects the following were noted:

- the prices for these boiler models are quite significant, as are their components;

- other boiler manufacturers offer wider design options than Viessmann.

An analysis of customer reviews of boilers from this manufacturer allows us to conclude that Viessmann is truly deservedly one of the best in the production of heating equipment. Many owners note that Viessmann boilers work “like clockwork.” There are practically no problems with the management and operation of the boiler. Among some negative aspects, high gas consumption was noted. But this problem can be solved by setting up the boiler, which is best left to qualified specialists. Most users note that the price for this boiler is really significant, but it fully corresponds to the quality of the device.

Error codes, their interpretation and how to solve the problem

Let's look at common errors in Viessmann boilers and how to eliminate them:

| Code | Decoding | How to fix |

| A0 | Burner blocked due to low gas pressure | Check the condition of the supply line or pressure switch |

| E0 | Boiler blockage due to draft overturning | Check the condition of the chimney and clean it if necessary. |

| F2 | Boiler overheating | Check the water level, if necessary, fill the system to the required volume |

| F3 | Parasitic flame (indicates the presence of a flame when the burner is not lit | Restart the boiler, check the condition of the ionization electrode and grounding. |

| F4 | No flame | Check the gas pressure, the condition of the ignition equipment, clean the contacts, restart the boiler. |

| F6 | Boiler blockage due to error E0 tripping 10 times within an hour | Check the draft sensor. Reboot the boiler. |

| F30 | Temperature sensor short circuit | Replace coolant temperature sensor |

| F38 | Temperature sensor break | Clean contacts or replace sensor |

| F50 | No DHW heating | Replace the DHW heating sensor |

| F51 | Short circuit of the output DHW temperature sensor | Replace sensor |

| F58 | Broken DHW boiler temperature sensor | Replace the sensor or clean the contacts. |

| F59 | Broken output DHW temperature sensor | Replace sensor |

| 10 | External temperature sensor shows zero temperature | Check the condition and, if necessary, replace the thermistor. |

Most problems that arise require solutions only with the participation of qualified specialists from the service center.

Gas boilers Viessmann Vitopend 100-W

Wall-mounted gas boilers Viessmann Vitopend 100-W are a series of units designed for heating small and medium-sized rooms. The optimal use case is apartments, residential buildings, office, commercial or public premises with an area of up to 340 m2.

The peculiarity of this series is its relatively low cost with full functionality and capabilities of the boilers.

It is possible to connect an external temperature sensor, which provides adjustment of the operating mode depending on the outside air temperature. It is possible to independently heat hot domestic water, or connect an external boiler, if necessary.

The boiler electronics have a built-in timer, with which you can program the operation of the installation for a week in advance. Low noise levels and the absence of foreign odors make the use of boilers in residential areas safe and comfortable.

Advantages and disadvantages

The advantages of Viessmann floor-standing boilers include::

- Traditional German quality of development and assembly.

- High strength and resistance of components to external and operational loads.

- Efficiency and economy of units.

- The absence of unnecessary parts allows for increased stability and reliability.

- High performance, power.

- Availability of a self-diagnosis system.

- The ability to remotely control the operation of units.

- All boilers are adapted to operating conditions in the exporting country.

The disadvantages of Viessmann boilers are considered to be:

- Energy dependence.

- High cost of equipment and spare parts.

NOTE!

All users note the high cost of equipment from European manufacturers, which can be considered a common feature of such products.

Varieties

It was already mentioned above that boilers from this manufacturer can be chimney and turbocharged. In addition, they are divided according to several other criteria. Boilers can be double-circuit or single-circuit. Their fundamental difference lies in the number of contours, as the name implies. That is, a single-circuit boiler is responsible primarily for heating the room, and a double-circuit unit heats water for both heating and domestic needs. But if you have a single-circuit boiler, the problem of hot water can be solved by installing an indirect heating boiler.

Boilers can also be of a traditional type or condensing type. The principle of operation of a traditional boiler is quite simple - combustion products heat water and evaporate through the chimney. But the principle of operation of a condensing boiler is much more complicated - in this case, the combustion products condense, that is, turn into liquid. The design of such a boiler itself is much more complex. Also, such a boiler has a coaxial chimney, which consists of two pipes of different diameters that are inserted into one another.

One of the most famous is the Viessmann Vitopend 100 WH1D 263 boiler model. This option has quite decent power - about 32 kW. This is a double-circuit boiler, which is used both for heating the house and for supplying hot water for domestic needs. The combustion chamber of this boiler is closed. The tank of the device has a large volume - 10 liters, as well as a powerful circulation pump with a safety valve. Such a boiler is guaranteed to heat the water to almost 80 degrees, and in a very short time. The price for this boiler varies within 45 thousand rubles.

Another gas boiler is the Viessmann Vitopend 100 WH1D 513. The heat exchanger of this boiler is divided into two parts. One of them is made of high quality copper, and the second is made of stainless steel. Such separations are called “primary” and “secondary” heat exchangers. The power of this unit is high - 33-35 kW. This is a single-circuit boiler that is designed for heating. The approximate price will be 36-38 thousand rubles.

The next model is the Viessmann Vitopend 100-W A1HB boiler, which has a power of 24 kW. The boiler is single-circuit. This is a simple and convenient model with a high-quality chimney system, small dimensions and low noise level. The boiler is capable of heating water up to 80 degrees. The chimney diameter is 60/100. This is an excellent choice for heating a private home with a decent level of efficiency. The price for such a boiler will be approximately 39-40 thousand rubles.

Peculiarities

The Viessmann Vitopend 100-W A1JB010 model has the following overall dimensions - 400x725x340 mm (WxHxD), while the weight is 32 kg. Installation is carried out on the wall, which saves space in the room.

Principle and main operating parameters.

The convection type of device involves the generation of heat from gas combustion, while the boiler operates on natural gas (methane, consumption 2.77 cubic meters per hour) and liquefied gas (propane-butane mixture, consumption 2.09 kg/hour).

To obtain the declared power of 24 kW, the pressure of natural gas must be at the level of 13-20 mbar, and the permissible pressure of liquefied gas - 37 mbar; when these parameters decrease, the thermal power will also drop. ExpertKotel.ru reminds that most often in domestic networks the pressure is 12-20 mbar. The efficiency of the heater, with such indicators, is at an excellent level and equals 91%.

Heating of water, coolant in pipes

. This boiler is capable of producing 11.2 l/min of hot water (t=30°C). The coolant temperature is 40-80°C, and in the hot water supply circuit - 35-57°C.

Circulation pump

necessary for the circulation of coolant (water, antifreeze) through the heating circuit, it is a mandatory component of a closed heating system; in our case, the pump is included in the kit.

Expansion tank

compensates for the expansion of the coolant in the pipes during heating and releases it back into the system during cooling. This maintains constant pressure in the circuit.

Fuel economy

Burner flame modulation

makes it possible to smoothly regulate the intensity of the fuel supply and reduce/increase the flame, which allows you to reduce gas consumption.

Auto-ignition (or Electric ignition)

allows the Viessmann Vitopend 100-W A1JB010 to start and extinguish the burner according to an algorithm when necessary, which saves fuel.

Gas consumptionValueNaturalLiquefied

| 2.77 cu. m/hour |

| 2.09 kg/hour |

Management and control

The Viessmann Vitopend 100-W A1JB010 gas boiler is electronically controlled, equipped with a display and has a port for connecting additional devices (most often thermostats, programmers, room remote controls, etc.). The advantage of the electronic system is that it does not require the constant presence of a person and allows significant fuel savings (as described above), the disadvantage is that it is more complex than a mechanical one and depends on voltage drops (it can fail during surges).

Thermometer and pressure gauge

. A thermometer is necessary to monitor the temperature of the coolant in the boiler, and a pressure gauge shows the pressure of the coolant; this is an important parameter, because exceeding it can lead to breakdown of individual parts or the system as a whole.

Protection systems

Gas control

- a useful and necessary function of the burner; if the flame goes out for any reason, it stops the gas supply automatically.

Safety valve

"Viessmann Vitopend 100-W A1JB010" protects the system from excess water pressure in the circuit in excess of the maximum permissible norm.

Air vent

. An important element of the safety group, when the pressure in the heating system increases, the air vent automatically releases excess air, most often working together with a safety valve.

Coolant freeze protection

independently turns on the burner for a short time, provided that the water temperature drops to a critical level and there is a risk of heating defrosting. It is worth remembering that for this there must be gas and electricity.

Pump blocking protection

activated when the boiler installation is idle for a long time, in this case the pump turns on for a while and turns off itself. This is necessary in summer when the heating circuit is not activated.

Coolant overheat protection

turns off the burner if an abnormal water temperature value is detected.

Connection

- The connecting size for the gas pipe is 3/4″.

- Hot water supply - 1/2″.

- To connect the heating circuit - 3/4″.

- The diameter of the coaxial chimney is 60/100 mm.

To connect the power supply, a 220 volt network with a pure sine wave and grounding is required.

Turning on the gas boiler, first start: instructions

Do you want to install individual heating in your home? Have you already installed and connected gas equipment? Great, then all that remains is to figure out how to turn on the gas boiler. Do you think it’s enough to insert the plug into the socket and select the temperature? No matter how it is. Before this, it is necessary to bleed the air and fill the system with water. You will find instructions with the sequence of actions in our article.

Other information

Note! Hot water capacity – up to 14 liters per minute. Gas freezing during cold periods is prevented thanks to new chimney designs.

A water heater with a volume of up to 50 liters complements the design of the Vitopend 222 model. Such products operate at a power of up to 10.5–24 kW, this is a kind of technical standard.

The most economical of all water heating boilers is the 100-F. The surfaces responsible for heating are made of special gray cast iron of the highest quality. Addition – lamellar or flake graphite. The thermal intensity of the boiler itself remains small.

The equipment is used to heat small rooms and water, since the power will be only from 29 to 140 kW. This option is also relevant for installation in utility rooms. The main thing is to remember which code is assigned to which error.

What series and models are floor-standing

There are 4 main series of Viessmann floor standing boilers:

- Vitogas. Extensive series of boilers with power from 29 to 420 kW. All models have a cast iron sectional heat exchanger and an atmospheric burner with partial mixing.

- Vitocrossal . A series of boilers with a total power from 2.5 to 1400 kW. Equipped with a heat exchanger having a smooth inner surface with a self-cleaning function. can be connected to a long chimney, allowing them to be used in tall buildings.

- Vitola . Heat exchanger with self-cleaning capability. The boiler power is 18-1080 kW. It is possible to replace the burner and switch to diesel fuel.

- Vitorond . Boilers that are similar in design to the Vitola series with minor differences.

IMPORTANT!

The ability to operate on liquid fuel does not increase the capabilities of the boilers, since for a full conversion it is necessary to organize the correct supply and storage of diesel fuel, which is very difficult and costly.

In addition, there is a line of floor-standing boilers of the Vitodens 222-F series, the remaining models of which are wall-mounted .

The cost of these models is very high, so only Vitogas series boilers are common.

Overview of Viessmann Vitopend boilers with closed and open combustion chambers

If you have an atmospheric boiler with an open combustion chamber, then its operation will be characterized by natural draft. Some consumers deliberately refuse such equipment, and here's why. For fuel combustion, air will be taken from the room where the equipment is located. Exhaust gases will enter the chimney under the influence of natural draft.

Such boiler equipment Viessmann Vitopend 100 requires intensive ventilation of the room, which is not always possible or profitable. The closed chamber is complemented by a smoke removal system. It has a built-in fan-exhaust fan, which is responsible for removing combustion products and draws in air, which is so necessary for the functioning of the boiler.

The operating principle is built around a coaxial chimney. The Viessmann Vitopend 100, which has a closed combustion chamber, has one important advantage in that the device does not burn oxygen in the room. Additional air from outside is used to burn the fuel. For such boilers, there are coaxial chimneys, for which you will have to make a hole in the wall. This, in turn, can become a stumbling block when choosing such equipment, especially for consumers in the northern regions.

Summary and evaluation

Let us list once again the key features of the Viessmann Vitodens 100-W WB1C110 that are worth noting: excellent efficiency of 108.4%, electronic control, thermometer, pressure gauge, connected underfloor heating, there is a circulation pump. The boiler is mounted on the wall, and the protection systems include, as described above: overheating protection, freezing protection, gas control and a safety valve. The heat exchanger is made of stainless steel, the combustion chamber is closed.

Sources

- https://remont-system.ru/kotly/obzor-gazovyh-kotlov-iz-lineyki-viessmann-vitopend-100-s-otzyvami-vladelcev

- https://stroy-podskazka.ru/kotly/gazovye/viessmann-vitopend-100/

- https://ExpertKotel.ru/cat/viessmann/viessmann-vitodens-100-w-wb1c110

- https://expert-dacha.pro/otoplenie/kotly-ot/gazovye-k/proizvoditeli-gaz-k/gk-viessmann/oshibka.html

- https://SdelaySam-SvoimiRukami.ru/3409-diagnostika-i-remont-pressostata-kotla.html

- https://sovet-ingenera.com/otoplenie/kotly/pressostat-dlya-gazovogo-kotla.html

- https://KotelStroi.com/practice/pressostat-gazovogo-kotla.html

Design options

There are different designs of Viessmann Vitopend 100-W boilers:

- Single-circuit. They are designated by the letters A1HB (for example A1HB001). They only heat the coolant for the heating circuit.

- Dual-circuit. These settings are designated A1JB (eg A1JB010, A1JB009). In parallel with heating the coolant, hot water is prepared for domestic needs.

All single-circuit boilers have the ability to connect an external boiler, which allows not only to heat the coolant, but also to supply hot water. At the same time, the volumes of hot water are much greater than what a standard plate heat exchanger of a double-circuit boiler can provide.

This is convenient if the room size is relatively small and the need for hot water is large.

Types

There are different types of Viessmann floor-standing boilers, which differ in design and method of transferring thermal energy.

Offered:

- Convection boilers . Their work uses a traditional heat exchange method, the efficiency of which has been brought to a high limit.

- Condensing boilers . They are equipped with an additional unit - a condensation chamber, in which water vapor is deposited from the flue gases. In this case, a significant amount of thermal energy is released, which is transferred to the coolant. Preliminary preparation allows you to reduce the heating temperature in the heat exchanger, which automatically reduces gas consumption.

Almost all models of floor-standing boilers are single-circuit, except for the only Vitodens 222-F line, equipped with a built-in boiler.

The absence of a DHW module does not mean that it is impossible to supply the premises with hot water. All models have pipes for connecting an indirect heating boiler, in which a hot coolant circulates through a copper coil, heating the water.

Models of floor-standing boilers have different capacities, usually quite large, designed for operation in larger areas.

Technical characteristics of Viessmann Vitopend 100-W boilers

Gas equipment has the following parameters that distinguish it from analogues:

- Stainless steel is the main construction material. The body and burner are made precisely on this basis. In wall-mounted devices, the heat exchanger is also made of steel, which helps to increase the service life for those who have a Vitopend 100 W gas boiler.

- Use of a large number of additional sensors. They help control the operation of the device remotely. This is a simple, convenient option.

- The design includes a special modulating burner. These are special designs that save up to 92% of gas. The effect is especially noticeable in the summer, when the device itself is not used.

For hot water, the boiler productivity will be from 10 to 14 liters per minute. It all depends on which model is chosen in a particular case. From a 220-volt power supply, energy consumption will be up to 120 W. Experts advise purchasing an additional voltage stabilizer for the Visman Vitopend 100 gas boiler to avoid additional breakdowns.

Note! With low fuel consumption, the equipment runs on natural and liquefied gas.

Device

The design of wall-mounted boilers Viessmann Vitopend 100-W is in no way inferior to the most advanced modern developments of the most advanced manufacturers.

Main components of the boiler:

- Atmospheric type gas burner.

- Heat exchanger.

- Diaphragm expansion tank.

- Fan for removing combustion products.

- Hydraulic group consisting of a three-way valve, a secondary heat exchanger, a circulation pump and connecting pipelines.

- Electronic control board, sensor system, external panel with display.

The coolant enters the boiler from the heating circuit. As it passes through the heat exchanger, it heats up, after which it immediately goes to the secondary plate heat exchanger, where it transfers part of the thermal energy to heat hot domestic water.

Then, in a three-way valve, it acquires the temperature specified by the program, for which the hot and cooled return flows are mixed. After this, the liquid again enters the heating circuit.

The operation of all elements is constantly monitored by a system of sensors connected to the control board.

How the device works

The operating principle of the gas boiler pressure switch is as follows. The sensor is equipped with a pair of contacts that are connected to two control circuits. In operating mode, one pair of contacts is closed; in standby mode, the other is closed.

Electrical resistance depends on gas pressure, and as pressure increases, resistance decreases. Since an increase in pressure characterizes either a violation of draft or overheating of the coolant, this parameter determines the possibility of normal operation of the boiler and, therefore, the need for its immediate shutdown. In the work of this type of indicator, two stages are clearly distinguished.

- Ignition of gas. The heating system microprocessor supplies operating voltage to the air supply fan to the combustion zone. At the same time, the flame control function is turned on and the boiler goes into operating mode.

- After the fan starts, the temperature drops, which triggers another pair of control contacts. If for some reason this does not happen, then when you try to re-ignite, only the fan will turn on, and the flame control function will not be activated. Thus, the boiler will not turn on. The launch will only take place when the air pressure is within the required limits.

Unlocking the emergency state of the boiler

- Use the heating temperature control knob on the boiler instrument panel to set the temperature to maximum.

- Then sharply turn off the temperature regulator to zero.

- We repeat the procedure 2-3 times, turning the sensor either to maximum or to minimum.

- We leave the regulator in the maximum temperature position and wait for the boiler to automatically unlock. The system should start automatically.

- We wait until the emergency stop light of the device goes out.

- After such manipulations, set the regulator to the desired temperature.

Characteristics

Among the gas double-circuit boilers of this manufacturer, two main types can be distinguished: chimney boilers and turbocharged boilers. A special feature of chimney systems is that they can only be installed in rooms that have adequate ventilation and chimney removal. The second model is characterized by the possibility of installation in almost any room and even in an apartment, since such devices do not require special ventilation, and combustion products are removed thanks to a fan.

The standard model is a chimney, and it is purchased much more often. This version of the heating system has the boiler itself, a mounting frame and corresponding pipes for installing the ventilation system.

In general, the Viessmann chimney boiler has the following technical characteristics:

- The power parameters of the heating device can be set independently depending on individual preferences. On average, the minimum rating for boilers of this type is 10 kW, and the maximum is 23 kW.

- The boiler has an expansion tank with a capacity of 6 liters.

- Temperature indicators are also set independently. Typically, the maximum water heating value is 85 degrees, and the minimum is about 30 degrees.

- The dimensions of the boiler are 40x72.5x34 cm, and the weight is about 35 kg.

The boiler has a control panel with an electronic indicator of the set values. This will not be particularly difficult, since all the controls are marked and understandable. A convenient display can show the temperature of the water in the system, the level of gas combustion, and if a malfunction occurs, it issues a special code, the designation of which can be found in the accompanying operating rules. There is also a pressure gauge on the panel (round scale with an arrow).

It is intended to indicate the pressure level in the heating circuit. After installing the entire system and starting to fill it with water, you must carefully monitor the pressure gauge readings. The manufacturer Viessmann indicates that the pressure should not exceed 1.5 bar. Also on the panel there is a button to turn the heater on and off.

Room thermostats are sold separately, on which the required temperature value is simply set, and the thermostat itself controls the heating device. Some thermostats have set temperature values that should change throughout the day. For example, during the day the boiler may heat less, but at night more. There are also devices that allow you to control the boiler remotely.

Series models

The Viessmann Vitopend 100-W series has two model lines:

- Single-circuit boilers are designated by numbers from 001 to 004.

- Double-circuit boilers are designated by numbers 009-012.

Numbers 001, 002, etc. indicate the boiler power.

Each model is marked with its own digital code:

- Number 001 is assigned to a single-circuit boiler with a capacity of 24 kW.

- 002 - single-circuit boiler, power 29.9 kW.

- 003 - power 34 kW.

Double-circuit boilers start with number 009:

- 009 - 12 kW.

- 010 - 24 kW.

- 011 - 29.9 kW.

- 012 - 34 kW.

Codes 004 to 008 are assigned to ready-made solutions, sets of single- or double-circuit boilers and external water heaters.

Digital marking is convenient in that it allows you to shorten long symbols to three digits, which accurately indicate a specific boiler model. This is convenient for both technical personnel and retail chain workers, speeds up model identification and simplifies document flow.

The lineup

Gas boiler Viessmann Vitopend 100-W WH1D514

Compare

| Type: | gas, convection |

| Fuel: | natural gas, liquefied gas |

| Number of circuits: | double-circuit |

| Power: | 12 kW |

| Dimensions: | 400x725x340 mm |

| Weight: | 36 kg |

Price:

RUB 34,300

Gas boiler Viessmann Vitopend 100-W WH1D274

Compare

| Type: | gas, convection |

| Fuel: | natural gas, liquefied gas |

| Number of circuits: | single-circuit |

| Power: | 24 kW |

| Dimensions: | 400x725x340 mm |

| Weight: | 31 kg |

Price:

RUB 34,474

Gas boiler Viessmann Vitopend 100-W WH1D262

Compare

| Type: | gas, convection |

| Fuel: | natural gas, liquefied gas |

| Number of circuits: | double-circuit, bithermic heat exchanger |

| Power: | 24.79 kW |

| Dimensions: | 400x725x340 mm |

| Weight: | 36 kg |

Price:

RUB 36,156

Gas boiler Viessmann Vitopend 100-W WH1D263

Compare

| Type: | gas, convection |

| Fuel: | natural gas, liquefied gas |

| Number of circuits: | double-circuit, bithermic heat exchanger |

| Power: | 31.19 kW |

| Dimensions: | 450x725x360 mm |

| Weight: | 39 kg |

Price:

RUB 40,559

Gas boiler Viessmann Vitopend 100-W WH1D513

Compare

| Type: | gas, convection |

| Fuel: | natural gas, liquefied gas |

| Number of circuits: | single-circuit |

| Power: | 31 kW |

| Dimensions: | 450x725x360 mm |

| Weight: | 38 kg |

Price:

RUB 42,695

Gas boiler Viessmann Vitopend 100-W A1JB009

Compare

| Type: | gas, convection |

| Fuel: | natural gas, liquefied gas |

| Number of circuits: | double-circuit |

| Power: | 12 kW |

| Dimensions: | 400x725x340 mm |

| Weight: | 32 kg |

Price:

RUB 38,963

Gas boiler Viessmann Vitopend 100-W A1HB001

Compare

| Type: | gas, convection |

| Fuel: | natural gas, liquefied gas |

| Number of circuits: | single-circuit |

| Power: | 24 kW |

| Dimensions: | 400x725x340 mm |

| Weight: | 31 kg |

Price:

RUB 41,167

Gas boiler Viessmann Vitopend 100-W A1JB010

Compare

| Type: | gas, convection |

| Fuel: | natural gas, liquefied gas |

| Number of circuits: | double-circuit |

| Power: | 24 kW |

| Dimensions: | 400x725x340 mm |

| Weight: | 32 kg |

Price:

RUB 43,158

Gas boiler Viessmann Vitopend 100-W A1HB002

Compare

| Type: | gas, convection |

| Fuel: | natural gas, liquefied gas |

| Number of circuits: | single-circuit |

| Power: | 29.9 kW |

| Dimensions: | 450x725x360 mm |

| Weight: | 38 kg |

Price:

RUB 46,358

Gas boiler Viessmann Vitopend 100-W A1JB011

Compare

| Type: | gas, convection |

| Fuel: | natural gas, liquefied gas |

| Number of circuits: | double-circuit |

| Power: | 29.9 kW |

| Dimensions: | 450x725x360 mm |

| Weight: | 39 kg |

Price:

RUB 48,491

Gas boiler Viessmann Vitopend 100-W A1HB003

Compare

| Type: | gas, convection |

| Fuel: | natural gas, liquefied gas |

| Number of circuits: | single-circuit |

| Power: | 34 kW |

| Dimensions: | 450x725x360 mm |

| Weight: | 38 kg |

Price:

RUB 52,543

Gas boiler Viessmann Vitopend 100-W A1JB012

Compare

| Type: | gas, convection |

| Fuel: | natural gas, liquefied gas |

| Number of circuits: | double-circuit |

| Power: | 34 kW |

| Dimensions: | 450x725x360 mm |

| Weight: | 40 kg |

Price:

RUB 54,960

Vitopend 100 – W WH1D

In the family of gas boilers, this model is the most compact and can be installed even in small spaces.

There is only one installation method for this boiler - a wall-mounted option. Technical and design features:

- Two modifications - one and two contour.

- The range of models in terms of power parameters is from 10.5 to 31 kW.

- Maximum overall dimensions – 360*450*725 mm (for 31 kW).

- Use of a modulated atmospheric burner in the design.

- Nominal efficiency – 93%.

- The maximum continuous volume of hot water is 14.7 l/min.

- Convenient control systems and advanced control of the boiler operation.

- Models are available with open and closed combustion chambers.

- A unique chimney design that prevents the formation of ice on its surface in winter.

- Expansion tank of membrane type. WH1D262 – 6 l.: WH1D263 – 10 l.

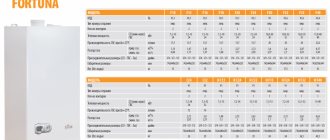

The main physical characteristics of the boiler are shown in the table:

click to enlarge

The Visman Vitopend boiler can operate on both liquefied and natural gas. An adapter kit is included as a basic package.

The cost of boilers varies depending on their power and design.

- 23 kW with a closed combustion chamber - 38 thousand rubles.

- 29 kW with a closed combustion chamber – 45 thousand rubles.

- 23 kW with an open combustion chamber – 34 thousand rubles.

Vitopend 100 – W WHKB

Almost completely identical to the boiler model described above.

The exception is the integrated storage tank with a capacity of 4 liters. As a result, the technical characteristics of the boiler are somewhat lower.

- Nominal efficiency – 90%.

- Hot water flow capacity – 14 l/min.

With the exception of these indicators, the boilers also differ externally in the control unit - in this model it does not have a liquid crystal display.

If you need a budget option for high-quality heating equipment, then Vitopend boilers will be the ideal solution - minimal overall dimensions, a large selection of design features and an affordable price.

Review of Viessmann Vitopend 100 gas boiler models

The Viessmann Vitopend 100 is offered for sale in many varieties. If you have WH1D519 equipment in front of you, then you will have to pay 93,500 rubles for it. The unit has a 100L stand-alone boiler, while the LAS will run through the wall. The kit also includes a temperature sensor.

WH1D520 has a 150 liter stand-alone boiler. The connection between the boiler and the boiler can be made by adding a temperature sensor to the system. WH1D521 is equipment for which you will have to pay 116,750 rubles. It has a separate 200 l boiler. The connection between the boiler and the boiler is made using a thread, and the system itself can be supplemented with a temperature sensor.

The above models have a power of 24 kW

If you need more impressive power, which is equal to 30 kW, then you should pay attention to the WH1D522 model, its cost is 97,600 rubles. The kit includes a 100 l stand-alone boiler

The volume of the stand-alone boiler will increase to 150 liters if we are talking about the WH1D523 model. Its cost is 115,000 rubles.

How to set up the device correctly

The initial setting of the boiler is carried out at the manufacturer, about which the user is notified in the instructions attached to the boiler upon sale. Installation and ongoing settings are carried out by technicians from the service center, so the user can only change the operating mode in accordance with the microclimate of the room and his own feelings.

All control is concentrated on the external panel. By pressing the “mode” button, you select a mode, and use the up and down arrow buttons to set the appropriate temperature.

There you can also enable summer and winter operating modes (DHW only or DHW together with heating).

Operating instructions and malfunctions

The Viessmann Vitopend 100-W series boilers operate automatically. The owner can, if necessary, adjust the temperature, turn off the heating circuit or the entire boiler.

No special measures are required from it, except for periodic cleaning of the case from dust and dirt.

Any breakdown, error on the display or shutdown of the boiler is a reason to immediately call a technician from a service organization.

Please note that the appearance of an error on the panel can be caused by various reasons, so it is usually first reset by pressing the “R” button. If after several attempts the error does not disappear, you should contact a specialist.

Any attempt to repair the boiler yourself is considered to be the end of the warranty period. You need to remember this and not take unnecessary risks.

Price range

Viessmann floor-standing boilers belong to the company's most expensive group of equipment. The price range is from 140 to 612 thousand rubles . It is necessary to clarify in advance the cost of equipment in a given region, since delivery significantly increases the price of the units.

In addition, you must immediately purchase a chimney, voltage stabilizer and other devices that guarantee high-quality and stable operation of the boiler.

The warranty agreement will also require certain expenses, but it should not be neglected . Technical support from qualified technicians will extend the life of the boiler and protect it from rapid failure.