Power 3-12 kW. Heated area, volume 30-85 m2, 80 - 220 m3 Single loading of coal (kg) at specific. weight 1.3 kg/l 110 Chimney diameter 127 mm Boiler dimensions (h*w*d) 1070*590*1250 More details >>

We are looking for a heating boiler, search result: Trio LLC produces 30 KW combined heating boilers, which are designed to supply water heating systems for residential premises with an area of up to 250 m2. Weight 140kg. Power up to 30 kW. According to functions, it can be a simple heating stove for a home (T) or (TE) combined with 6 kW heaters More >>

Advantages of the Teplotron boiler - Classic: • Works on any solid fuel (coal, firewood, sawdust, pellets, forest waste); • Does not require the constant presence of stokers, long-burning boilers; • Cleaning the boiler without stopping; • Self-sufficiency in less than one heating season (the cost of heat is 2-3 times lower than with central heating); • CO emissions less than 0. Read more >>

We are looking for a boiler that does not require the constant presence of stokers. We recommend long-burning boilers. Advantages of the Teplotron boiler - Classic: Works on any solid fuel (coal, firewood, sawdust, pellets, forestry waste); Cleaning the boiler without stopping; Self-sufficiency in less than one heating season (the cost of heat is 2-3 times lower than with central heating); CO emissions less than 0. Read more >>

Advantages of the Teplotron boiler - Classic: • Works on any solid fuel (coal, firewood, sawdust, pellets, forest waste); • Does not require the constant presence of stokers, long-burning boilers; • Cleaning the boiler without stopping; • Self-sufficiency in less than one heating season (the cost of heat is 2-3 times lower than with central heating); • CO emissions less than 0. Read more >>

Boiler for heating a cottage, private house, car wash or service station. For areas from 50 to 250 sq.m. Technical characteristics: Operating power in long-term burning mode: 5 25 kW (controlled automatically) Peak power: 60 kW Payload volume of the combustion chamber: 160 liters Burning time for the area (combustion indicators are calculated from the calorific value of coal at least 7500 kcal/kg). Read more >>

Advantages of the Teplotron boiler - Classic: • Works on any solid fuel (coal, firewood, sawdust, pellets, forest waste); • Does not require the constant presence of stokers, long-burning boilers; • Cleaning the boiler without stopping; • Self-sufficiency in less than one heating season (the cost of heat is 2-3 times lower than with central heating); • CO emissions less than 0. Read more >>

Advantages of the Teplotron boiler - Classic: • Works on any solid fuel (coal, firewood, sawdust, pellets, forest waste); • Does not require the constant presence of stokers, long-burning boilers; • Cleaning the boiler without stopping; • Self-sufficiency in less than one heating season (the cost of heat is 2-3 times lower than with central heating); • CO emissions less than 0. Read more >>

Solid fuel boiler for a large house or cottage, service station or car wash. For areas from 150 to 400 sq.m. Technical characteristics: Operating power in long-term burning mode: 15-45 kW (controlled automatically) Peak power: 90 kW Payload volume of the combustion chamber: 300 liters Burning time for the area (combustion indicators are calculated from the calorific value of coal of at least 7500 kcal/kg). Read more >>

I am looking for a reliable boiler for a large house or industrial premises. We recommend: For areas from 400 to 800 sq.m. Operating power in long-term burning mode: 35-70 kW (automatically controlled) Peak power: 110 kW Combustion chamber payload volume: 450 liters Burning time for the area (combustion indicators are calculated from the calorific value of coal of at least 7500 kcal/kg). Read more >>

Boiler for production, greenhouses, hotels, cafes, roadside service facilities. For areas from 800 to 2000 sq.m. Technical characteristics: Operating power in long-term burning mode: 15-45 kW (controlled automatically) Peak power: 90 kW Payload volume of the combustion chamber: 300 liters Burning time for the area (combustion indicators are calculated from the calorific value of coal of at least 7500 kcal/kg). Read more >>

We are looking for a heating boiler that is fired up once a season (if necessary) and operates continuously throughout the heating period. We recommend: The boiler runs on solid fuel and is practically omnivorous. Does not require constant monitoring of system operation. Reliable, simple and economical to operate. High heat transfer results. Coal or any other lump fuel automatically, under its own weight Read more>>

Automatic solid fuel hot water boiler. There are no complex mechanisms, easy to maintain and repair. Power 12 kW Heated area up to 120 m2 Fuel - Coal, firewood, sawdust Burning duration up to 5 days Overall dimensions WxHxD - 1.1x1.2x0.5 Hopper capacity up to 120 l Temperature control - Charge fan and electronic control unit Voltage 220 V Power 4- 87 W Read more>>

Important! The grate bars are made of thick-walled seamless pipe (STEEL20 alloy) designed for the entire service life of the heating boiler. The Polish Heat KO30GK boiler (horizontal heat exchanger) is made of high quality materials. The boiler is made of 5 mm steel grade 09G2S, including the doors. A 30 mm water jacket around the entire perimeter of the combustion chamber allows you to quickly release heat into the coolant Read more>>

Design features and operating principle

The inner part is used as a firebox. It is designed so that combustion occurs from top to bottom. This is helped by a special air supply directly to the combustion zone. The process is more reminiscent of smoldering with the production of gases from carbon-containing fuel. To a large extent, these gases are flammable. Due to their combustion in the upper part of the firebox, maximum use of thermal energy occurs, which allows increasing heat transfer and reducing fuel consumption.

The boiler chamber is divided into two parts by an air distributor. It has the shape of a pipe, to which a platform with blades is attached at one end, and the other end serves to supply oxygen.

Boilers with top combustion are characterized by cyclical operation, and until the first fill burns out, adding a second batch of fuel will not be necessary.

Device

The Nedelka boiler contains the following elements:

- partitions that direct the movement of hot air;

- combustion zone;

- multi-pass convective heat exchanger, increasing the efficiency of the boiler to 92%;

- a microprocessor and a fan that regulate the combustion process and maintain the set maintenance;

- door for fuel loading;

- boiler jacket made of steel 5 mm;

- door for removing ash;

- under-grid door for removing ash;

- grate made of seamless thick-walled pipe.

The structure of the Nedelka boiler

Technical characteristics of top combustion boilers using solid fuel

Top combustion boilers are produced with different powers from 8 to 95 kW. Some models can reach 1200 kW. The higher the indicator, the more efficient the unit’s operation and the larger the area that can be heated. Boilers with minimum power are designed for installation in small houses. Ukrainian "Burans" with 40 kW are intended for heating large houses or warehouses.

Solid fuel boiler BURAN-EXTRA 1200

Boiler manufacturing materials are cast iron or steel. A cast iron heat exchanger is more durable, but due to its heavy weight it can cause installation difficulties. Steel heat exchangers are made from steel of various qualities, from low-grade to high-quality, resistant to high temperatures. In addition, steel boilers are often protected by fireclay bricks.

Most often, top-burning boilers operate on wood, but there are models in which coal, peat briquettes, shavings and other fuel can be placed.

The boiler efficiency is 85-93%. According to the manufacturers, the operating time of the device after one load of firewood ranges from 8 to 31 hours, and on coals up to 5 days. The average inexpensive boiler produces heat within 5-8 hours.

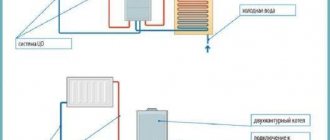

The water heating temperature is 70 0 C for wood and 85 0 C for coal. The recommended inlet temperature is from 60 0 C. The heating system can be either natural or forced circulation.

Advantages and disadvantages of solid fuel top combustion boilers

Top combustion boilers have been providing heat to users for over 15 years. During this time, they have fully confirmed their effectiveness, which is ensured by the following factors:

- when fuel is added, the distributor rises up, and after ignition it rests on the firewood and lowers as it burns out;

- at the point of air entry, incomplete oxidation of hydrocarbons occurs. Gas with ash particles is transferred to the upper part of the combustion chamber. There oxygen joins it, as a result of which it burns out and gives off the remaining heat;

- At the beginning of the gas combustion chamber, there is a draft regulator. With its help, the water temperature is automatically determined and the combustion rate of volatile compounds is adjusted.

The boilers have the following advantages:

- long operating time and minimal number of downloads;

- energy independence due to working with natural circulation and natural traction;

- the versatility of some units in terms of fuel: coal, firewood, shavings, peat, etc.;

- a small amount of fuel can ensure high operating efficiency;

- automated continuous operation of the boiler to supply hot water and heat;

- the absence of complex mechanisms makes operating the boiler simple even for beginners;

- high level of security;

- long service life of 10-15 years or more.

The top combustion boiler has a high level of safety

Disadvantages of solid fuel boilers with top loading:

- high cost compared to other installations;

- sensitivity to changes in heat exchanger temperature. Possible condensation and oxidation of steel elements;

- increased ash content can clog the combustion zone and reduce the level of heat transfer;

- it is necessary to manually clean the chimney and ash pan regularly;

- inconvenient stacking of firewood due to design features;

- Do not load large quantities of fuel, for example, unchopped firewood;

- the fuel must be completely dry, so you need to consider the conditions for its storage;

- incomplete loading makes ignition inconvenient, because the firebox is deep enough;

- You cannot reload if the process is already running;

- the support beam and disk, which serve as a partition between the combustion zones of solid fuel and gas, quickly fail.

As you can see, top-burning solid fuel boilers are not without their drawbacks, so before purchasing such a device, carefully weigh the pros and cons.

Nuances of the top combustion boiler control system

In long-burning boilers with top combustion, the main control principle is the regulation of air flows entering the combustion chamber. Standard units are equipped with a mechanical device for this purpose. The chain driven damper is driven by the thermostat.

The thermostat in the boiler is adjusted to a certain temperature. When the coolant heats up to the desired level, the damper is automatically set to a certain position, reducing the heating intensity. It is impossible to sharply reduce the temperature, because... The coolant will continue to heat up by inertia, heating the room.

Devices with fans work a little differently. If you need to increase the heat transfer force, this can be done using a fan. The device will pump air. Due to this, it is also possible to reduce the inertia of the boiler. Control occurs automatically, and sensors record the slightest changes in coolant temperature.

Domestic modifications

Among other heat generators, Nedelka is easily recognizable by its rectangular shape. Depending on the power and heated area of the house, domestic products can work without refueling for up to 7 days. The efficiency is high – 92%. The design includes automatic devices that regulate the temperature of the coolant. Multi-pass heat exchanger, firebox with grate partition and two doors: one for the ash pan, the other for the technological hatch. Designed to clean the internal walls of the firebox from settled soot.

The control unit is located on top. When disconnected from the power supply, the boiler slowly extinguishes; unlike analogues, “boiling” does not occur in it. When power is restored, it turns on automatically. The operation of the air blower fan is also regulated by a microprocessor; the supercharging is capable of igniting any type of fuel in a short time.

It’s easy to control: just set the temperature.

Review of the best top combustion boilers

Currently, the production of solid fuel boilers has expanded significantly and consumers have a choice of many models from foreign and domestic companies. Let's look at the best of them.

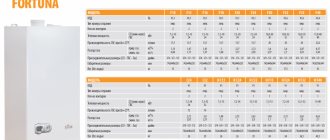

Stropuva

Boilers from the Bulgarian company Stropuva are compact units with high efficiency. The devices are equipped with a blower fan. The cylindrical body has a shaft design. The devices are distinguished by excellent performance characteristics combined with excellent design. Universal boilers can be heated with wood, peat or pressed briquettes. Model power 8-40 kW, heated area 30-400 sq.m. The permissible fuel moisture content can reach 45%, which fully meets modern requirements.

Liepsnele

In Lithuania, long-burning solid fuel boilers of a universal type are manufactured, i.e., operating on any type of fuel. The power of the units varies in the range of 10-40 kW, the heated area is up to 400 sq.m. The maximum operating time on one stack of coal is up to 7 days, firewood - up to 2 days. The design of the boilers is a classic shaft type with top combustion. Liepsnele boilers have high efficiency, at least 90%, regardless of the type of fuel and the choice of operating mode.

A week

The boilers are rectangular in shape, have an attractive design and compact dimensions. For more complete heat removal, channels are provided through which heated flue gases pass. Russian top-burning boilers, capable of operating on one load of coal for up to 7 days.

Boiler week

The Nedelka company offers four variants of boilers with different capacities, providing heating of rooms of different sizes: 50-250 sq.m., 150-400 sq.m., 400-800 sq.m., 800-2000 sq.m.

Many designs of heating devices have been developed for water heating of a private house. Mine boilers stand out for their efficiency and ease of maintenance. Their cost is quite high, so many craftsmen repeat factory models at home or make them according to their own designs.

A long-burning mine boiler differs from others in its combustion duration and device features. There is no need to add fuel often; it has a large-volume fuel chamber and burns slowly. Two types of mine boilers have been developed: conventional combustion and pyrolysis. Each has a similar device of two chambers: in one the fuel is burned, in the second there is a heat exchanger.

A shaft boiler with conventional combustion is simpler in design. Half of the total volume is occupied by a firebox with the height of almost the entire unit, but small width and depth. There is a fuel loading hatch on the side or top. When viewed from above, the combustion chamber resembles a shaft, hence the name. Under the combustion chamber there is an ash pan, separated from it by a grate. The ash door provides access not only to it, but also to the firebox. A damper located under the door regulates the air flow.

The shaft boiler does not require special control due to its burning duration

The second important part is a chamber with a heat exchanger filled with water or, if the boiler is not used for water heating, a fire tube. Gases enter it from the firebox through an opening and exit through the chimney, simultaneously heating the heat exchanger. From it, water flows through pipes into the system or hot air warms up the room.

A shaft-type pyrolysis boiler has a similar design, but is manufactured with some additional elements:

- 1. Chambers in which carbon monoxide burns and burns out. They are located at the bottom of the heat exchange space, the walls are lined with fireclay bricks.

- 2. Several pipes with a lot of small holes. Air is supplied through them for the combustion and afterburning chambers.

- 3. At the top of the wall there are valves to separate the two chambers.

The operating principle of a pyrolysis boiler is somewhat different. When burning, the air supply is limited; slow combustion causes the formation of a large amount of gases, which enter additional chambers and burn. Boilers burn any solid fuel: coal, wood, pellets. One load of coal is enough for five days, firewood - no more than thirty hours. Due to complete combustion, such boilers have high efficiency - up to 90%.

The proposed design has a power of 22 kW, efficiency 75%. It works on wood for 10 hours without additional loading, on coal for 24 hours. The firebox has a volume of 83 liters to the bottom edge of the loading hole. The boiler is equipped with automatic equipment made in Poland: a control unit with a KG Elektronik SP-05 temperature sensor and a DP-02 fan. The general view is shown in the drawing.

The device works as follows:

- 1. Firewood is loaded into the firebox and set on fire. The doors close hermetically.

- 2. The required heating temperature is set on the control unit, at least 50°. The unit button is pressed and the fan begins to pump air.

- 3. When the set temperature is reached, the air supply from the fan stops. The firewood smolders slowly and produces very little heat.

- 4. After some time, the temperature drops. The fan turns on again and combustion continues.

The electronic unit regulates the combustion process, which occurs at maximum efficiency. There is practically no smoldering; intensive burning and standby modes are used.

The following picture shows the inside view.

Solid fuel is burned according to the classical scheme: heat is directly transferred to the walls of the water jacket and the roof of the tank. A heat exchanger is built into it, taking heat from the gases. Heated air is supplied to the firebox through an air duct from below. Fuel loaded in large quantities ensures long operating time of the boiler. While waiting for the fan to turn off, the air is completely blocked by a gravity damper, activated automatically, and natural draft is blocked.

The drawing shows the rear end with a fire tube heat exchanger.

When assembling with our own hands, we use the drawings and adhere to the specified dimensions. The sequence is as follows:

- 1. Cut out the body from 4 mm metal: bottom, side walls, lid, doorways. Everything is grabbed onto the bottom, which extends to the sides, as in the drawing. Inside, we weld the corners, which will serve as a shelf for the grate.

- 2. We carefully weld the joints and proceed to the water jacket made of 3 mm metal. It extends 20 mm from the walls of the body and to install it, we weld steel strips onto the body. We weld the casing to them.

- 3. Installation of flame tubes on top of the boiler. We cut holes in the back and front walls, insert several pipes, and weld them at the ends.

- 4. We cut out the doors, weld two strips from the inside, and lay asbestos between them for compaction. We cut grates measuring 360×460 mm from the corners and weld them to the shelves with the outer corner.

- 5. We cut fittings into the walls of the tank for the supply and return pipelines and the smoke duct pipe. We weld the air duct from a 40x60 mm profile pipe. A fan will be attached to it through a flange. The air entry is made through the rear wall.

- 6. We weld door hinges and bookmarks to attach the decorative frame. We wrap the boiler tank with basalt insulation and secure it with a cord. We fasten the frame with self-tapping screws to the bookmarks and install the doors.

Time-tested choice

You can list five reasons why you need to choose Nedelka boilers.

- Versatility. Boilers are not only intended for heating private homes. Their operational characteristics allow them to be installed in industrial premises: they are not fire hazardous, environmentally friendly - all doors remain hermetically closed during operation, and are safe in the event of a power outage.

- Easy to maintain: for operation you do not need to undergo special training or obtain permits; one person can easily handle it. The boilers are as safe as possible to maintain: every few days the firebox is cleaned, the ash pan is emptied, and fuel is loaded.

- Difference in modifications. different power. The heat from KO-60 is enough to heat 300 square meters, the power of KO-110 is twice as high. Recently, due to the increasing demand for high-power heat generators, cluster modifications - modular boiler houses - have been developed.

- Affordable price. The cost of domestic models ranges from 110 to 220 thousand. Imported boilers of similar design and power are much more expensive. The use of various types of low-quality fuel when operating a heat generator leads to significant cost savings.

- The durability of the boiler is due to the use of rolled metal from durable alloys. It has high fault tolerance. The warranty period is 5 years, the actual period is at least 20 years without replacement of structural elements.

Before industrial production, long-burning heat generators were made by craftsmen using handicraft methods. The model has already been tested by time and allows significant savings on fuel. It is intended not only for heating systems, but can also be used as a water heater.

They do not take up time between loads; thanks to the control system, the boiler works independently.

You can learn how to install the Nedelka boiler from the video below.

The principle of operation of a wood heating boiler, long burning

The design and principle of operation of a wood-burning boiler for long-term operation from one load is aimed at recreating similar conditions in the limited space of the combustion chamber. Firewood does not burn in the full sense of the word, but smolders. The operating time increases, and the lack of heat is compensated by the afterburning of the released gases.

The design of long-burning boilers includes the following components:

- Combustion chamber - the device has two combustion chambers at once. The first firebox (with vertical or horizontal loading) is designed for burning wood. The second chamber is used to burn the produced carbon dioxide. To ensure complete combustion of the gas, the firebox is made of fireclay bricks, which prevents heat loss and helps maintain the temperature around 800°C.

How to choose a slow burning wood boiler

Long-burning wood-burning heating boilers are offered by several domestic and foreign manufacturers. The design of the equipment, as well as the thermal characteristics, differ significantly. When choosing a heat generator, pay attention to the following parameters:

- Performance.

- Design features.

- Manufacturer country.

Based on the three parameters listed above, a suitable boiler model for domestic needs is selected.

Power calculation

A properly selected long-burning wood-burning heating boiler can easily cope with heating a living space of up to 400 – 500 m². When choosing, take into account the performance of the heat generator. Power calculations are performed as follows:

- Calculate the total area of the house.

- Calculate the required boiler power using the formula 1 kW = 10 m².

- If the design has a DHW circuit, add 15-20% of the reserve to the result obtained.

The above calculations are suitable for buildings with an average degree of thermal insulation, located in the middle latitude of Russia and having a ceiling height of no more than 2.7 m. For rooms with a complex configuration, a large number of window and door openings, calculations are carried out using online calculators.

Wet coal - how does this affect consumption?

We would like to tell you about our client’s experiment and share our conclusions. Comments about condensate are among the most common, as are disputes about its origin. Some blame the vertical heat exchanger, others simply blame the manufacturer without any justification...

We would like to tell you about our client’s experiment and share our conclusions. Comments about condensate are among the most common, as are disputes about its origin. Some blame the vertical heat exchanger, others simply blame the manufacturer without any justification...

Features of operation of wood boilers with long burning

The burning time of one stack of firewood ranges from 8 to 24 hours. The battery life depends on several factors:

- Boiler type.

- Fuel quality.

- Correct operation.

Learning how to properly heat a boiler is much easier than it might seem at first glance. During kindling and further operation, adhere to the requirements specified by the manufacturer in the technical documentation. After several fires, the process becomes familiar.

How to make wood burn for a long time

You can achieve long burning of firewood by carefully following the manufacturer’s recommendations:

- Firewood is lit with the damper fully open.

- The boiler is switched to long-burning mode only after reaching a temperature of 600°C.

- The moisture content of firewood should not exceed 20%. It is not recommended to burn with coniferous wood.

Violations of operating rules lead to the formation of tar from the firewood in the boiler. Most often, the following conditions are not met:

- The minimum temperature of the coolant at the outlet should not fall below 65°C.

- It is correct to heat a boiler with hard wood: aspen, beech, acacia, oak, etc.

- High humidity of firewood leads to abundant release of resin.

Proper operation of long-burning boilers extends the service life of equipment and increases heat transfer.

How to load firewood correctly

Ignition is carried out exclusively with dry splinters. It is prohibited to use gasoline or kerosene to light firewood. From time to time, it is recommended to use special chemical briquettes that remove tar deposits on the walls.

How much firewood do you need for the winter season?

The long-burning boiler allows you to save on fuel by approximately 15-30%, depending on the chosen model. The approximate consumption of firewood is calculated as follows:

- It is generally accepted that to heat every 100 m², 3 Gcal/month is required.

- When burning a kilogram of wood, 3200 kcal is released.

- To obtain 1 Gcal, long-burning boilers burn 312 kg of wood.

- To obtain 3 Gcal, approximately a ton of wood will be required.

During the heating season, to heat a house of 100 m², you need 7-8 tons of firewood.

Rules and regulations for installing a long-burning wood-burning boiler

The installation of a long-burning boiler is carried out in compliance with the standards that apply to all wood-burning boilers. During installation work, the existing requirements of PPB and SNiP are taken into account:

- Installation is carried out on a solid non-combustible base. The walls and floor are lined with non-combustible building materials.

- The chimney is carried out in compliance with fireproof cuts. At the junction with a wall made of flammable material, fire-resistant insulation is laid. The material is lined with steel sheet.

Water heating from a long-burning wood-fired boiler is connected to special outlets located on the boiler body. The instructions indicate in detail which pipe goes to the supply and return of the water circuit.

- A boiler with a capacity of more than 40 kW is installed in a separate room.

- Volatile boilers are connected to the power supply through a stabilizer and an uninterruptible power supply. Be sure to use machine guns. The connection is made directly from the switchboard.

In the room used as a boiler room, it is necessary to have supply and exhaust ventilation and natural lighting. If necessary, it is possible to place the boiler in the basement.