In modern construction, materials of artificial origin are increasingly used, which successfully replace expensive equipment made of metals.

Polymer types of plastic are distinguished by their ability to be used universally, and the demand for products made of polypropylene has brought this material to second place among global consumer volumes.

Due to the technical characteristics of plastic, pipes are made from it for use in industry and utilities.

What is special about polypropylene pipes?

Polypropylene pipes have the following strengths:

- Light weight compared to a metal pipe. This greatly simplifies the installation and transport of pipes and fittings.

- Not afraid of rust, dirt, aggressive liquids.

- The organization of the pipeline occurs very quickly: no complex devices or special skills are required.

- Duration of operation – 50 years or more.

- Many types of polypropylene pipes have good sound insulation characteristics.

- Polypropylene for heating is completely environmentally friendly.

There are also some disadvantages:

- Significant coefficient of thermal expansion. Reinforced products have it at a level of 2-3.5 mm per 1 m, solid ones are 4-5 times more pliable.

- As for pipes with external reinforcement, it will need to be treated with special devices.

- The market is replete with counterfeits of polypropylene pipes: in this case, the outer layer is especially susceptible to defects.

- The high fluidity of polypropylene pipes means that even the product’s own weight can contribute to deformation. To avoid such phenomena, the polypropylene pipeline is equipped with special fasteners, which are installed every half meter.

- The significant rigidity of polypropylene implies the need for a large number of fittings when organizing rotary sections.

Standard Size Charts

Considering that pipes of this type are used almost everywhere, manufacturers produce products in a wide size range. Product sizes vary within the following limits:

- Diameter – from 5 to 400 mm . Small pipes are usually used when laying pneumatic systems, medium pipes are used for private and multi-storey construction, large pipes are used for the improvement of buildings where high throughput of engineering communications is required.

- Length - the standard value is 4 meters , however this is not a standard characteristic and remains at the discretion of the manufacturer.

- Wall thickness – 1.9-15.1 mm .

It should be clarified that polypropylene pipes can be made in the form of a monolayer or multilayer structure. The second option involves reinforcement: a five-layer structure, where there is an aluminum spacer between the layers of plastic. The thickness of the reinforcing layer usually varies between 0.1-0.5 mm .

| Outer diameter, mm | PN10 | PN20 | PN30 | |||

| Inner diameter | Wall thickness | Inner diameter | Wall thickness | Inner diameter | Wall thickness | |

| 16 | 10.6 | 2.7 | ||||

| 20 | 16.2 | 1.9 | 13.2 | 3.4 | 13.2 | 3.4 |

| 25 | 20.4 | 2.3 | 16.6 | 4.2 | 16.6 | 4.2 |

| 32 | 26.0 | 3.0 | 21.2 | 5.4 | 21.2 | 3.0 |

| 40 | 32.6 | 3.7 | 26.6 | 6.7 | 26.6 | 3.7 |

| 50 | 40.8 | 4.6 | 33.2 | 8.4 | 33.2 | 4.6 |

| 63 | 51.4 | 5.8 | 42 | 10.5 | 42 | 5.8 |

| 75 | 61.2 | 6.9 | 50 | 12.5 | 50 | 6.9 |

| 90 | 73.6 | 8.2 | 6 | 15 | ||

| 110 | 90 | 10 | 73.2 | 18.4 | ||

See size tables for water and gas steel pipes. Learn about nominal diameter and how to avoid confusion between inches and mm. Go to article >>>

| Equivalent passage, mm | Outer diameter, mm | ||

| Steel gas pipelines | Steel water pipes | Polymer | |

| 10 | 17 | 16 | 16 |

| 15 | 21.3 | 20 | 20 |

| 20 | 26.8 | 26 | 25 |

| 25 | 33.5 | 32 | 32 |

| 32 | 43.2 | 42 | 40 |

| 40 | 48 | 45 | 50 |

| 50 | 60 | 57 | 63 |

| 65 | 75.5 | 76 | 75 |

| 80 | 88.5 | 89 | 90 |

| 90 | 101.3 | ||

| 100 | 114 | 108 | 110 |

| 125 | 140 | 133 | 125 |

| 150 | 165 | 159 | 160 |

| 160 | 180 | 180 | |

| 200 | 219 | 225 | |

| 225 | 245 | 250 | |

| 250 | 273 | 280 | |

| 300 | 325 | 315 | |

| 400 | 426 | 400 | |

| 500 | 530 | 500 | |

| 600 | 630 | 630 | |

| 800 | 820 | 800 | |

| 1000 | 1020 | 1000 | |

| 1200 | 1220 | 1200 | |

What kind of polypropylene pipes are there?

There are two main types of propylene pipe structures - solid and reinforced. The latter variety has a significantly lower thermal elongation rate, which compares favorably with solid products. The different lengths of polypropylene pipes will help you quickly and efficiently select pipe sizes according to the project. It is also important to know what kinds of polypropylene pipes there are according to the method of reinforcement.

Polypropylene products are reinforced as follows:

- The outside of the pipe is covered with aluminum foil.

- Aluminum is located inside the pipe, near the outer edge.

- The pipe is reinforced with fiberglass.

- Composite material is used for reinforcement.

Solid polypropylene pipes

These products differ primarily in that special raw materials are used for their production. This is reflected in the differences in the characteristics and applications of solid polypropylene pipes.

Surfaces may have the following markings:

- P.N. Indication of stable internal pressure against a background temperature of + 20 degrees. The digital designation indicates the wall thickness. The most popular polypropylene pipes for construction activities are PN 10, 16, 20, 25, and the last two varieties are used for arranging space heating and pipelines for supplying hot water.

- Red or blue stripe. Blue color is used to indicate polypropylene pipes for cold water. The red stripe marks the material for hot water.

- The letters PP indicate the use of polypropylene as the initial raw material.

The following types of source material can be distinguished:

- PPH, PP-1, PP-type 1. Used for cold water and ventilation.

- RRV, RR-2, RR-type 2. For organizing hot water supply and heating.

- PPRC, PP-random, PPR. The innovative material “random copolymer” is used as a manufacturing material. These pipes are most often used in engineering communications. They are characterized by a high level of heat resistance. If installation is carried out outdoors, it is advisable to use products with solar protection.

Classification of fittings for PP pipelines

The material from which polypropylene fittings are made may have a different composition, which affects thermal stability.

Based on this feature, there are 3 types:

- homopropylene - abbreviated as PPG, marking - RRN, PP-1;

- block copolymer - denoted by the abbreviation PPV, markings - PPV, PP-S, PP-2;

- round copolymer - PPR, labeled - PP-3, PPRC, PPCR.

The first type is polypropylene with the inclusion of special modifying additives - nucleators, fire retardants, antiseptics. They impart a certain set of properties to the final product. Both pipes of this type and fittings are suitable exclusively for cold water supply.

The second is a polymer made up of homopolymer micromolecules arranged in a precise order. The finished product made from this material has high impact resistance. Since it can withstand high temperatures, it is suitable for hot water pipes.

Polypropylene has high impact strength. It is resistant to abrasion and bending. Has excellent dielectric characteristics, low gas and vapor permeability

The structure of the rondom copolymer is crystalline. The product does not lose its properties over a wide temperature range - -170 - 1400⁰. Elements made of this material can have a cross-section from 1.6 to 11 cm. They are used in many engineering networks. The characteristics of polypropylene also include such a parameter as MRS. This is a characteristic of the shortest duration of strength.

It is related to the maximum permissible pressure in the line. This pressure is guaranteed to ensure the impeccable service of the pipeline when transporting water with a temperature of 20⁰ for 50 years. The indicator is directly related to the thickness of the pipe wall.

Pressure values are encoded in the abbreviation PN with a digital prefix. It indicates the maximum permissible pressure during operation. The higher the digital designation, the greater the pressure load the pipe can withstand.

Examples: PN10 - a pipe with a designated pressure of 10 bar, a pressure of 16 bar corresponds to a PN16 pipe.

You can select both connecting elements and pipes for assembling heating and plumbing systems made of polypropylene according to their intended purpose:

- for passing cold water;

- for transporting hot (maximum 70⁰) water.

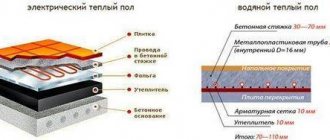

There are also pipes used to create heating systems: low-temperature (maximum 60⁰) floor systems and radiator systems up to 90⁰.

Features of polypropylene couplings

PP couplings have thickened walls. The pipes are inserted into the coupling joint using some effort.

Installation of a fitting with a diameter less than 5 cm is performed manually. Before connecting pipes using fittings, the pipes are cut at right angles and burrs are removed

The main thing is that the part of the pipe that gets into the coupling is absolutely smooth. The pipe is inserted into the connecting element until it stops, after fitting it is removed and heated on a welding iron to firmly and hermetically connect the parts of the PP pipeline.

Transition elements for products of different diameters

Products of different sections are connected using a special type of adapters. It performs the same role as the coupling, but connects different diameters. If you need to continue the polypropylene pipe with a metal one, these connecting elements are also used.

In this case, they differ from simple couplings in the presence of an internal thread on one side. This adapter hermetically connects smooth sections of the water main.

Corners and their scope of application

Plumbing is not always a perfect straight line. Sometimes it becomes necessary to form a right angle. Polypropylene is a rigid material and inflexible in working condition. But it can be bent if only preheated. Another thing is that you don’t need to do this.

If a polypropylene pipe is heated and then bent, the outer wall at the bend will become thinner. This will worsen the strength characteristics of the entire system. Folds will appear on the other side of the pipe, reducing its throughput.

When the design temperatures and pressures increase slightly, a leak may occur. The best solution in this situation is to use a fitting bent at the appropriate angle.

The bending angle is 45, 90⁰. There are corners with carvings on one side. So, when installing a faucet in a bathroom, use a corner with a cross-section of 2 cm on one side and a 3-quarter internal thread on the other.

Using tees and crosses

In situations where it is necessary to bring together more than two bends, tees and crosses are used. For example, it is necessary to supply water from the riser to the bathroom or to the kitchen sink.

Such fittings have many modifications. Some pipes run at a 90⁰ angle, others at an acute angle. To install shut-off valves on connections of this kind, fittings are produced with threads on one side. The second side is intended for welding.

The use of tees and crosses allows you to quickly and efficiently assemble polypropylene pipeline branches. To install shut-off valves in plastic pipelines, fittings are produced, one of the sides of which is equipped with a metal thread

The temperature and heating time of polypropylene parts are strictly regulated. The following article will introduce you to these values, in which, in addition to these important parameters, you will find a detailed guide to connecting PP parts by soldering.

Bypass elements for water mains

In the case of laying a water pipeline passing along a complex trajectory, it is impossible to do without bypass curved parts. They are necessary when the pipe needs to be laid to bypass obstacles located near the wall. They change the direction of the highway smoothly.

Visually, these parts are similar to squares, but their bend is more round. With their help, it is possible to rotate the water supply by 120⁰.

The bypass element is mounted using socket welding. The bypass ring is compatible with solid polypropylene pipes, as well as with reinforced reinforcement frames

They produce polypropylene bypass fittings from PPR brand PP. Such elements also fit well into corner joints, and this is important when communications are located externally.

Correct selection of fittings by diameter

The selection of plastic fittings, as well as the connection method, is carried out based on the material of the pipes. In any case, a diagram is first created, then the type of connecting elements is determined.

Fittings for diffuse welding or soldering are suitable for a system of polypropylene pipes. This is an inexpensive method, but it provides a monolithic and 100% tight connection of polypropylene pipes used in the assembly of heating, sewer and water supply networks of any complexity.

The diameters of the connecting elements are related to the diameter of the pipes. In turn, the latter value is interconnected with such a parameter as the throughput of the water supply system. When selecting the required diameter, you need to take into account several nuances.

The marking of pipe products includes the outer diameter, the value of which also takes into account the rather thick walls of the pipe. Therefore, with the same outer diameter, the permeability of a polypropylene pipe will be less than, for example, a metal-plastic one.

The polypropylene pipe inside is absolutely smooth, as opposed to steel. No deposits linger or accumulate in it. So if initially the internal diameter of this type of pipe was the same, the PP pipe will provide more efficient passage.

The greatest demand is for PP fittings and pipes with a diameter of 20 to 40 mm. There are also plenty of larger size products on the market, but they are not as popular

For water supply in a cottage or apartment with a standard set of water intake points, the best option would be a pipe with a diameter of 20 mm. Large diameters (50 mm) are more suitable for implementing water supply schemes for microdistricts.

Fittings are not needed in this case. Docking is done by welding. To include check valves and gate valves into the system, steel flanges are used.

Aluminum reinforcement

There are solid and perforated samples of this type. The perforation itself looks like a fine aluminum mesh. The process of extruding polypropylene is accompanied by the ingress of a fluid and viscous substance onto the perforation, which leads to adhesion of the metal and the polymer. Thanks to aluminum reinforcement, a noticeable reduction in the coefficient of thermal expansion is achieved.

However, such engineering systems are installed with some difficulties. When carrying out socket welding, it will be necessary to remove the aluminum shell and the outer polymer layer before starting work. Subsequently, the pipe is cleaned according to the parameter of the inner diameter of the fitting.

As for pipes in which the outer layer does not need to be removed before installation, they have the following disadvantages:

- The fitting can only fix the outer part of the product: usually this is half the wall thickness.

- The welding machine must have a nozzle.

- When the pipe is cut, it must also be terminated.

Reinforcement with fiberglass

The PPR-FB-PPR marking indicates that such a pipe consists of two polypropylene layers separated by a fiberglass gasket. This type of pipe is also called fiberglass.

Fiberglass reinforcement has some advantages:

- There is no need for calibration or cleaning during installation.

- Soldering here is the same as when connecting solid plastic or any polymer-protected pipes. This helps to increase the speed of work and reduce its cost.

- Thanks to fiberglass, delamination of polypropylene pipes is not observed. This is due to the uniformity of its structure, because the central fiberglass layer is literally fused into the polypropylene structure.

- Due to fiberglass, products become more rigid.

The disadvantage of fiberglass-type pipes is that they have greater thermal elongation when compared with pipes with aluminum reinforcement.

For stove heating

If you have a stove, don't rush to get rid of it. It is unlikely, of course, that anyone has a large Russian stove with a stove bench in their home, but small stoves are still quite common. And it turns out that such a novelty as air heating is actually not a novelty at all. The principle of stove heating is that heated air passes through specially equipped channels in the walls. This is the same direct flow, only the heater is not a gas boiler, but a wood stove or fireplace.

In addition, you can improve your existing furnace and add a water heating circuit to it. To do this, a water collector is placed above the firebox, in which the coolant is heated. It is then carried through pipes to radiators. What pipes can be used for heating a furnace:

- metal-plastic;

- RR;

- PEX;

- PVC;

- steel;

- copper.

In other words, everything that is suitable is the same as for conventional water heating. The only difference is in the form of the heater. Let's not forget that many autonomous circuits operate on solid fuel and the operating principle of such systems is the same.

Applying propylene to the internal surfaces of pipes

We are talking about metal-plastic pipes that have an outer polypropylene layer. They tolerate increases in temperature well.

The disadvantages of these products include the following:

- The presence of several layers. Three different substances are connected into one structure using an adhesive method.

- The fitting is attached only to the outer layer, which makes the connection not very strong.

- The transported medium often comes into direct contact with the reinforcement, which is why the material can gradually wear out.

Types of sewer pipes

Polypropylene pipes are often used to construct sewer systems of various types. When going to a plumbing store, it is important to know which polypropylene pipes are best to choose. Intra-house networks are equipped with products with a diameter of 110 mm.

Corrugated pipe is used to organize external communications. Polypropylene sewer pipes have a diameter of 150 mm and a length of 5 m; a diameter of 600 mm is up to 10 m. If it is necessary to drain aggressive industrial wastewater, a double-layer corrugated pipe is used.

Communications arranged in this way are able to withstand significant loads on the soil: this is favored by their high rigidity. Highways, airports and bridges can be built over such lines.

The PP product of SN8 stiffness class can be laid to a depth of 6-8 meters. To organize a sewer system from them, great efforts will not be required. Each of the pipes is inserted at one end into the socket, where rubber O-rings are used for tightness.

Material for the manufacture of water supply and sewerage systems

These products can be used to organize water supply and heating. How to choose polypropylene pipes for water supply based on its purpose?

The following restrictions apply to the transported liquid:

- Operating temperature – no more than +70 degrees.

- The pressure at a temperature of +70 degrees should not be more than 10 bar, at a temperature from 0 to +25 degrees - 25 bar.

- Short-term increases in temperature up to +90 degrees are allowed.

Depending on the purpose of the system, the selection of appropriate products will be required:

- Gray polypropylene pipes are characterized by the ability to withstand operating loads more resistant than similar white products. For heating products they are a more preferable option.

- For hot water, thicker pipes are used.

- Products with aluminum or fiberglass reinforcement are sometimes used in systems equipped with geysers. However, this is a violation of their operating conditions, which leads to a reduction in service life.

Rating of trusted manufacturers

Among companies engaged in the production of polypropylene pipes, the most popular brands are:

- WAWIN ECOPLASTIK . A Czech company that has managed to win a high rating among builders all over the world. The manufacturer's revolutionary solution is all-plastic FIBER pipes, which have minimal weight, but at the same time show high strength and resistance to linear expansion.

- FV-PLAST . Another Czech company presented on the market with reinforced pipes with perforated aluminum inserts. The products produced have a wide size range and are ideal for installing hot and cold water supplies.

- PRO AQUA . A Russian enterprise engaged in the production of multifunctional polypropylene pipes. The company's products are distinguished by high technical characteristics, while being sold in an affordable price range.

In addition, you can pay attention to the products of such companies: BANNINGER REISKIRCHEN (Germany) and VALTEC (Italy). Plastic pipes of these brands are in the high price segment, but have almost standard quality.

Ventilation material

Ventilation pipes ensure the flow of fresh air into the room and the removal of exhaust air: their strength in this case is not the main criterion. The main thing is that these products were lightweight, since they are often supported only by partitions or suspended ceilings.

Residential premises are equipped with pipes with a diameter of 100 or 125 mm; industrial systems will require preliminary calculations. The cross-sectional shape of such products can be square, round, oval or rectangular. The installation process uses the socket method, so no welding machine is required.

How polypropylene pipes are connected

All types of polypropylene pipes are connected to each other or other elements of the system by welding and connectors.

Polypropylene pipes and fittings are connected to each other in the following ways:

- Coupling or socket welding. Used for pipes whose diameter is less than 63 mm.

- Butt welding. Pipes with a diameter of more than 63 mm are directly welded together. In this case, no additional elements are required.

- Flange joint. Using this collapsible connection, pipes of large cross-sections are joined.

To connect a pipe made of polypropylene and metal, there are two ways: threaded and flanged. The first of them is suitable for products with a diameter of less than 40 mm: for this, various fittings are used that have a thread on one side and a smooth coupling on the other. Pipes up to 600 mm are connected using various types of flanges, since tightening the threads in this case is quite problematic.

To organize the transition between polypropylene and HDPE pipes, welding or fittings are used. Due to the different composition of materials, welding is less preferable in this case. It is better to choose compression or threaded fittings for these purposes. As for connecting polypropylene communications with this or that equipment, then fittings of various types come to the rescue.

If you are setting up a house or apartment

When creating a project for a standard private house or apartment, there is no need to carry out precise calculations. The number of plumbing fixtures will be minimal, and the difference in price for pipes of different diameters will differ minimally, which will have virtually no effect on the budget.

If you look at the faucet hose, you can see what a small diameter they have, that is, through what minimal holes water flows into the sink. Taking into account the fact that the cross-section of the polypropylene pipe will be much larger, it will always be sufficient, since the bottleneck in this case will be precisely this hose. That is, the patency of the entire system will rest on its narrowest point.

That is why the owners of private houses and apartments do not carry out complex calculations, but simply purchase a polypropylene pipe with a cross-section of 20 mm, saving their precious time. In the vast majority of cases, with a standard number of washbasins, sinks, bathtubs and other plumbing fixtures, such a pipe will be sufficient with a large margin.

conclusions

We hope everyone understands what diameter polypropylene pipes are measured by. Selecting them will not be difficult. As practice shows, you can often simply purchase the simplest and most inexpensive pipe - the result will be a high-quality and properly functioning water supply system.