- Introduction.

- History of the development of gas boilers.

- Types and differences of gas boilers.

- Other differences between gas boilers.

- Advantages and disadvantages of gas boilers compared to boilers using other fuels

- What else you need to know when installing boilers

There are conditions without which a person’s daily life will not be considered fully comfortable.

First of all, these are various life systems, which include heating and a source of hot water in the premises.

The first designs that made it possible to effectively heat the interior spaces of buildings appeared during the Ancient Roman Empire.

Initially, solid fuel (wood, coal, etc.) was used for this process, but the development of civilization led to the possibility of using electricity, liquid fuel, solar energy, and natural gas for such purposes.

Types of gas boilers by purpose

According to their intended purpose, the units are produced as single-circuit and double-circuit. And they differ in the number of installed heat exchangers, capable of independently heating water only for heating or both for heating and hot water supply.

In addition, these units are divided according to the heat exchanger material: cast iron, steel and copper.

The most durable is the cast iron option; it resists corrosion processes well, but is considered fragile and is susceptible to water hammer, especially during cold equipment starts.

Copper is used in wall-mounted boilers and has high thermal conductivity. But it is undesirable when installed in conjunction with aluminum radiators, since a galvanic couple is created that destroys aluminum.

Steel heat exchangers are most often used in floor-standing boilers and are inferior in characteristics to the first two modifications.

Modern boilers are grouped according to the degree of condensation of flue gases into condensing-type boilers or non-condensing units.

Double-circuit boilers

In double-circuit boilers operating on gas fuel, heated water circulates through 2 circuits, one of which is responsible for the functioning of heating, and the second for DHW.

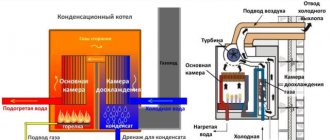

Diagram of a double-circuit boiler

Switching features of a dual-circuit unit:

- Heating. In most modern boilers, the heating circuit starts automatically after the primary temperature sensor gives a signal to the control panel, which increases the gas flow and the speed of the circulation pump for forced coolant circulation systems. The gas is burned in the boiler furnace. Hot flue gases give off their heat through a surface heat exchanger, heating the water, depending on the boiler model, from 75 to 90 °C. A centrifugal pump pumps the heated coolant through the in-house heating system from the boiler to the radiators, and then returns the cooled water to the boiler for a new heating cycle.

- DHW. When the user opens the hot tap on the water supply mixer, the three-way tap on the boiler transfers the coolant from the primary heat exchanger to the secondary one. In this mode, the heating boiler does not work, which is very inconvenient if the family is large. Significant heat consumption for DHW will be required; during this period, the heating system may cool down.

Single-circuit

A single-circuit gas boiler is the simplest in design; it is usually installed in heat supply systems with a small heating area.

They are easy to operate and have the lowest price among gas heating units. Many modern boilers have the design ability to connect an external indirect heating boiler, which is made in the form of a hot water storage tank.

Boiler diagram with one circuit and boiler

At the bottom of the boiler there are special DHW pipes, which are used to connect to an external heat exchanger. This scheme is very effective because it uses the boiler more efficiently.

When the water in the heating system is below the set temperature schedule, the coolant is heated for the heating circuit; when it reaches the desired temperature, the three-way valve switches the coolant to heating water in the storage tank.

At the same time, the DHW water supply will not affect the quality of heating in any way. To reduce heat loss in the heating system, experts advise placing an indirect heating boiler as close as possible to the boiler unit.

Types of gas boilers according to installation method

All gas boilers are grouped according to installation option - floor-mounted and wall-mounted. They all have their advantages and disadvantages; it is important to understand the criteria in which the device will perform best, especially in conditions of shortage of living space.

Wall boilers

These types of gas heating boilers appeared on the climate control market relatively recently, but have already won user sympathy. The modern level of performance of wall-mounted gas units allows them to be used as a mini modular boiler room.

The unit is factory equipped with not only the main but also auxiliary equipment. Typically, its kit includes a circulation pump, two heat exchangers, a fan, a safety group with instrumentation and primary sensors, an air vent and an expansion tank.

These units have a multifunctional mode with 100% automatic combustion process. They are easy to install and have the highest efficiency of up to 92%, since all auxiliary equipment is most carefully matched by the manufacturer to the thermal power of the boiler.

Floor-standing

A floor-standing gas boiler is a traditional option for placing a heating source, which came from a centuries-old Russian stove. These modifications are heavy because, as a rule, they are equipped with a powerful cast-iron heat exchanger. Floor-standing devices are designed for heating houses with a large heating surface.

To increase the thermal power of the heating source, they are equipped with blower fans to organize forced circulation of flue gases.

Depending on the power, the burners are atmospheric up to 80 kW and replaceable inflatable burners with a power of several thousand kW. Such devices are made to be volatile.

Some types of floor-standing units can also be non-volatile, when the heat transfer process is carried out without the need for electrical power, usually these are low-power devices capable of heating an area of up to 200 m2, using natural circulation patterns of the coolant and exhaust gases.

conclusions

All existing models of domestic gas boilers are capable of satisfying the necessary minimum needs of home occupants. The choice of boiler type should be tied primarily to the needs and operating conditions, so you should not purchase an overly powerful unit - a large supply of power will remain unclaimed. However, a low-power home boiler that does not meet the requirements is a waste of money.

At the same time, the price of the unit is not the least important criterion. Buying cheap equipment is fraught with frequent failures and will ultimately result in high costs for a low-quality boiler, so you should choose a device in the middle price range, the functionality and quality of products in which often differs from top models only in the absence of one or two rarely used options.

Boilers by combustion chamber type

The next important parameter for classifying types of gas boilers is based on the design of the combustion chamber. They come in open and closed types.

The first ones are simpler and cheaper, but have limitations on the heating area of no more than 250 m2. The latter are more expensive, energy-dependent and safe, since they do not burn oxygen in the house.

With open firebox

An open firebox means that there is a natural intake of combustion air from the room. This is the simplest design of a boiler unit, in which no electricity is needed to organize the combustion process, as well as the arrangement of air ducts and a blower fan. Boilers of this design are usually low-power and heat a living area of no more than 200 m2.

The disadvantage of this type of boiler units is the high requirements for organizing fresh ventilation in the room where it is located. Legislative requirements for ventilation systems for boilers with an open firebox are to ensure 3-fold air exchange through window and door structures.

Otherwise, the air will become dry and will negatively affect the microclimate in the room. In addition, these boilers often have problems due to imperfect smoke exhaust. If the vacuum level in the firebox drops to zero, carbon monoxide can enter the room, which is deadly for others.

Closed chamber boilers

This is a completely new type of smoke exhaust organization in which the firebox has no contact with the internal air in the room. Oxygen is taken to the burner through closed air ducts from the street.

The supply system is forced through a fan. The air enters through a special channel in which the fan is located. This principle is implemented, for example, in the Turkish Vitopend boiler.

The flue gas removal system in it is organized through a coaxial chimney, which is made of the “pipe-in-pipe” type. Exhaust boiler gases are discharged through the internal pipe, and air from the street is drawn in through the annular space by a fan.

The advantage of this system is that its operation does not affect the climate inside the room; installation of complex smoke ventilation ducts that ensure natural circulation is not required. Low space requirements for installation, allowing installation in standard kitchens.

The disadvantages of this design, users most often include their high cost and dependence on electricity.

Gas boilers by traction method

The organization of a chimney according to the principle of natural draft is a traditional scheme that has come to heating engineering since ancient times, starting from the hearth and the Russian stove. The movement of flue gases through the channels occurs due to the density difference between the hot flue gases and the cold atmospheric air.

The temperature pressure creates a vacuum in the furnace, due to which air flows from the room into the combustion area in the volume necessary for complete combustion.

Today this method cannot be considered effective; it is usually used in low-power boilers or when the house has an old chimney system.

In addition, it is a source of increased danger, due to the fact that conditions may be created when carbon monoxide begins to penetrate into residential premises.

Therefore, in more advanced gas boilers, a pressurized system is used, provided by a blower fan in a closed combustion space using a coaxial chimney.

For high-power boilers, not only a blower fan is used to supply air to the firebox, but also a smoke exhauster that pumps out boiler gases is installed behind the boiler in front of the chimney.

Advantages and disadvantages

The advantages of gas boilers include:

- high efficiency and cost-effectiveness;

- ability to work in automatic mode;

- there are many designs that have their own set of functions;

- a wide range of models from different manufacturers;

- availability of additional capabilities (remote control, programming of operation, changing the heating mode taking into account external conditions, etc.);

- the self-diagnosis system allows you to immediately turn off the gas supply and block the boiler if an emergency occurs;

- attractive appearance allows you to install boilers in kitchens and other rooms.

The disadvantages of gas boilers are:

- the need for periodic maintenance;

- imported models are sensitive to water quality and power supply stability;

- many units have redundant functionality that is not used during operation;

- Most imported models are highly sensitive to water quality and power supply stability;

- spare parts for imported boilers are very expensive;

- the cost of imported boilers is quite high, which limits demand.

Despite the existing disadvantages, the use of gas boilers for heating premises is considered the optimal choice of source of thermal energy.

How to choose a boiler

The choice of a heating boiler must be approached responsibly, since it must provide reliable heat supply to the house at the lowest negative outdoor temperatures and operate reliably for at least 10 years.

Several important parameters are taken into account when choosing:

- Determined by the installation method, depending on the free space.

- Determine the types of heat supply systems: heating for a private home or combined for heating and hot water supply.

- Selecting an option for preparing hot water: flow-type in a double-circuit boiler or in a storage boiler in a remote indirectly heated heat exchanger.

- Selecting a unit based on power, using a simple ratio for preliminary calculation: 1 kW per 10 m2 of heated area. For a double-circuit boiler for heating a private house, at least 20% of the power for heating DHW is additionally taken into account. You will also need to introduce correction factors for objects with poor thermal insulation at home.

- Type of heat exchanger material: cast iron, steel and copper.

- Type of coolant movement with natural or forced circulation with an electric pump.

- Type of flue gas removal: natural or forced using a centrifugal fan.

- Volatility and emergency power supply system: stabilizers and uninterruptible power supplies.

- Regulatory and safety system.

Popular manufacturers

Almost all manufacturers of heating equipment produce gas boilers. European companies are considered recognized leaders in this area, but Korean models are also highly appreciated by Russian users. Recently, Russian gas boilers have appeared on the market, manufactured taking into account the operating characteristics and technological conditions of our country.

Let's look at the most well-known companies that produce gas boilers for heating a private home:

Vaillant Germany

One of the most famous and reliable brands. Produces a wide range of heating boilers of all types.

Buderus Germany

All model lines are distinguished by high quality and reliability.

Viessmann Germany

The equipment is assembled using the most modern equipment from high-quality materials.

Ariston Italy

Equipment that successfully competes with boilers from any company. There are model lines adapted for use in Russian conditions.

Baxi Italy

High-quality and reliable boilers that can operate in different conditions and rooms.

Protherm Slovakia

High-quality units, each model bears the name of an animal.

Navien South Korea

Inexpensive but high-quality Korean boilers are highly appreciated among their owners.

Lemax Russia

Domestic equipment, manufactured taking into account the technical features and climate of Russia.

ZhMZ Russia

Non-volatile boilers, reliable and unpretentious in operation.

The list of manufacturers can be continued for a long time, but a simple listing will not provide any useful information. To make the right choice you need to have special knowledge.

The best brands of gas boilers

The TOP manufacturers of heating boilers for 2022 operating on gas fuel are compiled according to user preferences.

The most famous and popular manufacturers of units for heating houses with an area of 200-250 m2 include:

- Protherm Cheetah 23 MTV, Slovakia: wall-mounted, single-circuit, energy-dependent, heating output maximum/minimum 24/8.4 kW, modulating burner, electronic control unit, 2-year warranty, price - 40,400 rubles.

- Ferroli Domina F 24 N, Italy: wall-mounted, double-circuit, closed firebox, energy-dependent, heating output maximum/minimum 25.8/10.4 kW, ionization flame control, electronic control unit, 2-year warranty, price - 31,629 rubles.

- Bosch Gaz 6000 W WBN 6000-18C, Germany: wall-mounted, single-circuit, energy-dependent, closed firebox, heating capacity maximum/minimum 20/5.4 kW, modulating burner, electronic control unit, 2-year warranty, price - 46,141 rubles.

- Vaillant turboTEC plus VUW 242/5-5, Germany: wall-mounted, dual-circuit, energy-dependent, heating capacity 20 kW, modulating burner, electronic control unit, 2-year warranty, price - 81,380 rubles.

- Baxi ECO 4s 24F, Italy, wall-mounted, single-circuit, energy-dependent, heating output maximum/minimum 24/9 kW, modulating burner, electronic control unit, 2-year warranty, price - 38,140 rubles.

The market for domestic climate control equipment has enough offers from both Russian and foreign manufacturers, which have their own advantages and disadvantages.

Among domestic boilers for heating private houses, the most popular brands are Lemax, Zota and EVAN.

Customer Reviews

Sergey, Saratov: “3 years ago I bought a Beretta Boiler 28 BSI boiler, as this model was recommended by colleagues. The unit is installed in the country and consumes a small amount of fuel. It’s nice to have a hot water boiler.”

Elena, Bryansk: “When choosing a boiler, we paid attention to the Russian-made model Lemax Premium-30. We installed it in a private home and enjoy the warmth even on the harshest winter days. Recommended for all homeowners."

Alexey, Novgorod: “My choice is the Bosch GAZ 2500 F. The compact boiler heats a large two-story house and is not afraid of accidental surges in voltage or pressure in the gas main. I recommend it to those buyers who often suffer from interruptions in electricity or gas supply.”