Induction electric heating boilers have many characteristics that are superior to the still more common boilers with heating elements.

Electromagnetic induction was discovered by the English scientist Michael Faraday. The principle of its operation began to be used in the production of generators and electric motors, transformers. But only after some time did human thought reach the point that this principle can also be applied to residential heating systems. It was only in the nineties of the 20th century that the first induction electric boilers for home heating began to be produced.

Features of induction boilers

For many, the choice mainly comes down to one of the two most rational options:

- Application for heating boilers powered by gas;

- Electric analogues.

However, there is one indisputable fact that both gas fuel and electricity are constantly increasing in price. So the cost of heating a home does not become much cheaper.

As an alternative proposal, it is worth taking a closer look at using an induction boiler for heating a private home for these purposes and familiarizing yourself with its technical parameters.

- One of the main advantages, according to reviews of induction boilers, is that maintenance is not required for its normal operation, as is the case with other types.

- The vibration of the built-in element prevents the fixation of the resulting fractions, thereby allowing them to be freely washed out of the pipe.

- Therefore, it is precisely this equipment that allows residents of rural areas to feel calm in this regard.

- In addition, the boiler is resistant to voltage fluctuations, which is important for private owners.

The only thing that confuses buyers is that the price of induction boilers is almost twice as high as that of gas boilers.

conclusions

- Induction boilers are more economical and reliable than electric boilers of other designs.

- Their main drawback, high cost, can be avoided by making the unit yourself. According to the experience of the craftsmen, the boiler in this case will cost several times less. A properly manufactured induction boiler is not inferior in reliability to an industrial one.

- It is important to install an induction boiler correctly, ensuring all safety measures. Reliability and efficiency of induction boilers are crucial when choosing.

Classification of induction boilers

Power separation is the main characteristic according to which they can be distinguished:

- From two and a half to ten kilowatts of power, with a current frequency of fifty hertz and a supply voltage of two hundred twenty to three hundred eighty volts;

- From fifteen to sixty kilowatts with a power at a voltage of three hundred and eighty volts and a current frequency of fifty hertz.

An electrical network with three phases is required for normal power supply of equipment, starting with a power indicator of five or seven kilowatts. Its voltage should be three hundred eighty plus or minus three percent volts.

If we talk about the dimensions of induction-type boilers, then, for example, SAV equipment with a power of ten kilowatts has the following dimensions. The height is one thousand millimeters, and the diameter is one hundred and twenty-one millimeters. Without taking into account the weight of the control system, its mass is equal to seventy kilograms.

Based on the dimensions, it is already clear that in appearance the design of the equipment resembles one large cylinder with a metal body or can be represented by several smaller cylinders.

A little about the induction cooker

This miracle stove is not like ordinary stoves in that:

- Automatically recognizes suitable cookware (only made of ferromagnetic metals and with a flat bottom), and does not even turn on unsuitable ones.

- Heats up faster than gas or electric, therefore, food is prepared more quickly.

- Heats a strictly defined zone equal to the diameter of the dish. The rest of the stove remains cold.

The design of such a stove in different brands may differ significantly, but its basic structure is the same for all models:

- Glass ceramic surface.

- There is an insulating layer underneath.

- Under the insulation is an induction coil.

- Under the coil there is a control unit and a frequency converter.

The primary circuit in such a transformer is the coil inside the stove, and the secondary circuit is the cookware itself.

On the Internet you can even find funny diagrams of homemade heating systems using induction cookers. But they do not stand up to criticism.

Induction cookers operate at ultra-high frequencies from 20 kHz to 60 kHz. Carrying out measurements of radiation, it was revealed that part of it is absorbed by the slab itself, and the rest act strictly within a radius of 30 cm from the center of the slab. Still, despite proven safety, people with pacemakers are strongly advised not to use such stoves in order to avoid cardiac arrest. What about harmful radiation from an induction boiler? After all, it also operates at frequencies from 25 kHz and higher.

How does an induction boiler work?

The device includes:

- Inductor element with two windings;

- An inverter that converts incoming energy into high-frequency current;

- Heating element – metal pipe;

- Two pipes. One conducts the coolant, the second supplies water to the system.

The equipment works as follows:

- The flow of water is ensured by a pipe;

- When the inverter is turned on, high frequency current is supplied;

- The core is heated thanks to vortex flows along with the entire heating element;

- Heat enters the coolant, and from there into the heating system thanks to the outlet pipe;

The coolant can be water, oil, antifreeze, etc.

Thus, the simple operation scheme is quite suitable for independently designing and connecting such equipment.

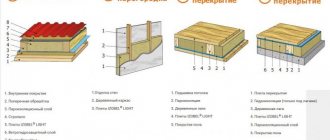

INSTALLATION OF THE ENTIRE HEATING SYSTEM

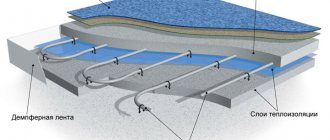

- Installing radiators or laying heated floors.

- Pipeline piping of heat exchangers (reinforced polypropylene pipes, metal-plastic pipes, polyethylene pipes) to the boiler room.

- Installation of a collector system, pumps and flow sensors.

- Boiler room piping, pumping and commissioning.

The price depends on the size of the house and the choice of type of heating system.

If you have a need for installation or installation, you can use the table, which is located in the left block of the entire site, select items of interest in it and send a request for a cost estimate.

We provide a guarantee for our work and provide a full range of equipment necessary for heating installations:

What to build a boiler from

When designing you will need:

- Plastic pipe as a body part;

- Stainless steel wire as a heating element;

- A piece of copper wire for an inductor;

- Adapters plus ball valves when connecting the boiler to a common system;

- Pliers with wire cutters.

Having prepared everything you need, you can start assembling.

Who invented the induction heating unit

The marketing argument about the innovation of the induction boiler does not stand up to criticism. The principle of induction was discovered back in the first third of the 19th century by Michael Faraday, a researcher known to us from a school physics course.

And at the very beginning of the 20th century, the first induction melting furnace for the metallurgical industry was released into the world in Sweden.

Of course, engineers and scientists were still considering induction for heating boilers in everyday life. But, having studied the pros and cons, we considered this option irrational.

Induction heaters for home and everyday use began to be used throughout the CIS in the mid-90s. Before this, high-power induction boilers were used in the USSR only in heavy industry for metal smelting.

Assembly order

A do-it-yourself induction boiler is assembled in several stages:

- First you have to cut the stainless steel into pieces of three or seven centimeters;

- Fill the void with plastic pipe with these pieces so tightly that there is no void;

- The tube ends are reinforced with mesh, which will prevent the segments from falling out;

- In the upper part of the pipe, as well as in the lower part, both pipes must be cut in. Through one, the coolant will enter the unit, and through the other it will be transferred to the heating system;

- Copper wire must be wound onto the pipe so that the resulting number of turns is ninety;

- Both ends are connected to the inverter;

- Connect the boiler to the heating system using ball valves with adapters;

- Install a circulation pump if it was not originally provided for in the heating circuit.

The high-frequency current should be supplied no earlier than the circulation pump is turned on and the equipment is fully filled with coolant.

INSTALLATION OF BOILER ROOM

- Installation of induction heater VIN, connection of electrics and automation.

- Piping of boiler room equipment - expansion tank, flow switch, gr. security, etc.

- Installation of a collector system, if there is a need for it.

- Pumping and startup of the system, commissioning.

Installation of the boiler room is carried out with a connected radiator system or heated floors, pipes brought into the room or place where the boiler and equipment are planned to be installed. The price starts from 15,000 rubles. depending on the amount of work.

Advantages and disadvantages

A boiler device that was made independently has many advantages, for example, an induction electric boiler:

- Provides rapid heating of the coolant within three to five minutes;

- The lowest temperature required for heating is no more than thirty-five degrees;

- Scale practically does not form due to the imperceptible work of vibration created by thermal energy;

- An almost 100% efficiency factor is ensured, that is, almost all incoming electrical energy is converted into heat;

- The operation of the unit is in no way connected with the release of harmful toxins, so there is absolutely no need to remove the chimney outside, as well as to carry out maintenance;

Such an aggregate device can function quietly for up to thirty years, because there is simply no mechanical movement of the parts, which means there is no damage to the component elements or wear.

Effective ways to save energy

The most effective way to save money is to install a multi-tariff meter, however, it must be borne in mind that this method already incurs considerable costs for its purchase and installation.

Multi-tariff meter (right)

Power limiters also cope very well with this task. After all, during the day we load the network in surges. The most logical thing would be to heat the house at night from 22:00 to 6 o'clock. For efficient heating operation, use a circulation pump; it is installed in the return network.