Solid fuel combi boilers Kupper quickly took a leading place in the market and there are good reasons for this. In addition to high performance, the equipment has an attractive design, compact dimensions and is absolutely safe for domestic use.

Kupper boilers have become the golden mean between expensive foreign analogues and low-quality domestic units. The official manufacturer and supplier of Kupper solid fuel boilers on the Russian market is the Teplodar company.

Installation procedure

The installation of the unit, piping of the heat supply system, flue, and gas burner device must be carried out by highly qualified craftsmen who have a license to perform such work. The validity of the warranty for the device and the auxiliary equipment that comes with it will depend on this fact.

All work on installing the unit must comply with the Rules for the safe operation of water boilers with a coolant temperature not exceeding 115 C.

Basic requirements and installation procedure for Cooper boilers:

- The boiler is installed at a safe distance from flammable materials: from the walls - 50 cm, from the ceiling 120 cm, and in front of the front - 125 cm.

- A safety valve must be installed at the outlet pipe of the hot coolant DN 40 mm to protect the structure from high pressure.

- The heating system must be equipped with air vents and an expansion tank.

- The boiler is connected to the heating system using pipe threads.

- Connections to the power supply line must be carried out by a licensed organization with qualified, certified personnel and comply with the requirements of the Electrical Installation Rules. Each electric heating element must be connected with a copper cable higher than 1.5 mm2 and 16 A circuit breakers. Parallel connection of 3 electric heating elements through a 30 A circuit breaker and a cable with copper conductors of at least 4 mm2 is allowed.

- To remove flue gases from the boiler, it is recommended to install stainless steel thin-walled pipes supplied by the same manufacturer. The best option for such devices is the installation of ready-made blocks with sandwich thermal insulation.

- It is allowed to use a brick chimney with a channel cross-section of at least 200 cm2, which must be uniform along the entire length.

- The height of the flue, starting from the grate, is at least 5 m.

Heating equipment Cooper

Cooper solid fuel boilers have become popular for obvious reasons, because:

- devices are presented on the market in a wide variety;

- have an affordable price;

- have a pleasant appearance.

In addition, the Cooper stove owes its long life to high-quality assembly. Experts believe that these heating devices deserve the attention of consumers. In order not to make a mistake when choosing a specific model of equipment of a given brand, you need to study the technical characteristics of the units, the principles of their operation, advantages and disadvantages.

Features and Benefits

Cooper solid fuel boiler has a simple operating principle and versatility in the use of solid fuel. It is loaded through a special door. Ignition is performed from below.

Water is supplied to the combustion boiler, made in the form of a water jacket. The efficiency of heating the coolant in this design is ensured by the multi-row design of pipes located in a checkerboard pattern, thereby ensuring the maximum possible contact of flue gases with the heated medium.

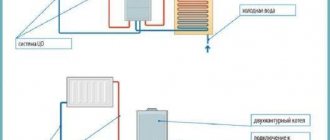

Fuel burning in the firebox transfers its heat to water, which at a temperature of 90-95 C is sent to the radiators. The movement of hot water can take place either according to the principle of natural circulation or forced circulation, using a circulation pump.

Flue gases, having given up their temperature to the network water, are released into the atmosphere through a smoke exhaust system consisting of a flue and chimney. The diameter of the exhaust gas outlet pipe for OK models is 150 mm, and for OVK - 120 mm.

Advantages of Kupper units operating on solid fuel:

- Multi-fuel - works not only on wood and coal, but also on electricity, main gas and pellets.

- Optimal ratio “cost - consumer quality”, lower price threshold from 20,000 rubles.

- Expanded functionality, food preparation permissibility for a number of models.

- A distinctive design solution and high quality paint coating.

- Optimal thermal insulation.

However, like absolutely all thermal power equipment, the Cooper PRO boiler has a number of disadvantages, which users include:

- Low level of brand awareness.

- A combustion heat exchanger made of steel has a shorter service life than cast iron.

- The package does not include a thermostat or control panel for heating elements; they must be ordered additionally.

- Single-circuit model, there is no possibility of obtaining hot water for domestic needs. To obtain hot water, it can be used in a circuit with an indirect heating boiler, which must be purchased separately.

Model range of Teplodar-Cooper products

The Cooper solid fuel boiler is produced in six modifications: OK-15; OK-20; OK-30; OK-42 and OVK-10; OVK-18. The abbreviation OK indicates that the product is a heating boiler, and the presence of a middle letter means the presence of a built-in hob used for cooking.

Next to the letter marking you can see numbers indicating the thermal power of a particular model. Cooper "Teplodar" heating stoves are presented on the market in a wide performance range of 10 - 42 kW.

A 10 kW boiler is capable of providing heat to a household with an area of up to 100 square meters, and the most powerful of the OK-42 devices can heat a household with an area of no more than 400 square meters.

In addition to the six previously described modifications, the Teplodar trademark is represented by a series of heating boilers Cooper Pro 36 and Pro 42. These models are long-burning units, they are distinguished by a significant volume of loading chambers. Due to the presence of these sizes, it is possible to reduce the number of fuel fills, since the next portion of firewood is placed in the boiler after about 8 hours.

Operating principle of boilers

In order to understand how Kupper equipment functions, let’s consider the principle of its operation using the OK models as an example. Briquetted peat, coal or firewood are used as the combustion material.

- Fuel is poured into the firebox through the open door.

- Below there is a special chamber where kindling occurs.

- The heat emanating from the burning fuel heats the water in the heat exchanger.

- The heated water begins to flow through the system according to the established pattern.

- Exhaust smoke goes into the chimney and is discharged outside.

Thanks to the special design of the heat exchanger and the staggered arrangement of pipes, the coolant is heated efficiently and evenly, which allows the room to be provided with heat uninterruptedly.

Long-term burning mode of heating equipment

In order for the device to function in economical mode, you should purchase a thermostat. For these purposes, the Cooper long-burning solid fuel boiler has a threaded fitting.

The thermostat is sold complete with a circuit. One end of it is connected to the regulator, and the other end to the damper of the kindling door. The thermostat has a temperature scale.

The thermostat, thanks to the presence of a circuit and a door damper, can regulate the air supply to the combustion chamber of the furnace. As a result, it maintains the required temperature, which leads to economical fuel consumption. Thanks to the use of a thermostat, Cooper long-burning solid fuel boilers can operate on one load of firewood for 7-8 hours.

Nuances of installing solid fuel boilers

Installation of a Kupper boiler

The uninterrupted operation and safety of boilers directly depends on the correct installation. Installation should only be carried out by a specialist, adhering to the following rules:

- the room in which the boiler will be installed must be well lit and ventilated;

- when adding a pellet burner to the boiler, electricity must be supplied to the room;

- the base on which the equipment will stand must be made of non-combustible materials, for example metal;

- the boiler is installed at a distance of at least a meter from the side walls and at least 2 meters from the front;

- the room must be equipped with a water drain connected to the sewer;

- A chimney with a pipe of more than 5 m is installed together with the boiler.

The height of the pipe above the roof must be at least 50 cm, and the pipe itself must be insulated from wooden surfaces.

Advantages and disadvantages of Kupper boilers

Based on user reviews, a number of advantages of Kupper solid fuel boilers can be identified:

- the versatility of the equipment, in which both wood and gas, electricity and pellets can be used as fuel;

- possibility of cooking on HVAC models;

- high-quality assembly and manufacturing materials;

- decent design that allows you to install boilers in a room with any interior;

- good thermal insulation and safe operation;

- acceptable price-quality ratio.

Along with the positive qualities of boilers, one cannot fail to mention some disadvantages, although very dubious:

- the steel used in production is not as durable as cast iron;

- the need to purchase additional options to improve equipment performance;

- All boiler models are single-circuit only.

Some consider it a disadvantage that Kupper is a new and not yet fully proven company, but those users who have already purchased the boiler boldly declare its excellent performance.

Rating of TOP 10 best models

| Place | Name | Price |

| TOP 10 best solid fuel boilers Teplodar | ||

| 1 | Cooper Practice 8 | 13 000 ₽ |

| 2 | Cooper OK 9 9 kW | 18 000 ₽ |

| 3 | Cooper Praktik 14 14 kW | 35 000 ₽ |

| 4 | Cooper OK 20 | 23 000 ₽ |

| 5 | Cooper OVK 18 18 kW | 25 000 ₽ |

| 6 | Cooper PRO 22 | 26 000 ₽ |

| 7 | Cooper PRO 36 36 kW | 35 000 ₽ |

| 8 | Uyut-10 10 kW | 19 000 ₽ |

| 9 | Cooper OVK 10 10 kW | 25 000 ₽ |

| 10 | Cooper CARBO 26 26 kW | 45 000 ₽ |

Kupper boiler design, additional options

The boilers are made of high quality low-carbon structural steel with a thickness of 3 mm. The device includes:

- combustion chamber;

- tubular heat exchanger;

- smoke removal;

- loading chamber;

- basalt layer around the entire perimeter of the boiler to improve thermal insulation;

- ash collection compartment;

- thermometer;

- Heating elements (in some models).

The Cooper Pro boiler, unlike other models, has not two, but three doors for different purposes:

- for cleaning and reloading - top;

- furnace - middle;

- ash - bottom.

Cooper Pro 36

Each Kupper solid fuel boiler can be completed depending on individual needs. Equipping with a heating element allows the equipment to operate on both fuel and electricity. Heating with a heating element with a power of 6 kW of a house whose area exceeds 100 sq.m. impossible, but it does an excellent job of maintaining the required temperature level. If your plans include full heating, then it is recommended to purchase a heating element with a power of 9 kW.

Additional equipment of the boiler with a control panel for water and air sensors will allow the user to easily set the necessary modes and control the operation of the heating elements.

To ensure the operation of boilers using gas or pellets, you need to buy an automatic gas (AGG) or pellet (APG) burner. They are installed in the place where the firebox door is located. The door is removed, and the selected burner is cut into its place.

Technical characteristics of boilers of OK and OVK versions

Cooper OVK 18

Cooper heating boilers have the following characteristics:

- heating output in the range of 9-42 kW;

- operating water pressure in boilers does not exceed 2 MPa;

- maximum water temperature at the outlet is 95 C, at the inlet - 60-80 C;

- supply voltage for heating elements - 220 V;

- heat exchanger jacket volume - 27-50 l;

- firebox volume - 18-40 l.

The maximum dimensions of heating boilers are 500x340x740 mm or 645x422x745/755/1000 mm. All no more than 145 kg.

Technical characteristics of Cooper Pro boilers

Cooper Pro

Cooper Pro boilers are recommended to be installed in rooms of 100-400 sq.m. The chimney diameter in models 22/28/36 is 150 mm, in model 42 - 200 mm. The remaining characteristics are as follows:

- heating capacity - 22-42 kW;

- working pressure - no more than 0.2 MPa;

- water temperature - outlet 95C, inlet - 60-80C;

- power of heating elements - 6 and 9 kW;

- supply voltage for heating elements - 220 V;

- heat exchanger jacket volume - 49-91 l;

- firebox volume - 35-63 l.

The dimensions of the most powerful unit do not exceed one meter in height and weigh no more than 180 kg.

Accessories

Buyers, purchasing Kupper heating boilers, receive multifunctional, combined units capable of operating according to the schemes: “coal - electricity” or “main gas - electricity”, this allows you to evenly maintain the temperature in the rooms throughout the day.

All Kupper OK boilers are equipped with electric heating elements - 6 kW, and models over 30 kW - 9 kW. Particularly promising for the use of such devices is the use of a diphtariff electricity metering scheme, when at night it can be switched to electric heating with the lowest tariff.

Be sure to check the boiler delivery package

For comfortable controllability of a group of heating elements of the unit, there is a control panel (CP) with temperature sensors that control water heating and internal air temperature in the room. The system operates automatically and can turn on heating elements alternately depending on the set mode.

Cooper boilers can operate on main gas fuel or pellets. The buyer can order a gas injector AGG-13/26/40K with a power from 13 to 40 kW or a pellet injector APG-25/42. Both are mounted in the area of the fire door.