Homeowners who use solid fuel stoves for heating know firsthand such a nuisance as the room cooling down after the wood in the stove burns out. This can happen at night or during a prolonged absence of the owners.

In these cases, a wood-electricity combination boiler for heating a private home will help maintain the temperature. Such heat sources are equipped with automation that monitors the system - if the stove goes out and the water in the boiler cools down, it sends a command to turn on the electric heating elements.

Externally, a combination boiler is practically no different from a standard one Source darizz.access.ly

Application of combi boilers

Today, such devices are universal and at the same time economical devices for autonomous heating at home. Their main trump card is that they are not tied to one type of fuel. If such a boiler runs on electricity, then during a sudden power outage you can light the wood stove to keep the house warm and vice versa.

Buying a combination boiler solves several problems :

- If there is no main gas pipeline in the village where the house is built, then it is possible to use two alternative types of energy at once - solid fuel and electricity.

- If a country house is connected to a weak power supply line, a combination boiler is almost an ideal option - you won’t have to freeze if you need to turn on another powerful electrical appliance for a long time.

- Eliminates cooling of the house when using solid fuel. Such a unit, connected to water heating, helps maintain a constant temperature in the system: if the fuel burns out, the boiler will automatically smoothly switch to heating through the heating element. This is especially convenient at night: you don’t have to get up and add wood to the stove’s firebox.

When a conventional boiler cools down, it must be lit immediately so as not to lose heat Source iobogrev.ru

Eventually

In each case, the homeowner himself decides how to organize an autonomous heating system. The proposed technical solutions will not only eliminate the unpleasant consequences of the main heater fading during severe winters, but will also provide some savings in energy resources.

The efficiency of operating solid fuel units and electric boilers in pairs has been proven by practice - the interaction of these devices provides greater comfort and guarantees reliable heat supply.

Principle of operation

The wood-electricity combination boiler operates according to the following algorithm :

- Melting and heating of the unit occurs in the traditional way. During the combustion of solid fuel (wood, coal, briquettes), the water temperature is maintained using a thermostat together with a sensor. Electric heating elements do not work at this moment.

- If you do not add fuel to the firebox in time, then after it burns out, the temperature of the water in the system gradually decreases to a certain value, after which a sensor is triggered, which closes the control contacts and the heating element (one or more) turns on. From this moment on, the boiler begins to operate from the mains.

- After the next loading of fuel, the water in the pipes is heated from the side of the firebox and, upon reaching the set temperature, the sensor is triggered again, but this time to turn off the heating elements. The electrical part of the boiler is again inactive until the water temperature decreases again.

Most often, the electric heater in a combination boiler is designed as an auxiliary heating device, but if you wish, you can choose a boiler model that, if necessary, can work continuously, providing hot water to the house and heating system.

A heating element with a sensor connected to a heat exchanger Source anapasunsity.ru

Disadvantages of equipment

Disadvantages of heating devices:

- High price.

- Large dimensions. The devices are made only floor-standing due to the wood-burning firebox. They will need a separate room.

- The need to install a chimney and forced ventilation.

- Large mass of cast iron firebox.

- The equipment will require a foundation or concrete pad.

- The power limit of the heating element is no higher than 30 kW.

- A complex device that increases the complexity of installation and the cost of repairs.

Pros and cons of combi boilers

When choosing any equipment, you need to focus not only on its positive aspects, but also study its disadvantages in order to understand which characteristics are more important to you.

Advantages

The advantages of wood-electricity devices compared to heating units that operate only on one type of fuel are obvious:

- Versatility of equipment. Electricity for a boiler can be either the main energy source or an auxiliary one - which priority will be decided only by you.

- Autonomy . There is no need for constant monitoring, since the boiler is equipped with automation.

- Economical . Firewood is one of the most affordable types of fuel in many regions of the country, and it is now almost impossible to find a house without an electrical connection.

- Convenient design . Constantly maintaining the set water temperature with minimal energy consumption.

- If a two-tariff meter is installed, you can program the boiler to turn on the heating elements only to maintain heat at night, when the tariff is much lower and thereby save electricity consumption .

With proper load distribution, a two-tariff meter saves from 30 to 65% on electricity bills Source zinoti.lt

- Long service life . Such boilers, when properly operated, operate for up to 25 years.

- The production of models with built-in pipes for the possibility of connecting a “warm floor” system .

Important! Wood-electric boilers operate effectively even in low-power modes.

Flaws

With all the advantages, such boilers also have disadvantages:

- Separate room . Units of this type require their own boiler room and an extension for fuel storage.

- Heavy weight . Most often, boilers are made of cast iron and require a solid concrete base to place it on.

- Device complexity . This factor affects the price of the boiler: it is 20-30% higher than the cost of units operating on one fuel.

On a note! Electric heating elements of most combination boilers are designed mainly to maintain heat. In winter, at external temperatures below –5 °C, they cannot completely replace the combustion of solid fuel due to their low power. If you plan to use electric heaters for a long time, you need to look for boiler models that operate on three-phase power (if this is installed in the house).

Powerful boilers are connected to a three-phase network Source tk-assortiment.ru

Double-circuit (43,000 - 99,000 ₽)

This group includes large-sized, universal equipment of a combined type. Its feature is the ability to simultaneously heat rooms and supply hot water for domestic and technical purposes.

| Place and name of product | Rating | average price |

| 1 Karakan 20 TEGV, 20 kW | 5.0/5 | 98 975 ₽ |

| 2 Karakan 30 TEGV, 30 kW | 4.8/5 | 43 800 ₽ |

| 3 Dragon KR-GV-20 | 4.6/5 | 98 975 ₽ |

| 4 CTC 1200 Family, 45 kW | 4.2/5 | 98 975 ₽ |

| 5 Atem Zhytomyr-3 KS-GV-012 SN, 12.5 kW | 3.7/5 | 98 975 ₽ |

1 place

Karakan 20 TEGV, 20 kW

5.0

6 ratings

~98 975 ₽

Characteristics

- combustion chamber type: open

- installation: floor

- dimensions (WxHxD): 455x785x820 mm

- non-volatile: yes

- control: mechanical

- weight: 101 kg

See all characteristics and prices

2nd place

Karakan 30 TEGV, 30 kW

4.8

~43 800 ₽

Characteristics

- combustion chamber type: open

- installation: floor

- dimensions (WxHxD): 480x910x940 mm

- non-volatile: yes

- control: mechanical

- weight: 125 kg

See all characteristics and prices

3rd place

Dragon KR-GV-20

4.6

~98 975 ₽

Characteristics

- combustion chamber type: open

- installation: floor

- dimensions (WxHxD): 500x1246x920 mm

- non-volatile: yes

- control: mechanical

- weight: 210 kg

See all characteristics and prices

4th place

CTC 1200 Family, 45 kW

4.2

~98 975 ₽

Characteristics

- mains voltage: single-phase

- burner: sold separately

- combustion chamber type: open

- installation: floor

- dimensions (WxHxD): 581x936x967 mm

- circulation pump: built-in

- control: electronic

- functions: frost protection, underfloor heating connection, power-on indication, overheating protection

- weight: 170 kg

See all characteristics and prices

5th place

Recommendations when choosing a boiler

Today the market offers a wide range of universal boilers, which differ in power, performance, design and configuration. But before purchasing such a unit, you need to weigh the pros and cons, and it is also useful to listen to the recommendations of professionals in this matter.

When purchasing a boiler, you must consider the following:

- Power . It depends on the fuel that will be a priority.

- The volume of one fuel load and the size of the combustion chamber . The duration of firewood burning depends on this parameter.

- Firebox material . These parts are made of cast iron and steel. It is preferable to choose chambers made of cast iron, since they are not subject to deformation when heated and retain heat longer, unlike a steel exchanger.

Components for combined boilers Source winplast.ru

- Grate bars . Two types are used: standard cast iron and the same, but coated with ceramic. The latter are used mainly for bulk materials, which consume more oxygen during combustion, and accordingly, the temperature is created higher.

- Weight and size . Typically, the body of such boilers is made of cast iron, which makes them much heavier than their “brothers”.

Advice! When buying a heating device, you need to take into account the area of the house. You should not purchase a boiler “with a power reserve”, as this will entail an overpayment - both during purchase and during operation.

Manufacturers rating

The quality and performance characteristics of heating equipment largely depend on the brand. Serious companies value their reputation and produce equipment of excellent quality. The most reliable boiler manufacturers are the following companies:

- Buderus is a German manufacturer of heating equipment. It produces products of various types and capacities. The company was founded in 1731 and is still in operation, which speaks volumes about the quality of its products.

- Kentatsu is a Japanese company with a century and a half history. The largest manufacturer of climate control equipment. A distinctive feature of boilers of this brand is reliability and durability.

- Lemax is a Russian manufacturer of heating equipment from Taganrog. Due to high reliability and affordable prices, the company's products are in great demand.

- ZOTA is a Russian brand. Produces a wide range of heating equipment of various capacities. Solid fuel units are made of steel. There are no cast iron models in the line.

- Teplodar is a well-established brand of Russian heating equipment. The line of manufactured equipment is not very wide, but the quality of the products is not inferior to the best world companies.

Installation Requirements

Combination boilers in accordance with SNiP 41-01-2003 must meet the requirements. At the same time, they have their own characteristics during installation and operation, which distinguish them from similar units operating on a single fuel.

These requirements and recommendations must be known and followed in order for the boiler to operate safely.

Premises requirements

Wood and electric boilers for home heating are produced only in a floor-standing version and are installed in a boiler room with ventilation, and in accordance with other SNiP requirements:

- The walls in the room are made of non-combustible material.

- Equipment in the boiler room is installed no closer than 300 mm from the walls.

Example of boiler installation Source pingru.ru

Features of the design of liquid fuel burners

Autonomous heating systems installed in residential buildings and industrial facilities can be powered by boilers adapted for liquid fuel.

This equipment allows you to heat a house with minimal human intervention, independently sucking a portion of diesel fuel from the container. Such boilers have high efficiency, since the combustion of diesel fuel produces more heat than the combustion of natural gas and solid fuel. In addition to diesel fuel (diesel fuel), the following energy carriers can be used: kerosene, fuel oil, heating oil, biofuel and waste oil. The most important element of this type of heating equipment is the liquid fuel (oil) burner, otherwise called a nozzle. Its main function is to proportionally mix air with fuel and supply the resulting mixture to the combustion chamber of the boiler.

Oil burners are classified according to operating mode into single-stage, two-stage and modulating models. The first type operates with constant power, which can be changed only after interrupting the operation of the boiler. The second type has two operating modes, through which the equipment is able to gradually reach full power. In addition, there are also fan (blown) burners with forced air injection and diffusion burners, capable of receiving the required volume of air from the surrounding atmosphere to maintain the combustion reaction.

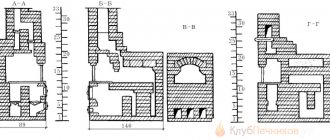

The main parts of an industrial-made liquid fuel burner connected to a tank for storing a small supply of diesel fuel

The main structural elements of railway burners are:

- air supply fan drive electric motor;

- a fuel pump with an electric drive motor, necessary to supply fuel through the fuel drive from a pressure tank;

- heating system for liquid fuel, which can thicken when the ambient temperature drops;

- servo drives for adjusting the air damper and fuel regulator, necessary for direct and precise connection of the actuators;

- an adjusting thermostat, with which the combustion temperature parameters are set and the burner is started;

- float with a microswitch that regulates the fuel level in the tank;

- a nozzle that sucks in and sprays fuel, as well as providing conditions for its ignition;

- burner control unit during operation;

- regulator of secondary air necessary to maintain the formed combustion torch.

In addition to the listed elements, the liquid fuel burner design always includes flexible hoses for supplying fuel. The pressure gauge shows the pressure in the fuel line. The flame sensor monitors the presence of a torch. The vacuum gauge monitors the levels of soot and nitrogen oxide in combustion products.

It is important to note that fuel is supplied from a tank next to the boiler, the volume of which in the main room of the house cannot exceed 50 liters. Larger containers (up to 1000 liters) can only be located in a separate boiler room, equipped in accordance with fire safety rules

The diagram shows the operating principle of a liquid fuel burner, which is based on mixing air with fuel and completely burning the resulting mixture

The class of a liquid fuel burner is determined by such performance characteristics as: fuel pump pressure; dimensions of the combustion space; dimensions of the pipe located in the combustion chamber; nozzle capacity.

Advantages of using boilers with an oil burner:

- Minimum level of emissions of harmful substances into the atmosphere.

- No strong vibration or operating noise.

- Wide choice of liquid fuels.

- The ability to quickly install equipment and configure it.

- All functional parts are easily accessible for maintenance.

- High efficiency, reaching 90-95%.

- Stability of the fuel combustion process due to effective regulation of air supply.

Another point - liquid fuel burners are structurally compatible with many models of heat generators and water heaters. When main gas is supplied to the house, the liquid fuel boiler can easily be converted into a gas unit. To do this, simply replace the iron burner with a gas burner.