Owners of private houses who use solid fuel stoves for heating are well aware of the problem of cooling down the home after the firewood or coal has completely burned out. This happens at night or in the absence of the owners, when there is no one to throw new logs into the firebox. The issue can be resolved in several ways:

- use a combined wood-electric heating boiler;

- install 2 separate heat sources - solid fuel and electric;

- do not mess with electricity and install a long-burning wood-burning boiler.

We suggest that you consider the listed options in detail in order to choose the most comfortable method of heating a country house.

Application of combi boilers

Heat generators operating on various energy sources did not appear yesterday. Since the times of the USSR, “dual-fuel” gas-wood boilers have been known; in them, to switch to wood, the burner device had to be removed. In modern heating units, solid fuel is combined not only with gas, but also with electricity, which is more important for users. A homeowner who decides to buy a heating boiler using wood and electricity solves several issues in one fell swoop:

- It uses two energy carriers for heating, alternative to natural gas.

- Eliminates cooling of the premises of a private house when the contents of the firebox are completely burned and a new portion of coal or firewood is not loaded.

- Increases the convenience of using water heating, since you no longer need to get up in the middle of the night and run to the boiler room.

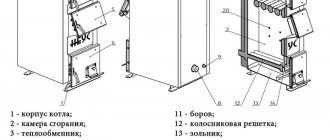

Construction of an electric wood-burning boiler "Kupper" from

New generation combined heat generators are designed in such a way that electric heating is switched on automatically when the water in the boiler tank begins to cool. Switching back to wood burning without the intervention of the owner of the house is impossible.

The principle of operation of an electric wood-burning boiler

The design of this type of heater is similar to that of a traditional solid fuel boiler, consisting of the following main elements:

- combustion chamber (firebox), where logs and coal are loaded;

- from the outside it is washed by a coolant enclosed inside a water jacket;

- a fire-tube or water-tube heat exchanger, where combustion products give off most of the heat to water before being released out through the chimney;

- the grate is located at the bottom of the firebox, and under it there is an ash chamber;

- the firebox and ash pan at the front are equipped with doors;

- To change the combustion intensity in the heat generator, a mechanical draft regulator or a fan - air blower is used (if manual control of the air damper is not provided).

Scheme of the Kuper-Carbo mine-type electric-coal heat generator

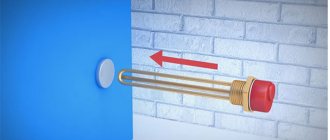

Domestic combined heating boilers are distinguished by the design of their water jacket, which provides space for installing a block of tubular electric heaters - heating elements. The heating part of the element is immersed in the coolant, and the contacts are brought out and connected by cable to the control panel.

The operating algorithm of a solid fuel heater equipped with electric heaters looks like this:

- The boiler is fired and heated as usual. While the wood is burning, the temperature of the coolant is maintained by a mechanical thermostat or a fan together with a sensor, and the heating elements are inactive.

- After the contents of the firebox burn out, the water in the system begins to cool, which is recorded by the temperature sensor. When the coolant has cooled to a certain point, the sensor signal will turn on the heating element (one or more). From this moment on, the boiler switches to electricity.

- After loading the next portion of solid fuel, the coolant is heated from the side of the combustion chamber, and the electrical part is automatically turned off until the next time it cools down.

The heater control unit can maintain a certain water temperature, based on the readings of a water or air sensor.

The transition from one mode to another allows for continuous heating of water, which is what the inhabitants of a private house require for comfort.

Pros and cons of universal heat generators

By installing a combination boiler for heating a private house with wood and electricity, you receive the following bonuses:

- Thanks to the built-in heating elements, water heating will continue to function after the main firebox goes out. This will keep the house warm, and during your absence will prevent pipes and heating radiators from defrosting.

- Comfort. Supporting the heating of the system with electricity will save you from night trips to the boiler room to lay logs.

- If electricity metering is carried out according to a multi-tariff scheme, then in addition to convenience you will receive savings from the operation of heating elements at night.

Electric heaters of a combined boiler are designed only to maintain the temperature of the water in the system; they cannot fully replace the combustion of solid fuel. The reason is the insufficient power of the heating element unit installed by manufacturers on TT boilers.

Example: all “Kupper” units of the famous Russian brand “Teplodar” with a power of 9...20 kW have the same electric heaters with a heat output of 6 kW.

This is what a 6 kW heating element block looks like, used in Russian-made Teplodar, Prometheus and ZOTA wood-burning heaters

This feature of combined heat generators can easily be considered a disadvantage. The exception is low-power heaters (the same “Cooper” 9 kW with 6 kW heating elements), purchased for small-sized dwellings (up to 100 m²). In this case, the heat transfer from electricity is comparable to burning wood, so in moderately cold weather (down to about -5 °C outside), the heaters are able to completely heat a modest-sized house.

Another important point. Like a conventional solid fuel heater, a wood-electric combination boiler should be connected to the water heating through a three-way valve, as shown in the diagram below. A small circulation circuit serves to protect the firebox from the harmful effects of condensate during kindling.

To prevent condensation from appearing on the walls of the combustion chamber due to temperature changes, the TT boiler must be connected according to the standard circuit with a three-way valve

If the power of the heating elements is enough to heat the coolant to a temperature of +55 °C and above, then condensation will never form in the combustion chamber of the combined boiler during lighting, and the unit with a three-way mixing valve becomes seemingly irrelevant. In reality, a small circulation circuit is still needed, at least in case of a power outage or failure of one of the heating elements.

Heating a private house with wood and electricity from one boiler also has other negative aspects:

- The heater block takes away the useful volume of the firebox to the detriment of combustion duration per load.

- The operation of the unit depends on the stability of the power supply.

- The prices of combined products are higher than classic solid fuel boilers.

- The efficiency of electric heaters when operating is reduced by 2-5% due to the air flow passing through the cooled firebox. The reason is the constant draft in the chimney, forcing air from the premises to escape through the fuel duct into the chimney pipe and cool the water jacket of the heater.

In order to fully replace natural gas with electricity and firewood, it is better to take a closer look at another option for heating the building - install 2 separate heat sources, properly tie them and connect them to the heating system.

Installation standards

Requirements for the installation of solid fuel heating boilers are regulated by Fire Safety Standards (FSN) and Construction Norms and Rules (SNiP)

It is very important to follow the provisions of these regulatory documents, since not only the efficiency of the heating system being installed, but also the safety of the residents of your home directly depends on this

General connection diagram for a solid fuel boiler

Basic standards for installing solid fuel boilers:

- the distance from the heating boiler body to the walls of the boiler room must be at least 0.5 m;

- there should be no gaps between the bottom of the boiler and the screed;

- the distance from the firebox door to the opposite wall of the boiler room must be at least 1.3 m;

- if the heating system is designed for natural circulation of coolant, the boiler should be placed so that its heat exchanger is lower than radiators and other heating devices;

- the first meter of the inlet and outlet pipes is made of steel pipe;

- the internal walls of the chimney are protected by stainless steel sheets; 3 options for arranging a chimney for a solid fuel boiler

- the cross-section of the pipe through which flue gases are discharged from the boiler must be no less than the cross-section of the chimney;

- the vacuum at the boiler outlet is regulated by the height and configuration of the chimney - it should be 10-80 Pa;

- the joint between the smoke outlet pipe and the chimney is compacted and sealed;

- the chimney must have a minimum number of bends;

- the temperature of the water entering the heat exchanger from the heating system must be at least 60 o C;

- when equipping the heat exchanger with a heating element, grounding the boiler is mandatory;

- the connection between the boiler smoke exhaust pipe and the chimney must be removable;

- if the roof of the building is made of flammable materials, the chimney must be equipped with a spark arrester;

- the chimney duct must be equipped with valves, as well as a hatch for cleaning soot.

Connecting a solid fuel boiler from different angles in the photo

What is described in the article is generally correct, however, the efficiency of a solid fuel boiler without a heat accumulator connected to it is reduced by 20-50%. At home, after purchasing such a tank, I reduced the consumption of pellets by 25 percent, and the convenience of the firebox became different. I bought it not long ago, from the Thermiko brand (I bought it because of the price, the tanks are made in Ukraine, so the prices are very good). I advise everyone who will install solid fuel boilers to immediately look at buffer tanks in stores

Home / Country house / Nuances of self-installation of a solid fuel boiler

Connecting boilers using wood and electricity

Without a doubt, purchasing, installing and wiring two separate units will cost you more than one combined heat generator. But by implementing this option, you get full heating with two energy carriers, operating effectively in automatic mode.

Reference. In non-gasified private houses in the Russian Federation, the combined operation of a solid fuel and electric boiler is used quite often, since this is the most convenient way to heat a home with wood. The combination of gas and wood is no less common, and the third place is occupied by the so-called multi-fuel boilers, which we will discuss in a separate article.

In our pair of heat sources, the wood (coal) boiler is the main one, and the electric one is the auxiliary unit. As the latter, you can use any of the three types of electric boilers offered on the market:

- traditional heating element with built-in circulation pump and control unit;

- electrode with remote control panel;

- induction with separate remote control.

We will not analyze the advantages and disadvantages of each type of electric boilers; this is the topic of another article. Here we will show in diagrams how to connect boilers using wood and electricity, so that the second one supports the first one automatically. Let's start with the joint piping of a wood-burning and heating element heating unit:

Connection diagram for 2 boilers - with electricity and wood. Thermostats ensure automatic starting of the electric boiler after the wood boiler is stopped and vice versa.

Reference. The presented circuit can be used for joint connection with a gas wall-mounted boiler, which is installed in place of the heating element.

The system operation algorithm looks like this:

- The TT boiler is inactive and its circulation pump is switched off. Heating devices receive heat from an electric boiler, which is guided by a room thermostat, where you have set the desired temperature. To prevent the coolant from moving in a circle through a parallel ring, the circuit uses 2 check valves.

- You have melted a solid fuel unit. For some time it will begin to gain temperature, and the water will circulate in a small circle, directed by a three-way valve with a thermal head. The pump will turn on at the command of the overhead thermostat installed on the supply pipeline.

- When the coolant in the small ring heats up to 55 °C, the temperature sensor of the thermal head located on the return line will operate. The three-way valve will open slightly and heat will flow into the heating system.

- The electric boiler will turn off the heating based on the signal from the room thermostat and go into standby mode.

- After the solid fuel burns out, the water in the system, followed by the air in the rooms, will begin to cool. The overhead thermostat of the TT boiler will “see” that the coolant has cooled down and will stop the pump.

- When the temperature in the house drops to the value you set, the room thermostat will turn on the electric boiler again.

Important! Since the internal circulation pump of a wall-mounted heat generator cannot be turned off, a more powerful unit must be selected for a solid fuel heat source. As a rule, a pump with a pressure of 0.6 Bar is sufficient (in an electric boiler it is usually set at 0.5 Bar). Point two: install all overhead sensors and thermostats on metal pipes; they will lie on metal-plastic or polypropylene.

Our expert Vladimir Sukhorukov will tell you in detail about how to properly connect an electric and solid fuel boiler in his video:

Induction and electrode heat generators are not equipped with their own filter and circulation pump, so the latter will have to be purchased and installed separately. This is all the difference in the connection diagram for heaters of this type, only the pump unit needs to be connected to the network through the control cabinet so that the room thermostat turns it off together with the electric boiler, as shown in the diagram:

In this scheme, the circulation pump of the electric boiler will be turned off along with it thanks to a separate control cabinet

If the heating system of a private house consists of several circuits (radiators on different floors, heated floors and an indirect heating boiler), then to work together, the wood-burning and electric boiler are connected using the method of primary and secondary rings. The operating principle of this type of harness is described here.

Connecting an electric and solid fuel boiler to the heating system using the primary and secondary ring method

Types of electric boilers, their advantages and disadvantages

The demand for electric heating boilers has given impetus to the development of new types, which are radically different in their operating principle.

heating elements new

The first type of electric boiler. Heating of the coolant is carried out by one or several heating elements. The heating element consists of the following elements:

- Outer shell: steel, titanium, copper or aluminum alloys;

- The internal heating element is nichrome wire.

- Dielectric (ceramic granules or quartz sand) – separates the spiral from the shell.

The device very quickly reaches its rated power, the coolant is heated within 10-15 minutes. The coolant is moved through the system forcibly using circulation pumps. Most models with a power of up to 12 kW are made in a wall-mounted version from a single-phase household power supply. More powerful devices are floor-mounted and require three-phase power supply.

Advantages. The heating elements of the heating element do not have direct contact with the coolant. They are separated from it by a thick layer of dielectric and a durable outer shell. This minimizes the chance of a short circuit. Modern models have a multi-stage safety system that protects equipment from overheating and coolant leakage.

Flaws. By analogy with a boiler on heating elements, as a result of operation, scale is formed, which significantly reduces the heating efficiency. To reduce the intensity of plaque formation, distilled water or special antifreeze is used.

Electrode

The operating principle of an electrode (ionization) boiler is as follows. Two electrodes are brought into the ionization chamber, creating a potential difference. An electrolyte with a high content of salt impurities is used as a coolant. It is in conjunction with such a coolant that you need to connect the electric boiler to the heating. Having high resistance, the coolant quickly heats up under the influence of electric current. It only takes a few minutes for the boiler to reach its rated power. The coolant can only be moved by force, using a circulation pump.

Advantages. High degree of automation, using external sensors, you can control not only the temperature of the coolant, but also the air in the heated room. High reliability is one of the key advantages of ionization boilers. They have a minimum number of parts that practically do not break. If there is a coolant leak, the electrically conductive medium disappears and the device simply turns off. It is recommended to install such boilers in areas with unstable electrical voltage, as they can operate successfully even at 180V.

Flaws. The high cost of the coolant and the need for its careful preparation, preferably before each heating season.

Using long-burning TT boilers

Not every homeowner has the technical ability to connect powerful electrical equipment, which includes combined and purely electric boilers. The reason is the limitation of the allocated power limit for a private house. The size of the limit depends on the capacity of local power supply networks, which the owner of a country cottage cannot increase.

In the absence of natural gas on the site or with the high cost of connecting to the main line, there is only one real solution - buy a long-burning wood and coal boiler or make it yourself. The operating time from 1 load for a conventional TT boiler is 3-6 hours, which forces the owner to work near it as a stoker. A comfortable interval between fuel additions is at least 8 hours, and not every heater provides that much.

The latest pyrolysis boiler with an increased firebox volume ATMOS D30

The trouble is that any seedy manufacturer calls their products long-burning boilers in order to sell them to an ignorant user. You can recognize the correct unit among other heat generators by the following features:

- with the same power, a boiler with a large power reserve is equipped with a firebox of increased volume (from 100 l) and differs in size;

- the passport indicates a burning duration of 8 hours (on wood);

- For convenience, the unit is equipped with an additional loading door.

Detailed information about heat generators of this type and recommendations for their selection are published in a separate topic.

Requirements for a room with two boilers

In the case when the same type of heating sources are selected, the requirements for the furnace are applied to the specific type of fuel used: gas, coal, pallets or electric heating.

The boiler room in the house needs to be treated with due attention

If units operating on different types of energy carriers are selected, the premises must comply with both, and the larger indicator is selected.

Requirements for units using solid fuel:

- The floor area of the combustion room is selected according to the total thermal power of the devices: up to 32 kW, 7.50 m2 is required, up to 62 kW - 13.50 m2, up to 200 kW - 15.0 m2.

- A unit of more than 30 kW is installed in the center of the combustion chamber to ensure reliable circulation of air masses.

- The surface elements of the combustion chamber: floor, walls, ceiling and partitions are made of fire-resistant building materials, using waterproofing protection.

- The boiler is installed on a reliable foundation made of fire-resistant building materials.

- For units up to 30 kW, the requirements for fire resistance of the floor are lower; it is enough to cover it with a steel sheet.

- The supply of solid fuel is stored in a separate dry room, and the daily supply can be located in the boiler room at a distance of at least 1 m from the boiler.

- The furnace room must have a door and windows installed that can provide reliable air circulation three times based on the existing volume of the room.

Requirements for furnace units with gas-fired boilers:

- Gas boilers with a total power of up to 30 kW can be installed in non-residential premises of a house where there are windows and doors that can provide 3 times air circulation.

- When the power of the gas source is more than 30 kW, a separate furnace room is required with a ceiling height of at least 2.5 m and a total area of more than 7.5 m2.

- If this equipment will be installed in a kitchen in which a gas stove operates, then the room must be at least 15 m2.