Combined heat generators are devices that produce heat by processing various fuels. When using different sources of thermal energy, heat exchange processes can occur both simultaneously and sequentially. Any heating system or heating circuit acquires the necessary stability if it is possible, manually or automatically, to quickly switch to the use of alternative energy.

Combined solid fuel boilers are universal units with a wide range of applications. There are models of multi-fuel installations in which you can use wood, coal, pellets, natural gas and electrical energy. This kind of combined heating boilers for a private home, the price of which is quite high, is rarely used. The most widespread heating equipment uses combinations of wood, coal/electricity or wood/gas.

Features of combination boilers

The use of fuel types with different physical properties in one device naturally leads to a more complex design. In addition, connecting and servicing combination boilers requires the qualified intervention of electricians, gas service workers, and specialists in working with liquid petroleum products.

Design

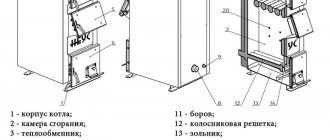

All solid fuel heat generators must have a combustion chamber, a heat exchanger and a smoke exhaust system.

Depending on the additional type of fuel used, the design of the combined devices is supplemented with:

- space for installation of electric heating elements;

- gas burner;

- nozzle for spraying liquid fuel;

- manual or automatic controls for switching to the fuel type corresponding to the operating mode.

If the wood/gas scheme is used, most models have two combustion chambers. In one, solid fuel is burned, in the second a gas burner is installed. When using liquid fuels, a tank for diesel fuel or used engine oil with a built-in or external fuel priming pump is installed as additional equipment to the boiler.

As a rule, all combined equipment has complex automation that requires a permanent electrical connection. Optionally, many manufacturers offer backup power supplies that ensure the operation of electronic units, electric drives, as well as fuel and water pumps in the absence of power.

Advantages

Multi-fuel equipment for heating systems allows you to create a mini-boiler room, in the operation of which a person takes minimal participation. Basically, the activity comes down to loading solid fuels, filling fuel containers, cleaning fireboxes and monitoring and debugging automation.

Installation of combined solid fuel units makes it possible to:

- use them as multi-circuit devices for water and heat supply;

- switch to an alternative type of fuel if reserves of the main fuel run out;

- use the most optimal combinations of solid fuel with gas and petroleum products;

- avoid defrosting of the heating system in case of prolonged absence of control.

Flaws

Combined devices are distinguished by a large number of additional elements. The presence in solid fuel units of servos, piezoelectric elements for igniting gases, heating elements (tubular electric heaters), etc. invariably leads to more frequent breakdowns and difficult maintenance.

In addition, combined boilers:

- have a relatively higher cost;

- are energy dependent on a stationary or backup source of electricity;

- require the need to coordinate projects for their installation with supervisory authorities;

- cause the need for re-equipment or retrofitting of electrical wiring.

Prices for combination boilers

combi boilers

Installation and operating conditions

A combined solid fuel boiler, like any other heating boiler, has the same installation and operating conditions.

First of all, it is worth understanding that placing such equipment in living rooms is impossible, since it can emit combustion products that are detrimental to human health.

Let's look at a few rules and recommendations that will help you choose the right installation location.

- Good ventilation. The room in which it is planned to install equipment of this type must be well ventilated so that all combustion products do not linger in the room and are not dispersed throughout the house. For this purpose, a special exhaust system is installed, which immediately draws out combustion products. The creation of a ventilation and exhaust system must necessarily provide for quick access for cleaning, because during operation it can become clogged and become less able to perform its function.

- Convenience of chimney installation. The best option would be to place the boiler as close to the external wall as possible. This is due to the fact that it will be much easier to remove the chimney, in addition, the supply of additional communications in the form of gas or electricity will also be greatly facilitated.

- Fire safety. Before installing the boiler, it is necessary to carefully prepare the room. It is not recommended to install floor structures on a subfloor; it is necessary to create a special stand made of concrete or brickwork. This will protect the subfloor from constant exposure to high temperatures. Wall-mounted models also need to be additionally protected by creating a kind of recess, which is assembled from fire-resistant materials with low thermal conductivity.

The principle of operation of the boiler using electricity and solid fuel

In low-rise construction, the most common type of combined heat generators are devices for which firewood, coal, peat or pellets are the main source, and electricity is the backup source of heat. The principle of operation is quite simple. If the solid fuel runs out or burns out in the firebox, the heating element (pipe electric heater) comes into operation, heating the coolant to the optimal temperature. The control control unit is usually responsible for the timely switching on and off of heating elements.

What is the versatility?

The key feature of these units is the ability to work with variable types of energy carriers. The following circuit diagrams are in greatest demand:

- Gas-diesel. Since gas and diesel heating units differ only in the type of burner, these designs can be used as one device. It is noteworthy that with a minimum of effort this system can be converted to a different coolant.

- Gas-diesel-electric heater. The presence of heating elements helps to improve the performance of heating equipment. This includes heating the coolant and protecting the system from freezing. By connecting a gas burner to an electrical device, it is easy to achieve significant gas savings.

- Gas-diesel-solid fuel. This is perhaps the most popular combination, which uses any type of solid fuel resources, including coal, firewood, peat briquettes, pallets, and wood waste.

Pictured is the Protherm Bizon 30 NL boiler, which runs on gas and diesel fuel. The

universal design, which runs on gas, solar and coal, is based on a classic solid fuel boiler. The device is highly reliable and efficient. It is worth considering that the “native” fuel option for such heating units is solid fuel. Alternative types of energy carriers are somewhat inferior in terms of efficiency.

Methods for switching fuel types

Combined units in general are designed to solve several problems at once, so manufacturers try to make their devices as minimally independent as possible from human intervention in their operation. Moreover, the integration of each element of the heating system into a complex that is popular these days, called a “smart home,” requires a fairly serious level of automation. A specific feature of solid fuel equipment is the mandatory human participation, at least when loading and igniting fuel.

Manual

Any type of solid fuel is placed manually. The process of its ignition at the initial stage should almost always be controlled. When the firebox reaches operating mode, you can make a transition to an alternative type of fuel in advance. For heating elements, the corresponding circuit breaker is turned on, and for gas or liquid fuel, main taps are opened.

Auto

For example, if a pellet bunker or one stack of a pyrolysis unit allows generating heat for more than a day, all issues related to combustion control or switching to alternative types of fuel are taken over by automation. The homeowner or summer resident can only set the necessary parameters in the programmer or control unit. Executing mechanisms in the form of servos or electric valves, when power is supplied to them, at the right moment transfer the operation of thermal equipment to the appropriate type of fuel. For liquid fuel equipment, power is also supplied to the fuel priming pumps at the right time.

Reviews of household dual-fuel models: advantages and disadvantages

| Advantages | Flaws |

| Independence from one energy source and the ability to combine fuel types to save money | In more than 90% of cases, the cost of a universal model is higher than two single-fuel ones |

| Significant space savings, which is especially important for small private houses and cottages with an area of up to 100 m2. A combined heating boiler is practically no different in size and piping from a single-fuel boiler | The efficiency of combined models (due to compromises in favor of versatility) is almost always lower. When planning to burn gas in the design of a typical solid fuel boiler, it is worth understanding that the compromise design accumulates on average 3-6% less heat |

| Some models have the ability to automatically switch from one type of fuel to another in case of interruptions | A heating system with two separate boilers is always more reliable than with one combined boiler. Although the design of universal models is quite simple |

| Availability of not only single-circuit, but also double-circuit models | Owners often note the noise level of the burners, which is not comparable to the standard burners of gas and liquid fuel boilers. |

| Most models are non-volatile - do not require connection to the mains | Advanced, efficient and multifunctional automation is used only in multi-fuel expensive models costing 100-300 thousand rubles. |

| Lack of wall-mounted boilers and generally a small selection of models |

Types of combined units

Manufacturers of heating equipment try to develop their devices so that the circle of potential customers is as large as possible. Equally important is the environmental characteristics of heating systems. A feature of pyrolysis water heaters is their “omnivorousness”. To produce combustible gas, they can use not only traditional firewood and charcoal, but also cellulose-containing waste, used motor oil and used car tires.

Most often, mini-boiler houses use complexes designed for combinations: firewood, coal, peat briquettes/electricity, pellets/gas/liquid petroleum products, firewood/electricity/gas/diesel fuel. Very often, boiler equipment that simultaneously operates on sawdust, substandard flax or sunflower husks is installed on farms or small agricultural enterprises. It not only effectively heats homes and technical premises, but also disposes of waste. Natural gas or fusic (substandard) oil is usually used as a backup option.

Solid fuel and electric

The solid fuel/electricity combination remains the most popular in low-rise construction. In this case, electric heaters perform an auxiliary rather than an operational function due to the relative high cost of electricity.

Solid fuel and gas

The combination of a combustion chamber and a gas burner is popular in gasified cottage communities and in rural areas. Heating with natural gas alone, especially a large house, is quite expensive. Based on the prices for firewood or coal in a particular area of residence, you can choose the fuel that will help you avoid unnecessary expenses during the cold season. Gas, if there is a connected pipeline, can always be an excellent insurance during periods of severe cold.

Diesel and gas

Diesel/gas units are designed with a single combustion chamber. In order to convert the device from one type of fuel to another, it is enough to change the burner. If for any reason the gas supply is interrupted, a special nozzle is installed to ensure atomization and combustion of diesel fuel in a housing with a heat exchanger. The fairly simple design of such combined heaters allows all operations to be performed with a minimum set of tools in just a few minutes.

Electricity, solid fuel, gas and diesel (multi-fuel installations)

Multi-fuel complexes are the most versatile, but also the most complex. Their purchase is justified if the user has at his disposal the entire range of fuel at an affordable price. They are also often used in remote or hard-to-reach areas, in which everything that is currently at hand is used for heating. In this case, the issue of survival in harsh conditions may be of paramount importance, and combined heat sources are used for heating and hot water supply.

Which boilers should you prefer: homemade or factory-made?

Multi-fuel heating boilers very clearly demonstrate their advantage over other types of devices, so there are often attempts to independently manufacture a universal boiler from a conventional solid fuel model. If necessary, you can actually make them yourself: special burners are available for sale that allow you to use different types of energy carriers.

But, despite the abundance of various schemes and instructions, professionals do not advise performing such operations, and they have reasons for this. Homemade units do not undergo proper testing and inspection, as a result of which fires and explosions of homemade boilers often occur.

Each universal heating boiler manufactured at the factory undergoes testing, which allows us to minimize the risk of hazardous situations during operation. In addition, when making boilers independently, calibration of the burners is not carried out - and it is precisely because of its correct adjustment that great savings occur, but only factory models can boast of such an achievement.

Of course, the homeowner will choose on his own, but it is much better to purchase a reliable and high-quality multi-fuel boiler that will be convenient, economical and functional.

How to choose the right boiler

To achieve the required temperature parameters, a building or room needs equipment that can provide them. The list of all elements of the heating system of even a small house contains tens and hundreds of items. The main thing on this list is a heat generator of a certain power. When choosing a unit based on power, you should maintain a balance. Low-power equipment will not be able to sufficiently heat the room; too powerful equipment will lead to excessive consumption of fuel or failure of the entire system.

The thermal power of any household heating device is indicated by the manufacturer in kilowatts. Ideally, it is better to entrust the calculation, selection and installation of the entire heating complex to specialists. Preliminary parameters can be set independently, taking into account that 1 kW of heat generator power is enough to heat 10 m2 of room area with average insulation and a ceiling height of 2.5 m.

Heating electrical installations

To work together with water heating, manufacturers produce 3 types of electric boilers:

- Heating elements. The device heats the coolant using tubular elements, which are used everywhere - in boilers, heat accumulators, heat pumps, and so on.

- Induction units heat water with a metal core placed inside an electromagnetic field.

- Electrode boilers use the conductivity of ordinary water. The current passes between two electrodes immersed in the coolant.

Mini-boiler room with tubular electric heaters placed inside a container with coolant

Heaters with heating elements externally and internally resemble mounted gas units. A circulation pump, a safety group and an expansion tank are usually hidden under the housing. Induction and electrode boilers need to be completed - buy pumps and other piping parts.

Advantages of electric water heaters:

- the best efficiency among all heat sources;

- noiselessness (excluding older models equipped with electromagnetic starters and contactors);

- low weight and size;

- low price of equipment;

- relatively simple installation;

- Full autonomy in operation, maintenance - annually at the beginning of the season.

The heating block of the electrode apparatus can be controlled remotely using room thermostats

Heat generators really do not require attention from the homeowner, except when setting the temperature. There are nuances in the operation of the electrode apparatus - the coolant must be salted, otherwise the heating intensity will decrease.

Disadvantages of electric heating boilers:

Review of popular models and prices

The choice of all kinds of combined devices is huge. The popularity of certain brands is due to both low cost and credibility. Domestic manufacturers confidently outperform many famous foreign brands in terms of price-quality.

KChM from OJSC Kirovsky produces its heating equipment using the method of vacuum-film molding of cast iron castings using the technology and equipment of the German company HWS. The housings of KChM universal units are completely cast iron with cooled grates and spacious combustion chambers. The plant offers this type of solid fuel equipment in a power range from 21 to 80 kW, and its main feature is the ability to convert to gas or liquid fuel.

Zota Mix

The main distinguishing feature of Zota Mix solid fuel heat generators is their efficient operation on almost any solid fuel, including brown coal. They also provide the possibility of installing a gas burner, fuel injector or heating element. This makes the Zota Mix equipment line in demand in the combined units market.

Prices for combi boilers Zota Mix

combi boilers Zota Mix

Smoke Series

The Dymok series includes five types of heat generators, well known under the Zota brand. They can be produced with or without a frying surface. All models are completely energy independent, but it is possible to separately purchase and install heating elements.

Karakan boiler series

The Karakan series of gas water heaters is a product of the domestic company STEN. The line includes devices with power from 7 to 12 kW. A key feature of the units is the possibility of retrofitting with heating elements, which will ensure the operation of the systems in the absence of gas or during maintenance work.

Reviews

Reviews about combination boilers are mostly positive. In order to fully realize their advantages, it is necessary to choose the right type of structure.

In some regions, electricity is more expensive than gas, so you need to choose a boiler that uses gas as the main fuel.

Solid-state coolants can be used as secondary fuel if conditions permit.

Negative reviews are also present, but are mainly related to incorrect selection or violation of the rules and operating conditions.

What is more profitable - a separate electric boiler or a built-in heating element?

According to many experts, a separate electric water heater is better, since it only heats the system coolant, excluding heating the boiler water jacket. True, in some models, built-in heating elements are installed in the upper part of the heat generator housing, which completely solves the problem. In this case, the advantages of a multi-fuel device are obvious.

The best models of pellet-wood boilers

Combined heaters are produced by many Russian and foreign companies. A number of models with the best price-quality ratio are especially popular.

Heiztechnik HT Daspell Duo

The Polish unit operates on all types of fuel, incl. on coal. The line includes models with power from 12 to 65 kW.

Description:

- 1 circuit;

- Heiztechnik Pellhard Plus torch burner with self-cleaning and ignition function;

- water-cooled grate;

- electronic weather-compensating automation;

- possibility of installing a display, ash removal system and Internet connection.

Heiztechnik HT Daspell Duo - Polish boiler.

The device is made of steel 5 mm thick.

Zota Pellet 15S

Russian 2-burner unit with a power of 15 kW.

Main characteristics:

- automatic switch to pellets after firewood burns out;

- maximum pressure of the working medium – 3 atm.;

- only forced circulation;

- 2-screw feed (protection against flame penetration into the hopper);

- flow meter – calculates daily and total fuel costs;

- control panel with the ability to connect up to 3 pumps and indicate their priority.

Zota Pellet 15S is a two-furnace unit.

Additionally you can install:

- 12 kW heating elements - turn on automatically if the user forgot to add solid fuel in time;

- GPS module for controlling SMS commands from a smartphone;

- Matrix uninterruptible power supply.

The fire is maintained at the top of the burner, which prevents the auger from burning out.

Automation – weather-sensitive, with programming function.

The device is resistant to high temperatures and voltage surges.

Stropuva Mini S8 P

Lithuanian top combustion boiler with a power of 8 kW. There is no automatic fuel supply. But due to the fact that the load is ignited from above and the air is supplied strictly to the combustion zone, the duration of operation is (in hours):

- wood-burning – 18;

- on briquettes – 30;

- on pellets – 42.

The firebox volume is 163 liters. It holds 106 kg of pellets.

Stropuva Mini S8 P is a top combustion boiler.

The advantage of the heater is energy independence. The coolant temperature and performance are controlled by a bimetallic mechanical sensor connected to the air damper.

Installation efficiency is 85%.

Svetlobor VD 16

Russian equipment with a power of 16 kW. Together with the boiler, a pneumatic fuel supply system from a remote storage facility is offered. It frees the user from even having to load pellets into the hopper. The boiler is approached once a month for maintenance.

Description:

- volumetric type burner;

- automatic cleaning of grates and heat exchanger, removal of ash;

- Efficiency – 94%;

- pellet consumption in nominal performance mode – 3.5 kg/hour;

- weight – 450 kg;

- option – GSM module.

Svetlobor VD 16 – Russian equipment.

The boiler tank is located vertically, which reduces the rate of formation of deposits on its walls.

The entry of flame into the feed auger and hopper is prevented due to the special shape of the burner. It is designed for pellets of any quality.

Metal Fach SD Duo 14

Single-circuit boiler with a capacity of 14 kW, made in Poland. Description:

- water-cooled grate;

- volumetric type burner;

- cast iron screw;

- Efficiency – 90%;

- control – electronic, information is displayed;

- weight – 485 kg;

- ability to connect 4 pumps, weather and room thermostat to the controller.

Metal Fach SD Duo 14 – boiler with a capacity of 14 kW.

The unit operates on all types of fuel, incl. on coal. Fire protection for the feeder must be purchased separately.

Faci Base 15

Italian 1-circuit unit with a power of 15 kW. Equipped with an automatic feeder for the following types of fuel:

- pellet;

- coal up to 15 mm in size.

The volume of the standard bunker (263 l) is enough for 3 days of work.

The device is made of heat-resistant steel and equipped with a volumetric pellet burner.

Fire precautions:

- 2-screw feed;

- screw temperature sensor;

- extinguishing system (emergencyly dumps all ignited pellets into the boiler).

Faci Base 15 is an Italian unit.

Options:

- auto ignition;

- GSM module;

- more spacious bunker.

Efficiency – 92%.

Conversion to gas is possible.

Gas boiler, but what gas?

Gas boilers operate not only on main gas (methane), but also on liquefied cylinder gas (propane-butane mixture) . After the specialist replaces the nozzles and sets the pressure settings on the gas valve, the unit easily switches from liquid gas to regular gas or vice versa. But for the user himself the situation changes dramatically.

In terms of operating costs and associated expenses, liquefied gas is significantly inferior to main gas and appears, as it were, in a different echelon, where it competes with diesel and solid fuels. If the main gas pipeline delivers fuel directly to the boiler, then when using liquefied gas the consumer will have to solve the problem of fuel delivery and storage himself. You will need to purchase and install a gas tank on the site, preferably with an extended tank neck to maintain productivity in winter; do not forget about Russian frosts. To heat a house with an area of 200 m², you need a gas holder with a volume of 2700 liters; for a house with an area of 400 m², a tank with a capacity of 4800 liters is more suitable. The total cost of installing a gas tank (4800 l), including excavation work and commissioning, starts from 200,000 rubles. The price of propane-butane in the Moscow region, including delivery, is about 15 rubles/liter.

Gas tank installation

Calorific value of different types of fuel:

| Type of fuel | Calorific value |

| Dry firewood | 3,900 kW/kg |

| Wet firewood | 3.060 kW/kg |

| Anthracite | 5,800 kW/kg |

| Brown coal | 2,900 kW/kg |

| Diesel fuel | 11,700 kW/kg |

| Natural gas | 10,000 kW/m³ |

| Liquefied gas | 20,800 kW/m³ |

| Eurodrova | 5,300 kW/kg |

| Pellets | 5,000 kW/kg |

Is liquefied gas a worthy alternative to main gas?

The price of liquefied gas (propane-butane mixture) is significantly higher than main gas (methane), but if there is no choice; then today it is quite an interesting alternative to diesel fuel, electricity and solid fuel pellets. The only nuance associated with liquefied gas is its storage. The fact is that installing a gas tank is quite an expensive proposition, and it makes sense to bury money in the ground only if main gas is not expected, even in the future. Working with cylinders and constantly changing them in a house with an area of more than 150 m² is very labor-intensive, since in the cold winter one 50-liter cylinder will last for a maximum of one or two days.

In addition, we must remember that it is not recommended to remove more than 10 kW from each cylinder, otherwise freezing of the cylinder and the gas reducer may occur. For example, for a 24 kW boiler it is better to place 3 cylinders in parallel. In general, the safety requirements for such systems are specified in regulations. For example, cylinders cannot be placed in basements, since liquefied gas is heavier than air. At least once every six months you need to check the tightness of gas reducers and gas pipelines, and even better, install a gas leak detector. Many models of gas boilers can operate on liquefied gas if you change the nozzles and reconfigure the equipment, but the adjustment must be carried out by a specialist.

What is important to consider before installing such heating equipment?

Before installing such a heating system in your home, you should fulfill several important requirements. The boiler, as well as the entire system, must be installed:

- in a separate room;

- at a sufficient distance from the walls;

- only on a concrete foundation.

When the boiler and its elements are placed in an isolated room, this guarantees your safety. Under no circumstances should any objects, clothes, or shoes be stored in such a room. In short, there should be no flammable elements near the boiler other than fuel for equipment or boiler components.

Of course, if you are not a professional in this matter, then it is best to turn to the experts for help with installation. They will do their job efficiently and without any complaints. At the same time, if you have certain skills, you can take on this work yourself. All necessary materials and tools can be purchased at the store where the boiler was sold.

When connecting and setting up the unit, it is important to remember that good draft and high-quality ventilation are important for the full operation of the system.

The best manufacturers

Ratings of combination heating boilers can include dozens of models from a variety of manufacturers. Among them there are those that are especially popular among buyers and are rightfully considered one of the best.

Protherm

This European manufacturer of heating boilers is distinguished by a wide range of products, numbering more than 90 items, including heat generators of almost every type, including innovative condensing models. Products are supplied to more than 25 countries from Europe, Asia and Africa, where they have earned the trust of consumers.

Protherm boilers are certified according to ISO 9001, have an affordable price for a wide range of buyers and a wide range of models. In addition, the manufacturer provides professional service both through its own services and through partner companies, whose employees must undergo special training.

Roda

The products of the German manufacturer Röda are represented on the domestic market by electric, gas, solid fuel and, of course, combination boilers. Roda is European quality climate control equipment with service throughout the Russian Federation and a wide network of dealers.

Roda solid fuel boilers all have natural draft, and the combustion intensity is adjusted using a thermomechanical regulator. On the other hand, you can retrofit the heat generator with automation. It is also possible to install a control unit and a forced air intake fan.

ZOTA

The domestic manufacturer ZOTA offers customers, among other things, combined heating boilers using wood and coal with the ability to connect heating elements as an option.

They have an affordable price tag, and there are models with a hotplate. Some solid fuel heat generators fully provide long-term combustion, amounting to 8–12 hours, depending on the type of energy carrier.

Teplodar

Another domestic manufacturer that offers customers not only boilers, but also stoves and even fireplaces. Teplodar has been working in the heating industry for 20 years and has more than 50 patents for unique developments.

High-quality materials are used in production, and the reliability of the products is confirmed by various certificates. The model range includes horizontal heat generators of the “Comfort” series with a spacious firebox designed for firewood up to 50 cm long.

© 2022 All rights reserved