If there is no central heating in a country house or cottage, the ideal solution for heating the home is a wood-electricity combination boiler. On the heating equipment market, about 70% of all models of heat generators designed for heating private homes are multi-fuel devices.

Combined devices are an excellent guarantee that with the onset of cold weather, the most comfortable temperature in the house will always be maintained, even if there are interruptions in the supply of one type of fuel. In addition, the necessary supply of firewood for the winter can be created in advance, and the availability of electricity in homes is not always stable, especially in bad weather.

Features of combined heating boilers

Today, dozens of domestic and foreign companies are engaged in the development and production of combined heat generators. Combined wood-electric heating boilers, the price of which can vary depending on the power and manufacturer, are steadily in demand.

First of all, this is due to the competitive advantages of this type of equipment, including:

- relative simplicity of design;

- use of available fuels;

- possibility of integration into heating systems of both closed and open types;

- compatibility with various switching devices and units;

- maintaining the set temperature of the system for a long time in automatic mode;

- availability and interchangeability of standard electric heating elements;

- low cost;

- high service life.

Like any type of heating equipment, electric wood heat generators have a number of disadvantages:

- the need to allocate a special room for installation of equipment with a ventilation and smoke exhaust system;

- low power of the electrical component for domestic boilers powered by a single-phase network;

- large weight, which determines the possibility of only floor installation, sometimes requiring reinforcement of the base;

- dependence on energy supply;

- heat loss through the chimney when electric heaters are turned on, which reduces the overall efficiency by 2-5%.

Installation methods and operating features of equipment

It is no secret that the installation method depends on the type of equipment. Therefore, the type of device in question requires special installation and maintenance. Installation recommendations are followed with particular care when installing the equipment yourself.

The unit requires a separate room because it uses gas. In addition, for normal operation, a concrete pad and ventilation must be installed under the boiler. In addition, the unit requires a chimney arrangement.

Tip: Don't try to install such complex equipment yourself if you don't understand everything. It is better to entrust this process to specialists. The craftsmen will quickly and, most importantly, efficiently install a complex heating system.

Connecting the combi boiler to the heating system

Heating a large house without gas

After installation, the technicians check the heating and operation of the device. Turning to specialists has another benefit - a warranty card, with which you can contact the service center in the event of a breakdown.

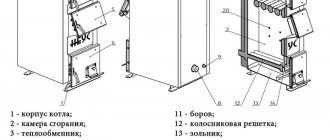

Electric wood boiler design

Multifuel heat generators use a combination of elements capable of converting energy received from various sources into heat. Electric wood-burning units are practically no different in design from conventional boilers that burn wood and coal.

Structurally they consist of:

- a housing, inside of which there is a water jacket or a heat exchanger of a heat- or water-tube type;

- combustion chamber with air supply and smoke exhaust system;

- ash chamber for accumulation and removal of solid combustion products;

- A heating element (tubular electric heater) or a block of heating elements;

- control equipment.

Depending on the chosen method of controlling the air supply to maintain combustion, heat generators operating on solid fuels can be equipped with either a mechanical draft regulator or an electric boost fan.

Principle of operation

The operation of a combined wood-electricity heat generator is based on the principle of automatic or manual switching from solid fuel to electricity. At the moment when the firewood placed in the combustion chamber burns out, electric heaters come into operation, maintaining the temperature of the coolant within the specified limits. Turning on and off a heating element or a block of heating elements is carried out by a switching device when it receives a signal from a temperature sensor installed in the heating circuit.

Benefits of use

The presence of an electrical component in a solid fuel boiler can significantly increase the reliability of the entire heating system and the ease of use.

A relatively small complication of the design of the combined unit during operation allows:

- maintain a comfortable temperature when heating the house both during the day and at night;

- avoid defrosting the heating circuit of a country house, cottage or cottage in the event of a long departure;

- use electricity during periods of absence of firewood or coal as a backup heat source.

Automation of home heating with wood

So, during the operation of the boiler, one bookmark burns for 3-4 hours. This is acceptable when it is possible to be near the boiler.

And it is completely unacceptable when there is a need to leave for 8-10 hours, for example, to go to work or, simply, to go to bed.

If nothing is done, then after 4 hours the coolant will begin to cool and the temperature in the interior of the house will begin to drop.

In this case, the electric heating element is automatically switched on based on the coolant temperature.

That is, after laying firewood in the evening, you can safely go to bed. After about 4-5 hours, when the temperature of the coolant begins to decrease, an electric heating element will be connected to the heating, which will maintain the desired temperature.

Of course, a 3 kW heating element will not be able to heat a house with an area of 150 or 200 square meters. But, nevertheless, it will not allow the coolant to cool down too much.

And in the morning you can wake up in a relatively comfortable temperature and make the first addition of fuel to a warm boiler.

Types of boilers

One of the main parameters by which combined heat generators are classified is the types of fuel used.

This is usually reflected in the marking, which consists of several letters meaning:

- T - solid fuel (wood, coal, pellets, peat, etc.);

- G - gas;

- E - electricity;

- F - liquid fuels (fuel oil, kerosene, used engine oil, diesel fuel, etc.).

For example. the combination of the letters “TG” in the name of the heat generator means that it can operate on solid fuel and gas, and the design will use a design with two combustion chambers. If necessary, you can buy a multi-fuel unit, the name of which contains four letters “TGEZH”. Such heat generators are the most versatile devices, however, the complexity of the design and high price do not have the best effect on their prevalence among consumers.

The most optimal solutions for private homes remain devices using two types of fuel.

Gas/electric combination

Electric gas equipment is usually used in gasified areas where interruptions in the supply of pipeline gas occur. Considering that the cost of electricity is approximately three times higher than the cost of gas, in combined units of this type gas is used as the main source of heat, and electricity as a backup. Compared to solid fuel heaters, gas-electric heaters are more compact and are often mounted on the walls of residential premises, significantly saving space.

Wood/gas combination

Wood-gas heat generators are represented quite widely on the heating equipment market. They are popular in gasified areas with harsh climates, where the use of two types of fuel during an extended period of cold weather can reduce overall heating costs.

Prices for combined boilers ZOTA

combi boilers ZOTA

There are two types of solid fuel-gas installations:

- Units that use gas as the main fuel and wood as an alternative fuel. To switch from one type of fuel to another, a small upgrade is required.

- Universal heat generators in which the gas turns on automatically when the wood burns out.

This type of equipment usually has two combustion chambers with a common chimney. Grate bars are installed in one chamber, and a gas burner is installed in the other.

Wood/electricity combination

In those regions where the cost of firewood is low and there are no gas mains, combined wood-electricity installations remain the most preferred and in demand. Two sources of thermal energy not only minimize heating costs, but also increase the overall stability of the system. The heating circuit is inertial. Constantly maintaining the required coolant temperature by electric heaters reduces the consumption of firewood for heating it when igniting, which makes it possible to use less wood.

Multi-fuel installations

The prevalence of multi-fuel installations in private homes is hampered by two main factors: high price and difficulty of maintenance. The use of fuel with different physical properties in one unit requires the installation of a larger number of burners, pumps, nozzles and other elements. This leads to more complex control automation and a decrease in overall reliability.

For private households, a maximum of three fuel combinations are usually used, including wood, gas and electricity. Combinations such as pellets/liquid fuel/gas are very rare.

Tips for choosing

- It is worth installing a boiler for which it is easier and cheaper to buy fuel. If coal or firewood is cheaper in the installation region, you should give preference to equipment using such fuel. If at certain times of the year one type of fuel is cheaper (for example, coal), and at other times another fuel is cheaper (for example, peat), then you should choose a universal boiler that uses different types of fuel.

A very effective universal heater is a device with a combination of the ability to operate on solid fuel and gas.

- If there is always a person in the house who can regularly add fuel to the boiler, then it is better to choose the classic option.

- To heat a large room, it is better to install a more advanced model - pyrolysis or long-burning.

- For constant use, a cast iron device is better suited; for use as an additional heater, it is worth installing a steel version.

- For heating and hot water supply, you should purchase a double-circuit version or a set of single-circuit and indirect heating boiler.

Heat exchanger material

Since the thermal efficiency of a heat generator is decisive for the entire heating system, manufacturers use materials with high thermal conductivity to manufacture heat exchangers. Typically this is steel and cast iron for solid fuel installations, and copper and aluminum for gas installations. In modern combined units, especially those with a dual-circuit layout, heat exchangers made of cast iron, steel or non-ferrous metals or their alloys can be used simultaneously.

Prices for Kentatsu combi boilers

Kentatsu combi boilers

The choice is obvious - maximum comfort in fuel combination

The benefits of using combined options make them extremely popular in modern conditions. Efficient and economical automated solid fuel boilers with electric heating elements are increasingly appearing in homes far from the benefits of civilization.

In such devices you can burn not only wood. Coal, capable of burning for up to 70 hours in a row, provides heat no worse than wood. In addition, today in many cities the production of fuel pellets has been established, which provide more energy than simple firewood.

Even small-sized objects can be equipped with autonomous heating devices - boilers for wood-burning saunas cope perfectly with the fairly high requirements for such premises in terms of temperature conditions. And supplemented with electrical elements, they will be able to maintain an optimal atmosphere in them even during the downtime of the sauna between visits.

Each homeowner will be able to see for himself by testing modern heating boilers in his home - this is the most optimal option for combining heat sources for a private home, allowing for the efficient and economical use of heating equipment.

Criteria for choosing a wood/electricity boiler

When choosing reliable heating equipment, it is not enough to be guided only by the availability of a certain amount of money and personal preferences. The main thing in this complex matter is the technical parameters that ensure the efficiency of the entire system.

When choosing a boiler, be sure to take into account:

- thermal power and area of heated premises;

- type of fuel intended for use;

- possibility of connection to gas mains and electrical networks;

- the presence of special premises for the installation of equipment, equipped with ventilation and a system for removing combustion products;

- type of heating circuit (open or closed);

- the need for coordination with licensing technical authorities.

The ideal option before purchasing any type of heat generator would be to develop a project with an accurate professional calculation of all system parameters. Errors at this stage can lead not only to the fact that the already assembled system will not provide the necessary heat, but also to its complete failure.

Advantages and disadvantages

A boiler for heating a private house has its positive aspects:

- During the cold months, you don’t have to worry about your entire heating system. Automatic connection to the power supply will prevent freezing of the coolant and failure of the boiler, despite the long absence of the owners.

- Most combined devices can operate equally effectively on different types of solid fuel (briquettes, firewood, coal, etc.). Homeowners can buy the type that is easier and cheaper to find in their area of residence.

- At night, switching to a reserve type of energy eliminates the need to add logs to the firebox. A multi-tariff payment scheme for electricity at night will allow you to save on the operation of the device.

- Double-circuit heaters can not only heat the room, but also provide the cottage with hot water supply.

- With proper operation, the devices are designed for 25 years of service.

It is necessary to note the disadvantages of such units:

- The efficient operation of the automatic system depends on an uninterrupted supply of electricity.

- The coolant should be loaded regularly (at least 2 times a day).

- For optimal operation of the device, a chimney with good draft is required.

- The volume of the combustion chamber is smaller than that of solid fuel boilers due to the heating element, so a small amount of firewood is used for loading.

- It is necessary to periodically clean the combustion chamber from ash and soot.

- Prices for combined heat generators are higher than for the classic type of stoves.

Combination boilers operate efficiently using briquettes, wood and coal.

Tubular electric heaters in multi-fuel units often have low power and are designed only to maintain heat.

At low air temperatures, it will not be possible to replace completely solid fuel.

Installation nuances

The operation of home heating equipment is associated with a significant risk to health and life, therefore manufacturers and regulatory authorities have developed clear rules for its installation, use and maintenance. They are set out in the technical documentation attached to each unit and SNiP (Building Norms and Regulations) standards.

Their strict observance eliminates the possibility of a fire in the home, a gas explosion, and poisoning by combustion products.

Premises requirements

The ideal option for installing the entire complex of equipment is to organize a special room - a boiler room.

This takes into account:

- size of ventilation holes;

- area and volume of the room;

- distance from the protruding parts of the boiler to the walls;

- the presence and size of windows and doors;

- type and power of ventilation;

- presence and nature of electrical wiring and lighting.

If for solid fuel units the presence of a separate room is mandatory, then, for example, for gas-electric boilers with closed combustion chambers, installation in kitchens is allowed. In this case, a coaxial chimney is installed to ensure combustion of gas and removal of its combustion products.

Chimney installation conditions

When purchasing combined heating units, be sure to check that the hole for the chimney matches the dimensions of the chimney pipe. Depending on the model, the gas exhaust hole can be either rectangular or round. If these parameters do not correspond, it will be impossible to install the chimney properly or the installation of additional transition elements will be required.

In cases where the installation of heating equipment requires forced ventilation, you should ensure that the supply duct is larger in area than the chimney duct.

Prices for combined boilers Teplodar

combined boilers Teplodar

Requirements and rules for connecting to the electrical network

In the furnace of small private houses and cottages, electrical equipment is usually installed, consuming from 1 to 5 kW and operating from a single-phase network. In this case, the connection of electric heaters or heating element blocks occurs without significant alteration of the house's power supply system. For more powerful equipment, 380 V power cables are laid.

Lighting in boiler rooms and furnaces should ensure comfortable maintenance of all systems at any time of the day. The SNiP standards in the section “Natural and artificial lighting” discuss in detail the requirements and rules for its technical arrangement.

Installation Requirements

Almost all combination boilers are manufactured in a floor-standing design and require a separately equipped boiler room. In addition, when installing them, it is necessary to comply with a number of fire and electrical safety requirements, as well as compliance with SNiPs. Below are the main installation features.

Room

- Availability of a reinforced individual foundation for installation of boiler equipment.

- Compliance with fire safety standards.

- Dryness in the boiler room, protection from moisture penetration.

- Non-combustible wall material.

- The minimum distance between the boiler and any wall is 300 mm.

Chimney

- Sealing of joints.

- No cracks or other mechanical damage.

- Insulation that prevents the formation of condensation and ice, which can lead to blockage of the chimney duct.

- The head is at least 500 mm high.

Circuit

Here it is important to eliminate the possibility of contact with water of any current-carrying elements, if any. Also a mandatory requirement is the correct selection of the cross-section of the supply wiring, which is calculated based on the total power of the powered equipment and the current consumed

Cost of combination boilers of different types

The cost of combined units depends on many factors, including:

- brand awareness;

- boiler power;

- number of types of fuel used;

- equipment.

Standard boilers operating on two types of fuel remain the most affordable today.

Universal equipment using 3 or more types of fuel is the most expensive due to the complexity of the design. The wider the functionality, the more elements are involved to implement it.

The excessive costs of expensive multi-fuel models are not always justified, and during operation it turns out that many functions are simply not used. Simple and reliable equipment with a combination of wood and electricity in most cases copes perfectly with the tasks of heating private houses. Find out which is better stone wool or mineral wool at the link.

Technical design features

Combination heating boilers use four types of fuel:

- gas;

- electricity;

- solid energy carriers (coal, firewood);

- liquid fuel (fuel oil, used motor oils).

Contour

There are the following types of combined heating units: single-circuit and double-circuit.

The first ones have limited functionality - they provide heating for the house, while the double-circuit ones also heat the water.

Since universal boilers are made of cast iron, they are quite massive and therefore have only a floor-mounted design. Cast iron has high corrosion resistance, which is important if liquid fuel is burned.

Tank

Certain models include a hot water tank. Some dual-circuit devices are not equipped with a container; then they are connected to a reservoir, which is installed near the unit.

Almost all heating units are controlled automatically. This is very convenient because you can arbitrarily select a program, adjust parameters and monitor the operation of the equipment.

To ensure warm water supply, combined double-circuit boilers include a heat exchange unit, which is characterized by increased productivity - up to 250 liters of water every hour! It is possible to install a boiler. A double-circuit water heater has several outlets. This will allow you to make warm floors at home and produce heating using radiators.

How to choose an electric wood-burning boiler

Before purchasing a boiler of this type, you should decide on some of its parameters:

1. Boiler power

Power selection is carried out in the same way as for any other boiler. It is best to order a thermal calculation and heating system design from a specialized company. If this is not possible, you can use the average statistical value of the specific power of heating systems, which is 130 W / per square meter. m for houses with an area of 100 - 150 sq. m and 85 W/sq. m for houses with an area of 400 - 500 sq. m. By multiplying the specific power by the heated area, you can determine the required boiler power. So, for example, to heat a house with an area of 125 square meters. m you will need a unit with a power of 125x130 = 16,250 W or 16.25 kW.

Do not forget that an electric wood-burning boiler places special demands on home wiring. Make sure that it will be able to “pull” the unit you like.

2. Weight

Devices of this type, especially powerful ones, are quite massive. Before purchasing a boiler, evaluate the load-bearing capacity of the floor and the possibility of strengthening its structure in the room where the boiler room will be located.

3. Material and design of the grate

If wood fuel predominates, you should choose a boiler with a cast iron grate. If you plan to use bulk fuel frequently, choose a model with a honeycomb grille, which is made of ceramic and steel.

4. Availability of a second heat exchanger

Today, a combined wood-electricity boiler with the ability to connect to a hot water circuit is a fairly popular product, but it is not suitable for everyone

The fact is that at the moment of using hot water, all the attention of the boiler switches to it. In this case, the heated coolant stops flowing into the heating system, since it is it that is used to heat water in the second heat exchanger

If for some needs you have to open the hot water tap for a long time, installing a double-circuit boiler does not make sense. In this case, you will simply be left without heating.

5. Heat exchanger material

Cast iron heat exchangers are considered the most preferred. They are not subject to corrosion, due to their high heat capacity they can smooth out short-term drops in boiler power and do not have weak points in the form of welding seams, since they are prefabricated. The steel heat exchanger is a welded structure, it is less durable and is susceptible to rust, but, unlike cast iron, it does not collapse under sudden temperature changes.

Features of the use of multi-fuel systems

Any option has advantages and disadvantages: an electric wood-burning boiler is no exception.

- For example, compact heating devices cannot be fully dual-mode. To heat a medium-sized home, a solid fuel boiler with a capacity of 20 kW is required. To fully replace the energy source, a heating element of similar power is required. In fact, multi-boilers use heaters with a power of no more than 6 kW. We are talking about systems that are affordable. Of course, the efficiency of an electric heater is higher than that of solid fuel, but still, 5–6 kW is not able to warm up an entire house. Therefore, the system considered is only auxiliary. If you want to use electricity to its fullest, you should install a double-circuit storage boiler.

In this case, you can accumulate heat using an electric heating element, using it during low tariff periods (for example, at night). Then organize heating with solid fuel, with heat backup from the boiler. - Another problem is condensation on the inside of the firebox. An inoperative solid fuel combustion chamber, together with a hot coolant, provokes droplet formation. This leads to unwanted corrosion. To prevent this phenomenon, install a small circuit with a three-way valve.

When kindling, condensation will not occur, and dampness will not interfere. - When the boiler is left unattended and the wood burns out, cold air moves in the combustion chamber. The jacket with the coolant, which is heated by the heating element, is forcibly cooled, reducing efficiency. This cannot be dealt with, since the operation of the automation that closes the chimney damper can lead to carbon monoxide entering the room (such devices exist, but they are quite expensive). Therefore, you have to put up with this problem.

Using long-burning TT boilers

Not every homeowner has the technical ability to connect powerful electrical equipment, which includes combined and purely electric boilers. The reason is the limitation of the allocated power limit for a private house. The size of the limit depends on the capacity of local power supply networks, which the owner of a country cottage cannot increase.

In the absence of natural gas on the site or with the high cost of connecting to the main line, there is only one real solution - buy a long-burning wood and coal boiler or make it yourself. The operating time from 1 load for a conventional TT boiler is 3-6 hours, which forces the owner to work near it as a stoker. A comfortable interval between fuel additions is at least 8 hours, and not every heater provides that much.

The latest pyrolysis boiler with an increased firebox volume ATMOS D30

The trouble is that any seedy manufacturer calls their products long-burning boilers in order to sell them to an ignorant user. You can recognize the correct unit among other heat generators by the following features:

- with the same power, a boiler with a large power reserve is equipped with a firebox of increased volume (from 100 l) and differs in size;

- the passport indicates a burning duration of 8 hours (on wood);

- For convenience, the unit is equipped with an additional loading door.

Detailed information about heat generators of this type and recommendations for their selection are published in a separate topic.