Operating a stove in a home requires the removal of smoke from fuel combustion to the outside. For this purpose, its design has a special pipe with access to the roof. Let's look at what a brick chimney is and how it works, what are its main advantages and disadvantages, what types of it exist, what main parts it consists of and how to correctly calculate them, what stages the laying procedure consists of and what are their features, and also what are the recommendations for its maintenance.

Brick chimney on the roof of a house Source etokirpichi.ru

Chimney - what is it, purpose, principle of operation

Any home stove must be equipped with a smoke exhaust structure. As a rule, this is a pipe made of the same material as the stove itself. The chimney is mostly vertical. In the upper part it opens onto the roof to release fuel combustion products into the surrounding space. The lower part is connected to the upper passage of the furnace itself.

The mechanism of operation of the chimney is based on a natural law - draft due to the difference in the density of heated and cold air. As you know, the denser always tends downward, and the less dense always tends upward. Therefore, the air heated inside the furnace with smoke particles rushes upward. At the same time, the smoke exhaust system additionally performs the function of ventilation of the room, since operation requires a constant flow of fresh air.

The intensity of traction is influenced by 2 main factors:

- The cross-sectional area of the smoke exhaust duct. It should be at least 10th of the area of the combustion opening.

Good draft in the chimney Source aqua-rmnt.com

- Pipe height. The higher its value, the better the traction. In addition, this allows you to compensate for the loss of draft in the case of an excessively wide chimney channel. It is considered optimal when the pipe outlet is located 5 meters or higher from the grate.

Note! A common cause of loss of draft in a chimney is condensation on the surface of the bricks inside the chimney. This happens due to hypothermia of its surface due to its large length and lack of insulation. Over time, this can lead to structural failure. The only correct solution to the problem is external insulation using plaster or thermal insulation materials.

Make it yourself or order it

You can make some elements yourself for installing single-layer pipes or lay out a brick structure (if you have the skills of a qualified mason).

But the installation of prefabricated structures can be done with your own hands - this will help save a considerable amount from the family budget. You will have to pay a lot for the services of a qualified team - the amount is comparable to the cost of materials. There is a risk of running into unskilled workers.

When deciding whether to do the work yourself, you need to carefully analyze your capabilities:

- How accessible is the roof;

- do you have friends or relatives who can help;

- Do you have a fear of heights?

- What are your qualifications in performing repair work?

Advantages and disadvantages

The main advantages of a brick chimney:

- The ability of the material to retain heat for a long time. This reduces the risk of condensation, which significantly extends service life.

- Classic style. Thanks to this, the chimney is combined with a wooden, brick, concrete, frame house.

- High strength.

- Low cost of material , especially in comparison with modern analogues made using sandwich technologies.

Brick is the most affordable material for laying a chimney Source oboiman.ru

- Fire safety. The passing gases do not have time to heat the chimney to a critical level.

However, this design is not without several significant drawbacks:

- The internal rough surface is an effective soot collector. Therefore, without regular cleaning, the chimney will simply stop functioning.

- Laying a brick chimney pipe is quite complex both technically and physically - delivering heavy material to the roof, preparing mortar, etc. procedures.

- Large weight of the structure - it is necessary to create a powerful foundation.

- Not the best aerodynamic performance of square and rectangular strokes with a rough surface, for example, in comparison with smooth round metal counterparts.

On a note! The average service life of a brick chimney is 10 years. However, with regular cleaning, care and proper protection, it can be extended several times.

Timely cleaning is the key to successful chimney operation Source mybuilding.tips

See also: https://m-strana.ru/brands/remont-krovli/

Brick chimneys

A brick fireplace system consists of many parts, each of which has a specific purpose. Use Full Service Chimney Diagrams to see the major internal parts of your fireplace system.

The anatomy of a fireplace system consists of many different parts. Every part works to keep the fireplace in your home functioning properly. If any part of the fireplace is not working or is damaged in any way, the system will not function. This can lead to many problems. Learn more about some common problems.

Internal masonry

- Fireplace Chimney Tile: The vertical passage up the inside of the chimney is the chimney. The damper is often called a chimney, but a chimney is a passage. Clay chimney tiles are the most common material used for lining chimney masonry during construction.

- Smoke shelf: The area below the smoke chamber.

- Lintel: The lintel is part of the architectural design of the fireplace. This is the horizontal space between the fireplace opening and the damper.

- Grate: A fireplace grate is usually made of heavy-duty stainless steel and is installed in the firebox to add wood for combustion. The grille is open at the bottom to allow air flow.

- Firebox: A firebox is a box in which a fire is built and burned. It consists of three walls and a floor, built from fire-resistant bricks and fire-resistant mortar.

- Fireplace Damper: A damper is a plate or valve that closes the fireplace flue when the fireplace is not in use. There is a wide variety of damper types due to the unique nature of many fireplaces, and some are easier to replace than others. (If you are having problems with your fireplace damper, please visit our service page for more information).

- Smoke Chamber: The triangular shaped area above the mouth of the fireplace leading to the chimney is called the smoke chamber. (*See example image of smoke chamber).

- Spark Screen/Doors: (not pictured) A screen or glass doors installed in front of the fireplace to prevent sparks from hitting combustible materials around the fireplace opening.

- Hearth Extension: (not pictured) The outer hearth extension is the home's protection zone. This is usually the carpet or the area in front of the fireplace that is not exposed to sparks from the flames.

What is smoke chamber parga?

A smoke chamber is naturally a very rough surface. Often this is simply the way old chimneys were built. Our technicians perform a process that smoothes the smoke chamber to improve the flow of your fireplace. Paring the smoke chamber reduces smoke turbulence, allowing for increased flow, which can greatly improve the performance of your fireplace!

A brick chimney consists of many parts, and each of them has its own purpose. Use our diagrams to see the most basic parts of a chimney.

The anatomy of a chimney system consists of various parts. Each part helps your home's fireplace function properly. If any part of the chimney is not working or is damaged, then your fireplace will not function and will pose a threat to your safety.

External parts of a brick chimney

- Cap with Spark Arrestor: Not all caps have spark arrestors, but we recommend caps with spark arrestors. A spark arrestor is usually a metal/mesh covering that, when properly installed on your chimney cap, prevents embers or sparks from flying out of the chimney (from a burning fire in the fireplace below) and also prevents animals or debris from getting inside.

- Chimney Crown/Cap: The cap is a protective metal covering connected to the chimney crown, which is the top of the chimney and can be a flush crown or an overhang crown (Full Service Chimney™ specialty).

- Brickwork: Masonry chimneys are constructed from layers of brick and mortar.

- Flashing: On the roof, your chimney is covered with a thin layer of sheet metal that is used to protect it from rain or moisture. This layer is applied to the joints where the chimney meets the roof, shoulder, etc. Learn about step and counter flashings and other leakage control methods such as the cricket system.

- Fireplace Chimney Tile: The vertical passage up the inside of the chimney is the chimney. The damper is often (incorrectly) called a chimney, but a chimney is a passage. Clay chimney tiles are the most common material used to line masonry chimneys during construction.

Learn about our stainless steel chimney lining systems to see why chimney lining is the best decision you can make for your home's fireplace and the safety of your family.

Types of chimneys

Based on structural characteristics, chimneys are divided into the following 3 main types:

- Mounted. It is a part and continuation of the stove itself. Mounted on top, it is compact and easy to assemble. It practically does not take up free surrounding space. Disadvantage - can only be used for one specific oven.

- Wall-mounted. It is located as part of a permanent external or internal wall. The purpose of such a chimney is to collect smoke from several sources simultaneously. In addition, having a large area, it can itself serve as an additional heat generator. The disadvantage is massiveness, heavy weight, the need to create a powerful foundation.

- Root. It is a free-standing brick pipe with side entrances into which the chimneys of adjacent stoves are connected through metal pipes. This design takes up a lot of space, so it is installed in cases where other options are not applicable.

Wall view of the chimney Source stroy-podskazka.ru

Recommendation! If one side of a wall chimney faces the street, it must be insulated. Otherwise, condensation will form on its inner surface, which will significantly reduce traction and reduce the service life of the structure.

Fire safety rules

When constructing chimneys, fire safety regulations must be strictly observed.

Particular attention is required to the chimney assembly diagram and the correct arrangement of the nodes for the passage of smoke exhaust channels through the ceilings and roof. You should also not overload solid fuel heating appliances with wood.

The chimney should be isolated from combustible structures by laying basalt insulation. If it is used for non-thermally insulated pipes, then the layer thickness is 300 millimeters; when brick or metal products are used, then 150 millimeters is sufficient.

Device

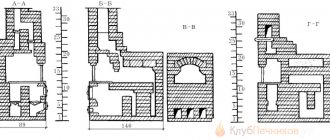

As a rule, the chimney is an extension of the stove, passing through the ceiling, attic and roof and going out onto the street. It contains the following main elements:

- Fluff. It is a section of pipe at the point of contact with the ceiling or rafters. The thickness of its walls is 2-3 times greater than the standard one. The main purpose is to prevent the transfer of heat to easily flammable structural elements of the house.

- Riser. This is part of the chimney that goes from the ceiling to the roof in the attic.

- Otter. A thickened pipe element resembling fluff. It is located immediately after the chimney exits the roof and has an inclination angle similar to the roof slope. The bottom is framed by a metal apron. Designed to protect the pipe outlet from precipitation.

- The neck of the chimney is a continuation of the chimney after the otter.

Construction of a brick chimney Source hometi.ru

- Top protection. The brick cap acts as an umbrella for the lower part of the chimney.

The topmost part is covered by a cap. It protects the chimney channel from precipitation.

Chimney system design

Before we can learn about the anatomy of a chimney, we must understand that there are different types of fireplace chimneys.

There are two main styles:

- Traditional stonework.

- Factory design.

Find out more about prefabricated systems. Which are prefabricated fireplaces built into a structure and made up of different parts than those you find on this page.

This article mainly focuses on the details of masonry fireplaces and the parts that make up your chimney system as a whole. Towards the end we will also discuss gas chimneys (as in a basement or utility room connected to a gas furnace and water heaters).

Use the infographic to reference numbered definitions and descriptions of the 25 different parts of a chimney and fireplace. *Believe it or not, this is not a complete list of chimney and fireplace parts. For example: the smoke shelf, lintel and throat damper are not visible in the first illustration, but can be found in a separate illustration on this page. It shows close-ups of the various parts of the fireplace. Be sure to also check out our blog for more helpful resources on all things fireplaces and chimneys!

Calculation of parameters

When building a chimney, first of all, the cross-section of the channel and the height of the pipe relative to the roof ridge are calculated. The first parameter can be calculated using the formula if the pipe serves as a heat generator and its power in kW is precisely known. For a conventional oven the following rules apply:

- A section of 125x125 mm is formed by a masonry of 4 bricks. Used for summer kitchens and low-power stoves.

- A section of 125x250 mm is formed by 5 bricks. It is used for heating and heating-cooking stove versions, as well as fireplaces.

- A section of 250x250 mm gives 6 bricks. Purpose - structures with maximum fireboxes - fireplaces, Russian stoves.

Depending on where the chimney is installed, the following rules for calculating the height apply:

- At least 0.5 meters above the ridge - when the pipe is no further than 1.5 m from the ridge.

- At the ridge level - at a distance of 1.5 to 3 meters from the ridge.

- At an angle of 10 degrees. between the upper edge of the pipe and the ridge - at a distance of more than 3 meters from the ridge.

Rule for choosing the height of the pipe above the roof Source odstroy.ru

Important! The cross-sectional size of the brick chimney channel and the height of the pipe above the roof directly affect the draft force, and therefore the overall performance of the stove and fuel consumption.

Did you call a chimney sweep?

It is also necessary to take care of cleaning the stove chimneys. For a flow chimney, one or two cleaning doors are sufficient; in a bell-type system, it is necessary to install from two to four such doors, because ash and fumes are deposited evenly over the entire surface of the dome, as well as in the places of transitions from one dome to another.

Gradually, row by row, raising the firebox and chimney passages, we are gradually approaching the moment of installing the cast iron stove. To do this, you need to select a groove in the bricks and mount the hob.

Stages of masonry, choice of mortar and brick

Installation of a mounted chimney is carried out according to the following algorithm:

- The necessary parameters are calculated, bricks, mortar and the necessary tools are prepared.

- The first row is laid around the furnace outlet opening.

- The 1st row is checked with a building level for compliance with the horizontal and vertical planes.

- The subsequent rows are being installed.

- After laying 3-4 rows, the channel is cleared of excess mortar on the walls.

- Before the 3rd row reaches the overlap, a fluff is formed while maintaining the internal cross-section of the channel.

- The laying of rows of fluff continues to a level slightly above the floor of the attic.

- Next, the laying of the riser continues along the original perimeter.

- When the roof masonry is reached, the formation of the otter begins.

- The laying of otter rows continues until its bricks go beyond the roof level located closer to the ridge.

Installation of a chimney on the roof Source legkovmeste.ru

- Afterwards, the laying of the finishing part of the chimney begins to a given height with a protrusion of bricks at the cut - to form the head.

- Finally, a cap is installed to protect against precipitation.

To install a stove chimney, a special masonry mortar is used - ordinary construction mortar will not work. Its composition depends on the location of the pipe section:

- From the pipe to the ceiling in the room, a classic clay-sand mixture is used - similar to that used for laying the stove itself. As a rule, 3 parts clay and 1 part sand are used for preparation.

Delivery of materials

I decided to do all the work on installing the stove and chimney myself during my vacation. And before that, he began to calculate how exactly to bring the chimney through the wall, and what type of chimney to choose.

There was still a problem - how to bring the stove, it weighs 100 kg? After much doubt, the Predatory Mouse decided to do everything alone. At the store, upon purchase, they helped load it into the Chevrolet Niva. And at the dacha he unloaded it himself, carried it without outside help and installed it in the house.

He went to pick up the stove and pipes twice. First I bought a stove and all the necessary components for the chimney. And then he had to buy a stove stand, glass for the stove. For the chimney I bought: pipes, adapters, a tee, a wall outlet, thermal insulating filler - cotton wool, fasteners to the wall and a cap. Everything metal he bought was stainless steel.

After walking around the market and comparing prices, the Predatory Mouse decided not to take a tiny metal reflector measuring 0.5m - 1m for 500 rubles, but purchased 2 galvanized sheets measuring 2m - 1m for 560 rubles each. This was enough for him to protect the wall from the heat of the stove, for the floor under the stove, and still remained to cover the roof of the well.

Video description

Video about how a brick chimney differs from analogues made from other materials:

- Area in the attic - some cement and slaked lime are added to the mixture.

- The pipe above the roof is laid on a mortar consisting mainly of sand, cement, lime and a small addition of clay.

The composition of the masonry mortar must be such that the joints formed are able to withstand the loads occurring in the relevant area. Closer to the firebox there is a lot of heating, in the attic there is an effect of dampness and slight heating, above the roof there is precipitation and temperature changes.

Various types of bricks are used in construction, but which one is better to make a chimney from depends on the characteristics and operating conditions for which they are designed. For example, silicate and pressed ones, despite external suitable signs, are clearly not applicable, since they are not intended for the level of heat produced by a conventional stove.

All that remains is the red fired clay. Specimens of the 1st and 2nd grades, full-bodied with a standard single size, are suitable for masonry. Grade 3, as a rule, is not used due to its increased fragility and brittleness.

Maintenance Recommendations

After installation, the chimney definitely needs maintenance. The first and most important procedure is cleaning. It can be done in several ways:

- Traditional. It is carried out by burning non-resinous wood, such as aspen.

- Reactionary. Along with regular fuel, a special block of combustible components is placed in the firebox. When burned, gases are formed that promote peeling from the walls.

- Mechanical. It involves cleaning the chimney channel with special brushes and brushes on cables. The method is characterized by maximum efficiency.

After the chimney laying is completed, you can heat the stove without problems for a whole season - then soot will begin to actively deposit on the surface of the bricks. Therefore, cleaning must be performed periodically, at least once - before the start of the heating season.

Advantages and disadvantages of installing a steel chimney along the facade and indoors

The answer to the question why most people choose a steel chimney is simple:

Let's move on to the pros and cons of installing a chimney system outside and inside the building.

Ilya Manaev

Helpful information! Steel chimney systems are assembled without the use of sealants. All elements have socket connections. The DS parts are inserted into one another and crimped with a clamp. This guarantees tightness and high reliability of the system. Sealing compounds can only be used to connect the chimney and the heating device.

Advantages of installing a chimney on the facade:

- saving space indoors;

- DS cleaning takes place outdoors (no moisture or dirt);

- it is easier to install the chimney to the facade;

- there is no need to violate the integrity of the roof and ceilings.

Disadvantages of a chimney on the facade:

- if the heating device operates irregularly, an air lock may form in the internal chimney channel;

- a pipe running along the facade can reduce the aesthetic component of the building;

- Ice may form if proper condensate drainage is not organized;

- Single-wall chimneys cannot be used; only double-walled insulated steel chimneys are recommended.

Advantages of installing a chimney inside a building:

- optimal traction is created;

- the service life of the chimney is extended when compared with outdoor placement;

- no negative impact of wind loads and precipitation;

- the risk of damage to the chimney by third-party factors is minimized.

Disadvantages of a chimney indoors:

- during installation it is necessary to violate the integrity of the roof and ceilings;

- when the chimney is located in residential premises, cleaning and drainage of condensate is difficult;

- it is difficult to fix the DS to the mounting surface;

- the chimney may not fit into the design of the room.

Briefly about the main thing

A stove chimney is an essential part of any stove. It has a vertical design and allows you to effectively remove smoke from fuel combustion to the street. The pipe operates on the natural law of draft, the force of which in turn depends on the cross-sectional area of the chimney duct and the height of its location relative to the roof ridge.

According to the type of construction, chimneys are:

- Mounted.

- Wall ones.

- Indigenous.

Their main parts are fluff, riser, otter, neck, head, cap. The main advantages of a brick chimney are the ability to store heat, stylish appearance, affordability, and fire safety. Disadvantages: heavy weight, accumulation of soot, difficulty in installation. The masonry must be carried out strictly in accordance with the instructions. The chimney duct must be cleaned at least once a year using effective methods.