Often, choosing heating for a private home confuses people. Dazzling advertising promises reliability, cheapness and comfort at the same time. In most cases, painfully familiar and outdated heating systems are served under this sauce: gas, diesel, electric. Nothing new except the wrapper! But the future has already arrived and all this has a worthy alternative.

Technological Electrolux inverter convectors, produced by one of the leaders in this field, serve as the basis for creating an inexpensive and, most importantly, highly efficient heating system. The inverter system has a number of undeniable advantages compared to heating with an electric boiler with water radiators.

Inverter heating system based on Electrolux convectors with digital INVERTER control unit and WiFi module

What is an inverter

An inverter is a device that converts direct electric current into alternating current or increases the voltage and frequency of alternating current.

The need for such a transformation arises when creating devices and mechanisms with a sensitive system of settings that respond to the slightest change in environmental parameters. Inverters are used in many areas: electric welding (in fact, a welding machine is a type of inverter), control of electric motors and electric drives, production of air conditioners and heaters, etc. As an integral part of the device, inverters look different and can be customized not have.

The use of inverters in heating

In the production of heating devices, inverters are used as a device that allows precise pre-setting or adjustment during operation of the unit.

High-tech electric heating devices that do not have heating elements, lamps, filaments and heating coils in their design necessarily include inverters as devices for increasing the functionality and efficiency of the heating unit. Such heating means include vortex induction heaters (VIN) and inverter air conditioners. Both of these devices are descended from their less advanced predecessors: VIN - from induction boilers of the SAV type, inverter split systems - from conventional air conditioning systems.

Installation

Installing an induction boiler yourself will not cause much trouble. You just need to follow a few rules:

- do not forget about the mandatory installation of an expansion tank and, in most cases, a circulation pump in the system;

- the power supply network and wiring must correspond to the power of the device; automatic protective equipment will not be superfluous;

- the boiler should be placed at a certain distance relative to the nearest objects;

- The device must be grounded.

Methods for installing inventory heaters

The absence of the need to equip a separate room for an induction boiler, its ease of maintenance, safety, noiselessness and other numerous advantages give this device an undeniable advantage over other devices of similar purpose.

Equipping it with something like an electronic programmer will also allow you to remotely control the heat in your home, which may be a pleasant addition for owners of periodically visited country houses.

How it works: device and principle of operation

In heaters, the operation of the inverter is tied to controlling the ambient temperature and optimizing heat flow. The principle of operation can be clearly seen by comparing the operation of a simple heater (A) and an inverter heater (B).

- Simple heater:

- when connected to the network, the device heats the air to the value set by the user;

when the temperature exceeds the temperature sensor, the device turns off;

- After some time, the air in the room cools down and the unit turns on at full power.

- Inverter heaterThe inverter is built into the control unit, where it converts alternating current into direct current and back into alternating current, but at the required frequency.

- When turned on, the heater brings the air to the user-set value;

- when the desired temperature level is reached, the operating power is automatically reduced - to 5-10 percent of normal power;

- In this way, the temperature will drop at a slower pace and heating will start when the set value is passed.

The consequences of cyclic on-off switching are a jump in power consumption in the network, maximum load on the device during startup and wear of parts.

The figure shows a comparison of the operation of a conventional air conditioner and an inverter.

Separation of electric boilers by type of installation

Depending on their installation location, electrical devices are available in two versions:

Floor-standing versions are used for large volumes of heating of buildings and structures. For small volumes, such as small apartments, private residential buildings, country houses, compact wall-mounted 220V electric boilers are used. They are hung on the wall. They take up little space. They are very convenient to use.

The design of the 220V electric boiler consists of two parts. This is a heat exchanger and a control cabinet. In the heat exchanger, water is heated using thermal heaters; a control cabinet allows you to control the performance of a 220 V electric boiler and maintain the specified parameters of the coolant.

Since heating of objects using these 220V electric boilers is mainly of a closed type, many electrical devices have a built-in or additionally included expansion diaphragm tank. which compensates for excess coolant pressure in the network. They can also have circulation pumps for better distribution of coolant with large volumes.

Thermostats and programmers can be installed, which allow the operation of an electrical device to be used more economically in automatic mode. 220 V electric boilers are most often made as single circuit boilers. To obtain hot water, it is necessary to install an additional water heater, storage or instantaneous.

Main characteristics

The service life of inverter heaters is longer due to the absence of peak loads

The installation converts the incoming alternating current into direct current, and then again converts the direct current into alternating current, but with different characteristics. As a result, the device does not work with mains electricity, but with current with improved performance. This prevents damage to the device during power surges: the heater lasts longer and operates with greater efficiency.

The work scheme is also changing. A conventional heater, when turned on, heats the air to a specified temperature, and when reached, turns off completely. When the sensor signals a decrease in the temperature in the room, the device turns on again. However, starting the device causes a short-term peak load. This mode contributes to rapid wear of parts.

An inverter heater for a home works differently. When turned on, the heater heats the air to the specified temperature, but after reaching it it does not turn off, but reduces the operating power to 5–10%. When the temperature drops below the marked value, the heater increases power.

In this mode, the power gradually increases and decreases, and there are no peak loads. The temperature also changes more smoothly, which allows you to increase shutdown time and reduce electricity consumption.

Inverter heater, convector with inverter control unit, principle of operation.

The inverter heater (also known as a convector with an inverter control unit) first appeared on the market in 2017 under the Electrolux and Ballu brands. The main feature of these heaters is their record low energy consumption - 80% lower than conventional heaters with a mechanical thermostat.

Operating principle of an inverter heater

An inverter convector can most clearly be compared with the climate control system in a car: as soon as we get behind the wheel, the heater turns on at full capacity, using all its resources to heat the car interior as quickly as possible. After it achieves its goal, it does not turn off, but goes into minimum power mode or into temperature monitoring mode. An inverter convector works in exactly the same way: at first it works using all its power, and when approaching the desired temperature, it gradually reduces it, switching to partial load mode.

What it looks like in practice: There is a convector with an inverter control unit and a power of 1.5 kW. There is a room of 20 m2. We need to warm it up to +25 degrees. We turn it on, the heater works at maximum, and the closer the desired temperature gets, it reduces the power of the heating element (therefore, energy consumption decreases) so that the room is not overheated, and when the desired point is reached, it works in minimum mode or simply monitors the temperature. The minimum mode is approximately 300 watts. What is 300 watts? The power of the old Soviet boiler is 300 watts. This power is sufficient when the heater simply has to operate in support mode.

At the same time, if we open a door/window and it becomes noticeably colder in our room, the inverter convector notices the difference in temperature changes and immediately begins to heat at higher power in order to return the temperature set by the person. There are no efficiency tricks here, everything happens by measuring the temperature dynamically (every 10 seconds the control unit measures the temperature and understands what it needs to do - increase/decrease/do nothing) and smart control of the heating element.

Graphic representation of the operation of an inverter heater

Below is a schematic representation of the operating principle of an inverter convector. As you can see, it never turns off, is always in a partial load state, ensuring always even temperatures and minimal power consumption. Inverter convector - green line, conventional - orange line.

Control, safety levels

Simple household convectors are equipped with a subsystem for regulating energy consumption. Switching can be two-stage (full, half power), three-stage (50, 75, 100% power). Most convector heater models are equipped with a thermoregulation stage. The capabilities and accuracy of adjustment of cheap and expensive heaters differ radically.

Of course, the cost of an electronic control unit, compared to an electromechanical one, will be many times higher. Thanks to the high accuracy of temperature control, the energy consumption of an electronically controlled device is reduced by 4-5%. The next adjustment scheme will make electricity consumption optimal - a timer. The watch allows a person to maintain the desired temperature conditions depending on the time of day.

When choosing the best convector heater, pay attention to efficiency indicators and protection levels. The passport of the convector heater indicates the protection class of the heating element from external influences and high humidity

According to international standards, the protection class is marked with IP letters and numbers. If the convector's passport indicates IF24 and higher, the device is used in wet rooms.

Convectors are equipped with protection levels that reduce the level of fire hazard. In practice, the products are equipped with protection against overheating - if the temperature of the heating element exceeds the permissible norm, the convector automatically turns off. Mobile heaters are protected against tipping over. A special sensor controls the vertical position of the device. When deviating from the vertical position, the heating element turns off.

When comparing the variety of types of heaters, it is unlikely that it will be possible to clearly determine which is better - a heater or a convector. Different types of heating devices have different principles of operation, level of energy consumption, and efficiency. When choosing a heater, we proceed from the specific tasks and characteristics of the room. Infrared heaters are suitable for temporary heating of a country house, and mobile electric convectors work advantageously “paired” with the central heating branch as additional heating devices.

Types of inverter heater

The devices can operate on liquefied gas and are suitable for country houses

The inverter is capable of changing the characteristics of the heater if the latter is electronically controlled. The actual design of the heater does not matter. But since the technology is expensive, the unit is installed on high-end models.

By type of fastening

These units can be floor-mounted, wall-mounted or baseboard-mounted.

- Floor-standing ones are distinguished by the presence of wheels, which allows you to transport the unit from one room to another. This suggests that floor-standing options are mobile. For example, when heating one room, you can then warm up another. And given the low power consumption, this device has even more advantages.

- Wall-mounted devices are mounted on vertical surfaces. Less mobile than floor or baseboard ones.

- Due to their special structure, baseboard They have the principle of operation of a water baseboard, when the entire area is heated at once. Another advantage is that the presence of any cold places is suppressed by the heat created, various changes in the room temperature are prevented, and rooms do not fog up. This type of equipment can also be easily moved and transported, just like floor-mounted equipment.

By type of heating element

Presented in 3 types:

- electric;

- gas;

- energy saving.

Electric ones operate from the mains. Such devices are popular among those who purchase them for an apartment.

Gas models operate using gas. The main function is to maintain heat in small areas or even in some unheated rooms. The advantage is that with low fuel costs, the device effectively heats the entire room.

Ergonomics, simplicity and high mobility make them an ideal option for their price.

Energy saving is suitable for those people who do not have a particularly powerful electrical system. Considering the increased efficiency (compared to other equipment of this type), this feature makes this type of equipment even more preferable. If you look at statistical calculations, you can see that the total amount of electricity saved is up to 60%. Very serious numbers, especially with high efficiency.

Also, the elements themselves can be of different types.

- A heating element in the form of a tape or needle. The loops are located on the sides of the plate, and these loops are frangible. Due to the fact that the design does not include fins, the air heats up rather slowly. Nowadays it is rare to find such equipment, since it has not been produced for a long time.

- A heating element (tubular electric heater) can also heat. The tube consists of ribs. The greater their number, the more heat the room will receive. The heating element can heat up to a high temperature, so the efficiency of this device is higher than that of a tape or needle.

- The monolithic type has a special design. The nichrome thread is housed in a ribbed housing made of aluminum. Thanks to this, the likelihood of losing heat is extremely low. Low noise level.

Gas

Such heaters operate on natural or liquefied gas. Since it is a cheap fuel, heating a room costs only slightly more than using hydronic heating. It is designed for heating large areas and is perfect for a summer residence.

Inverter technology increases the efficiency of the device. The burning intensity of the burner changes smoothly, which eliminates the risk of extinguishing the flame. Fuel is consumed even more economically. Inverter units are more compact than conventional gas heaters.

Infrared

The principle of IR heaters is to heat objects in the room, which then radiate heat

The heating elements emit infrared radiation - this is a plus. In this case, it is not the air in the room that heats up, but surfaces, objects and people. This makes it possible to provide comfort at an actually lower temperature.

The heater works the same way as the others: it turns on when the temperature drops and turns off when it rises. An inverter electric infrared heater works without switching off, only reducing the heating intensity. The device consumes much less electricity with high heat transfer. This is important because electricity is expensive.

With heat pumps

This refers to air conditioners that can operate in reverse mode - not only for cooling, but also for heating. The fan blows cold air from the outside, but since the temperature of the refrigerant is still much lower, the latter boils and condenses at the compression stage, releasing heat. The heat is transferred to the air in the room through the heat exchanger. Thus, an air conditioner with a heat pump receives heat from air with a temperature of up to 0 C.

Such a system turns out to be cheaper than an electric heater. An inverter unit makes the air conditioner even more economical. When the desired temperature is reached, it does not completely turn off the installation, but switches it to minimum power mode. Without peak loads, the device operates longer and consumes less electricity.

Convectors

The inverter operating circuit has been introduced into convection-type heaters

The inverter is also installed in electric convectors. Such models are presented by Electrolux and Bally. The principle is the same: the unit does not turn off the device, but reduces the power. The heater operates in maintenance mode most of the time. At the same time, it consumes less electricity and wears out less.

In this mode, heating elements heat up to a lesser extent and less oxygen is burned. Inverter convectors are safer for health.

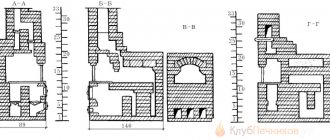

Beam wiring diagram

Pipelines are usually placed in a cement screed on the subfloor. One end is connected to the corresponding collector, the second is brought out from the floor under the corresponding radiator. The finished floor is laid on top of the screed. When installing a radiant heating system in an apartment building, a vertical line is installed in the channel. Each floor has its own pair of collectors. In some cases, if the pump pressure is sufficient and there are few consumers on the top floor, they are connected directly to the collectors of the first floor.

Diagram of a radiant heating system

To effectively deal with traffic jams, air valves are placed on the manifold and at the end of each beam.

Preparatory work

During preparation for installation, the following work is performed:

- establish the location of radiators and other heat consumers (warm floors, heated towel rails, etc.);

- perform a thermal calculation of each room, taking into account its area, ceiling height, number and area of windows and doors;

- select a radiator model taking into account the results of thermal calculations, type of coolant, pressure in the system, calculate the height and number of sections;

- make a routing of forward and return pipelines from the collector to the radiators, taking into account the location of doorways, building structures and other elements.

There are two types of tracing:

- rectangular-perpendicular, pipes are laid parallel to the walls;

- free, the pipes are laid along the shortest route between the door and the radiator.

The first type has a beautiful, aesthetic appearance, but requires a noticeably higher pipe flow. All this beauty will be covered with a finished floor and floor covering. Therefore, owners often choose free tracing.

To trace pipes, it is convenient to use free computer programs; they will help you perform the tracing, allow you to accurately determine the length of the pipes and draw up a statement for the purchase of fittings.

System installation

Laying a radiant system on a subfloor will require a number of measures aimed at reducing transport heat losses and preventing freezing if water was chosen as the coolant.

Between the rough and finished floors, a distance should be provided that is sufficient for thermal insulation.

If the subfloor is a concrete floor (or foundation slab), then a layer of heat-insulating material will need to be laid on it.

For beam tracing, metal-plastic or polyethylene pipes with sufficient flexibility are used. For radiators with a thermal power of up to 1500 watts, 16 mm pipes are used; for more powerful ones, the diameter is increased to 20 mm.

They are laid in corrugated sleeves, which provide additional thermal insulation and the necessary space for thermal deformations. After a meter and a half, the sleeve is secured with ties or clamps to the subfloor to prevent it from moving during the cement screed.

Next, a layer of heat-insulating material at least 5 cm thick is installed, made of dense basalt wool, penoplex or expanded polystyrene. This layer also needs to be fixed to the subfloor using disc dowels. Now you can pour the screed. If the wiring is done on the second floor or higher, it is not necessary to install thermal insulation.

It is important to remember that there should be no joints left under the poured floor. If there are few consumers on the second, attic floor, and the pressure created by the circulation pump is sufficient, then a scheme with one pair of collectors is often used

Pipes from collectors on the first floor extend pipes to consumers on the second floor. The pipes are collected into a bundle and carried through a vertical channel to the second floor, where they are bent at right angles and led to the consumer locations

If there are few consumers on the second, attic floor, and the pressure created by the circulation pump is sufficient, then a circuit with one pair of collectors is often used. Pipes from collectors on the first floor extend pipes to consumers on the second floor. The pipes are collected into a bundle and carried through a vertical channel to the second floor, where they are bent at right angles and lead to the consumer locations.

It is important to remember that when bending, you must observe the minimum bend radius for a given tube diameter. You can view it on the manufacturer’s website, but for bending it is better to use a manual pipe bender

At the exit point of the vertical channel, sufficient space must be provided to accommodate the rounded section.

Pros and cons of the device

Advantages of an inverter heater:

- When the desired temperature is reached, the unit does not turn off, but switches to operation at low speeds.

- It doesn't waste a lot of energy because you don't have to constantly turn the device on and off. Energy savings compared to other heating devices are 30-50%.

- Maintains the set air temperature by smoothly controlling the speed of the compressor motor.

- The device has high performance. It is capable of heating even at very low temperatures.

- Safe and environmentally friendly.

- It operates almost silently, thanks to the built-in fan.

Advantages of inverter devices

The disadvantages include:

- High cost compared to other heating devices.

- Sensitivity to voltage changes.

- Spare parts are not standardized, so repairs may take several weeks.

The language of numbers

The most expensive budget items when installing heating are the purchase of equipment and installer services. The minimum you can expect when installing an electric boiler on a house with an area of 120 square meters. m. - approximately 220 thousand rubles.

The cost of inverter heating for a house with the same area, which means 7–9 inverter convectors, will be 70–80 thousand rubles. To this amount will be added minor costs for cables and sockets.

Convector control via the Hommyn mobile application

Why is it economical

Inverter heaters are considered one of the most cost-effective devices. How does this manifest itself? Let's start with the fact that such systems, having reached the required temperature level, do not completely turn off. The device continues to operate, reducing the speed to a minimum. This process leads to maintaining a comfortable and favorable climate in the room. At the same time, the heater does not waste extra electricity turning it on and off.

In addition, inverter heaters do not use “high current” for starting during their use. This is also beneficial for consumers. When starting the unit, the current does not exceed the rated current. And this has a positive effect on the service life of such devices. In this case, the device is not constantly in the on and off mode. Such cycles significantly reduce the life of the equipment. It is worth noting that, unlike conventional heating devices, inverter heaters can save up to 40% of electricity.

Performance and practicality

Now you know what inverter heaters are. Such heating devices differ from others not only in efficiency, but also in productivity. It is worth noting that an inverter heater is capable of heating a room even at the minimum temperature. At the same time, the efficiency remains quite high. During operation, the equipment shows the ratio of energy expended and the amount of heat generated. This proportion is designated EER. This indicator for inverter heaters is almost equal to 4.

In other words, with a unit consumption of 250 kW, 1 kW of heat is obtained. This indicator is quite good for household appliances.

Operating rules

In order for the device to serve for a long time, it is necessary to adhere to certain rules during operation:

- The distance from the heater to any object must be at least 500 mm.

- The unit cannot be placed under a window opening.

- Experts do not recommend leaving the device turned on overnight; this can only be done if there is a thermostat inside it that regulates the frequency of operation.

- You should not dry things on a heater.

Energy efficiency is now considered one of the most important criteria when choosing heating devices, so you should carefully approach the purchase of heaters. Unlike convective heating (central heating, oil radiators), inverter devices allow you to warm up that part of the air mass where people are, which is very convenient and profitable.

No pipes!

The simplicity and low cost of installing an inverter heating system lies in the complete absence of pipelines. The fact is that the element of the system, the convector, is both a generator and a source of heat. It does not require complex piping, like between the boiler and radiators. There is no need to tap walls, pay increased attention to the reliability of connections, or use a lot of shut-off and control valves.

WiFi module for connecting the device to the WiFi network at home

Manufacturers and popular models: ranking of the best and prices

The most widespread use of inverter heaters in everyday life is in convector heaters and split systems - a new generation of air conditioners with an improved freon conversion mechanism.

Split systems

Among the manufacturers with a developed dealer network on the Russian market are Mitsubishi, Toshiba, Samsung, Aeronik. The most popular are models in the middle price segment, designed to heat a room of 20-30 m2. These are models with low noise levels - within 15-30 dB.

Ballu BEC/EVU-2500

pros

- Convenient control via smart Wi-Fi module

- Easy to install even by yourself

- There is overheat protection

- Interesting design

Minuses

- Short power cord

From 4,000 ₽

The review begins with the best heater, capable of heating the space around it in the shortest possible time. In this case, the module itself does not overheat, but remains at operating temperature. It works almost silently and is absolutely safe. If you are installing it on a wall, then the included mounting brackets are quite suitable. Otherwise, you may need to purchase additional fasteners.

Electrolux ECH/R-1500 T

pros

- Warms the air evenly

- Low cost

- Possibility of connecting a control unit

- Great design

- Convenient wall mounting

Minuses

- Gets dirty easily

From 3,000 ₽

If you need to choose an inverter heater for your home, it is recommended to pay attention to this model. Compact device with good characteristics. Guarantees excellent air heating at some distance from the source. At the same time, energy consumption is much more economical. Manufacturers have slightly modified the shape of the body so that the blinds redirect air flows with the greatest efficiency. The device reaches the desired temperature quickly enough.

Split system Aeronik ASO/ASI-12HM

Development of the Australian company Aeronik PTY LTD. The ASO/ASI-12HM model is positioned as the best solution for allergy sufferers; it is equipped with additional air purification and ionization filters. Another feature of this model is the interchangeable mirror panels of different colors, which allows you to conveniently fit it into the interior.

Characteristics:

- Power in cooling mode: 3200 W

- Power in heating mode: 3400 W

- Heating power consumption: 987 W

- Heating area: 33 m2

- Dimensions of the inner side (WxHxD): 80x29x18.6 cm

- Dimensions of the outdoor unit (WxHxD): 74.5×55.2×32.8

- Price: 23,600 rub.

Toshiba RAS-07EKV-EE/07EAV-EE

Split systems of the EKV series are manufactured at the Toshiba plant in Thailand. The model is positioned as a low-power solution for servicing city apartments with small rooms.

Characteristics:

- Power in cooling mode: 2000 W

- Power in heating mode: 2500 W

- Heating power consumption: 590 W

- Heating area: 20 m2

- Inner side dimensions (WxHxD): 79×27.5×20.5

- Dimensions of the outdoor unit (WxHxD): 66x53x24

- Price: 25,100 rub.

Climate control unit Mitsubishi Heavy Industries SRK-25ZM-S

In terms of consumer properties, this is a premium model. It implements the most comfortable options for the distribution of heat flows. Air purity is ensured by multi-stage filtration, and constant ionization is also carried out even when the system is turned off due to the tourmaline coating of the block elements.

Characteristics:

- Power in cooling mode: 2500 W

- Power in heating mode: 3200 W

- Heating power consumption: 800 W

- Heating area: 25 m2

- Inner side dimensions (WxHxD): 79.8×29.4×22.9

- Dimensions of the outdoor unit (WxHxD): 78x54x29

- Price: 39060 rub.

Samsung AR09HSSFRWK/ER

Modern split system from a South Korean manufacturer. The model belongs to the Luxury line. The AR09HSSFRWK/ER uses its own Visual Doctor technology to purify the air. Can operate in fan mode.

Characteristics:

- Power in cooling mode: 2500 W

- Power in heating mode: 3200 W

- Heating power consumption: 620 W

- Heating area: 26 m2

- Inner side dimensions (WxHxD): 93.6 x 27 x 26.4

- Outdoor unit dimensions (WxHxD): 79 x 54.5 x 28.5

- Price: 35,000 rub.

Convector heaters

According to consumers and experts, the most popular are convector heater models with a built-in inverter from Timberg and Huyndai.

Timberk TEC.E0 M 2000

Timberk convectors are manufactured in Finland. The TEC.E0 M 2000 offers floor and wall mounting options, rollover protection and UltraSilence technology.

Characteristics:

- Heating power: 2000 W

- Overall dimensions (WxHxD): 80x45x8 cm

- Weight: 4.6 kg

- Price: 2600 rub.

The “heart” of the convector is the heating element

The design features of the heating element (heating element) determine the performance of a convector heater:

- durability;

- efficiency;

- energy consumption level;

- price.

If the price of the device is low, a primitive heating element is installed inside - an open spiral. The mentioned convector models are produced by domestic and European manufacturers. Devices equipped with an open spiral have a low IP housing protection class and cannot be used for heating rooms with high humidity. The operating temperature of the open spiral is high (500 degrees), burning dust will cause an unpleasant odor, burn out oxygen, and become the source of a fire when large flammable bodies fall to the surface.

Electric convector heaters with closed-type heaters will be safer and more reliable in operation. Heating elements are formed by a steel tube in which an incandescent filament is placed. The operating temperature of a closed heating element is low - does not exceed +100 degrees. To make heat transfer more efficient, the steel tube is equipped with an aluminum radiator. Due to the high thermal conductivity of aluminum, the radiator quickly heats the circulating air.

The most modern (expensive) models of electric convectors are equipped with a monoblock heater. The heating element and radiator are a one-piece construction. Heating elements are reliable in operation - the product service life reaches 20 years. The heating filament of solid-cast heating elements is placed in a special backfill, which consists of tiny quartz crystals and some other substances. Aluminum alloys are used to make the body. For example, convector heaters (France) of the Noirot brand are equipped with a cast silumin heating element.

The most efficient heating with minimal energy consumption will be provided by combined models, for example, a convection-infrared heater. In addition to the heating element, an infrared panel is installed. Distinguish the unit from a typical convector by its appearance - the front panel of the convective infrared heater is perforated, the flow of infrared radiation unhindered illuminates the room.