The use of autonomous units for generating electricity is justified from both economic and practical points of view. However, for people living far from civilization, it is quite expensive and troublesome to purchase and transport natural gas or liquid fuel to their homes. In such a situation, a wood-burning gas generator comes to the rescue. Let's look at what this equipment is, how it is designed and on what principle it works, what types it is divided into, what its pros and cons are, and the rules for installing modern models.

Checking the operation of a wood-burning gas generator Source ytimg.com

Wood gas generator - what is it, device, principle of operation, application

In autonomous installations for generating electricity for the needs of a private home, an internal combustion engine is used. It can operate on gasoline, diesel fuel or natural gas. However, when it comes to remote areas, delivering such fuels will be economically unprofitable and technically difficult.

An alternative solution to this situation is a wood-burning gas generator. The motor of such a unit is powered by a mixture of gases - mainly hydrogen, carbon monoxide, methane and some other hydrocarbons. They are formed under special conditions during the thermal decomposition of wood, coal, peat, organic matter and other suitable types of solid fuel.

Device

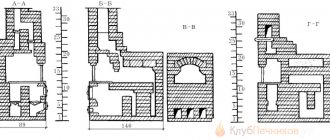

A classic domestic wood-burning gas generator installation consists of the following main components:

- Frame . It is made of steel and can have a cylindrical or rectangular shape. Installed on special legs.

Diagram of a wood-burning gas generator Source gengas.lagunof.com

- Loading department . It is located and secured inside the housing. Designed for loading fuel through a special hatch, the edges of which are equipped with a special fire-resistant seal.

- The combustion chamber . It is heat resistant and is located at the bottom of the loading section. It directly burns fuel. To carry out thermal decomposition of resins, a special neck is equipped in its lower part. In the middle of the chamber there are special lance openings connected to an air supply device. The latter is equipped with a check valve to prevent the escape of flammable gases.

- Fan . If it is necessary to increase efficiency, as well as improve the combustion of certain types of fuel or very damp wood, the air distribution module is additionally equipped with a fan or turbine for increased air supply to the firebox.

- Grate bars . Installed at the bottom of the combustion chamber. Their main purpose is to support hot burning coals and separate the burnt substance - shedding ash into a special ash pan located below.

Gas generator installed on a car Source hsto.org

- Hatches . Special hermetically sealed lids - the top one for loading fuel with a device for equalizing pressure inside, the side one for loading into the recovery zone and the bottom one for removing slag.

- Gas pipeline . A pipe for removing the resulting mixture of gases from the combustion chamber. Due to the high initial temperature and the need for cooling for further use, it is specially carried out along a ring-shaped path in the cavity between the installation body and the loading chamber. This allows not only to cool the gas, but also to pre-dry the fuel before it enters the firebox.

- Filtration system . After leaving the chamber, the gas requires mandatory cleaning from soot and other suspended solids. Therefore, it is first fed hot into a coarse filter, and then, when cooled, it is subjected to finer filtration.

Upon completion, the purified and cooled gas mixture is fed into the mixing unit. Here the gas is saturated with oxygen to the required degree. Only after this is it supplied to the internal combustion engine.

An example of a household wood-burning gas generator Source ytimg.com

See also: Catalog of companies that specialize in electrical work of any complexity

Mechanism of action

The operating principle of a wood-burning gas generator boils down to the fact that under conditions of elevated temperature (about 1200-1500°C) and low oxygen levels, the wood does not burn as usual, but smolders, releasing generator gas, which serves as fuel for the internal combustion engine. The mechanism of operation of the installation is reduced to the following step-by-step processes occurring in the corresponding zones of the generator:

- Drying fuel . At a temperature of about 160-190°C, the firewood located in the uppermost part of the loading section is dried under the influence of gases passing through a ring pipeline.

- Dry distillation . In the middle part of the unit, where the heating level reaches 450-500°C, the wood is charred. As a result, in addition to coke, tars, acids and other products of low-temperature decomposition of fuel are formed.

- Burning . In the lowest part of the installation, at a maximum temperature of 1100-1500°C, charred fuel and decomposition products burn to carbon dioxide and carbon monoxide.

Reverse gas generator design Source uazbuka.ru

- Recovery . Carbon dioxide formed and heated in the lower part rises to hot coke and interacts with carbon and water, resulting in the formation of carbon monoxide and hydrogen.

In the combustion and recovery zone, not only combustible gases are formed, but also ballast gases. The former include carbon monoxide, hydrogen, methane and some unsaturated hydrocarbons, the latter – carbon dioxide, nitrogen, oxygen and water vapor. In addition, raw flue gas contains many inclusions in the form of slag, ash, and organic acids. Therefore, before putting it into the internal combustion engine, it must be thoroughly cleaned. For this purpose, coarse and fine filters are used.

Application

With high quality fuel, well-established technology and forced air supply, wood-burning gas generators achieve such high efficiency that they are even installed on cars. However, in most cases, their main area of application is objects and houses with an abundance of wood and difficult access to other types of energy resources (electricity, gas, gasoline, fuel oil, etc.).

Gas generator near the house Source ytimg.com

Wood generators are used in the following cases:

- For electrification of houses in remote areas without access to power grids.

- To ensure uninterrupted supply of electricity at facilities of high importance - military, scientific, medical bases.

- In industry - as an alternative source of electricity generation in the presence of associated production waste - wood chips, sawdust, scraps of building materials, etc.

Note! For stable and high-performance operation, the generator requires initially loading well-dried fuel. Thus, the use of raw firewood reduces efficiency by 25%. In addition, when raw wood smoulders, refractory resins are formed, which quickly clog the pipeline system, which will already lead to a decrease in the efficiency of the unit and will require frequent cleaning.

How does not stop working on coal, wood, coke

different types of solid fuel as fuel : coal, firewood, charcoal. Most consumers use specialized waste obtained after processing plants. The most important argument for excellent heating of the device is the heat transfer of solid fuel, due to this, most consumers use fuel with the highest efficiency.

Most solid fuel generators are capable of delivering an efficiency of 90% . The devices provide heat for 5-8 hours , and one addition of solid fuel is sufficient.

The most popular boilers are made of cast iron or steel . Cast iron hot water boilers are very popular, as this metal is capable of generating heat for a long time.

However, this material is quite fragile, since cast iron is subject to overheating , and as a result, cracks appear on the boilers.

Steel boilers are less susceptible to temperature changes, but have a number of other disadvantages.

When working with these heat generators, it is worth regularly loading fuel into the combustion chamber. Equipment operating on solid fuel requires special and continuous attention from humans, however, at the same time, their convenience lies in the general availability of solid fuel.

Advantages and disadvantages

A gas generator machine for the production of flue gas, operating on wood, is characterized by the following number of advantages:

- High efficiency. Under accompanying conditions, the value can reach 95%.

- Up to 25 hours of burning per load of firewood.

Large sawdust gas generator for electricity generation Source d-system.ru

Tips for choosing

Before purchasing a heat generator, it is worth deciding on the parameters for which it will be responsible. The type of fuel on which the heat generator will operate is selected in advance Gas is the cheapest.

If the durability of the device is important, then you need to look at diesel backup power plants. They are also productive, but have the disadvantages of noisy operation of the device.

Electric generators do not require specialized permits, but are not very popular among consumers due to the low price of electrical energy

The power parameter is a key factor when choosing heating devices. If installation is required for private use, then do not purchase models that generate excess energy.

Installation Rules

When installing gas generating units using wood, it is recommended to follow the following rules:

- Installation of equipment is allowed anywhere in the house - basement, basement, room - as well as outdoors, subject to safety precautions and technical conditions.

- Models designed for loading long firewood are best installed outdoors near the fuel storage area.

- For installation inside the house, it is better to choose a generator that runs on pellets. Since their storage and operation does not involve the generation of waste.

- In the case of using flue gases for heating and minimal cooling, pipes to the house from a unit installed on the street are laid in thermal insulation and underground.

Recommendation! Gas generators exhibit maximum performance when fully loaded. However, the amount of energy generated can be excessive. Therefore, in order to preserve it, for example, for heating, it is necessary to use special heat-insulated containers - heat accumulators.

Alternative options

With the help of modern technologies, it is possible to further improve the overall heating system; for example, pyrolysis boilers, which are designed specifically for heating with wood, are becoming increasingly popular. They are not particularly sophisticated and are gradually appearing in many homes (more details: “How to make pyrolysis boilers with your own hands”). The main difference between such boilers and stoves is that they operate on the principle of gas generators, that is, the room is heated when the wood burns out. This allows the entire system to work autonomously, since it does not require electricity (pro

Briefly about the main thing

Modern models of wood-burning gas generators are so effective that they can even be installed on a car. However, in most cases, it is a successful way to save on fuel for remote areas where, apart from firewood, there are no other types of energy resources, and delivering them there is unprofitable. Simplified, the unit consists of a housing, a loading chamber, a firebox and an ash pan. Its operating principle is based on the thermal decomposition of wood or coal at low oxygen levels, and subsequent reduction to carbon monoxide and hydrogen.

Flue gases are cooled, purified and mixed with oxygen before entering the internal combustion engine. The main advantages of gas generators of this type:

- Great efficiency.

- Up to 25 hours of burning per load.

- Complete burning of wood.

- Power adjustment.

- No harmful emissions.

- Economical.

- Possibility of using raw wood.

- Operation on other types of fuel.

- Safety.

- Large chamber volumes.

The disadvantages are manifested in the high cost, energy dependence of modern models, the possibility of clogging, gas temperature control, manual loading, and the need to use dry fuel. In this case, there are 3 varieties - direct, reverse and horizontal. Each of them has its own pros, cons and application features. The installation of the unit must be carried out in accordance with the regulations.

Specifics of heat generators using liquid fuel and gas

This type of heating unit can operate on natural gas or diesel. New models have a function for quickly changing the type of fuel . For this purpose, a specialized burner and an additional power distribution cabinet are provided.

This type of generator does not stop working according to the following principle : fuel enters the firebox, where it is mixed with air entering through the ventilation, after which the heated air goes through the heat exchanger and spreads throughout the room.

?

The characteristic feature of liquid fuel heat generators is their ease of operation . To start heating, just fill in the fuel and start the device. And the low price .

Such heaters are mobile , so their use will not cause unnecessary problems.

Air heating

Air heating is required to maintain a comfortable temperature during the cold period. And what exactly this temperature is is described in GOST 30494-96. So, for residential premises the norm is +20 degrees, for corner living rooms - +22 degrees. For the kitchen - +18 degrees, the bathroom - +25 degrees, and the toilet - +18 degrees. Note that such standards are suitable for apartment buildings.

The power calculations that designers usually rely on when creating air heating and ventilation give fairly average values - and it will be difficult to accurately determine heat leaks. In addition, they change depending on the current temperature, wind and humidity outside.

Components of air heating

But for quite a long time there has been a methodology that can be based on in the case of independent design. The instructions here are quite simple: for 1 cubic meter of room you need 40 W of thermal power. We add 100 W of heat to each window opening. For each door that leads to the street - 200. The coefficient for corner apartments is 1.2-1.3, for private houses - 1.5. A regional coefficient is also applied: 0.7-0.9 for warm regions, 1.2-1.3 for the European part of the Russian Federation, 1.5-2.0 for the Far North and Far East. When the temperature outside is warmer, in order to regulate the temperature in the house without opening the windows, you can replace the radiator valve with a throttle or thermostatic head.

How to choose a heat generator for a private home: recommendations, calculations, invisible moments

When choosing, the main thing is not to forget to take into account these parameters, such as:

- The area of the heated area - the higher it is, the more powerful the fan must be in the set;

- Heat capacity of the room - determines the power of the upcoming unit, calculated by the formula:

p – heat capacity (required value);

V is the volume of the heated area (calculated by multiplying the length, width and height of the residential area);

?T – temperature difference in the heated room and outside it;

K – thermal insulation indicator (you can look it up in the reference book, knowing what materials the building itself is made of); most popular indicators:

- 1-1.9 – double layer of brick (thick wall);

- 3-4 – sheet of profiled flooring or wood panel;

- 2-2.9 – a simple layer of brick;

- 0.6-0.9 – modern walls with hydro and thermal insulation.

860 is a multifunctional indicator that demonstrates the number of kilocalories in kilowatts.

- The presence of a working ventilation system guarantees proper operation without interruptions in the heat supply. Generally accepted standards indicate that for 1 kW of generator power, at least 30 cubic meters of forced air are required.

Of these three indicators, heat capacity is considered one of the most important when choosing the optimal model. Knowing this value, you can choose a similar model that will ultimately satisfy the heating needs. Let's look at an example of how this looks in action.

We have been given a house with an area of 100 m2? and a wall height of 3 m 50 cm. The house was built from a double layer of brick. The temperature we need, which must be maintained in the room, is 25°C. The temperature behind the surfaces of the walls of the house (the average standard for all winter months is taken) is -14°C. So, we calculate according to the formula, substituting all the necessary values:

In other words, in order to have a temperature of at least 25°C in a house with double wall surfaces when it’s cold outside, our heat generator must have a power of at least 8.6 kW.

Before purchasing a heat generator, you must do three things:

- Clear the chimney where toxic gases generated during fuel combustion will escape.

- Take care of creating ventilation ducts through which warm air will circulate.

- Determine, using the proposed formula, what the smallest power of the unit will be needed for real heat supply.

Only after this can you go to the supermarket and choose the best heat generator model. A large number of manufacturers, as well as a number of models, will make even an experienced specialist get lost. To choose the highest quality model that will serve you well for many years, you need to pay special attention to such invisible points as:

- the type of burner and its design - this will be required when it becomes necessary to remake it, changing the type of fuel;

- the presence of technical passports, as well as a coupon for warranty repairs, will protect the client from counterfeiting, and will also protect against low-quality equipment;

- the quality of product parts - the higher it is, the more expensive the cost, but this also increases the service life.

Recommendations during purchase

Recommendations and advice can help avoid troubles, and will also protect everyone from bad goods.

- Purchase equipment only from certified points of sale (the document must be available and freely available to consumers) - purchases via the Internet or from wholesale stores very often drive the client into a frenzy. Qualified marketing masters, under the guise of good equipment, sell defective equipment. The halved price is a trap. It’s better to pay a couple thousand more, but still get quality and reliability, than to purchase another generator a few years later.

- If it is not possible to calculate the required power, you can go to the supermarket knowing the total area of the house, the height of the walls and their thickness. Qualified craftsmen will make the calculations on their own, offering the most suitable models specifically for your home.

- Buy well-known brands or those that have good reviews on the Internet. Nowadays, reading a review about any product without purchasing it is very easy. This will give you the opportunity to learn about how the device behaves in operation and what its operating features are. All comments in most cases are written by people who are considered customers of heat generators, thanks to this you can learn from other people’s experience and get to know the model before it ends up in your home.

The best models for home use

Among the most affordable and best models of heat generators that have shown their best side, it is necessary to highlight the following:

- Airmax D 28 - this model has a power of 28 kW, which is quite enough to heat a private home. The stationary floor model can be located both in the basement of a residential building and outside it (in a barn or an extension).

- Titan 25 (30, 35) – with a power of 25 kW and a large-diameter fan, you can quickly heat areas of up to 250 square meters. As a rule, it has different burner configurations, making it possible to use both solid and liquid fuels.

- Fuela is a diesel heat generator designed to heat up to 100 square meters.

- TG-7.5 is a heat generator using gas. With a power of 7.5 kW, the device is quite profitable.

- Dragon 12 is a solid fuel multifunctional heat generator capable of running on wood, cake, manure and coal. Convenient when used on a farm.

Likewise, heat generators used to heat large areas may vary from one to the next.

Their significant advantage over other types of heating systems is their high efficiency, which is achieved due to the absence of an intermediate heating element. The fuel obtained during the combustion process is completely spent on heating the air, which is circulated thanks to ventilation. Boilers can be located both indoors and outdoors. The variety of choices will help you choose a device of any power and innovative indicators, which are sufficient for a properly functioning heating system.

Rules for the safe use of guns

It is no secret that all home-made devices are objects of increased danger, because improper design and assembly can cause fire, electric shock and other troubles.

But most accidents occur not so much due to design errors, but rather due to simple neglect of safety measures.

Heating with heat guns is a popular technique in the cold season, but it is important to ensure a uniform flow of heat and prevent frozen car parts from touching the hot heater elements

Let us recall the basic operating rules:

- All direct heating heat guns can only be used if there is good (preferably forced) ventilation. But even in such conditions, staying longer than a couple of hours in a room with a direct-flow diesel or gas gun is fraught with headaches and other symptoms of poisoning.

- The body of the gun (especially if it is made of metal) gets very hot during operation, because, unlike factory models, homemade devices are not equipped with heat-insulating layers inside the casing. Therefore, it is important to take care of a stable base, which will prevent the cylinder from spontaneously rolling, and a handle that does not heat up.

- The “barrel” of units with open burners should be covered with a protective mesh screen, and it is advisable to equip the electric gun with grounding.

- Never direct hot air towards fuel cans or gas cylinders. And in general, the distance from the hot air outlet to the nearest object should be at least 2 meters.

- To ignite the burner in a gas and diesel gun, use a special lighter with a long handle.

- Before turning off, let the fan run without fuel for a few minutes so that it can cool the device.

And lastly, no matter how confident you are in the quality of the assembly and the safety of the connections, never leave your homemade gun to work unattended.