Korean heating equipment is reliable, as confirmed by experts and users. But it happens that she also refuses to work. Navien gas boiler repair statistics show: in 80–90% of cases, problems that arise can be dealt with on your own . The article deciphers the symbolism of errors appearing on the display and gives recommendations for troubleshooting.

Photo of the main panel of the Navien boiler

* Navien gas boilers are available in different modifications: convection (with atmospheric burner), turbocharged, condensing. The malfunctions that arise are identical for all types of heating equipment of this brand. Therefore, errors appearing on the display are interpreted in the same way, with rare exceptions.

Heating boiler Navien: the best of its kind

The Navien boiler is considered the most popular among heating and heating devices. The company presents only high-tech models for installation in all kinds of premises. On sale, everyone will be able to find a device that will serve them well for a very long time - and all this at a fairly attractive price. Wall-mounted solutions are best suited for heating apartments and small private houses.

Korean Navien gas boilers are double-circuit boilers that have an open and closed combustion chamber. They are used for heating and heating water for domestic and technical purposes. The entire automation system and documentation have been translated into Russian, thanks to which everyone can easily study the existing instructions, as well as successfully save on heating costs by continuously maintaining the desired temperature in the premises. Uninterrupted and safe operation of the boiler is possible even in conditions of frequent power outages. If the voltage in the network fluctuates, the SMPS protection system is activated, after which the boiler continues to operate properly. In particular, thanks to this function, these double-circuit boilers have a long service life without breaking down or requiring subsequent repairs.

Types of wall-mounted boilers

Atmospheric gas boiler NAVIEN ATMO 24-AN

There are three types of wall-mounted heating devices of this class on the domestic market:

- Navien atmospheric (open) boiler;

- turbocharged wall models;

- condensing devices.

Each of these positions requires separate consideration.

Atmospheric gas boilers

Units of this type have an open combustion chamber. Represented by the Navien Atmo model. It is intended for operation in conditions of uneven gas pressure (its differences can reach 8-17 mbar) and the coolant itself - from 0.6 to 8 bar. The power of the offered units varies from 13 to 24 kW. At an operating temperature of 80°C, the coolant heats hot water to 60°C with a production volume of 10 liters per minute. To remove combustion products, they are equipped with standard chimneys.

The heating circuit in atmospheric boilers is made of copper, and the heat exchanger body is made of stainless steel.

Turbocharged units

Turbocharged boiler Navien Deluxe 10 Coaxial

The group of units of the second type (with an isolated combustion chamber) includes models of the following series:

- Prime, represented by boilers with a capacity of about 13-35 kW;

- Deluxe, whose declared power ranges from 13 to 40 kW;

- modern Smart TOK models with an indicator of 13-35 kW.

Portions of air are forced into the isolated combustion chamber - they are pumped through a special fan installed in a coaxial pipe. Thanks to this, units with a Coaxial design have a higher efficiency, sometimes reaching a record figure of 93%. Gas boilers from the Navien Deluxe series are able to withstand significant changes in supply voltage, as they are equipped with a built-in stabilizing device. In addition, they have the option of automatically maintaining the temperature of the media at a level not lower than the “cooling point” (6-9 degrees).

Condensing boilers

Condensing gas boiler Navien NCN 40KN

The third type of Navien gas boilers is represented by samples of equipment from the NCN and NCB series. Due to additional heating of the carrier with the heat of the condensate, their efficiency was increased to 99%. The functionality of these units is even higher than that of turbocharged boilers - the controller built into them allows you to set temperature parameters for a week in advance.

The Navien NCN product series includes four varieties with power from 22 to 40 kW, and NCB has the same number of products with ratings of 24-40 kW. The water in them is heated to 65°C, and the coolant circulating through the pipes is heated to 90°C. These units are able to withstand media pressure up to 10 Bar.

The air supply in equipment of this class is organized through a coaxial or conventional chimney.

Features of choice

Gas boiler Navien DELUXE COAXIAL 24K

The most popular among consumers are the white varieties of Navien boilers with a stated power of up to 16 kW. They are represented on the sales market by the following original models:

- Deluxe Plus 16K brand products;

- wall-mounted boilers Deluxe Coaxial 16K White;

- equipment under the brand name ATMO.

All units marked with the Kotel brand name have similar characteristics, and minor differences mainly concern only individual components and parts. When purchasing them, special attention is paid to the warranty provided by the manufacturer and the presence of a quality certificate. The demand for boiler samples with a declared power of more than 25 kW is not so great, since their cost is significantly higher.

Gas boiler care

To avoid problems with the boiler, you should master the basic techniques for caring for it. In order not to lead the situation to the need for repairs, the user must adhere to the following operating rules:

- keep the boiler clean, avoiding accumulation of large amounts of dust;

- periodically check the voltage in the network;

- control the coolant pressure and prevent it from falling below the limit level.

To ensure reliable protection of the purchased equipment, careful familiarization with all typical errors and the ability to eliminate their consequences will help.

. and without construction experience

My works for 2022.

How I set up the Navien boiler, pump and blower run-out

First, the question is, why regulate the run-out of the pump and blower, well, probably so that they work less and wear out less, as I noticed, while with the experience of the boiler in winter mode, the blower spins after stopping the boiler for another 1 minute, at this time there is cold air from the street, no longer heating up in the coaxial chimney, it intensively cools the boiler heat exchanger, which is generally detrimental to its health, and unnecessary heat loss into the atmosphere, i.e. it is possible, without damage to the boiler, to reduce the fan run-out time, about this procedure, and at the same time, about the procedure for reducing the pump run-out (relevant in summer mode, when the boiler is turned on only to heat hot water, and turns off again), in more detail and in order

Post-purge control mode (pump and fan run-on)

The procedure for installing stages on the boiler remote control display

1 Turn off the power from the boiler remote control

2 Press the “battery” and “hot water” buttons

buttons battery and hot water

3 The display will show mode P1 for setting the pump run-on in summer mode

mode P1 will be displayed

4 Press the “hot water” button to set the pump run-on in summer mode

Press hot water button

5 Press the + or - buttons, the display will show the numbers 10 or 40, when selecting number 10, the pump run-out will be 5 minutes, when number 40 = 20 minutes, select the option you need

Press the + or - buttons to select the coasting option

6 Press the “hot water” button to exit the pump overrun setting mode

Press hot water button

7 Click the + button

8 The display will show mode F1 to set the blower run-on in summer mode

The display will show F1 mode

9 Press the hot water button to set the blower run-on in summer mode

Press hot water button

10 Press the + or - buttons, the display will show numbers 1 or 2 or 4, when selecting number 1 the blower will run for 30 seconds, when number 2 = 1 minute, when number 4 = 2 minutes, select the option you need

Press the + or - buttons

11 Press the “hot water” button to exit the blower run-on setting mode

Press hot water button

12 Click the + button

13 The display will show mode P2 for setting the pump run-on in winter mode

P2 mode for setting the pump run-on in winter mode

14 Press the “hot water” button to set the pump run-on in winter mode

Press hot water button

15 Press the + or - buttons, the display will show the numbers 10 or 40, when selecting number 10, the pump run-out will be 5 minutes, when number 40 = 20 minutes, select the option you need

Click the + or - button

16 Press the “hot water” button to exit the pump overrun setting in winter mode

Press hot water button

17 Click the + button

18 The display will show mode F2 for setting the fan run-on in winter mode

F2 mode for setting the fan run-on in winter mode

19 Press the “hot water” button to set the fan run-on in winter mode

Press the "hot water" button to set the fan overrun

20 Press the + or - buttons, the display will show numbers 1 or 2 or 4, when selecting number 1, the blower will run for 30 seconds, when number 2 = 1 minute, when number 4 = 2 minutes, select the option you need

Press the + or - buttons

21 When all settings have been made, you must wait 10 seconds, or press the off button on the remote control once

Wait 10 seconds or turn off the boiler from the remote control

That's it, all settings are completed, you can use it

If anything, I have an engineering menu file for download from the Koreans with a crooked translation, but in it everything that I could tell on the pages, well, maybe a little more, there is just a mention that if the boiler remote control fails, then by shorting the remote control wires from the boiler itself, you can turn it on, but it will heat the heating system up to 80 degrees, but at least we won’t freeze until we buy a new remote control, or the repair team arrives with a spare remote control!

How to reduce the power of a gas boiler: ways to reduce

Hello, dear readers. Many owners are interested in how to reduce the power of a gas boiler? After all, it begins to consume a lot of fuel, strong noises and clicks appear in it. It feels like it might explode. To resolve the issue, there are general recommendations and points for certain brands and models.

A gas boiler is a necessary device in the house. It handles heating tasks and solves the hot water dilemma (if the model has two circuits). However, there are often cases when the power of the equipment goes off scale, which is fraught with significant waste of fuel and strong heating of the device. Therefore, the question arises of reducing these parameters.

Classic methods

To reduce the power of equipment, you need to apply these methods (one or both):

- Burner power decreases. Parameters are achieved at which the automatic system sets the stable operation of the device with a connected heating system.

- Increasing the maximum power parameters of the heating circuit. The process comes down to installing additional radiators or replacing existing ones with more powerful analogues.

Both options can be used. To do this, the difference between the power of the heating circuit and the device itself is reduced: radiators are changed or more powerful units are installed. The existing difference can be compensated by adjusting the power of the boiler itself.

Method No. 2 is less financially profitable, but if there is an urgent need, it is inevitable. Especially when there are radiators that do not have thermal power reserves.

And in cold weather, to maintain optimal temperature data in the room, it is necessary to send water with readings of more than 75 degrees to the radiators. In this situation, organic dust particles burn on the radiators, and a foul smell is formed in the room.

The boiler also has a negative impact - its polymer, plastic and rubber components deteriorate.

It is more effective to reduce the power of boilers of this brand by reducing the fuel supply to the burner. To do this, reconfigure the gas valve.

The Proterm Cheetah model is taken as an example.

A Honeywell valve is used here. Externally, it is a yellow connector with wires. It is mounted on a stepper motor, which helps change its settings.

The specified electric motor is controlled through the control panel: you need to go to the service menu. Access to it appears after entering the code.

The procedure is as follows:

- Press and hold the “Mode” button for 6-7 seconds. The display will show the number 0.

- Use the + or – buttons to enter the number 35. This is the code. Press the indicated button again.

- When the first line of the menu with 0 signs appears on the screen, also using the + or – buttons, enter the number with the required line number: d.**.

- Changing parameters. “Mode” is pressed again. This is a transition from line numbering ** to the indicators themselves. The “=” symbol and the power parameter are displayed in turn on the screen. Change the values using + or -. After three seconds, the new setting is automatically confirmed.

- Return the display to its original state: press “Mode” for three seconds. After 15 minutes the screen will return to functional mode.

Navien devices

To reduce the power of many Navien models, just use the remote control and visit the engineering menu.

- The remote control is turned off. Press + and – for 5 seconds. This is how the regime is established.

- The numbers displayed on the remote control panel are 8,9 or 10. They change to values in the range 2 -20. Most often the figure is 12 or 13.

- After 5 seconds the remote control goes out. The boiler is disconnected from the network for 10 seconds.

Baxi products

If you have a small apartment, then for optimal power of the Baxi boiler, the F08 and F10 indicators are set to a minimum.

The modulation interval of a 24 kW device starts at 40% of the maximum power. Then the minimum parameter for its operation is 9 kW. This is enough to heat an area of up to 80 sq.m.

You can also connect a room thermostat to many models. The boiler will start only by its signal when the temperature in the room drops below the set values.

Thanks to programmable thermostats, you can flexibly adjust different modes throughout the day. Even if you reduce the indicator by 1 degree every day, you can save up to 4-5% of fuel per year.

Basic malfunctions and their solutions

Any faults that occur are shown on the display as a numeric code. Each of them corresponds to a specific error, i.e. a signal from a specific sensor about the failure of the corresponding node.

Let's look at them in more detail:

- E 01. Exceeding the heating temperature. Indicates a failure of the circulation pump or a clogged coolant filter.

- E 02. Exhaust circulation error. Possibility of coolant leaks.

- E 03. Gas does not burn. Check whether the gas supply valve is open.

- E 04. Parasitic flame. The sensor may spark and perceive it as an open fire.

- E 05, E06. Exhaust temperature sensor short circuit. Occurs due to the appearance of condensation on the board with the sensor.

- E 07. DHW temperature sensor failure. Check sensor contact.

- E 08. Short circuit of the DHW heating sensor. Replacing the sensor.

- E 09. Fan failure. Replace the fan.

- E 10. Problems in the smoke removal system. The chimney may become clogged or the outlet channel may become icy.

There may be additional codes that must be carefully reviewed in the user manual.

Filling the boiler and heating system with water

Error code 02 indicates that there was an attempt to start the boiler, but there is no water in the system, or there is not enough water. What to do:

- The appliance is unplugged and the gas supply is cut off.

- At the bottom of the boiler, among many elements, you need to find a make-up valve. Turning it counterclockwise opens it, and turning it clockwise closes it.

- When the tap is open, monitor the pressure gauge. You need to close the tap when it shows 1.3 - 2 bar.

- Now the boiler is connected again, gas is supplied and the start is made.

Don't worry if error 02 appears again. This may be caused by the fact that after bleeding the air (which is automatically done at startup), the water level is again insufficient. The filling operation must be repeated.

Features of the Navien gas boiler

Navien produces devices of various capacities designed to provide heating for gas-fired homes. However, the technical features of the models allow them to be converted to an autonomous gas supply, that is, connected to cylinders.

A wide range of models allows you to choose a model to suit any needs and capabilities.

- wall and floor;

- single-circuit and with hot water supply;

- with atmospheric and closed combustion chamber;

- with different heating outlet sizes (three options: 20, 25, 32);

- with different chimney diameters;

- and of course, the models differ in power and size.

The manufacturer did not neglect the design.

The devices have an elegant appearance and fit well into a kitchen or any other interior.

Security systems supplied with Navien boilers:

- Modulated turbocharging.

- Protection against coolant freezing.

- A special chip (SMPS) protects against 30% power surges.

- A control panel with a temperature sensor that allows you to maintain t constant and adjust the operation of the boiler to special circumstances.

Modulated turbocharging. The system is based on the interaction of a fan supplying combustion air and a pressure sensor (APS).

The fan rotation intensity changes in proportion to how much gas is supplied at the moment. This allows you to use resources economically and increase efficiency without wasting fuel.

Owners take the choice of equipment such as a gas boiler seriously. Read information about the Baxi gas boiler, the manufacturer, as well as the unit models on our website.

Read about the purpose of an air valve for heating here. Operating principle and design features.

And in this topic https://microklimat.pro/sistemy-otopleniya/elektricheskoe-dachnogo-doma.html we will consider options for electric heating of a private house. Types of electric heaters and electric boilers.

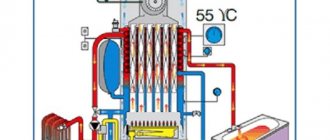

Design and main elements of the boiler

It is important to know your boiler in order to carry out basic maintenance. Although the model may vary from model to model, the main elements can be found in the case:

- combustion chamber;

- heat exchanger;

- expansion tank;

- gas burner;

- circulation pump;

- Control block.

Particular attention should be paid to the design of the lower part of the case, since this is where the inputs and outputs of the circuits are connected, and other important parts are located.

Navien boiler diagram

Closer to the wall there are 4 connecting pipes:

- Feed input.

- Return inlet (with safety valve).

- Hot water outlet.

- Cold water.

Next is a small gas supply pipe.

In front of the return inlet there is a hot water filter, and even closer there is a drain plug.

In front of the DHW outlet there is a make-up tap, through which the system is filled with water.

If the temperature continues to drop and it reaches -6°, the burner is activated, which heats the water to +21°.

Range

The assortment of the South Korean company Navien is constantly expanding, which allows customers to purchase gas boilers that are optimally suited in all respects.

Therefore, it is impossible to talk about all representatives of the model range. Instead, we will look at Navien equipment, which can be divided into three broad categories.

- Wall models. Wall-mounted boilers have a double heat exchanger and are labeled as Ace, Deluxe. Deluxe are dual-circuit models that have a wide power range from 13 to 40 kW. All Deluxe series boilers are turbocharged. Turbocharged Deluxe equipment can have a coaxial or separate chimney. In addition to Deluxe, the Ace series of wall models is in great demand. The Ace series is divided into Turbo and Atmo. The difference between them is that Turbos are fully adapted for operation in conditions of non-steel gas and electricity supply to the boiler. An additional advantage of Ace Turbo is frost protection and burner turbocharging. If we talk about Atmo, then this is a classic gas boiler that perfectly provides heating for a private home. Atmo has all the strengths of the Turbo, except for the turbocharging of the burner.

- Floor-standing boilers from Navien. If wall-mounted models do not suit you for one reason or another, floor-standing models have earned excellent reviews. They are used for heating and hot water supply of private houses. The distinctive features of floor-standing models of Navien boilers include their compact size, ease of operation and convenient installation. Each boiler comes with detailed instructions, according to which even a novice in such matters can carry out the installation. Wall-mounted models are somewhat easier to install, although there are no problems with them. A double heat exchanger significantly increases the efficiency of heat generation in a gas boiler.

- Condensation. Deluxe, Ace and other models of the Navien company recently received a serious competitor in the form of South Korean condensing boilers. They are marked NCN. Their distinctive feature is increased power, the range of which is 19.6-37.9 kW. These boilers use fuel efficiently, using less fuel but providing higher quality heating. The efficiency of Navien condensing-type boilers reaches 108 percent. This was made possible by using the heat that is released when steam condenses. This way, consumers save money on gas bills, but heat their own homes more efficiently. The heat exchanger here is slightly different. Its design is unique and is distinguished by the presence of a system for preliminary creation of a combustible mixture. The burners are necessarily modulating, the range of operation of which is amazing.

By choosing boilers from the Navien company from the Deluxe, Ace or other ranges, you are buying quality and reliability. This is one of the few cases where the manufacturer does not demand more just for the brand. The high level of Navien boilers is beyond doubt.

Starting the Navien Ace boiler: complete instructions

Navien Ace is one of the most famous boiler models from the famous Korean manufacturer Navien. In addition to their low price, these boilers were distinguished by their simplicity and reliability. In addition, you can do the installation yourself, without turning to specialized organizations.

We have prepared this material specifically for home craftsmen who want to figure out how to turn on the Navien Ace gas boiler. It is enough to carry out the actions that we describe step by step, and you will definitely succeed.

So, how to enable navien ace and make it work.

Please note that correctly starting the Navien Ice boiler is the key to its long-term and reliable operation! Therefore, please take the necessary time to do this.

1. Before starting the boiler, you must check that the equipment is installed correctly.

2. The boiler must be connected to the gas main by a metal pipe with a shut-off valve and filter.

3. It is also necessary to have a dielectric bushing on the gas pipe.

4. It is better to additionally check the tightness of the connections for gas leaks (if the connection was made by the gas supply organization in your presence, and you are sure that they checked the connections for leaks, this is not necessary.

5. The hydraulic connections of the boiler must be equipped with shut-off valves. This will allow you to service and repair the boiler without draining the water. It is better to install filters on the return pipelines leading to the boiler to prevent dirt from the heating system from entering the boiler.

6. A surge protector and/or voltage stabilizer is required. This will help protect the boiler in case of voltage surges and avoid costly repairs.

7. Before filling the system with coolant, it is necessary to check the air pressure in the expansion tank. The pressure in the expansion tank should be around 0.8 of the system pressure (approximately 1-1.2 bar).

8. We unlock the circulation pump.

To do this: unscrew the screw on the front of the pump.

9. Use a screwdriver to make several revolutions of the pump rotor. This simple operation will avoid damage to the pump when the voltage is turned on. For example, the pump could jam if it was stored for a long time at the supplier, and when turned on, it would simply burn out. By turning the rotor, we completely eliminate this scenario.

10. To fill the system, it is necessary to open the heating taps, the hot water outlet tap and the cold water supply tap. To fill the heating system, it is necessary to open the feed tap, as a result of which water from the water supply system enters the heating system. When the pressure reaches 1.5 bar, it is necessary to close the make-up valve tightly to avoid further increase in pressure.

The make-up tap, standardly installed by the manufacturer, can not be used to fill the system, since with frequent use, these taps easily break down. Therefore, you can install an additional tap between the boiler return and the cold water supply.

11. Connect the electric cord of the boiler to the power supply network.

12. Open the plug of the automatic air valve on the circulation pump.

13. On the control board, switch 1 to turn on automatic forced circulation of the pump.

At this time, you need to ventilate the radiators using Mayevsky taps, and constantly replenish the system with coolant. Once the system has been de-aerated, return this switch to its original position.

Let's start the boiler. It must be borne in mind that in “winter mode” the boiler works both to heat hot water and to heat the heating system. In “summer mode” - the boiler only works to heat hot water, the heating will not heat up. It is MANDATORY to adjust the gas valve of the boiler to the static and dynamic gas pressure in the line. This work can ONLY be performed by certified specialists.

14. Using switch 3 on the control board, turn on the minimum operating mode of the boiler.

And by releasing the lock nut on the adjusting screw, we set the gas pressure value corresponding to the minimum modulation level of the gas valve. Having achieved the required value, fix the locknut and return switch 3 to its original position - to remove the boiler from the minimum boiler operating mode.

To adjust the maximum operating mode, we force the boiler (using switch 2 on the control board) to the maximum operating mode.

And using the potentiometer on the control board, we set the gas pressure value corresponding to the maximum operating mode of the heat generator. In fact, this is the most important stage of commissioning work to start up the boiler.

Since the stable operation of the boiler in this particular line, and the provision of the declared parameters for the amount of heat and hot water by the boiler, will depend on the adjustment of the gas valve. Having received the desired indicator, we remove the boiler from the forced maximum load mode (return switch 2 to its original position).

This process is described in great detail in the boiler operating instructions. There is also a table of gas valve pressure values depending on the pressure in the gas line. At the end of the commissioning work, it is imperative to check whether the fittings for measuring the gas pressure are tightly screwed in, and we also check the connections that were loosened and unscrewed for gas leaks.

Having completed all the steps in the instructions, you will fully know how to put the navien ace boiler into operation, even if you have never started a boiler yourself before

Please note that to adjust the gas valve, you will need a specialized tool - an electronic gas pressure gauge.

Possible malfunctions and ways to eliminate them

Navien error codes:

- 01 – overheating (check if the pump is working and if the filter is clogged).

- 03 – no gas (check if the tap is open).

- 04 – false flame signal (check the serviceability of the gas valve, replace the electrodes or board).

- 05 – 06 – Short circuit on the temperature sensor or open circuit.

- 09 – problems with the fan.

- 10 – problems with smoke removal (check the operation of the fan, whether the chimney is clogged, whether the fan pipes are connected correctly, gusty wind could also be the cause).

- 013 – Short circuit on the OM flow sensor.

If the boiler does not give any errors, but works much worse, the reason may be a clogged filter or an airy system.

Navien boilers, like any other equipment, require good care and proper handling. Regular checks and service control will help avoid breakdowns.

Installation of an internal electrical network is an important stage in the arrangement of a new building. Electricity in a private house with your own hands - how to do the wiring correctly? Read the advice of professionals.

27E

An error typical for Navien atmospheric models. Caused by a malfunction of the air sensor (APS) or lack of communication between it and the boiler board.

Other codes are also displayed on the Navien display. But almost all such malfunctions are associated with the boiler’s electronic board. The only thing you can do yourself is to make sure that the contacts are tight and correct the connectors on the module. It cannot be repaired, especially at home.

Navien boiler control panel

Useful tips

- Before removing the casing of the Navien boiler and trying to solve the problem with it yourself, you should make sure that the warranty for the sample has expired (according to the mark in its passport). If it works, you need to call specialists from a service organization - you won’t have to pay for repairs.

- The risks of Navien errors can be minimized by proper arrangement of the heating system: power supply to the boiler via a UPS, high-quality water treatment, filters on the pipes of connected communications. Plus – professional installation of equipment.

- Navien boilers break down extremely rarely. If errors appear on the display, you should immediately check the corresponding sensors and connecting wires. In 85% of cases, the reason is precisely in them or in external factors (mismatch of parameters of house systems; for example, pressure in the main line).

The documentation for Navien heating installations contains scant information, including information on errors that appear. the user to contact an affiliated service center in case of problems with the operation of the equipment. This must be taken into account when calling a specialist. It’s not a fact that this department has manuals for repairing Navien boilers!!!

Navien mounted boiler: characteristics

was in a warmer zone, we immediately realized that this was not suitable for us, at first there were thoughts of moving the remote control downwards, closer to the floor, but, firstly, this is inconvenient for control, secondly, domestic cats could ruin it, thirdly, the boiler could do not turn off, trying to catch up with the temperature below, when it is already hot in the middle part of the room in height.

The room temperature test did not pass and was not suitable for me, at the same time I remembered the person who connected the gas, who advised that the boiler should not be turned on in this mode.

Time passed, but the cycles did not give me peace, and one day it occurred to me, while regularly observing the boiler, that the hysteresis (delta) in the turn-on-switch-off segment of the gas boiler was probably too small, and I would like the boiler to drive the coolant longer to a higher level. low CO temperature, but it was unclear how to do this, I certainly know how to program, but programming languages for this boiler are inappropriate, and I don’t have equipment to connect to the “brains” of the boiler, and one day, purely by chance, I came across one well-known forum for a person who knows how to do this, and with the help of only one remote control, by entering the engineering menu of the Navien boiler!

This is literally what needs to be done. to change the delta between boiler start-stop.

1. With the Navien boiler remote control turned off, press the + and - buttons for 5 seconds

mode setting

2. The number 8 or 9 or 10 will appear on the remote control display (for me)

3. Again, use the + or - buttons to change the value (this is delta) in the range from 2 to 20 (I set it to 12)

4. We wait 5 seconds, after which the boiler remote control goes out

5. Turn off the boiler by removing the plug from the socket for at least 10 seconds

6. Temperature difference value saved

Having done all this, I immediately realized the difference, the intervals between starts and stops of the boiler increased, although it raised the delta by only 2 degrees!, a useful thing, the engineering menu of the Navien boiler!

How to increase the time between starting and shutting down a gas boiler?

If there is a problem with frequent switching on and off (“clocking”) of a gas boiler, you can change the difference between starting and stopping the unit. This is possible using the Navien engineering menu:

- Turn off the remote control and press two buttons “+” and “-” at the same time.

- A number from 2 to 20 appears on the display. Usually 8 or 10.

- Use the “+” and “-” keys to increase the delta value between start and shutdown.

- After 5 seconds, the remote control goes out.

- The boiler is turned off and then turned on again.

Now the gas unit will operate in a new mode.

Pros and cons of Navien gas systems

A gas boiler for heating a private house Navien has a number of undeniable advantages:

- Frost protection.

When the indoor temperature drops, the system automatically starts the frost protection mode. When the water temperature drops below 10 ºС, the circulation pump is turned on, ensuring constant circulation of the coolant in the heating system. When the temperature drops below 5 ºС, the burner lights up and the coolant warms up to 22 ºС. - Availability of a turbocharging system. The turbocharging fan in such boilers is located under the combustion chamber and changes its rotation speed according to the counter. It is directed from the APS air pressure mechanism. It turns out that air enters the combustion chamber in a volume proportional to the volume of supplied gas. Only such an Ice Turbo system with an installed fan and APS mechanism makes it possible to ensure complete combustion of gas with minimal heat loss.

- The presence of a stainless steel heat exchanger. Unlike copper, it has high oxidation resistance. This nuance significantly extends the life of Navien wall-mounted gas boilers. However, even taking into account the high resistance of stainless steel to rust, such heat exchangers are used in boilers extremely rarely, since they have a much lower level of thermal conductivity compared to a copper heat exchanger. And only Navien ace Turbo wall-mounted gas boilers have a simulated turbocharging system to increase the efficiency of the entire system.

- Long-term and safe operation of the system in conditions of constant external failures. The SMPS function found in the microprocessor protects the system from damage during power outages. Only Navien boilers manage to function normally under conditions of significant fluctuations. This extends their service life significantly compared to other heating devices.

- The ability to heat the room and heat water in conditions of low pressure in the system.

The automated mobile heating control system, thanks to the presence of built-in temperature sensors, makes it possible to significantly save on gas consumption.

Navien Deluxe gas valve adjustment

To set the gas pressure of Navien boilers (Ace, Deluxe, Prime, Atmo), you will need a differential digital pressure gauge with a mm H2O scale.

A table with gas pressure values for various Navien boiler models is given at the end

1.With the boiler turned off, attach a pressure gauge to the gas pressure control fitting on the burner

3. Set DIP switch 3 on the control board to the “ON” position, which will correspond to the minimum load.

4. Set the minimum gas pressure according to the table using the screw for setting the minimum pressure (Increase - counterclockwise, decrease - clockwise)

5. Set DIP switch 3 on the control board to the “OFF” position (Main state)

6.Set DIP switch 2 on the control board to the “ON” position, which corresponds to the maximum load

7. Set the maximum gas pressure in accordance with the table using the adjusting screw (Increase - counterclockwise, decrease - clockwise)

9. Disconnect the differential pressure gauge hose from the gas valve fitting

10. Set the DIP switch to the “OFF” position (Main state)

12 . Check the tightness of the gas valve (Fitting). If abnormal noises appear, you need to check the boiler for gas leaks.

The material was prepared by an employee of heating-mtsensk.rf - Warm Home.

Source

Adviсe

Even the exceptional skill of South Korean manufacturers does not allow 100% to eliminate the occurrence of violations and problems during operation. Poor water heating is mostly due to the filling of the heating system with air pockets. The problem is solved by removing accumulated air or changing the automatic vent. It is also possible that the filter in the heating circuit is dirty.

This situation can be corrected either by adding water or eliminating the leak. Code 3 indicates that gas is not supplied to the burner. It is necessary to check what position the valve is in, whether the fuel in the cylinder has run out, and whether there are any accidents on the line. Judging by the reviews of the owners, South Korean boilers are more compact than many other versions and are characterized by rapid achievement of the set temperature. But it is noted that there are no control elements on the boilers themselves and that occasionally turning on two hot taps on the water supply reveals insufficient heating power.

If the boiler is leaking, in many cases it is water leaking from a drain plug that is closed too loosely or is leaking for some reason. When the cause is more complex, you will have to remove the problematic unit, disassemble it and clean it. Unscrew the clamping nut and remove the air vent. Using a hexagon, unscrew the plug, then remove the rubber band (a needle or screwdriver with a thin tip will do). The piston and spring are removed, and when the float falls out, you need to wash it and then return it to its place (in the reverse order).

A more detailed overview of the Navien Deluxe boiler can be seen in the following video.

Korean-made Navien heating boilers are popular in our country. They are reliable and at the same time affordable in price. Due to the great demand for these devices, setting up a Navien gas boiler is a pressing issue among buyers.

Navien boiler fluctuates heating temperature - Engineering systems

Korean-made Navien heating boilers are popular in our country. They are reliable and at the same time affordable in price. Due to the great demand for these devices, setting up a Navien gas boiler is a pressing issue among buyers.

Manufacturers of Navien produce devices of different capacities, floor-mounted, wall-mounted and with a hot water supply function. They can be connected both to a centralized line and to gas cylinders. The units have a modern appearance that allows them to fit into any home interior. Navien gas boilers are equipped with a safety group, which includes:

- modulating turbocharging;

- protection against coolant freezing;

- SMPS chip that protects against power surges;

- temperature sensor control panel, which allows you to adjust the operation of the unit to certain circumstances.

The most common model of Navien gas units is Deluxe, so let’s look at them in more detail.

Gas boiler Navien: faults and their elimination

Heating a private home » Boilers and boiler equipment » Gas boilers

Navien boiler

An autonomous gas heating system today is popular not only among residents of country houses, but also among apartment owners in multi-story buildings.

This is explained by the numerous positive qualities of modern devices, the ease of their installation and operation.

Among the large range of heating products, Navien gas boilers are especially in demand, the malfunctions of which and how to eliminate them will be discussed below.

Source: https://in-service47.com/kotel-naven-skachet-temperatura-otopleniya/

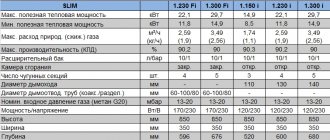

Specifications

| Indicators, units | NAVIEN Ace-13A Atmo | NAVIEN Deluxe-16K | NAVIEN Deluxe-20K | NAVIEN NCN-25K |

| Heating area, m2 | 98.0 | 128.0 | 160.0 | 220.0 |

| Condensing type | No | No | No | Yes |

| Thermal power, kW | 13.0 | 16.0 | 20.0 | 25.0 t |

| Combustion chamber | open (chimney) | closed (turbo) | closed (turbo) | closed (turbo) |

| Electrical power consumption, for own needs, kW | 110.0 | 150.0 | 150.0 | 130.0 |

| Min. t in the heating circuit, °C | 42 | 42 | 42 | 30 |

| Max. t heating circuit, °C | 80 | 80 | 80 | 95 |

| Max. pressure in the DHW system, bar | 8.0 | 8.0 | 8.0 | 10.0 bar |

| Max. t DHW, °C | 65 | 65 | 65 | 65 |

| Capacity (Δt=25°C), l/min | 9.0 | 13.6 | 13.8 | 14.0 |

| Capacity (Δt=35°C), l/min | 5.5 | 8.6 | ||

| Summer operating mode | Yes | Yes | Yes | No |

| Hot start mode | Yes | Yes | Yes | No |

| Efficiency, % | 86.0 | 91.0 | 91.6 | 98.2 |

| Nominal gas pressure in front of the boiler, mbar | 18.0 | 18.0 | 18.0 | 18.0 |

| Max. hourly gas consumption, m³/hour | 1.33 | 1.72 | 2.15 | 2.51 |

| Expansion tank capacity, l | 6.5 | |||

| Chimney diameter, mm | 130.0 | 60/100 | 60/100 | 80/125 |

| Price as of 07/01/2019 | 32780 rub. | 35200 rub. | 37880 rub. | 69800 rub. |

Important! The model is equipped with a closed firebox with an outdoor cold air intake

Deluxe Coaxial 16K

This is a wall-mounted model with a closed combustion chamber and two heating circuits. The turbocharged fan changes speed based on a signal from the built-in air sensor, which ensures complete combustion of fuel in the firebox, which reduces heat loss through flue gas emissions and increases the efficiency of the installation to 91%.

Benefits of Deluxe Coaxial 16K:

- High performance for hot water supply and heating;

- low contamination of the coolant in the heating system;

- low maintenance and repair costs;

- room temperature control;

- Russified control panel with a large LCD display;

- optimal balance of the gas-air mixture;

- innovative mode of modulation of the gas burner device;

- high-quality warranty service;

- easy setup of the Navien boiler;

- low cost of chimneys and gas transmission systems.

| Parameter | Deluxe | Deluxe coaxial | Deluxe Plus | Deluxe ATMO |

| Boiler type | Gas wall-mounted double-circuit | |||

| Combustion chamber type | Closed | Open | ||

| Efficiency | 91,7 % | 86 % | ||

| Thermal power of the boiler according to the air conditioner | 9-40 kW | |||

| Primary heat exchanger material | Stainless steel | Copper | ||

| Coolant temperature in the heating system | 40°-85° | |||

| DHW temperature | 30°-65° | |||

| Control type | Electronic | |||

| Mains voltage | Single phase, 230 V, 50 Hz | |||

| Weight | 28 kg | 26 kg | ||

| Case dimensions | 440x695x265 mm | 430x720x340 mm |

Setting up dip switches for Navien Deluxe

ien Ace/Atmo

| DIP switch no. | Description | ||||||

| Function | ON position | OFF position | |||||

| 1 | Commissioning | Commissioning | Normal operation mode | ||||

| 2 | Job status | Maximum gas pressure | Normal operation mode | ||||

| 3 | Minimum gas pressure | Normal operation mode | |||||

| 4 | Installation of chimney | FF | FF | ||||

| 5 | Selecting the fuel type | Liquefied gas | Natural gas | ||||

| 6 | Model installation | Model with DHW temperature sensor | Model without DHW temperature sensor | ||||

| 7 | frequency Hz | 50 Hz | — | ||||

| Performance | 10 kW | 13 kW | 16 kW | 20 kW | 24 kW | 30 kW | 35 kW |

| 8 | ON | ON | ON | OFF | OFF | ON | OFF |

| 9 | ON | ON | OFF | ON | ON | OFF | OFF |

| 10 | ON | OFF | OFF | ON | OFF | ON | ON |

Tips and recommendations for operating the Navien boiler

The main advice from experts regarding the safe operation of the boiler:

- The room where the unit is located must have good ventilation.

- The unit must have a separate independent connection to the electrical network.

- The boiler must operate in a fully assembled and protective housing.

- The user is prohibited from independently repairing the gas equipment of the boiler.

- The boiler must undergo an annual inspection by representatives of Gorgaz.

- The boiler owner must periodically check the joints of the boiler and the gas pipeline for leaks with a soap solution.

Additional Information. If leaks occur, immediately turn off the gas valve, ventilate the room and call the emergency gas service.

Navien gas boilers have been used by Russian consumers for a long time. They have rightly earned the trust of customers. The lightweight layout with the widest range of modern water heating functions allows you to choose these models from a large list of offers on the heating equipment market.

- Languages: Russian

- Type: ZIP

- Size: 21.31 MB

- Description: Wall-mounted gas boiler

Setting up a Navien gas boiler

Next, we’ll look at how to set up a Navien Deluxe gas boiler with your own hands. Manipulations are carried out using a remote control with a built-in room temperature sensor.

Heating settings

To set the heating mode and set the coolant temperature, hold down the button with the image of a radiator until the same icon appears on the screen. If the “radiator” picture blinks, it means that the set coolant temperature is displayed on the screen. If the symbol does not flash, the actual water heating level is displayed.

Navien wall-mounted gas boilers - model range, pros and cons

How they work and what are the advantages of Navien Ace gas boilers

To set the desired temperature, use the “+” and “-” buttons with the “radiator” icon flashing. The possible range is from 40ºC to 80ºC. Once the temperature is set, it will be automatically saved. The “radiator” icon will blink for a few seconds, after which the actual temperature of the coolant will be displayed on the screen.

Heating with air temperature control

To set the desired air temperature in the room, you need to hold down the “radiator” button until the image “house with thermometer” appears on the screen. It means “Heating with room temperature control” mode.

When the “house with thermometer” symbol is flashing, the desired room temperature is displayed on the screen. When the icon is not flashing, the display shows the actual room temperature.

When the icon is flashing, using the “+” and “-” buttons, the desired level of heating in the room is set, adjustable in the range of 10-40ºC. The temperature is then automatically saved and the icon stops flashing.

Setting the hot water temperature

To set the hot water temperature, you need to hold down the “water tap” button until a similar flashing symbol appears in the right corner. You can then set the desired hot water temperature between 30ºC and 60ºC. The settings will be automatically saved and the “water tap” symbol will stop flashing.

Note! In the “Hot water priority” mode, the water heating temperature is regulated differently. Now let's look at how to configure the Navien Deluxe gas boiler in the "Hot water priority" mode

To activate it, hold down the “water tap” key until the “faucet and light” symbol appears on the screen. Now you can set the desired temperature using the “+” and “-” keys. When changing the DHW temperature, the “water tap” icon should flash above the “tap and light” symbol.

Now let’s look at how to configure the Navien Deluxe gas boiler in the “Hot water priority” mode. To activate it, hold down the “water tap” key until the “faucet and light” symbol appears on the screen. Now you can set the desired temperature using the “+” and “-” keys. While the DHW temperature is changing, the “water tap” icon should flash above the “tap and light” symbol.

The “Hot water priority” mode involves preparing a supply of water at a given temperature even if it is not in use. It allows you to supply heated water to the consumer a few seconds earlier.

Away Mode

The “Away” mode means the gas boiler operates only for preparing hot water. To switch the unit to this mode, you need to press the button that shows an arrow and a water tap. The “water tap” symbol that appears on the screen means that the “Away from Home” mode is set. The actual temperature in the room is displayed next to it.

Note! This mode is convenient for use in the warm season, when hot water supply is necessary, but there is no need for heating

Operating modes

Like many heating appliances, Navien boilers have winter and summer operating modes. On the display, the mode change button is indicated by the “Snowflake” and “Sun” icons.

By pressing this button again, you can change the options:

- Winter mode activates heating and hot water supply.

- Summer is only hot water supply for household needs.

You can adjust the coolant temperature on the remote control when the heating radiator icon lights up on the display.

In some models, to do this you need to press the “Heating Mode” button, in others you need to turn the knob with this icon.

A flashing radiator icon means that the numbers you see show the set temperature of the coolant.

If the “radiator” just lights up, the actual temperature in the heating is displayed.

Having selected “radiator”, you need to press the “+” or “-” keys to increase or decrease the temperature. A few seconds after the desired temperature is set, the radiator icon stops blinking, and the display will show what temperature the coolant is now, and the device will begin to gradually heat it (or cool it) to the selected one.