The use of autonomous units for generating electricity is justified from both economic and practical points of view. However, for people living far from civilization, it is quite expensive and troublesome to purchase and transport natural gas or liquid fuel to their homes. In such a situation, a wood-burning gas generator comes to the rescue. Let's look at what this equipment is, how it is designed and on what principle it works, what types it is divided into, what its pros and cons are, and the rules for installing modern models.

Checking the operation of a wood-burning gas generator Source ytimg.com

Wood gas generator - what is it, device, principle of operation, application

In autonomous installations for generating electricity for the needs of a private home, an internal combustion engine is used. It can operate on gasoline, diesel fuel or natural gas. However, when it comes to remote areas, delivering such fuels will be economically unprofitable and technically difficult.

An alternative solution to this situation is a wood-burning gas generator. The motor of such a unit is powered by a mixture of gases - mainly hydrogen, carbon monoxide, methane and some other hydrocarbons. They are formed under special conditions during the thermal decomposition of wood, coal, peat, organic matter and other suitable types of solid fuel.

Device

A classic domestic wood-burning gas generator installation consists of the following main components:

- Frame . It is made of steel and can have a cylindrical or rectangular shape. Installed on special legs.

Diagram of a wood-burning gas generator Source gengas.lagunof.com

- Loading department . It is located and secured inside the housing. Designed for loading fuel through a special hatch, the edges of which are equipped with a special fire-resistant seal.

- The combustion chamber . It is heat resistant and is located at the bottom of the loading section. It directly burns fuel. To carry out thermal decomposition of resins, a special neck is equipped in its lower part. In the middle of the chamber there are special lance openings connected to an air supply device. The latter is equipped with a check valve to prevent the escape of flammable gases.

- Fan . If it is necessary to increase efficiency, as well as improve the combustion of certain types of fuel or very damp wood, the air distribution module is additionally equipped with a fan or turbine for increased air supply to the firebox.

- Grate bars . Installed at the bottom of the combustion chamber. Their main purpose is to support hot burning coals and separate the burnt substance - shedding ash into a special ash pan located below.

Gas generator installed on a car Source hsto.org

- Hatches . Special hermetically sealed lids - the top one for loading fuel with a device for equalizing pressure inside, the side one for loading into the recovery zone and the bottom one for removing slag.

- Gas pipeline . A pipe for removing the resulting mixture of gases from the combustion chamber. Due to the high initial temperature and the need for cooling for further use, it is specially carried out along a ring-shaped path in the cavity between the installation body and the loading chamber. This allows not only to cool the gas, but also to pre-dry the fuel before it enters the firebox.

- Filtration system . After leaving the chamber, the gas requires mandatory cleaning from soot and other suspended solids. Therefore, it is first fed hot into a coarse filter, and then, when cooled, it is subjected to finer filtration.

Upon completion, the purified and cooled gas mixture is fed into the mixing unit. Here the gas is saturated with oxygen to the required degree. Only after this is it supplied to the internal combustion engine.

An example of a household wood-burning gas generator Source ytimg.com

See also: Catalog of companies that specialize in electrical work of any complexity

Mechanism of action

The operating principle of a wood-burning gas generator boils down to the fact that under conditions of elevated temperature (about 1200-1500°C) and low oxygen levels, the wood does not burn as usual, but smolders, releasing generator gas, which serves as fuel for the internal combustion engine. The mechanism of operation of the installation is reduced to the following step-by-step processes occurring in the corresponding zones of the generator:

- Drying fuel . At a temperature of about 160-190°C, the firewood located in the uppermost part of the loading section is dried under the influence of gases passing through a ring pipeline.

- Dry distillation . In the middle part of the unit, where the heating level reaches 450-500°C, the wood is charred. As a result, in addition to coke, tars, acids and other products of low-temperature decomposition of fuel are formed.

- Burning . In the lowest part of the installation, at a maximum temperature of 1100-1500°C, charred fuel and decomposition products burn to carbon dioxide and carbon monoxide.

Reverse gas generator design Source uazbuka.ru

- Recovery . Carbon dioxide formed and heated in the lower part rises to hot coke and interacts with carbon and water, resulting in the formation of carbon monoxide and hydrogen.

In the combustion and recovery zone, not only combustible gases are formed, but also ballast gases. The former include carbon monoxide, hydrogen, methane and some unsaturated hydrocarbons, the latter – carbon dioxide, nitrogen, oxygen and water vapor. In addition, raw flue gas contains many inclusions in the form of slag, ash, and organic acids. Therefore, before putting it into the internal combustion engine, it must be thoroughly cleaned. For this purpose, coarse and fine filters are used.

Application

With high quality fuel, well-established technology and forced air supply, wood-burning gas generators achieve such high efficiency that they are even installed on cars. However, in most cases, their main area of application is objects and houses with an abundance of wood and difficult access to other types of energy resources (electricity, gas, gasoline, fuel oil, etc.).

Gas generator near the house Source ytimg.com

Wood generators are used in the following cases:

- For electrification of houses in remote areas without access to power grids.

- To ensure uninterrupted supply of electricity at facilities of high importance - military, scientific, medical bases.

- In industry - as an alternative source of electricity generation in the presence of associated production waste - wood chips, sawdust, scraps of building materials, etc.

Note! For stable and high-performance operation, the generator requires initially loading well-dried fuel. Thus, the use of raw firewood reduces efficiency by 25%. In addition, when raw wood smoulders, refractory resins are formed, which quickly clog the pipeline system, which will already lead to a decrease in the efficiency of the unit and will require frequent cleaning.

Making gasgen for a car

Before making a working gas generator for a car, we suggest that you familiarize yourself with some recommendations:

- Organizing the supply of power gas in a modern car with an injector is not an easy task. You will have to change the controller settings (firmware), otherwise the wood fuel motor will not work. You need a car with an old fuel supply system - a carburetor.

- The greater the power and displacement of the engine, the higher the performance of the gas generator. Accordingly, it will grow in size.

- To fit the installation into the trunk of a passenger car, you will need to cut out part of the bottom. If you do not want to touch the body, then immediately plan to install a wood-burning generator with filters and a cooler on the trailer.

- To make a gasification chamber where the temperature exceeds 1000 °C, use low-carbon thick steel (4-5 mm).

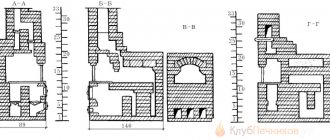

- To reduce the resin content in the gas mixture, make a chamber with a neck, as shown in the drawing.

Important point. You should not increase the diameter of the gasification chamber (in the drawing it is 340 mm) in order to achieve greater productivity. The increase will be negligible, and the quality of wood processing will deteriorate. But it is not necessary to maintain a height of 183 cm, unless you place the unit on a trailer or on a truck frame. The fuel hopper and ash pan can be shortened.

To assemble the inside of a car gas generator (bunker), an old propane cylinder, a receiver from a KamAZ truck, or a thick-walled pipe will do. Considering that the diameter of the steel vessel is 300 mm, the remaining dimensions must be proportionally reduced. The exception is the gasification chamber, its minimum diameter is 140 mm. The casing and cover of the generator will use metal 1.5 mm thick. The latter is sealed with graphite-asbestos cord.

Options for fuel mixture coolers from a car radiator and radiator

Related units - filters and coolers - are made like this:

- Weld a cyclone from a used fire extinguisher or a piece of pipe with a diameter of 10 cm, as shown in the drawing. Attach the inlet pipe to the side, the outlet pipe to the top.

- It is better to make a power gas cooler from steel pipes in the form of a coil. There are other options: using old convectors, radiators and radiators.

- Make a fine filter from any cylindrical container (for example, a barrel) filled with basalt fiber.

You can get more detailed information about assembling a gas generator yourself by watching the video:

To ignite and start the gas engine, you will need a snail-shaped fan installed in the engine compartment (a household vacuum cleaner will also do for testing). The requirement for it is simple: parts in contact with the gas mixture must be metal. The fuel line leading to the carburetor is laid under the bottom of the car and is made of steel pipe.

For reference. If you use charcoal instead of firewood, then there will be significantly fewer impurities at the gas generator output, which is good for the engine. Such fuel is burned from wood using a simple technology - in a closed barrel or pit.

The charcoal bunker fits into the trunk of a Zhiguli.

Advantages and disadvantages

A gas generator machine for the production of flue gas, operating on wood, is characterized by the following number of advantages:

- High efficiency. Under accompanying conditions, the value can reach 95%.

- Up to 25 hours of burning per load of firewood.

Large sawdust gas generator for electricity generation Source d-system.ru

Self-installation

To install a solid fuel boiler yourself, you need to take into account several rules.

- It is better to place such a boiler in a separate room. This could be a room inside the house or in the basement. A former children's bedroom or any other small room (required area - 8-10 square meters) is suitable for this, if a special room for heating devices is not allocated during construction. As a last resort, you can simply partition a large room in half (it is advisable to make the partition brick, rather than using drywall), making one or two exits - inside the room, outside, or both at once.

- The floor of the room where installation is planned must be made of fire-resistant materials. And the boiler itself should be installed directly on a concrete screed (about 10 cm thick).

- It is necessary to provide the premises with forced ventilation, power and water supply if they are not available.

- If the boiler is not installed in a specially designed boiler room, you should purchase and install a chimney in advance.

When starting installation, you need to prepare the tools and equipment that will be needed for this: electrodes, welding, level, keys, screwdrivers, meter, metal saw, screws, as well as materials: plumber’s tape, sheet of metal and sealant.

- Unpack and prepare for assembly the parts included with the boiler.

- Place the metal sheet on the floor at a distance of at least 0.5 m from the side wall(s) and 1 meter from the front and securely fix it.

- Place the boiler level on a metal sheet, checking the correctness of the level.

After the preparatory work, the boiler itself is assembled:

- Wrap the combustion regulator with one turn of plumbing tape, secure it with a screw, and set the temperature to 30 degrees.

- Install the thermostat and heater or their plugs.

- Assemble the air and safety valves, pressure gauge into a safety group.

- Install the faucet and connect it to the pipes.

- Connect the safety group in front of the locking device.

- Connect the boiler to the chimney using sealant.

- Push in the draft flap and the cleaning plug.

- Connect the water and check the system for leaks.

- Light the boiler by closing the damper.

- All that remains is to check the quality of installation and operation of the boiler and carry out pilot heating.

In order to determine the approximate cost of materials and equipment required for installation, their estimated price is given below.

- Heat-resistant sealant 100–200 rub.

- Sheet of metal (3 x 1,250 x 250) about 3,000 rubles.

- Plumbing tape about 500 rubles.

- Long-burning boilers RUB 60,000–120,000.

- Steel transition 57–32 30 rub.

- Steel bend Du-5016 from 100 rub.

- Ball valve Du-15 from 100 to 1,000 rubles.

- Ball valve with duct DU-50 about 2,000 rubles.

- Chimney for a solid fuel boiler RUB 20,000–50,000.

The choice of heating boilers should be based on the availability of a particular type of fuel in the region or its presence in the house. Heating with solid fuel boilers using firewood is second in cost only to gas-powered devices; electricity and diesel fuel are more expensive, and coal-based units come in last. This is not least due to the fact that solid fuel boilers have insufficiently high efficiency indicators (compared to electric ones, for example). However, two-level combustion systems can save fuel consumption by up to 9%.

The most environmentally friendly heating devices among solid fuels are pyrolysis gas generator boilers, since the fuel they use burns almost completely, which reduces the level of air pollution.

The video shows how gas generator boilers work:

Installation Rules

When installing gas generating units using wood, it is recommended to follow the following rules:

- Installation of equipment is allowed anywhere in the house - basement, basement, room - as well as outdoors, subject to safety precautions and technical conditions.

- Models designed for loading long firewood are best installed outdoors near the fuel storage area.

- For installation inside the house, it is better to choose a generator that runs on pellets. Since their storage and operation does not involve the generation of waste.

- In the case of using flue gases for heating and minimal cooling, pipes to the house from a unit installed on the street are laid in thermal insulation and underground.

Recommendation! Gas generators exhibit maximum performance when fully loaded. However, the amount of energy generated can be excessive. Therefore, in order to preserve it, for example, for heating, it is necessary to use special heat-insulated containers - heat accumulators.

Principle of operation

The gas generator boiler uses the principle of “pyrolysis” in its operation. This equipment has two combustion chambers, and the supplied fuel goes through several stages of combustion:

- It is dried in a special chamber.

- In the first combustion chamber, the fuel slowly smolderes at a temperature of 200-850 degrees Celsius without access to oxygen - pyrolysis. During the pyrolysis process, a large amount of “wood” gas is released from the fuel, which then enters the second chamber, where it is successfully burned using a burner and pressurizing a large amount of air.

- In this case, the coolant and water heating circuit (in double-circuit boilers) is designed and mounted in such a way as to absorb thermal energy from both combustion chambers.

A gas generator boiler can operate not only on wood, but also on any wood waste, as well as on briquettes and eco-pellets.

Pyrolysis gas-generating solid fuel boilers have the following advantages over other types of solid fuel equipment:

- High Efficiency Coefficient and almost complete absence of solid combustion waste.

- Availability and replenishment of fuel.

- A relatively long period of operation and the possibility of loading a large amount of fuel - the combustion chambers of pyrolysis boilers have a large capacity.

Briefly about the main thing

Modern models of wood-burning gas generators are so effective that they can even be installed on a car. However, in most cases, it is a successful way to save on fuel for remote areas where, apart from firewood, there are no other types of energy resources, and delivering them there is unprofitable. Simplified, the unit consists of a housing, a loading chamber, a firebox and an ash pan. Its operating principle is based on the thermal decomposition of wood or coal at low oxygen levels, and subsequent reduction to carbon monoxide and hydrogen.

Flue gases are cooled, purified and mixed with oxygen before entering the internal combustion engine. The main advantages of gas generators of this type:

- Great efficiency.

- Up to 25 hours of burning per load.

- Complete burning of wood.

- Power adjustment.

- No harmful emissions.

- Economical.

- Possibility of using raw wood.

- Operation on other types of fuel.

- Safety.

- Large chamber volumes.

The disadvantages are manifested in the high cost, energy dependence of modern models, the possibility of clogging, gas temperature control, manual loading, and the need to use dry fuel. In this case, there are 3 varieties - direct, reverse and horizontal. Each of them has its own pros, cons and application features. The installation of the unit must be carried out in accordance with the regulations.

How to choose long-burning gas generator boilers

First you need to decide what kind of fuel you have more at your disposal - wood or coal. If coal is a more acceptable option, you should opt for top-combustion boilers, and if heating is planned using wood, it is more profitable to purchase a bottom-combustion boiler, since its efficiency is higher than the previous one.

Boilers with bottom combustion are the most environmentally friendly and economical. This is due to the presence of two or three combustion chambers in them, which provide additional combustion of fuel particles.

A cast iron boiler is more durable, since condensation from coal combustion causes corrosion of steel. In addition, steel heat exchangers burn out faster. Cast iron boilers consist of sections, which, in case of possible depressurization, allows you to simply replace the damaged part (whereas steel boilers require complete replacement); this fact also ensures ease of transportation when disassembled (however, it should be remembered that cast iron parts are fragile and sensitive to shock).

If you need a boiler that provides heating and hot water to your home, a double-circuit solid fuel boiler is suitable. The principle of its operation is as follows: the first circuit (for heating the room) is turned on when the heat sensor is triggered; the second (for supplying hot water) is activated when the pressure drops.

If the house has a working boiler, it can be connected to the heating boiler. On the one hand, this will provide great savings on the heat source, on the other hand, it will ensure a stable supply of water.

To determine what boiler power you need, proceed from the calculation of 1 kW for every 10 sq. m (with wall heights up to 3 m). It should be remembered that the boiler power itself varies depending on the calorie content of the fuel and its humidity.

Homemade stations

Also, many craftsmen create homemade stations (usually based on a gas generator), which they then sell.

All this indicates that you can independently make a power plant from available materials and use it for your own purposes.

Next, let's look at how you can make the device yourself.

Based on a thermoelectric generator.

The first option is a power plant based on a Peltier plate. Let us immediately note that a device made at home is only suitable for charging a phone, a flashlight, or for lighting using LED lamps.

For production you will need:

- A metal body that will play the role of a furnace;

- Peltier plate (purchased separately);

- Voltage regulator with installed USB output;

- A heat exchanger or just a fan to provide cooling (you can take a computer cooler).

Making a power plant is very simple:

- We make a stove. We take a metal box (for example, a computer case) and unfold it so that the oven does not have a bottom. We make holes in the walls below for air supply. At the top you can install a grate on which you can place a kettle, etc.

- We mount the plate on the back wall;

- We mount the cooler on top of the plate;

- We connect a voltage regulator to the terminals from the plate, from which we power the cooler, and also draw terminals for connecting consumers.

It works simply: we light the wood, and as the plate heats up, electricity will begin to be generated at its terminals, which will be supplied to the voltage regulator. The cooler will start working from it, providing cooling of the plate.

What kind of firewood is needed for a generator?

Any standard options for conventional ovens are suitable here. This can be wood chips, branches, firewood and even wood waste. The main thing is that the firewood must be of the right size.

To simplify the process of chopping firewood to the desired size, an unusual tool for chopping firewood - a standard “kolundrov” wood splitter will help. This kind of wood splitter is safe because it is simply impossible to get hurt by a wood splitter. The cleaver is suitable for use by almost anyone who wants to practice splitting firewood, including older people and women.

The operating principle is extremely simple. It is enough to place the log in the ring of the cleaver and hit it from above with a sledgehammer or something heavy. Unlike an axe, the impact force is concentrated in one place, which inevitably leads to splitting even damp and knotty logs. Heating a house is no longer a problem, since even a pensioner can handle chopping firewood with a good “kolundrov” wood splitter.

Wood-burning generators also become common equipment for modern fishermen and hunters, summer residents and hikers. After all, completely abandoning civilization in the forest is not very convenient.

We recommend reading: Temperature sensor for heated floors - installation diagram, principle of operation, instructions with photos

Selecting and purchasing a firewood splitter for any type of generator will greatly simplify the process of procuring the necessary fuel and will take much less time.