The principle of heating materials by induced high-frequency currents has long been used in industry. The method can be used in everyday life to heat water, including for heating a house, since energy transfer occurs more efficiently and with fewer losses. Let's look at what an induction heater is, how it works, what pros and cons it has, and what are the features of making it yourself.

Induction type water heating unit Source by.kotel-electr.ru

Structural elements of the induction system

The composition of the main components of the heater manufacturing includes the following components, parts and assemblies:

- Generator installations for alternating current conversion. As an option, a special version of the device is used, which converts the standard frequency of 50 Hz into higher parameters of a household electrical network with high frequency characteristics.

- Inductor design. A special device in the form of a cylindrical coil, which is based on copper wire, the principle of operation of which depends on the electromagnetic field present.

Copper coil for heater

Heating component or assembly, element. The part used is a special metal pipe of standard diameter and size or a rod that is inserted into a magnetic field.

Subsequently, when assembling an induction heater from a welding inverter with your own hands, all interconnected components interact as follows:

- The generator naturally increases the frequency of the current used and, in the transboundary version of the modified state, transmits the received energy to the main coil.

- The inductor, according to its parameters, receives a highly partial available current, then it is converted into an electromagnetic field of the corresponding alternating type. In this case, a complex change in the direction of the vector of the electromagnetic characteristics of the wave values occurs, and necessarily with a high frequency of the action principle.

Ultimately, the required level of electricity is transferred, without visible conditional losses. The efficiency of the inductance data is sufficient to heat the required area of the building.

In the future, the general principle of distribution of the received energy may be trivial. So, you can transfer energy to heat the liquid in the coolant, or use it for other purposes where it is necessary to use elevated temperature operating conditions. Energy consumption is carried out in a tubular coolant, where natural circulation occurs. It is noteworthy that if the induction heater from the welding inverter does not heat, then it can be used as a cooler for the same version of the heating system.

Popular models from the store

The WXJR-B6 induction instantaneous water heater with the highest power of up to five kilowatts is based on the method of heating liquid from the magnetic field of a coil. The rectangular device has dimensions of 270 x 200 x 68 mm and consumes electricity economically. The output is a constant current of water heated to 60 °C. It processes from 6 to 11 liters per minute, the operating time is not limited, it is used for large baths and pools with a volume of about 1 thousand liters.

The high-frequency water heater VIN 7 is produced for heating water or operating in the heating system of a house with an internal volume of up to 350 cubic meters. The power rating at the limit is 7 kW, the equipment is powered from a 220 V network. The device is round in shape with a height of 615 mm and an external diameter of 13 mm. Inlet and outlet pipes with a diameter of 20 mm. Effectively heats a large amount of water per minute, the output power is 5 thousand 900 kcal per hour.

The Edison 4.7 induction device for heating liquid in the water supply and heating system produces 3 thousand 950 kcal per hour and consumes 4.7 kW. Connection to a household power supply is possible. Suitable for buildings with an internal volume of up to 240 cubic meters. The kit includes starting equipment, temperature and level sensors, and a control cabinet. Manufacturers talk about reliable operation over a 30-year period.

Manufacturing process

To make such a device yourself, you do not need to have serious knowledge in electrical engineering, and any person can handle the assembly of the structure.

For this we need a piece of thick-walled plastic pipe. It will work as the body of our unit. Next, you need steel wire with a diameter of no more than 7 mm. Also, if you need to connect the heater to heating in a house or apartment, it is advisable to purchase adapters. You also need a metal mesh that should hold the steel wire inside the housing. Naturally, copper wire is needed to create the inductor. Also, almost everyone has a high-frequency inverter in their garage. Well, in the private sector such equipment can be found without difficulty. Surprisingly, you can make induction heaters with your own hands using improvised materials without much expense.

First you need to carry out preparatory work for the wire. We cut it into pieces 5-6 cm long. The bottom of the pipe should be covered with a mesh, and pieces of cut wire should be poured inside. The top of the pipe must also be covered with a mesh. You need to sprinkle enough wire to fill the pipe from bottom to top.

Next we will make a coil. The base will be a plastic body. You need to wind 90 turns of copper on it.

When the part is ready, you need to install it in the heating system. The coil can then be connected to electricity via an inverter. It is believed that an induction heater made from an inverter is a very simple and extremely cost-effective device.

You should not test the device if there is no water or antifreeze supply. You'll just melt the pipe. Before starting this system, it is advisable to make a ground connection for the inverter.

Water boiler with transformer

To get started, get or buy an inexpensive welding inverter (transformer) with current regulation of 18-25 amperes. Small pieces of wire rod or stainless steel are used as elements for heating water in a water heater. The wire is cut into pieces of length from 3.8 to 5.5 cm (if a wire rod with a diameter of 6-8 mm is used). Then the heater body is made from a thick-walled plastic pipe with a diameter of 45-50 mm. One end of this section of pipe is covered with a fine mesh and cut wire is poured from the free open end of the body.

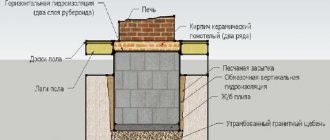

induction heater design diagram.

Having filled the pipe to the top with scraps, they begin to manufacture the inductor coil. Take an enameled copper wire of at least 1.5-2 mm and wind it around the made body. The number of turns varies (depending on the amperage of the welding inductor) and is 85-95. The coil is placed in the center of the body (pipes with scraps). The heater is connected to the water supply system or heating network using adapters.

To make a vortex induction boiler-water heater based on the resulting heater, you need to weld a structure resembling a donut from two pipes. This is a water heating element. Take any tank of suitable diameter and insert the inlet (in the upper part of the tank) and outlet pipes for water into it. The previously made induction coil is inserted into this housing. Then attach the heater (donut) to the nozzles so that it passes inside the inductor strictly in the center. The output ends of the coil are insulated and connected to the transformer. To prevent heat from leaving the water heater, it is covered with a heat-insulating screen.

Water, passing through the pipes inside the coil, heats up and comes out of the outlet pipe hot.

It must be remembered that such a boiler can be used in closed heating systems, with water circulation using a pump.

Such an induction boiler-water heater can also be connected to a system made of plastic pipes. To ensure safety, the boiler is installed at a distance of 80-90 cm from the floor and ceiling and 30-40 cm from the wall. This water heater must be equipped with a valve installed on the pipe to bleed air from the system. Such a boiler can also be used as a heater for a small room by adding a heating radiator.

Equipment advantages

An induction-type room heating device has its advantages:

- requires minimal investment;

- has a high efficiency;

- you can assemble such equipment yourself, at home;

- the efficiency factor is almost one hundred percent. The device loses almost no heat during heating;

- usually when heating heating elements or boilers form scale in the system. In this type of heater, there is no such problem;

- when heated, it does not emit any harmful substances, which means it has an environmentally friendly operating process;

- You can pour not only water into the system, but also antifreeze and oil;

Induction heater: operating principle

- does not require constant equipment maintenance;

- Even a non-professional can handle the installation and operation does not require special knowledge;

- The boiler is very well protected from a fire safety point of view. The electrical component is quite reliable and does not fail;

- this type of heater can be used in conjunction with others;

- can operate on both direct and alternating current;

- operation is possible for twenty years;

- The device is very well suited for cottages or private buildings.

But even with so many advantages, the boiler has disadvantages:

- the price of such a device is quite high. And it is unlikely to pay off within 1 – 2 heating seasons;

- there is a need for a constant electrical power supply;

- the device is heavy;

- Installed only with a closed heating system.

But if you decide to replace your wood stove or boiler with a heater of this type, you can immediately get rid of several problems:

- there will no longer be a burning smell in the home;

- there is no soot when lighting the boiler;

- there will be no need to remove soot and ash;

- There will be no need to purchase firewood or coal.

In addition, there is no need to take up space or a special room for storing solid fuel.

https://youtube.com/watch?v=k6fXWhDlyXc

How to make such equipment with your own hands

Due to the high cost of the device, many owners decide to make a heating system with their own hands. With some effort, you can find a diagram on how to make an induction heater with your own hands. There are enough articles on the Internet on this topic. Here I would like to describe the principle of how to make the simplest device at home.

For the simplest system you will need a small set of tools: a screwdriver, a soldering iron and wire cutters. And the manufacturing instructions look like this:

- take a 7 mm stainless steel wire and cut it into pieces of about 5 mm;

- We prepare a pipe, it doesn’t matter whether it’s made of plastic or metal. We make sure that the thickness is approximately five millimeters. This thickness is necessary to protect against overheating;

- fill the pipe with pieces of wire;

- Cover the holes at the ends of the pipe with a mesh so that wire scraps do not accidentally spill out;

- then take the copper wire and wrap it around the pipe in a spiral, about 80-90 turns;

- cut a rectangular hole in the pipe.

- insert the manufactured device into this hole.

- For the next step, you need a high-frequency inverter, which can be purchased at the store.

Operating principle

If you disassemble an induction type boiler, you will find the core, electrical and thermal insulation, then the body. The difference between this heater and those used in industry is the toroidal winding with copper conductors. It is located between two pipes welded together. These pipes are made of ferromagnetic steel. The wall of such a pipe is more than 10 mm. As a result of this design, the heater has much less weight, higher efficiency, and is also small in size. A pipe with a winding acts as a core here. And the other serves directly to heat the coolant.

The induction current, which is generated by a high-frequency magnetic field from the external winding to the pipe, heats the coolant. This process causes vibration of the walls. Thanks to this, scale does not deposit on them.

Heating occurs due to the fact that the core heats up during operation. Its temperature rises due to eddy currents. The latter are formed due to the magnetic field, which, in turn, is generated by high voltage currents. This is how an induction water heater and many modern boilers work.

Electromagnetic induction in the service of humans

The essence of the phenomenon of electromagnetic induction is the formation of an electric current inside a conductor, provided that the magnetic flux passing through it changes over time. This can be achieved in different ways: either by changing the parameters of the field itself, or by moving the conductor within a constant field - the main thing is that the number and intensity of the lines of force passing through it constantly change.

The benefits of this phenomenon cannot be overestimated. It is on this that the operation of any electric generator is based - from a small gasoline installation to a giant power plant with a capacity of 3000 MW. It is also used in induction heating systems.

Law of electromagnetic induction

The idea of induction heating is simple: if you use an alternating magnetic field to excite an electric current in a material with high resistance, the latter will begin to heat up. The method has become widely used in industry, for example, in metallurgy, where it is used to melt and harden metals.

Gradually, the technology migrated to the domestic sphere. Induction cookers and cooking surfaces have appeared on which it is impossible to get burned. Then - induction heating boilers and water heaters.

An induction furnace is used not only for melting metal, but also for heating a home. You can easily make such a device yourself. Do-it-yourself induction furnace: operating principle, design and parameters, as well as operating features, read carefully.

What criteria should you use to choose an electric storage water heater? Read here.

Which water heater is better to choose: storage or instantaneous? Here https://microklimat.pro/otopitelnoe-oborudovanie/vodonagrevateli/kakoj-luchshe-protochnyj-ili-nakopitelnyj.html you will learn all about the features of each type of device. Comparison of economy and practicality.

Advantages and disadvantages of the device

There are a lot of “advantages” of a vortex induction heater. This is a simple circuit for self-production, increased reliability, high efficiency, relatively low energy costs, long service life, low probability of breakdowns, etc.

The productivity of the device can be significant; units of this type are successfully used in the metallurgical industry. In terms of heating rate of the coolant, devices of this type confidently compete with traditional electric boilers; the water temperature in the system quickly reaches the required level.

During operation of the induction boiler, the heater vibrates slightly. This vibration shakes off limescale and other possible contaminants from the walls of the metal pipe, so such a device rarely needs to be cleaned. Of course, the heating system should be protected from these contaminants using a mechanical filter.

Constant contact with water minimizes the likelihood of the heater burning out, which is a fairly common problem for traditional boilers with heating elements. Despite the vibration, the boiler operates extremely quietly; additional sound insulation at the installation site is not required.

Another good thing about induction boilers is that they almost never leak, unless the system is installed correctly. The absence of leaks is due to the non-contact method of transferring thermal energy to the heater. Using the technology described above, the coolant can be heated almost to a vapor state.

This provides sufficient thermal convection to encourage efficient movement of coolant through the pipes. In most cases, the heating system will not have to be equipped with a circulation pump, although it all depends on the features and design of the specific heating system.

Sometimes a circulation pump is necessary. Installing the device is relatively easy. Although this will require some skills in installing electrical appliances and heating pipes.

But this convenient and reliable device has a number of disadvantages that should also be taken into account. For example, a boiler heats not only the coolant, but also the entire working space surrounding it. It is necessary to allocate a separate room for such a unit and remove all foreign objects from it. For a person, staying in close proximity to a working boiler for a long time can also be unsafe.

The device requires electricity to operate. In areas where there is no free access to this benefit of civilization, an induction boiler will be useless. And even where there are frequent power outages, it will demonstrate low efficiency

An explosion may occur if the device is handled carelessly

If you overheat the coolant, it will turn into steam. As a result, the pressure in the system will increase sharply, which the pipes simply cannot withstand and will burst. Therefore, for normal operation of the system, the device should be equipped with at least a pressure gauge, and even better - an emergency shutdown device, a thermostat, etc.

All this can significantly increase the cost of a homemade induction boiler. Although the device is considered virtually silent, this is not always the case. Some models may still produce some noise for various reasons. For a device made independently, the likelihood of such an outcome increases.

Customer Reviews

Andrey, Moscow : I live in St. Petersburg, I purchased a locally produced heater. It works properly, with one exception: the machine regularly knocks out. What's the matter - I haven't figured it out yet. But the savings on electricity are obvious. I specifically checked meter readings and accounts. In general, it is an interesting technology, but it is not yet familiar and therefore sometimes raises questions. It is not entirely clear how to use them correctly, what can be done and what cannot be done.

Marat, Moscow : I have had this heater for 2 years now. The savings on electricity are obvious. There were no breakdowns during this time. Plus, with a water heater using a heating element, I always had to look for a suitable anode to replace the failed one. No such problems arise here. And yet, despite all the advantages, I think that its cost is incredibly overpriced. The design is simple, there are no complications or expensive parts.

Assembling a vortex induction heater

In order to assemble this device, you will need a choke. It can be found if you open the power supply of a regular computer. Next you need to wind a ferromagnetic steel wire and 1.5 mm copper wire. Depending on the required parameters, from 10 to 30 turns may be needed. Then you need to select field-effect transistors. They are selected based on the maximum resistance of the open junction. As for diodes, they need to be taken under a reverse voltage of no less than 500 V, while the current will be somewhere around 3-4 A. You will also need zener diodes designed for 15-18 V. And their power should be about 2-3 Tue. Resistors - up to 0.5 W.

Next you need to assemble the circuit and make the coil. This is the basis on which the entire VIN induction heater is based. The coil will consist of 6-7 turns of 1.5 mm copper wire. Then the part must be included in the circuit and connected to electricity.

The device is capable of heating bolts until they turn yellow. The circuit is extremely simple, but during operation the system generates a lot of heat, so it is better to install radiators on the transistors.

Features of safe use

Remember that an induction heater is a structure that runs on electricity and has its own hazard class. A set of rules necessary for the manufacture of this device:

- Install a temperature sensor on the device. If the system suddenly overheats, the temperature sensor will trigger and the device will turn off;

- homemade products require separate electrical wiring with power designed for increased load;

- exposed areas of electrical wiring must be insulated in order to protect yourself and your loved ones from unwanted electric shocks;

- Before turning on the device, you must check the presence of water in the pipe. Its absence can lead to breakdown of heating equipment;

- Do not install the equipment in your home under any circumstances. It is necessary to remember the bad influence of electromagnetic waves;

- When installing an induction boiler, observe the installation boundaries - 80 cm from the floor and 30 cm to the ceiling;

- carry out grounding;

- After installing the device, you need to connect the automatic toggle switch. In case of network congestion, it will turn off;

- you need to install a safety valve to reduce the pressure.

Induction boiler in the heating system

Based on this, it is not difficult to conclude:

- The efficiency of the heater is very high and amounts to almost one hundred percent;

- the device is used for heating water and as a system heater for heating a house;

- Such a device is not difficult to assemble on your own, since the assembly is very simple and understandable even to a non-professional.

When considering all the advantages, do not forget that the decision to make an installation is made strictly independently and individually. Therefore, you need to approach this issue as seriously as possible:

- remember that this equipment consumes a lot of electrical energy;

- An induction heater is not 100% reliable from a safety point of view.

The device emits electromagnetic waves that are harmful to living beings. For this reason, it cannot be installed in a home, but it is better to have a separate room for it.

Manufacturers

- Galan boilers are popular. Equipment made in Russia. Components are used that are supplied from abroad. The devices are automatically controlled and accessible.

- "Nevsky". Used in closed heating systems. The necessary temperature parameters are automatically set, the device provides comfortable conditions. When the set temperature is reached, the device turns off until it cools down slightly. The boiler has a reliable assembly and components.

- Imported manufacturer Dakon (Czech Republic). There are about 30 models of units with heaters from Dakon. Models with additional equipment are possible - circulation pump, expansion tank.

- Kospel boiler (Poland). Used in single-circuit heating systems.