When designing and assembling a heating system in your home, safety should always remain the main criterion. Whatever the type and design of the system, you should still protect yourself from any emergency situations, because in case of any breakdowns, expensive repairs will be affected, and maybe the health of the residents, which should not be allowed. A safety group for a heating boiler is a necessary and mandatory component, which has long been produced in ready-assembled form, standardized and thought out to the smallest detail. It is only necessary to determine the characteristics of the unit for a specific heating system and install it taking into account all the rules and requirements.

How does it work

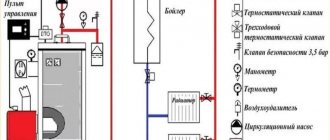

The safety group is a set of elements responsible for the overall safety of the heating system. By default it includes:

- pressure gauge;

- air vent;

- safety valve.

All three elements are fixed on one base - a console, which is a piece of pipe with a set of necessary fittings, an inlet and an outlet. Optionally, taps can be added to connect an expansion tank, additional sensors or backup systems, including automation.

The pressure gauge indicates the current actual pressure in the heating system, from which one can judge its general condition and take action in the event of unacceptable deviations. High blood pressure always indicates the presence of a problem, and a critical one that requires immediate action. Low pressure indicates an insufficient volume of coolant, a leak in the pipeline, boiler or radiators.

The air vent is included in the safety group as a safety element, which allows not only to solve the problem of air pockets that can negate the coolant circulation, but also to obtain reliable values and adequate operation of the pressure gauge and safety valve.

The safety valve automatically releases the coolant when the pressure rises above the permissible threshold. The valve is triggered if, for some reason, the expansion tank did not cope with the task assigned to it, or the pressure increased so much that the tank was physically not enough to eliminate the imbalance. The safety valve protects the system from rupture in the event of boiling of the coolant in the boiler or a gradual increase in pressure due to uncontrolled accumulation of gases, for example due to a chemical reaction of aluminum, in radiators with water.

Each element has special characteristics necessary for adequate operation. The pressure gauge must have a measurement range corresponding to the design pressure in the system. If, according to calculations, the pressure in the boiler should be 3 atmospheres, then the pressure gauge should be able to measure pressure up to 4-5 atmospheres. This is enough for diagnosis.

The safety valve must operate at the upper threshold of the permissible pressure for the boiler. This value is indicated in the instructions and technical data sheet for the boiler equipment. Accordingly, the valve is selected strictly for it.

An automatic air vent is the most unpretentious; it is enough to know that it is capable of venting air, and primarily at the connection point of the safety group, in order to nullify any errors in the operation of the valve and pressure gauge.

The console for the group is made of steel or brass, as a single block. Often, for safety or aesthetic appearance, the console and installed devices are closed in a protective casing, a common plastic or metal case.

For solid fuel

In a solid fuel boiler, the risk of the coolant boiling is much higher than in any other. The main element of the safety group is the safety valve. It is extremely important to select its settings and characteristics in accordance with the requirements of the boiler manufacturer. You should always have a few removable valves on hand for quick replacement in case the equipment involved fails.

You can choose the simplest pressure gauge with the desired measurement range. In any case, it will not be possible to diagnose a malfunction based on minimal changes in pressure. It is more important to record only significant fluctuations. The best option is to have additional arrow indicators that will mark the maximum and minimum values achieved during the observation period.

For gas

In wall-mounted gas boilers, the safety group is almost always already included in the equipment, so there is no need to install an additional one. However, it is important to check this point in advance. The group is mounted inside the housing as high as possible.

For floor-standing gas boilers, the safety group will most likely have to be installed independently outside the boiler body. A pressure gauge for a gas boiler should be selected with a minimum measurement error and an extended scale. This will allow you to more accurately diagnose a heating problem in the event of an emergency. The explanation of the readings and the necessary actions should be found in the boiler instructions.

Multi-level floor

To zone the space, craftsmen install floors at different levels. They advise installing a podium to separate the kitchen and dining room. This option is considered one of the most practical because, among other things, the owners have additional free space where they can hide something.

It is convenient to use boxes or crates for this. Wicker baskets will look good. But such space can remain free.

They will zone the space between the living room and the kitchen and protect the podium from damage. For example, tiles are laid in the kitchen area, and laminate flooring in the dining room. The main thing is to choose colors and textures and combine the finishes correctly.

Watts ksg 30

Approximate cost: 3500-7500 rub. (depending on modification).

The safety group made in Germany is intended for closed heating systems with a power of up to 50 kW. The modification with a ¾-inch connection is used in systems up to 100 kW. The safety valve is set to 3 bar. Options include different types of consoles. The following materials are used:

The layout may also differ. KSG 30 N is a compact assembly in which the valve and air vent are located closely, and between them there is a pressure gauge located forward. A group with elements arranged in a row is more often used. Options marked ISO1(2) are made with thermal insulation using polystyrene foam or polyurethane foam.

Installation and maintenance rules

According to modern safety requirements, each radiator must have a shut-off valve in front of it in case it fails and repair work is carried out without stopping the entire system. Which is especially important in the cold season. The safety group for the heating system should be installed similarly - the tap that shuts off the coolant MUST BE AFTER the safety system.

A common mistake is to install a shut-off valve between the boiler and the security system itself. In this case, if you need to stop the boiler as quickly as possible (especially a solid fuel boiler, for example, if pipes rupture or a radiator leaks), then it will be impossible to do this without consequences. After all, the coolant will continue to heat up for some time and will not find a way out. As a result, pressure increases and either pipes burst in another place or the boiler collapses. Both lead to significant losses.

After the device is installed according to the instructions, it is put into operation by opening a special cap on the automatic air vent. Please pay special attention - it is forbidden to remove it completely

Also, depending on the quality of the coolant and the degree of operation of the entire system, it is necessary to periodically (on average, once a month) inspect the valve for contamination between the seat and the plate. Because if dirt is not removed for a long time, this can lead to further leaks - just turn the device in the direction of the arrow and it will clean itself.

During installation, you must adhere to certain rules that will ensure the safe operation of the entire heating system. Firstly, there should be no foreign objects or pipes in front of the group so that they do not obscure the view of the pressure gauge. The best location is considered to be one in which, upon entering the boiler room, the readings of the measuring device are immediately visible. Secondly, it is prohibited to install other elements on the pipe between the group and the heat exchanger. Ideally, this pipe should be as short as possible in length and located as close to the boiler as possible. The manifold has threads on all outlets. Actually, installing a boiler safety group means screwing all the parts onto the crosspiece and installing it on the pipe. To prevent leaks, FUM tape, sealing paste or flax are applied to the threads before installation. Compliance with these simple rules during installation will allow the boiler equipment to operate without leaks and dangerous situations.

valtec vt.460.0.0

Complete safety group for heating systems up to 44 kW. The safety valve and pressure gauge are designed to work with nominal pressures up to 10 bar. A distinctive feature of the assembly is the presence of an additional pipe for connecting a ¾” expansion tank. The main connection to the main line is made through a pipe with a 1" internal thread.

Maintenance

- It is advisable to check the status of all modules of the security group every 2-3 months.

- The safety valve must be cleaned every 6 months to prevent leaks and contamination. To do this, it must be opened by turning the valve cap in the direction of the arrow.

- After 5-7 operations, it is recommended to replace the safety valve due to wear on the spring, which can lead to leakage and operation at lower pressures in the system.

kss g234

Safety group for a range of models of Buderus solid fuel boilers. Ideal for use with equipment from other manufacturers. Includes a standard set of safety valve, pressure gauge and air vent mounted on a single console. It should be taken into account that the connection of the console to the main line is lateral 1”. The valve is designed for a pressure of 2.5 bar. Directly next to the inlet pipe there is a threaded connection for connecting the expansion tank.

(VT.460.0) Complete safety group for equipping boilers and boilers of autonomous heating systems, hot water supply. It is used in installations with a thermal power of up to 44 kW (determined by the standard safety valve), a nominal pressure of no higher than 10 bar, and an operating temperature of no more than 120 °C. Acceptable working medium is steam, water, non-freezing coolant (maximum glycol content - 50%). Product composition: safety valve (fixed setting, 3 bar), automatic air vent, pressure gauge, nickel-plated brass body. A threaded pipe is provided for connecting an expansion tank (diameter – 3/4”). The boiler safety group is mounted at the outlet of the heat generator. Connection thread – internal, 1”.

| vendor code | Size/Quantity | Unit price |

| VT.460.0.0 | 1″ | 1769 p |

| * Manufacturer's recommended retail prices (RUB) are indicated. | ||

Passport: Boiler safety group (PDF, 366 KB)

Declaration of conformity with the technical regulations of the Customs Union (PDF, 1.15 MB)

Exemption letter in the field of fire safety (PDF, 564 KB)

Compact boiler safety group for autonomous water heating systems

A person physically cannot stay in the boiler room all the time to monitor the health of the heating line, temperature indicators and pressure level of the heating device. The main assistants in this matter are additional devices that automatically monitor the functioning of the system.

We will tell you what devices the heating safety group includes, how they operate, and how they protect the system. Taking into account our advice, you can easily select the necessary components. The article describes the rules for assembling and connecting this important link, which is responsible for trouble-free operation.

Prices: summary table

| Manufacturer and model | Maximum CO power, kW | Response pressure, bar | Thread diameter, inch | price, rub. |

| TIM JH-1024-1.5 | 50 | 1,5 | 1″ BP | 990-1 200 |

| VALTEC VT.460.0 | 44 | 3 | 1″ BP | 1 650-1 800 |

| Watts KSG 30 | 50 | 3 | 1″ BP | 2 600-3 400 |

| Caleffi 302631 | 50 | 3 | 1″ BP | 4 500-4 750 |

Security block design

The main reasons for a malfunction in a closed boiler system are increased pressure or excessive filling of the pipeline with coolant, i.e. water. The boiler heat exchanger is the first device to react to such deviations, which is why it fails.

Why might an accident happen?

To prevent such failures in the heating system, a safety unit is used. With its help, the required coolant pressure is achieved in the boiler, pipeline and batteries.

At the moment of excessive pressure, the excess heated coolant is discharged. Emerging emergency situations, such as overheating of a water heating boiler, lead to an increase in pressure in the line. This process is a consequence of exceeding the temperature norm of the coolant.

When heated, the liquid tends to expand, which a closed-type heating system is not designed for - an expansion tank is included in its circuit as an additional reserve. However, its volume is also limited.

Why is this necessary?

Let's not go too deep into technical aspects. Suffice it to remember the school physics course - when heated, bodies expand, and when cooled, they contract. Consequently, when heated, the coolant will increase in volume and if this is not compensated, then the probability of system failure with all the ensuing consequences is extremely high. To prevent accidents, a safety group for the heating system is needed. This is especially true when solid fuel boilers are used, because they have a fairly high thermal inertia.

Operating principle of the safety unit

The security group works according to an extremely simple scheme, where each of the modules is responsible for maintaining the standards of certain indicators in a private boiler room:

- Thanks to a convenient pressure gauge, the user can monitor the pressure readings at the moment the line is filled with coolant, as well as during the operation of the boiler.

- The safety valve protects the heat generator from critical pressure drops.

- The main functionality of the air vent is based on the automatic release of air entering the pipeline during its initial filling or during operation.

All safety modules are represented by a single unit and are equipped with a special housing - a manifold.

Water heater protection

Indirect heating boilers and electrical storage devices that prepare water for household needs also require protection. In this case, the danger is represented by pressure surges in the water supply and expansion of the liquid in the tank due to heating. To prevent the tank from leaking, a boiler safety group is installed at the water supply, consisting of the following parts:

- brass body;

- a check valve that does not allow water to flow from the container back into the pipe;

- safety valve that relieves excess pressure;

- ball valve to close the hot water supply line.

Storage water heater safety group from the VALTEC brand

In addition, indirect heating boilers are equipped with an automatic air vent mounted in the upper part of the tank and a dial temperature meter. A pressure gauge is optionally installed on the unit.

Equipment selection rules

For each model of the protective block, the accompanying documentation specifies the parameters for which it is designed.

The main criteria influencing the choice of device:

- thermal characteristics of the boiler for which the unit is designed, kW;

- maximum coolant temperature, °C;

- nominal pressure;

- compatibility with coolant - water, steam or antifreeze;

- diameter of the connecting thread - if there is a mismatch, it will be enough to purchase adapters of the required diameter.

Correct selection of the power of the safety unit ensures reliable protection of the boiler from any malfunctions in the operation of the heating circuit.

Purpose

Security mechanisms are actively used in private homes that use a gas boiler to heat the room. Indeed, with such a heating system, the following situations often arise:

- insufficient draft in the chimney, there is a danger of burning;

- in the supply pipeline the gas pressure is either very high or too low;

- The flame on the igniter went out.

All this can lead to the main burner going out and gas pollution in the room.

Some gas boilers are equipped with a circulation pump. It ensures uniform movement of coolant through the heating system.

Rating of popular models

Among the manufacturing companies involved in the development of safety valves, the following popular companies can be distinguished: Watts and Valtec. The manufacturer Watts is famous for its fairly extensive range of devices for the heating system, among which the safety unit occupies an important place.

The KSG series has various threaded body devices, differing in their sizes (from standard to compact) and material of manufacture:

Additionally, some models come complete with heat-insulating casings. Units from the KSG line are typically equipped with a relief valve designed for a critical pressure of 3 bar. Installation into the heating main is carried out using a 1-inch diameter connector with internal thread.

Valtec is not inferior in quality to its products to the previous brand. The company presents a line of devices for boilers and expansion tanks - the VT 460 and VT 495 series, respectively.

The VT 460 model range is designed to operate with domestic heating units with a power of up to 44 kW, at a maximum pressure of 3 bar. However, the prices for ready-made devices are far from cheap, so the solution of self-assembly of such a unit can be called advisable.

Assembling the security unit yourself

There shouldn't be any difficulties in making the safety unit.

To start the process, you will need to prepare the following modules and tools:

- relief valve;

- pressure gauge;

- air vent;

- wrench;

- gas keys;

- two squares with a threaded connection of external and internal type;

- union;

- crosspiece;

- adapters;

- sealant;

- sanitary flax for sealing and sealing joints.

Initially, the squares must be screwed into the crosspiece. For a tight connection, the flax strands are wound onto the threads in a clockwise direction, and the distribution of the sealant over the surface should be the same.

A thin layer of sealant is applied on top of the threads. Next, using a wrench, screw the squares into the crosspiece perpendicular to one another.

Now you need to install the pressure gauge, safety valve and air vent. If parts have different diameters, appropriate adapters are used. After the final assembly of all modules, the operation of the mechanism must be checked under pressure - the device should not leak, and all parts should be in working condition.

Connection to the heating system

First of all, it is necessary to correctly determine the installation location of the security group.

There are certain requirements that must be met:

- this should be a horizontal section of the pipeline next to the heat generator;

- on the supply line after the boiler;

- some boilers provide for installation of a safety unit directly on the unit itself; for this purpose there is a special connector on top of the heat generator;

- the distance from the heating device to the protective block should not exceed 1.5 meters, less is possible;

- for a pipe running vertically upward from the boiler, for example, to the next floor, it is necessary to arrange a branch. This is done using a corner so that the safety group can be positioned in a horizontal plane and the units look “heads up”;

- for a very powerful boiler, it may be necessary to install another protective unit.

A very important rule that must be followed is that shut-off valves are not installed between the safety group and the boiler. It would be advisable to install a protective block up to the first shut-off valve located on the line.

It is worth checking the functionality of the safety valve in a timely manner. This procedure is performed using the following method - after installation, open the cap in the direction indicated by the arrow on the device.

After installing the protective device, it is necessary to check the correct operation of all modules. To start using the air vent, you will need to unscrew the top cap and bleed the air. Now the lid is returned to its original position, but the device must remain slightly open.