Home / Heating

Back

Published: 02/25/2020

Reading time: 5 min

0

18785

The expansion tank in the heating system is designed to compensate for pressure drops in the coolant liquid that occur during starts and stops of the heating network. This phenomenon is explained by the thermal expansion of water or another coolant - antifreeze.

In order to perform its functions, the internal cavity of such a protective device is divided into 2 parts by a membrane - air and water.

The first has preset pressure parameters, which may drop during operation, so the user needs to know how to pump up pressure in the expansion tank of the boiler.

- 1 Design and purpose of the expansion tank

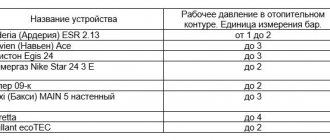

- 2 Correct pressure in the expansion tank 2.1 Norm for different models

- 5.1 Other troubleshooting methods

How to pump up the boiler expansion tank?

The expansion tank in a heating boiler performs an important function - it compensates for pressure surges when the temperature values of the coolant change, be it ordinary water or antifreeze.

The tank itself consists of two parts, between which there is a membrane. One part contains the coolant, the other contains air, through which the required pressure is created. And for normal operation you need to periodically pump up the tank. Next, you will learn how to pump up the boiler expansion tank and how to detect when you need to do so. A common situation: you turn on the water and run a bath. At this time, the boiler switches from heating mode to hot water supply mode. While the water is being collected, the coolant gradually cools down, and the expansion tank does not function at this time. And when you turn on the tap, the boiler should start heating again, but this does not happen. The reason is a sharp drop in pressure, as a result of which the automation simply blocked everything. This means it's time to pump up the air and increase the pressure in the tank.

Hot and cold H2O - is there a difference in the way the gap is sealed?

It's all about the difference in coolant temperature. It is this factor that is decisive when choosing a material.

With hot pressure, minor damage can heal without outside intervention . Larger gaps can be easily repaired with regular salt and a bandage.

But when the water cools, the flow will resume. It will not be possible to fix a leak in a cold water pipe with salt and a bandage. It is easier to repair a failed hot water pipe in the summer when it is turned off. Then you don’t have to control the temperature in the room while fixing the leak.

If you need to order high-quality installation of engineering systems (heating, water supply), please contact DESIGN PRESTIGE by phone +7 , and we will install the system at a professional level in accordance with high quality standards.

How to pump air into the boiler expansion tank?

Please note that you will not be forcing air into the system itself, but only into the expansion tank. Accordingly, it is not advisable to look at the boiler pressure gauge. Your main reference point is the pressure gauge on the pump itself. You can use a regular pump that is used to inflate car tires. You can, of course, use a compressor. Although not necessary. Your task is to pump up the pressure to just 1 atmosphere. An ordinary pump will handle this quite well.

The upload process consists of four steps:

- First, unplug the system and remove the plug from the outlet. This will primarily keep you safe.

- Next, drain the water from the boiler. If the equipment is new and installed correctly, then there is no need to drain all the water. It is enough to turn off the cold water supply, open the hot water supply tap, and also open the hot water supply valve on the closest mixer. This way the water contained in the boiler will be completely drained. Most modern boilers have special fittings for draining water. You can use them, but it is inconvenient - you will have to drain the water into buckets, basins, large bowls, then pour it out and repeat the procedure. The first method is faster and easier. Draining water from a gas boiler is necessary to make sure that you will pump air into the expansion tank. If there is any water left in it, it will be ineffective.

- Pump up the tank. Each tank has a regular nipple to which the pump can be easily connected. In most cases, you do not have to remove the boiler lid to access the nipple. When you pump up the tank, constantly monitor the pressure gauge on the pump. Your task is to pump up to approximately 1.2 atmospheres. This is the optimal value. If it turns out more, you need to loosen it. Otherwise, the system may simply not work until the pressure returns to normal. If you see water still coming out of the faucet while pumping, this is normal.

- Connect the boiler. When the pressure in the expansion tank reaches normal, you can reconnect the boiler. First, close the water supply tap and open the cold water tap. At the same time, dirty water and air bubbles will begin to flow. When this stops, the tap can be closed. Next, the feed tap must be opened again to fill the boiler to its operating condition. Here you need to look at the pressure gauge located on the body.

After this, you can open the supply and return taps. If you see that the pressure is weakening, you can add water. Next you need to remove air from the pump. Unscrew the plug at its end and bleed the air in the same way as is done on Mayevsky taps.

An important question for owners of wall-mounted and floor-mounted heating boilers: “how often do you need to pump up the expansion tank?” We recommend doing this every two years in new boilers, and every year in boilers that have already been in service for several years. Optimally - before the start of the heating season.

Operating principle of the Navien boiler

The operating principles of modern gas boilers are almost the same for all manufacturers, the only differences are in the configuration of the equipment and the internal arrangement of the actuators. The flow diagram of water in the boiler is shown in the figures. The Navien boiler works either to maintain the required temperature in the CO, when heated water from the first heat exchanger is pumped by a circulation pump in a large circle, or in the DHW preparation mode. The DHW mode is a priority, which means that if it is necessary to heat the water, a special three-way valve switches the circulation to the DHW plate heat exchanger, and the coolant flow through the heating circuit is blocked. The signal to switch the boiler to the DHW preparation mode comes from the flow sensor located on the hydraulic unit with the make-up tap.

How to identify a malfunction and why does the pressure in the expansion tank drop?

The most common signs of malfunction:

- “Jumping” pressure during boiler operation. For example, when the system operates for heating, it increases, and when switching to hot water supply it decreases. In the latter case, the indicator may even drop to zero.

- You have to constantly recharge the heating system, although leaks cannot be detected, and the heat exchanger works normally. Often the problem arises when there is a heated floor in the house.

In some cases, the reasons for the drop in pressure can be discovered independently. Very often they arise precisely because of coolant leaks. Moreover, more often when using antifreeze as a coolant. Antifreeze, due to its consistency, can penetrate even the smallest cracks, and the pressure drops. To correct the situation, you need to find the leak and fix it, then pump up the tank to the required pressure.

During operation, the pressure in the boiler itself may drop and return to normal after startup. If it does not align, this is a sign of a malfunction. Further, the system will fail even more. In such a situation, it is best to immediately contact a specialist for diagnostics, service and repair.

Design features and operating principle

All tanks are similar in design. They have a metal body, divided from the inside into two rolled compartments. The tank has a nipple on one side, and on the other there is a neck designed for connection to pipes.

There is a diaphragm inside the body. When the container is empty, it fills most of it, and the remaining space is occupied by air. During the operation of the network, the coolant heats up, its volume increases, and the excess penetrates into the cavity between the diaphragm and the housing.

After the temperature drops, the working medium decreases in volume, and the previously pumped air squeezes it back into the system.

If you need boiler repair or maintenance, call Profteplo

We work in Kaluga and the region, diagnosing, servicing and repairing systems of any complexity. We carry out both simple tasks of pumping air into an expansion tank, and complex complex repairs of modern systems. We provide a guarantee for all types of work.

If you need advice or want to use the service, just call the number or leave a request directly on the website. The master will arrive on the day of your call and will perform all the necessary types of work.

Source

If the water supply pump starts to malfunction, and it is difficult to drain the system, there is nowhere to go, there is no desire, and so on

- We turn it off from the network.

- We connect the air pump to the expansion tank. Electric is better. But not the pipe from a powerful compressor!

- What is our water pump shut-off pressure (maximum water pressure)? Let's assume 4 atmospheres.

- We pump up the water tank with air to 4 bar. It may take very little time if the tank is full of water.

- We drain the water into the bucket until the air pressure drops to 3.6 bar.

- Then we pump it again and drain it again. About 15 liters need to be drained. Once they drained it, they set it to 3.6 atmospheres and called it a day.

- We check with a soap solution or saliva to see if air is coming from the nipple. If it doesn't work, then good. If it does, then bleed all the air and change the nipple. We install the nipple EXACTLY THE SAME as it was!!! If you put a long nipple instead of a short one, you can pierce the pear with it. It can be completely pressed by rubber to the nipple. We buy a nipple at a car store.

Example Knowing the pump activation pressure, the volume of the tank and the knowledge obtained above in this same article, we can estimate how much water the pump pumps in one cycle of increasing pressure from minimum to maximum. For example, we have a 60 liter tank. On pressure 1.5 bar, off pressure 3.6 bar. Let's assume that the tank pressure without water should be 1.3 bar. The undrained residue in the tank (the moment the pump is turned on) will be approximately 9 liters. When the pump is turned off, there should be about 46 liters of water in the tank. At one time, the pump pumps 37 liters into the tank. When calculating, I meant that 1.5 bar differs from 1.3 bar by 0.2 bar, which is 13% (!!!). And 3.6 bar differs from 1.3 bar by 2.3 bar, which is almost 77% from 1.3

Expansion tank

Diary entry created by user igor197475, 03/25/10 .976,

This is not news for people involved in boiler repair/maintenance... but for those who are encountering this for the first time, it may be useful.

The expansion tank is necessary so that water... when heated in the heating system, goes into it, and does not increase the pressure in the system... and when it cools, CO expansion. the tank pushes water into the system, preventing the pressure from falling below the minimum permissible.

By the way, boiler manufacturers equip boilers with a built-in tank of 7-8 liters (depending on the model)... which is designed for approximately 120-140 liters of the heating system.. if you have a larger capacity, you need to install an additional tank. Signs of a problem with the expansion tank. 1When the boiler is operating, the water pressure “walks” and increases. and when using hot water (10-15 min) it usually drops to 0.0.6. but if there is no air in the RB at all, the pressure drops to 0 in a very short time. less than a minute. 2.You have to top up the heating system at least once a week...if there are no leaks in the heating system. How to properly pump air in the expansion tank. 1. Close all valves of the boiler supply and return. 2. Open the drain fitting in the boiler. Drain the water from the boiler. The pressure in the boiler should be “0” 3. Measure the pressure in the boiler with a pressure gauge, the drain fitting is open. There should be no water in the Expansion tank. 4. Use a pump (to the spool valve RB) to pump air until water stops flowing from the drain fitting. 4.1 You can also disconnect the RB hose from the boiler. (Whose it is connected with a hose) 4.2 The main goal is to free the RB from water 5. Bleed the air. 6. Inflate again (checking the pressure with a pressure gauge). The pressure in the RB should be within 1.1-1.3 bar. (See the passport. Often indicated) 7. Close the drain fitting. 8. Open the boiler...everything that was closed. 9. Feed the boiler..about 1-1.2 bar and can also be found here www.forumhouse.ru/threads/50746/ Perform in strict sequence.

Recommendations from professionals for carrying out preventive work

In order for the water supply system with a diaphragm tank to operate uninterruptedly, and, after several years, it does not have to undergo major repairs, it is necessary to carry out the following control measures for preventive purposes:

- Once every six months, the tank must be emptied and the quality of the internal membrane, as well as the tightness of all its connections, checked. The adjustment of air pressure in the accumulator depends on the condition of the diaphragm.

- Pumping equipment should be checked more often - once every 1 - 2 months.

- For the system to work smoothly, you need to know how to pump air into the accumulator. You should also check the pressure gauge at least once every 3 months.

- Once every 6–9 months, you need to check the relay to ensure that the settings are saved and the algorithm for turning the pump on and off is performed. Every homeowner should understand how to adjust the pressure switch on the accumulator.

- If voltage surges are detected, the best solution would be to install a stabilizer to avoid failure of the pumping equipment. Otherwise, the adjustment of the water pressure switch for the hydraulic accumulator may be disrupted.

- Every season you need to monitor the condition of the filters - both the reverse osmosis system and the mesh installed on the nozzles of the diaphragm tank.

Timely detection of defects, constant monitoring of air pressure in the hydraulic tank and quick elimination of minor faults will allow the water supply system with a pump and hydraulic accumulator to operate uninterruptedly for many years.

In the video you can see how to properly operate the water supply system at your dacha:

Water pressure and air pressure

In this article, I first examine the problem from a theoretical perspective. I don’t even take the tank itself, but an ideal model and see what processes take place in it. And only towards the end of the article I point out how our ideal model differs from a real tank

These are, as they say in Odessa, two big differences. Water is incompressible, so it is basically impossible to create pressure in a water supply by compressing water. And due to what is it possible? Due to just two things. Due to water stretching everything that can be stretched. For example, pipes or hoses.

A more workable idea is to create water pressure using air. Air, in fact, compresses very well and can simply act like a spring. That is why it is used in closed expansion tanks. Let's look at the following diagram. On it I depicted an expansion tank. But conditionally, so that you can understand how it works from the point of view of principle, and not from the real device. Everything is very simplified here. We have a cylinder in which a piston moves. On one side of the piston there is water, on the other there is air. The main physical law that will interest us is that when the volume of a gas decreases at constant gas weight and temperature, the pressure increases. The dependence is linear. Reduced the volume by 2 times - the pressure increased by 2 times.

Differences between Navien Ace and Navien Delux

Navien Delux is a modified model that replaced Navien Ace. Navien Delux Coaxial is a series of boilers with two heat exchangers with a power from 10 to 30 kW with a closed combustion chamber and forced smoke removal using a turbine. The manufacturer notes the following features of Navien Delux:

Frost protection system. Unlike boilers from other manufacturers, in addition to automatically turning on the burner when the temperature drops below 6 degrees, at temperatures below 10 degrees the boiler ensures continuous movement of the coolant by activating the circulation pump.

Fan with variable speed. Navien Delux boilers are equipped with a turbine with adjustable blade rotation speed depending on the readings of a special air pressure sensor. This ensures an optimal gas-air mixture ratio and increases boiler performance.

The heat exchanger is made of stainless steel. By using a fan with variable rotation speed and increasing combustion efficiency, it became possible to replace the copper heat exchanger with a stainless steel heat exchanger, which certainly has a significantly longer service life.

It is also noted that the boilers are protected from the influence of mains voltage surges by a special protective chip and the ability to operate at low (up to 4 mBar) pressure of main gas and water. In other words, the manufacturer tried to make a product that is maximally adapted to the worst operating conditions.

We have created air pressure, but the water is not connected

Suppose we pumped our tank on the right with air to a pressure of 1 bar on the pressure gauge. In this case, it is quite obvious that the piston under air pressure will be pressed against the left end of our cylinder. Suppose we placed some negligible amount of water on the left. Well, 1 gram, or 1 thimble, or 1 cubic cm. doesn't matter. Question. What pressure will this drop of water be under? Under pressure 1 atmosphere. In fact, a little more, because this drop moved our piston by some micron, the volume of gas decreased and the pressure increased. But since the amount of water is negligible, we will not consider the increase in pressure either. What else is important here? The fact is that we could only place this drop on the left side of the tank using a device (pump) that creates a pressure greater than the air pressure, because we act with water against the air. In our case, this is more than one bar.

Types of hydraulic tanks

A hydraulic tank is a metal reservoir designed to accumulate water from a well and then distribute it to consumers under pressure. The internal space of the steel tank is divided into 2 zones - dry and wet, by means of a flexible elastic membrane. Nitrogen or atmospheric air is injected into the dry zone, as a result of which the membrane stretches, creating pressure in the hydraulic tank on a poorly compressible medium - water located in the wet compartment. As a result, the liquid tends to leave the membrane tank, and when the tap in the bathroom is opened, pressure appears.

Hydraulic tanks on the market are divided into several types according to different criteria:

- By type of design - horizontal and vertical. The first type is used in small houses, with 1 - 2 points of analysis, as it has a small working volume of the wet chamber - up to 50 liters. The second type of tank is more common among owners of private residential buildings, and household hydraulic tanks of this category are offered on the market with a volume of up to 200 liters.

- By type of elastic diaphragm - balloon and membrane. In balloon devices, the rubber shell is made in the shape of a pear, and the pumped air is distributed only over the surface of the polymer material. Membrane tanks are separated into two compartments by an elastic diaphragm that stretches under the influence of compressed air. The shell is attached to the inner surface of the steel vessel by flanges, and the injected gas has direct contact with the steel walls.

- According to the location of the device - most often, floor-mounted storage tanks are used, on 3 steel supports. However, in order to save usable space, there are tanks with built-in brackets designed for wall mounting.

- An important question is what pressure should be in the hydraulic tank? Each of the hydraulic tanks available for free sale has its own technical characteristics. Tanks differ in the maximum force from compressed air, which can be set in a dry chamber, the volume depending on the number of analysis points, the method of removing excess air, as well as the diameter of the pipes for connection to the system.

We begin to fill the tank with water

What happens if we fill the tank with water to half its volume? The volume of air will decrease by 2 times. The pressure in the empty tank was 1 bar. Half filled with water it became 2 bars. The pressure in the water supply also became 2 bar. Everything is very logical. Can we put another quarter tank of water on the left? Let's assume yes. Can. In this case, the volume occupied by air will decrease by another factor of 2 and we will obtain an air pressure of 4 atmospheres. The water pressure in the system will also be 4 atmospheres.

To what volume can we compress the air on the right? In an ideal scheme, I think, very much. Until the air becomes liquid, I suppose. In real conditions, we still have not a piston, but a rubber bulb, and I have never seen anywhere in the characteristics of real tanks an indication of the maximum volume of water in them (additional information is below). I believe everything is governed by common sense, namely reasonable limits for turning the pump on and off. And let's finally move on from ideal schemes to real questions.

Navien boiler error 10

This error is related to the smoke removal system of the gas boiler. Combustion products must be removed; for this purpose, the boilers are equipped with a fan. To control the operation of the fan and determine the presence of permissible draft for boiler operation, a differential relay is used, which is connected to the turbine by two plastic tubes. When the fan is running, a vacuum is created, the relay closes, and the boiler functions normally.

Reasons for error 10

may be a clogged chimney, the presence of reverse draft, or incorrect connection of the air pressure control sensor to the fan. For the latter case, you need to check that the yellow tube is connected to the bottom of the fan, and the transparent one is connected to the top, and the tubes themselves are not damaged, deformed or condensation inside.

Increased resistance in the chimney can occur due to direct gusts of wind or blockage of the chimney (bird nest or cobwebs, freezing in winter). That's right, the location of the chimney should be taken into account the direction of the winds of a particular region at the design stage and the chimney should not be installed on the leeward side of the house.

We focused on the most common malfunctions of Navien boilers, but in fact there are significantly more error codes. Methods for checking and troubleshooting are the topic of a separate article. For convenience, here is a summary table of codes with a brief description:

| Fault number | Brief description of the problem |

| 02 | Low water pressure in the heating system or breakdown of the flow sensor |

| 03 | No signal from the ionization electrode |

| 04 | Incorrect signal from flame sensor or short circuit. Make sure there is no contact of the ionization electrode with the boiler or burner body, and diagnose the control board. |

| 05 | Damage to the heating temperature sensor. Measure the electrical resistance of the sensor and its compliance with the temperature table, and make sure that the connection between the sensor and the control board is secure. |

| 06 | Short circuit of the heating water temperature sensor circuit. Ring or replace the sensor. |

| 07 | Damage to the DHW temperature sensor. Check the dependence of the resistance on the temperature on the sensor, make sure that the connection of the sensor to the control unit is secure. |

| 08 | Short circuit of the DHW temperature sensor. Ring or replace the sensor. |

| 09 | Fan failure. Measure the resistance of the fan winding (test value is approximately 23 Ohms). Make sure that there is a voltage of 220 V at the fan terminals. There may be a problem with the control board circuit (diagnostics of the Navien board is required) |

| 10 | Malfunction of the combustion products removal system |

| 13 | Short circuit of the CO flow sensor. The sensor is stuck or the control unit is faulty. |

| 15 | Internal control board error (requires diagnosis and repair) |

| 16 | Boiler overheating. Signal from the emergency thermostat. The causes of overheating may be insufficient coolant circulation (see error 02), a clogged heat exchanger, or a malfunction of the thermostat itself. Operation occurs at 98 degrees, the alarm turns off when it cools down to 83 degrees. |

| 27 | Open or short circuit of the air pressure sensor circuit |

How does the above ideal diagram differ from a real expansion tank?

To many. We don't have a piston. Instead of a piston, we have a rubber bag that collapses under pressure. There are no means for neatly folding the bag. The bag wrinkles as it wants. Obviously, it forms all sorts of folds. When water rushes into the bag, it straightens these folds. Again, this bag has a seam.

Rubber itself also stretches, which introduces some nonlinearities into the described process.

And in general, all laws about the relationship between pressure and volume (Boyle-Mariotte) were written for an ideal gas and ideal conditions. In practice, only molecules were considered and that was all. With real gas, especially with air, which is a mixture of gases, everything is more complicated, of course.

In a real system there are contributing factors. Such as the quality of the rubber, the quality of the tank, the setup of the equipment on which the tank was produced, the team of workers who made these tanks. I am sure that tanks made by workers from Albania will be different from tanks made by workers from Serbia. I’m not saying who will do it better - I don’t know. But it is absolutely certain that they will differ.

How to stop a leak in a hidden pipe?

You won’t be particularly happy when a pipe hidden under a building structure starts leaking. Especially if the renovation has only recently been done. Since it is not always possible to quickly reach the source, you need to know how to temporarily stop the flow.

Here are a few techniques that are suitable for a water supply system in a private home:

In just a couple of hours, mustard will seal microcracks from inside the pipeline. When the leak is fixed, the circuit should be flushed.

- The heating system is temporarily filled with industrial sealant. It will settle on the internal surfaces of the pipeline and thereby stop water from seeping through microscopic gaps. After a major overhaul, the coolant is replaced with a new one.

Large holes cannot be sealed this way. Then they turn off the system, drain the water from the riser and begin straightening. Namely, it will be necessary to dismantle the structure and replace problematic spans. If you live in an apartment building, neighbors are warned about the upcoming event.

Pump on/off pressure

What happens if all the water leaves the tank and the pump does not turn on? In our tank, pumped up to 1 bar when empty, the minimum water pressure is 1 bar. That is, our water flows out, the pressure decreases and after the 1st bar it should simply drop to zero. Simply because there is no water. It's over. The motor starts running and the entire system experiences an unexpected load. Water is shot out of the pump, hits the pipes and is extinguished by the tank membrane, which takes the entire impact. This is not very comfortable and quite dangerous. It is much better if the pump turns on when there is still water in the tank! But not too much. In our case, the pump should turn on when the water pressure is greater than 1 bar. How much more? If it is much more, then we will reduce the amount of accumulated water and increase the frequency of pump activation (it will turn on more often and for less time), which is not good. Now we are beginning to understand why we were advised to pump the tank 2 tenths of a bar less than the pump activation pressure. In this case, when the pump is turned on, there will be a reasonable water level in the tank. Reasonable means justified by the manufacturer.

How to adjust a water supply system with a pump and hydraulic tank

What air pressure should be in the accumulator cavity to ensure normal operation of the water supply system? To adjust the pressure in a water supply system with a hydraulic tank, it is necessary to install additional devices that provide control and the ability to adjust indicators:

- How to properly pump air into a hydraulic accumulator? An initial pressure is created, pumped into the dry compartment of the accumulator and determined based on the above calculations. Pressure in the accumulator of 24 liters or more is pumped through a nipple on the body using a car pump with a flexible hose and a pressure gauge.

- After the operating pressure in the accumulator has been set and normal pressure has been established in the network, it is necessary to connect a programmable relay to the device. The device is connected to the electrical network, and the upper and lower limits of the permissible pressure in the water supply network are set on it.

If, based on the example discussed above, the optimal pressure in the receiver of a water pumping station is 1.55 atm, then the boundary conditions for the automation to operate can be set in the range from 1.6 to 3 atm.

Thus, if the accumulator pressure switch is correctly connected and configured, after its value drops to 1.6 atm, the pumping equipment will automatically start working. When the operating pressure reaches the maximum value of 3 atm, the pump will turn off and water will be collected until the indicator drops again to 1.6 atm. Hydraulic accumulator setup is complete

To mechanically control the operating pressure in the network, a pressure gauge is mounted on the outlet pipe of the membrane tank, which shows the exact current readings, in atm. or bar.

To connect the main pipeline, drain valve, relay and pressure gauge into one structural unit, a special device is sold in plumbing stores - a five-pin fitting. The fitting is screwed at one end onto the unit pipe, and the remaining elements are mounted to 4 other connections of different diameters to ensure uninterrupted operation of the system. The operation and adjustment of the water pressure switch for the hydraulic accumulator from the deep-well pump depends in this case on the tightness of all connections on the fitting.

The detailed algorithm for adjusting the system is described below:

What are the benefits of very large expansion tanks?

I will give an abstract example. We have a tank of 100 liters of total volume. We pump it up with one bar. We set the pump to turn on at 3 bars, and turn off to 4. In this case, the minimum remaining water in the tank will be more than half a tank (more than 50 liters). Our tank will operate in a range of about 12 liters. That is, the pump turns on every minute and a half. I think that the pump will withstand such a rhythm, but we get a super comfortable water supply system, in which the hot water in the shower does not “walk” around us due to changes in pressure. I mean a fairly common case when hot water cools down as the pressure in the water supply decreases, and then gets hotter again as the pump works to increase the pressure.

And if we assume that we are standing in the shower with a soapy head and the light turns off. What do we think? With a tank that is adjusted until it is almost completely dry, we do not know how much water we have left in the tank, even if the tank is a hundred liters. It is quite possible that the power outage caught us when the tank was completely running low! And in my scheme proposed above, the undrained residue is as much as 50 liters. I definitely have enough water to even finish washing my head and body. There’s nothing to even think about! You just need to shout to your wife to bring a candle.

How to adjust the relay

To understand how to adjust the pressure in the accumulator, you need to correctly configure the relay. After connecting the automation elements, as mentioned above, it is necessary to configure the relay by setting the system boundary parameters on it. This procedure is carried out in accordance with the following algorithm:

- When the water chamber is empty, the set parameter in the dry compartment is checked. It must correspond to the calculated values.

- When adjusting the hydraulic accumulator, the tightness of all threaded connections is checked, since if a leak forms during operation of the system, the pressure will begin to drop.

- Boundary conditions are characterized as the maximum and minimum values of a parameter in the system at which the device sends a signal to the pumping equipment to turn on or off. These indicators are written, respectively, as Pmin and Pmax.

- In the factory version, the pressure in the accumulator is already adjusted, and certain values are set on the relay, and the device is configured by checking and adjusting these indicators.

- The system is put into operation, and the pump pressurizes the accumulator by 50 liters or more. At this time, it is necessary to observe the pressure gauge readings. Upon reaching a certain value, the pump will automatically turn off, which will indicate that the relay is working. The resulting Pmax indicator is recorded on paper to ensure correct adjustment of the pressure switch for a hydraulic accumulator of 50 liters or larger.

- In the second stage, the tap is opened at the nearest disassembly point, and the pressure in the network begins to gradually drop. Similar to the previous case, when the pressure gauge needle shows a certain value, the pumping equipment will again begin to pump up pressure. At this moment, the position of the arrow on the indicator will indicate the Pmin parameter, and both values will be the starting point for setting the required relay settings. The entire setup of the accumulator pressure switch, if you follow the instructions, takes no more than 1 hour.

- The cover is removed from the relay, under which you can see two screws with springs - large and small.

- The pressure switch for the hydraulic accumulator is adjusted using a regular screwdriver. The large spring is responsible for the Pmin value. By tightening the screw clockwise, the value increases, and by loosening it, you can achieve a lower value.

- To check the correctness of the settings, you will need to perform the check algorithm described above with the automation activated several times.

- When the Pmin indicator is set to the most suitable position, it is necessary to adjust the small spring in the same way, and the pressure adjustment in the accumulator and pressure switch is completed. The screw is responsible for the difference between Pmax and Pmin. Thus, when turning the spring, the optimal value Pmax is achieved.

But how, after all, do you pump up the water tank?

We may only have two tank faults that are related to air pressure. If the pressure is too high (the tank is over-inflated) or too low (the tank is deflated).

If the tank is pumped, then we experience the water pressure gauge needle dropping to zero, and only then the pump turning on. For example, the switching pressure is 2 bar, the air pressure is 3. The arrow drops to three bar, then sharply drops to zero, the pump turns on.

The tank is under-pumped. You know, in this case it would have to work somehow until it deflates completely. If our tank deflates, then we get an increase in the remaining water in the tank. In this case, the pump runs for a shorter and shorter time. After all, he needs to pump less and less! And, by the way, the time before switching on is reduced. As a result, the air pressure in the tank disappears. It is completely filled with water and begins to “blink”, that is, frantically turn on and off.

Thus, in a pressurized system it is not at all easy to determine if there is a problem!

If the tank is over-inflated, the pressure must be released through the nipple. If the tank is under-pumped, you need to measure how much water it accumulates. Then, knowing the switch-on pressure and switch-off pressure of the pump, you can determine, at least approximately, how much water it should pump in one session.

Without knowing how much water is in the tank, we will not be able to accurately determine the air pressure. We can only act approximately.

Features when setting up a hydraulic accumulator pressure switch for a 50-liter water supply system

Owners of summer cottages often wonder how to set the accumulator pressure switch to 50 liters. A compact water supply system installed in a country house, to which no more than 2 sanitary and hygienic appliances are connected, requires a vertical or horizontal membrane tank with a working chamber volume of 50 liters. To set the optimal operating parameters of such a system, the following steps are required:

- What is the pressure in a 50 liter hydraulic tank? Air is pumped into the storage membrane tank until the reading on the pressure gauge reaches 1.5 atm. This parameter is considered optimal for the water supply network of a small private house. When the pressure in the accumulator increases, the volume of the wet chamber of the membrane device will decrease and the system will not work correctly.

- After it has become clear what pressure is needed in a hydraulic accumulator of 50 liters without water, the pump is turned on, the pipeline and membrane tank begin to fill with liquid.

- According to the algorithm described above, real readings on the relay, Pmax and Pmin are checked. The results are recorded on paper, and the technician understands what pressure is in the hydraulic tank.

- The operating parameters Pmax and Pmin are set on the relay.

- For the Pmax indicator in this system, the recommended value is 3.2 atm.

- The minimum pressure in the hydraulic tank is 50 liters, Pmin, this parameter is considered optimal when the reading on the pressure gauge is 2.0 atm.

Upon completion of setting the settings, a final control measurement is carried out to monitor the pressure gauge readings at the time the pumping equipment is turned on and off. If the set values of Pmax and Pmin correspond to the recommended figures, then the system will function without any problems.

The pressure in the accumulator is 100 liters for cold water. Considering the similar nature of operation of the system, with an increase in the volume of the working chamber, the nominal pressure increases slightly to 1.6 - 1.8 atm. The pressure in the hydraulic equipment of 100 liters for cold water depends on the number of storeys of the house, which, in most cases, does not exceed 2 - 3 floors.

The same applies to smaller tanks. For example, on forums homeowners often ask what pressure is needed in a 24-liter Gilex hydraulic accumulator? For normal operation of the water supply, the indicator should be within the same 1.5 atm.

Heating devices

In systems with natural circulation, you can use only radiators, as well as thick pipes as radiators (they have less hydraulic resistance).

But, alas, you cannot use convectors - natural circulation simply will not flow through them.

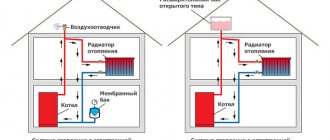

To summarize the above, an open system is a thing of the past. Slow heating, high inertia of the system, a large amount of soluble air, bulky pipes, and low efficiency make it unattractive for modern heating systems. So it is used in extreme cases - for example, in areas where electricity is often cut off.

The most popular now are closed systems with forced circulation of coolant, two-pipe or collector-beam.

Today no one will be surprised by an autonomous water supply system. Such designs are very convenient and practical, but their operation often requires devices that a person who uses only a centralized water supply may simply not know about. For example, an autonomous water supply system will operate uninterruptedly for a long time only if it includes an expansion tank for water supply. Modern industry produces many different models of such devices. To choose the best option for yourself, you need to navigate the types of equipment and have a good understanding of the principle of its operation.

Basic Concepts

First, let's look at the features of pressure and the main concepts.

- There are several units for measuring pressure: atmospheres, bars, megapascals.

- Even in a non-working unit there is pressure - it is called static.

- During boiler operation, all network elements are subject to dynamic pressure.

- The maximum permissible pressure is the last value after which a tragedy can occur.

- The internal boiler radiator is the most sensitive part of the system, especially susceptible to pressure surges. But batteries and pipes can fully withstand fairly high values, although almost everything depends on the material from which they are made, their “age” and other characteristics.

What pressure should be in a gas boiler depends greatly on the characteristics of the system itself - the number of batteries, the equipment used, materials, etc. If you have a one- or two-story private house, the operating pressure should not exceed 1.5-2 atmospheres. If the number of floors is more than 2, a higher value is allowed - up to 4 atmospheres. But in both cases, we recommend installing pressure gauges on each floor. This will allow you to take clear characteristics and, if necessary, take measures.

How to choose the right device?

The main characteristic on the basis of which equipment is selected is its volume. In this case, the following factors must be taken into account:

- Number of people using the water supply system.

- The number of water intake points, which include not only showers and taps, but also household appliances, for example, a washing machine and dishwasher.

- The likelihood that water will be consumed by several consumers at the same time.

- Limit number of start-stop cycles in one hour for installed pumping equipment.

Experts recommend using the following indicators as a guideline when choosing an expansion tank:

- If the number of consumers does not exceed three people, and the installed pump has a capacity of up to 2 cubic meters. m per hour, a tank with a volume of 20 to 24 liters is selected.

- If the number of consumers is from four to eight people and the pump capacity is within 3.5 cubic meters. m per hour, a tank with a volume of 50 liters is installed.

- If the number of consumers is more than ten people and the productivity of the pumping equipment is 5 cubic meters. m per hour, choose an expansion tank of 100 liters.

When selecting the desired device model, it is worth considering that the smaller the tank volume, the more often the pump will turn on. And also the fact that the smaller the volume, the greater the likelihood of pressure surges in the system. In addition, the equipment is also a reservoir for storing a certain supply of water. Based on this, the volume of the expansion tank is adjusted. You should know that the design of the device allows the installation of an additional tank. Moreover, this can be done during the operation of the main equipment without labor-intensive dismantling work. After installing the new device, the volume of the tank will be determined by the total volume of the containers installed in the system.

In addition to technical characteristics, when choosing an expansion tank, special attention should be paid to its manufacturer. The pursuit of cheapness can result in much more significant expenses. Most often, to produce models that are attractive for their cost, the cheapest materials are used, and, as practice shows, they are not always of high quality. The quality of the rubber from which the membrane is made is especially important. Not only the service life of the tank, but also the safety of the water that comes from it directly depends on this.

When purchasing a tank with a replaceable membrane, be sure to check the cost of the consumable element. Very often, in the pursuit of profit, not always conscientious manufacturers significantly increase the price of a replacement membrane. In this case, it will be more appropriate to choose a model from another company. Most often, a large manufacturer is ready to be responsible for the quality of its products because it values its reputation. Thus, it is worth considering models from these brands first. These are Gilex and Elbi (Russia) and Reflex, Zilmet, Aquasystem (Germany).

The volume of the expansion tank for water supply may vary; it is selected based on the needs of the users. If a larger volume is subsequently required, an additional device can be installed

Features of self-installation

All expansion tanks can be divided into two groups, determined by the connection method. There are vertical and horizontal models. There are no special differences between them. When choosing, they are guided by the parameters of the room where the equipment will be located. During the installation process, you should adhere to the following recommendations:

- The expansion tank is installed in such a way that it can be easily accessed for maintenance.

- It is necessary to provide for the possible subsequent dismantling of the connecting pipeline to replace or repair the equipment.

- The diameter of the connected water supply cannot be less than the diameter of the pipe.

- The device must be grounded to avoid electrolytic corrosion.

The device is installed on the suction side of the pump. In the section between the pumping equipment and the connection point, it is necessary to exclude all elements that can introduce significant hydraulic resistance into the system. We connect the make-up line to the circulation circuit of the entire system.

According to the type of installation, expansion tanks of horizontal and vertical connection are distinguished

Please also pay attention to the material about what malfunctions most often occur in pumping stations, and how to fix them yourself: https://aqua-rmnt.com/vodosnab/nasos/nasos-stancii/remont-nasosnoj-stancii-svoimi-rukami .html

The expansion tank is an integral part of an autonomous water supply system. It maintains the required pressure in the system, prevents premature damage to the pump and retains a certain supply of water. However, all these functions are performed only if the structure is correctly selected and installed correctly. Therefore, if you lack experience, it is better not to get carried away with amateur activities, but to find qualified specialists who will install any device with high quality.

The expansion tank performs two tasks: compensation for the increase in liquid volume during heating and protection against water hammer.

To prevent damage to heating systems, such devices must be installed in them.