Baxi is a line of gas boilers from an Italian manufacturer. The best option for maintaining a comfortable temperature in the room.

Gas boilers from this company are safe, environmentally friendly, durable, virtually silent, durable and economical, have high performance and are quite easy to operate, in addition, they are affordable. Even if a decrease in gas pressure is noted in the network, the boiler will not stop operating. Baxi boilers operate on liquefied natural gas. Modern design allows you to organically place the boiler in the interior of any room.

In order to select the correct spare parts for the boiler after an identified breakdown, you need to know its series and model. The most common: Baxi Luna (Comfort, Comfort Combi, Silver Space), ECO, Nuvola (included with a stainless steel boiler), Slim, Main.

The volume of boilers ranges from super-compact to 80 liters. They can be installed on the floor or mounted on the wall. Structurally, boilers are divided into: single-circuit and double-circuit.

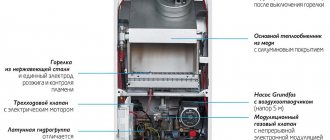

Advantages and structure of Baksi gas boilers

Each series has its own technical parameters and operating features. Characteristics, installation and maintenance requirements are specified in the manufacturer's instructions. The basic structure of the main components is the same. The models are compact. Connection of a floor- or wall-type structure occurs according to the standard scheme. Using a temperature control sensor ensures smooth and stable operation.

The appliances have chimneys and exhaust devices that serve to remove combustion products. The thermostat signals a change in the temperature in the room. For the production of combustion chambers, which have a heat insulator on the outside, high quality metal is used. The heat exchanger, made of copper, is located above. An electronic control system is integrated into the device.

Advantages of Italian brand equipment:

- overheat protection;

- ergonomics of the model range;

- maintaining temperatures set by the owner;

- adjusting parameters;

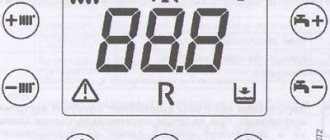

- self-diagnosis with error codes displayed on the display;

- work in automatic mode;

- reliability.

If a malfunction is identified, it is easy to fix the breakdown. High level of repairability. The undoubted advantage is the price. The cost depends on the size, power, type of boiler and burner. The price increases with additional features that improve performance and enhance safety.

Ways to solve the problem

The problem can be solved in ways that require significant investment, for example:

- using an indirect heating boiler together with a boiler,

- purchasing a new boiler with a built-in boiler.

However, there is a less expensive, but very productive method - inserting an electric storage heater into the hot water supply circuit. Moreover, for this purpose, any standard heater with a volume of 30 liters is quite suitable, regardless of the manufacturer.

Operation under pressure reduction

It is difficult to start and set up a boiler with insufficient water pressure. The control system will signal errors. The device will constantly turn off.

Main problems and ways to solve them:

- Pressure sensor short circuit. With this problem, the device produces incorrect data. The solution is to replace the component or remove the terminals and short them with jumpers.

- Connecting a warm floor. You will need to purchase and install an additional expansion tank of suitable volume.

- Incorrect information coming from the pressure gauge on the pump suction pipe. The solution is to replace the device with a pump to increase the pressure.

In order for the structure to work smoothly, prevention and maintenance are necessary. Our technicians will carry out complex work, troubleshoot problems, and perform configurations.

The boiler does not heat water for heating

So, let's look at the main reasons why a gas boiler does not heat water for the heating system and what to do about it:

- airlock. It is necessary to inspect the heating system for the presence of air in the radiators. To eliminate this problem, you need to install an air vent. Its operating principle is similar to that of an expansion tank, but it is capable of maintaining pressure in the system. Using an air vent, you need to bleed air from the system. It is important to inspect the valve itself for mechanical blockages - scale may be present there;

- corrosion in radiators. Clogging of heating devices can be determined by draining water from the system. If the water flows dirty, then you need to flush the system until visually clean water appears;

- connection errors. Hot water may not flow if the diameter of the pipes is not as specified in the project or instructions. It is necessary to check the compliance of the pipeline, the correct connection and the quality of installation of shut-off valves;

- insufficient pressure in the network. You should try adding water to the heating system, as there may not be enough pressure to trigger the automatic ignition of the burner;

- presence of scale in the heat exchanger. The first sign is prolonged heating of the coolant and heating of the batteries. It is necessary to get rid of sediments and carry out boiler water treatment. To do this, you need to disassemble the boiler and remove the heat exchanger assembly.

Before doing this, you need to shut off the flow of gas and water to the device. Then flexible connectors from the pump are connected to the heat exchanger and it is washed with a composition containing a special cleaning agent, which can be purchased over the counter. After which the parts are washed with water.

Some manufacturers allow the use of antifreeze instead of water in the heating system. This substance can be used in the following boilers: “Baxi”, “Vaillant”, “Proterm”, “Beretta”, “Korea Star”. However, it should be understood that each manufacturer recommends using its own antifreeze;

- filter clogging. If the filter screens are clogged with mechanical debris, the radiators may also have poor heating. Therefore, the filter should be checked and cleaned regularly by rinsing with water. If clogging occurs too often, then such a part must be replaced;

- incorrect setting. First of all, if there is weak or no heating, you need to check the settings of the control unit. The temperature may be set insufficiently and the gas does not heat the water;

- malfunctions of pumping equipment. If the pump power is not enough to ensure good circulation, it may turn off if it overheats. This can happen when the DHW circuit is turned on;

- incorrectly selected heating devices. If the system has radiators with unsuitable heat transfer and design parameters, this can also lead to low heating;

- incorrect slope of pipelines. Most often this problem occurs in systems with natural circulation. Regulatory documentation specifies that the slope of pipes should be 10 mm per meter of pipe. If these requirements are not met, circulation may be disrupted and, as a result, there may be no heating due to low coolant flow.

Pipe diameter narrowing

The occurrence of blockages leads to a change in the diameter of the pipes. The result is a reduction in the consumption of working fluid. As a result, the Baxi gas boiler begins to work incorrectly and turns off. The solution is to find the blockage and clean it. Pneumatic and hydraulic equipment is used for flushing.

Before work, it is necessary to test the tightness of the system. After checking, disassemble and clean the circuit. Flushing is performed using a pumping device. Under the influence of high speed movement of the working medium through the heating system, hydrotreating is performed. The result is that all contaminated liquid is removed.

If flushing does not solve the problem, clean the pipes. The area where the blockage is detected is closed with taps, and then the working fluid is drained. Cleaning is carried out using a brush placed on a wire. After this procedure, washing is done. Upon completion, the blocked area is returned to working condition. The heating boiler is ready for operation.

What happens when hot water is turned on simultaneously at two points of intake

The scheme becomes more complicated if, while using hot water at one point of intake, it becomes necessary to turn it on at another point, for example: when the shower is turned on in the bathroom, it becomes necessary to wash your hands in the toilet washbasin. In this case:

- the rate of hot water use increases sharply, its consumption increases,

- weak pressure of hot water appears;

- the flow of cold water into the boiler increases,

- a drop in the temperature of the boiler heat exchanger leads to the fact that the water temperature at the first intake point ceases to be comfortable,

- a few seconds are required to turn on the boiler automation for heating,

- a few more seconds for both users at two points of collection to be able to use water at a comfortable temperature.

Filter clogged

Baxi gas boilers are equipped with a smart control system. After switching on, the device reaches the required temperature. When the set value is reached, it turns off. The action starts again when the system cools down.

A clogged filter occurs due to the accumulation of various impurities that come from the water supply. To avoid the problem, it is necessary to install a filter mesh. The element will retain particles whose size exceeds the dimensions of the cells. The mesh component must be cleaned periodically. You need to close the taps in front and behind the mesh, and then remove it. After thorough cleaning under a strong stream of water, the element is installed in place.

To troubleshoot problems, you need knowledge of the operating features of Baxi gas boilers. If knowledge and experience are not enough, then it is better to call a specialist who will carry out diagnostics, maintenance or repairs.

Sensor diagnostics

If the flow sensor is a microswitch, then for diagnostics it is enough to check the contact closure with a tester. To do this, disconnect the contacts from the sensor, connect the tester in “dialing” mode, and turn on the water tap. If a short circuit does not occur, it means that the sensor is faulty and requires inspection and, if necessary, replacement. It happens that accumulated dirt interferes with the circuit and it is enough to clean it. Poor quality of tap water and lack of pre-filters are the most common problem. Reed sensors contain a magnet, so they attract microparticles of rust and quickly fail.

Sensors with a flow meter record the amount of water flow, which can usually be displayed on the boiler display. For BAXI boilers you need:

- hold the “i” button to access the information menu for 5 seconds

- Use the DHW temperature adjustment buttons to scroll to parameter A08 (actual flow rate of water passing through the sensor, liters per minute * 10)

Now all that remains is to compare the actual water flow from the tap with the flow according to the sensor. If the actual flow rate does not correspond to the sensor value, then most likely it needs to be replaced.

Since the mechanical part of the flow sensor is a turbine, if it gets dirty, it can jam and the signal from the sensor disappears. There is no signal from the flow sensor - the boiler stops heating water.

The pump is not working reliably

The circulation pump is characterized by high quality and trouble-free operation. The reason it fails is because the rotor is broken or a large volume of air has accumulated. As a result of such malfunctions, the Baksi gas boiler turns off. To prevent the pumping of the working fluid from stopping, it is necessary to remove the liquid from the pump and then turn the axle with a regular screwdriver.

Pumping equipment is installed before the boiler, because the coolant leaving it is hot. This temperature can damage the structure. Installation in front of the boiler is effective for the equipment as a whole. The service life of the autonomous system is significantly increased. Additionally, a filter is required in front of the pump.

The burner starts and turns off at certain intervals. The indicators are individual for each system. The equipment manufacturer provides a warranty period only for the temperature range. It does not depend on the frequency of operation of the burner component.

The owner of a Baxi gas boiler switches the operating mode of the device depending on the time of year and comfortable room temperature. In order for the device to work reliably and without failures, it is important to configure the burner device. The owner must fill the circuit with a sufficient volume of liquid and select a location for installing the thermostat.

Why are the batteries in the apartment cold? Let’s find out the reasons

First you need to make sure that the heating is really turned on, and the heating system of the apartment receives coolant at the required temperature. You should start worrying if:

- the risers are hot, but the radiators are not,

- the neighbors have heat, but you don’t,

- the battery does not warm up completely (only from the bottom or top, or from one side),

- the radiator is slightly warm, and the riser is boiling water,

- the pipes made a lot of noise for more than two days, but heat still did not enter the apartment,

- The housing office told you that heating was installed in your house more than a week ago, but the radiators and risers are cold.

In the absence of problems with the central network, the causes of cold radiators include:

- presence of air pockets in the system;

- clogged batteries;

- Incorrect connection of heating network elements.

In each situation, a certain amount of work will need to be done to make cold radiators hot.

Smart control system

Owners must immediately understand and understand the electronic system that is responsible for the operation of Baxi gas boilers. The control unit signals errors, which are displayed on the display in the form of codes. Many problems can be fixed on your own. Complex breakdowns require the help of specialists. Periodic switching on and off can be eliminated without resorting to the help of specialists. Regular self-diagnosis of the “smart system” helps with this.

Practical recommendations

You can eliminate the appearance of “random” errors (and they are regularly displayed as a result of instability of the power supply) by connecting the gas Baxi to the network via a UPS. Various modifications of blocks are available for sale, designed to work together with household boilers.

The stabilizer and UPS are connected to the Baxi boiler

Unlike a stabilizer, this device will supply voltage to the heating unit even in the event of power line breaks and a malfunction of the backup generator. The autonomy of the UPS is ensured by built-in (or attached external) batteries. Users note that after its installation at the site, the number of Baxi boiler errors that appear is sharply reduced.

FULFILLMENT OF WARRANTY OBLIGATIONS.

If malfunctions occur during the warranty period, warranty work is performed by the organization that commissioned the product (in the absence of other warranty agreements). BAXI SpA provides compensation for the cost of failed boiler components under warranty through official dealers of BAXI SpA. In turn, official dealers of BAXI SpA compensate the cost of these components to trading companies. To compensate for the cost of a failed component, the service organization must provide, along with the faulty components, a completed “individual repair report form” of the established form or provide the same data in electronic form (using a template file from BAXI SpA). Spare parts are purchased by trading companies or service organizations from official dealers of BAXI SpA for products or spare parts.

Cleaning the heat exchanger circuit

If the heat exchanger is clogged, there may be a decrease in temperature and heating efficiency of the room with a simultaneous increase in fuel consumption. It is difficult to clean the primary and secondary circuits of the heat exchanger yourself, since it is necessary to use appropriate chemicals and special equipment that provides increased pressure in the system. Cleaning the primary heat exchanger is carried out according to the following scheme:

- The master drains the water by opening the appropriate taps and pipes.

- Water is also drained from the heating system.

- A device for pressurizing the system is connected to the heating pipes of the boiler.

- On the device, unscrew the lid and pour liquid from deposits and scale into the heat exchanger.

- The liquid used must circulate in the system for at least two to three hours. This time is enough to dissolve and remove even old deposits.

- Turn off the device, unscrew the taps and drain the water from the boiler. All flushing liquid must be removed from the equipment, after which it is filled with coolant.

When cleaning the heat exchanger circuit yourself, pour active liquid into the boiler through the lid, turn on the device for heating and let it work for several hours. After this, a complete replacement of the antifreeze is carried out with the obligatory de-airing of the system.

A similar scheme is used to clean the secondary heating circuit of the Baxi boiler. The gas tap must be closed while simultaneously opening the heated water supply tap. The liquid with the cleaner will be driven through the secondary short heating circuit, dissolving existing deposits and removing dirt accumulated in the pipes and heat exchanger.

Baxi boilers are popular in the market due to their functionality, versatility, automation and fuel efficiency. But even such equipment may break down during operation and require qualified repairs. If there are malfunctions in the operation of heating equipment, it is best to contact specialists who are well aware of the features of the equipment and use special equipment and chemicals to clean the circuit. This allows them to offer high-quality repair and maintenance services for Baxi equipment.

AUTHORIZED SERVICE CENTERS AND AUTHORIZED SERVICE PARTNERS OF BAXI SPA

Service organizations can enter into service contracts and thus become authorized service centers and authorized service partners of BAXI SpA. BAXI Authorized Service Partners (ASP) are organizations that have the right to perform first start-up, service maintenance and warranty on behalf of BAXI SpA. repair of BAXI equipment. BAXI Authorized Service Centers (ASC) are organizations that have the right to perform the first start-up and service maintenance of BAXI equipment on behalf of BAXI SpA and assume the following additional obligations: - upon contact, perform the first start-up and carry out subsequent warranty and service maintenance of any BAXI equipment purchased from any trade organization or installed by another organization; - sell BAXI spare parts to all applicants.

Authorized service centers and service partners of BAXI, in agreement with the representative office of BAXI SpA, have the right to extend the warranty period. Also, during warranty repairs, BAXI SpA, in addition to compensation for spare parts, pays the cost of travel and work (according to the contract). BAXI SpA carries out compensation under the warranty through official BAXI dealers, or through direct payments. Authorized service centers and service partners of BAXI are created either on the basis of trading companies that regularly work with BAXI products, or on the recommendation of these trading companies.