To grow vegetables all year round, the greenhouse requires artificial heating. After all, sun, warmth and water are the most important three factors, without which it is impossible to grow even berries. By using heating in a greenhouse, a gardener can easily extend seasonal work by more than three months, and grow seedlings as early as the end of February. So in a year you can harvest three harvests of one crop. But which heating is better to choose? What are the pros and cons of each type? The modern construction market offers many types of heaters for greenhouses, the three most promising of which are: cable, infrared film and infrared ceiling. Why these? Read on.

- 2 Cable soil heater

- 3 Ceiling and wall infrared heaters

Types of gas heaters

According to the degree of attachment to specific places in the greenhouse, gas heating devices are divided into stationary and mobile (portable).

Did you know? In addition to their intended purpose, IR emitters can effectively combat harmful microorganisms, of which there are a lot in greenhouses.

Stationary

Stationary gas devices installed at a permanent and specific place in the greenhouse can be attached:

- on the ceiling;

- on the wall;

- at the baseboard;

- in limbo.

Portable

Mobile types of gas heaters are able to change location inside the greenhouse depending on current needs. For this purpose, they are equipped with wheels or special legs.

Mobile heat generators in agriculture

In small greenhouses it can be beneficial to use compact mobile heat generators of the AGRI series.

These heat generators are designed to work with a full-fledged pressurized burner, which can be liquid fuel (diesel), gas (using bottled or main gas) or universal - using waste oil, vegetable oil, diesel fuel, etc.

The use of burners for processing in agriculture can significantly reduce the cost of production.

| Heat generators Tecnoclima AGRI Convenient for organizing temporary heating of easily assembled greenhouses or premises for livestock and poultry during the cold season. They can easily move on their own wheels, which allows them to be stored in a separate room. | Air flow, m3/hour | Consumption power, kWt | Supply voltage, V/f | |

| Agri-C 60 | 53 | 4500 | 0,40 | 220/1f |

| Agri-C 85 | 75 | 6000 | 0,53 | 220/1f |

| Agri-C 120 | 105 | 8500 | 1,00 | 220/1f |

| Agri-C 175 | 153 | 13000 | 1,35 | 380/3f |

| Agri-C 240 | 209 | 16000 | 2,20 | 380/3f |

Read more about the Tecnoclima brand...

Order us a calculation of your heat generator:

Heating a greenhouse with gas heaters: pros and cons

- During the operation of gas infrared units, many of their positive qualities were recorded:

- they heat primarily the soil rather than the air;

- do not create strong forced air flows, which makes it difficult to move dust and pathogens;

- low noise operation;

- infrared radiation spreads at an angle of 120°, which allows heating a large area;

- quick heating of the greenhouse and long-term heat retention;

- economical fuel consumption;

- long-term continuous operation;

- compactness;

- ease of installation;

- versatility of use;

- absence of moving parts in the design, which facilitates maintenance of the units.

- The disadvantages include:

- high cost of heaters;

- the opportunity to purchase a fake that is not durable;

- the need to carefully calculate the number of necessary devices for a specific greenhouse space.

Did you know? Why do IR heaters heat surfaces without heating the air? In the infrared wavelength range there are peculiar “windows” in which these waves are minimally absorbed. In one of these “windows” there is air, which is almost transparent to infrared waves.

Advantages

If we evaluate the capabilities of a gas heat generator for air heating of greenhouses, then in many respects it surpasses the already familiar wood-burning stoves and electric convectors. The advantages of the device are as follows:

- To heat the air, one of the most accessible types of fuel is used, which allows significant savings on energy resources.

- Air heating occurs almost instantly - in a short period of time you can heat large rooms.

- Traditional coolants replace air masses, and this makes the unit safe and environmentally friendly.

- The device is versatile - it can be used for a space of any size, not only for heating, but also for ventilating the room.

- Maintenance of the air heater does not require special attention, since many processes often occur automatically. Its use helps reduce labor costs - greenhouse owners do not need to hire many workers, so the wage fund can be reduced.

- The absence of coolant liquid prevents the system from leaking and freezing when turned off.

- Organizing air heating is cheaper than installing water heaters of similar thermal power.

The use of air heat generators ensures complete air circulation in greenhouses, which has a beneficial effect on the development of plants. Heated air masses absorb a large amount of moisture, thereby reducing dew from polycarbonate or polyethylene film. Reducing the humidity level, in turn, minimizes the entry of harmful microorganisms onto plants and helps protect seedlings from many diseases.

Classification

Infrared heating devices differ in the sources of energy released, types of heating elements, installation methods and some other characteristics.

You will be interested in learning how to heat a greenhouse using wood.

Source of released energy

Today there are 3 sources of thermal energy released by heaters, according to which devices are divided into:

- electrical;

- gas;

- diesel

Heating element type

Heating elements in gas infrared heaters are:

- metal in the form of meshes, heated to high temperatures;

- ceramic in the form of tiles, which have great strength and the ability to quickly heat up to a high temperature and quickly cool down;

- metal in the form of tubes, giving a lower temperature.

We advise you to find out how to remove condensation in a greenhouse.

According to the type of heating elements, gas infrared heaters are divided into:

- light, which, causing a visible glow, heat metal mesh or ceramic tiles to temperatures above +600°C;

- dark, heating metal tubes to temperatures below +600°C.

Form

Light heaters, as a rule, have a round or rectangular shape and are not equipped with a smoke exhauster. Dark versions of these devices have an elongated shape and are equipped with a smoke exhauster that drives combustion products through a tubular heating element.

Find out how to make automatic watering in a greenhouse with your own hands.

Installation method

As mentioned above, depending on the installation method inside the greenhouse, heating devices are divided into mobile and stationary. Since gas heaters are tied to a gas supply, they are usually made stationary and mounted on the ceiling, walls, baseboards, or suspended from the ceiling.

Typically, baseboard heaters are mounted under windows, which allows them not only to perform the functions of a heating device in a greenhouse, but also to eliminate the entry of cold air from outside into the room. Suspension devices are fixed under the ceiling using special brackets and anchor bolts. Together with ceiling devices, they are most preferable for fully heating the soil in a greenhouse.

Heating temperature

Gas heaters heat up to temperatures from +400°C to over +1000°C . The required temperature directly depends on the area and height of the greenhouse. At the same time, in infrared sources, the heat flow mainly (over 60%), unlike a convector, is formed from electromagnetic radiation produced by heating elements heated from gas combustion.

We recommend reading how to make a ventilation system in a polycarbonate greenhouse.

Emission range

Wien's law explains the dependence of the heating temperature of the irradiated surface on the wavelength of electromagnetic radiation. The higher the temperature, the shorter the electromagnetic waves. In this regard, the radiation range is divided into:

- long wave;

- medium wave;

- shortwave.

Thus, short-wave radiation is used for large industrial greenhouses.

Important! The profitability of gas heaters is due to the lower price of gas compared to electricity. A 50-liter gas cylinder can provide fuel for heaters throughout the winter months.

Cable soil heater

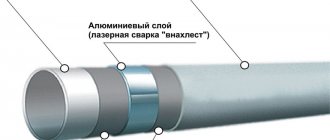

This type of heating for greenhouses is a cable with special polypropylene insulation, braided armor in the form of galvanized steel wires and a special sheath. Its diameter is 6 mm and its bending radius is 35 mm.

The advantages of a cable heater are:

- Installation of the heater is relatively easy

- Plant growth accelerates

- Harvest season extended

- The range of plants grown is expanding significantly

- The harvest is richer

- The degree of soil heating is easily adjusted

Traditional electricity consumption for cable heating is 75-100 W/m2. And to regulate the temperature, it is best to use special thermostats. For example, for most crops the most optimal soil temperature is 15-25˚С, and for beds with seedlings and peat pots – 30˚С.

If you heat the soil with an electric cable, the heating element is located either directly in the soil or under an asphalt concrete monolith under the ground. But to heat the air, such elements are suspended on building structures of protected soil, and a voltage of 380 or 220 V is supplied to them separately. By the way, heating elements can also be located in pipes - there they are well protected from mechanical damage and moisture, but the pipes themselves, True, you will have to buy a lot.

But the safest ones in a greenhouse are cable heaters that are made in the form of an asphalt concrete monolith or asphalt expanded clay concrete slabs - they have a much greater storage capacity and heat the soil more evenly. And, of course, completely electrically safe.

How to choose infrared heaters for greenhouses?

The choice of the optimal heating device for a particular greenhouse is determined by many factors:

- room area, which, if more than 20 m², requires the use of a stationary option, and if the area is smaller, a mobile one;

- the power of the unit, oriented to the volume of the room;

- the efficiency of the device, which determines its efficiency;

- cost of energy sources;

- type of radiation;

- operational safety;

- ease of installation.

Biological heating of a greenhouse using biofuel

The essence of biological heating of a greenhouse is that aerobic bacteria that decompose organic materials (manure, sawdust, garbage) when exposed to air, release heat in an amount sufficient for heating.

Biofuel is any organic material that can be consumed by microorganisms, releasing thermal energy. The temperature of biofuel can reach +72°C, therefore the process of decomposition of biofuel with the release of heat is called combustion. Hot biofuel is used in greenhouses to maintain temperatures at an optimal level for plants.

Horse manure is the best biofuel for heating a greenhouse

The following are used as biofuels:

- animal manure mixed with loosening materials (straw, sawdust, peat, leaves), see Table 2

- waste from wood processing enterprises (bark, shavings, sawdust, chips), see Table 3,

- urban waste consisting of organic waste, see Table 3.

Table 2. Characteristics of manure as a biofuel for greenhouse heating

| Characteristics of biofuel | Manure | |||

| Horse | Bovine | Pork | Sheep | |

| Weight 1m3, kg | 350-450 | 400-500 | 400-500 | 550-700 |

| Acidity, pH | 8-9 | 6-7 | 7-8 | 6-7 |

| Humidity, % | 65-70 | 75-80 | 65-67 | 73-77 |

| Max. stack temperature, °C | 60-72 | 40-52 | 55-60 | 20-30 |

| Interruption period, days | 7-9 | 18-20 | 9-10 | 20-30 |

| Avg. temperature, °C | 33-38 | 12-20 | 30-35 | 14-16 |

| Burning duration, days | 70-90 | 75-100 | 90-120 | 60-70 |

Table 3. Characteristics of household waste as biofuel for heating a greenhouse

| Characteristics of biofuel | Household waste | |||

| Sawdust | Bark | Household waste | Compost from garbage | |

| Weight 1m3, kg | 150-200 | 400-500 | 700-750 | 650-750 |

| Acidity, pH | 5-6 | 5-7 | 7-9 | 7-8 |

| Humidity, % | 30-40 | 60-75 | 35-60 | up to 50 |

| Max. stack temperature, °C | 30-40 | 40-50 | 60-65 | 50-60 |

| Interruption period, days | 20-25 | 10-15 | 10-12 | 5-7 |

| Avg. temperature, °C | 15-20 | 20-25 | 36-48 | 30-35 |

| Burning duration, days | 40-60 | 100-120 | 80-100 | 120-180 |

Read more about the characteristics of biofuels in the article: Manure and straw; wonderful greenhouse! Biofuel for heating a greenhouse

If it is necessary to protect biofuel from combustion, it is placed in a stack and compacted. In a compacted state, biofuel will not burn or will burn weakly.

To heat the biofuel, it is crushed and loosely placed in a stack; hot stones or burning coal are placed inside the stack. After 3–5 days, the biofuel begins to burn and can be used to heat the greenhouse.

Biofuel heats up well in the presence of nitrogenous nutrients. Therefore, sawdust is watered with slurry or animal urine. Mixing manure with wood waste has a good effect. Active activity of microorganisms is possible with sufficient moisture content. Therefore, biofuel is humidified if necessary.

The temperature of the biofuel reaches its maximum a week after heating and then begins to decrease. The heat generation continues for 2-3 months, gradually fading.

Heating a greenhouse with biological waste helps to utilize it, rationally using the energy stored in biofuel, and also improves the air-gas environment in the greenhouse by releasing large amounts of carbon dioxide, which plants need for photosynthesis.

Spent biofuel is suitable as an organic fertilizer both in greenhouses and open ground.

Biofuel stacking. Hot biofuel is placed loosely in the greenhouse, evenly distributed over the area and slightly compacted with a pitchfork. Fertile soil is poured onto the biofuel in a layer of 15–18 cm for growing seedlings; if seedlings are grown in pots, then the soil layer is reduced to 7–8 cm. When growing vegetable plants, the thickness of the soil layer should be increased to 20 cm.

Sowing and planting of plants begins after the soil has warmed to the optimal temperature.

The disadvantage of biological heating is that it is impossible to control the thermal regime if it is necessary to raise the temperature to the required level.

Features of installation and placement

When installing heating devices in a greenhouse, in addition to strictly following the included instructions, the following factors must be taken into account:

- The infrared heater should be installed at least 1 m from the ground surface.

- Since the distance from the device to the plant must be the same, during installation it is necessary to take into account the possibility of changing the position of the device as the plant grows.

- It is recommended to place infrared heating units closer to the walls and ceiling around the perimeter of the room.

- The distance between adjacent low-power devices should be at least 1.5 m.

- In large greenhouses, the best option is to arrange the devices in a checkerboard pattern.

Storing vegetables

Humidifiers and dehumidifiers for vegetable storage

Maintaining optimal humidity and temperature conditions is necessary, among other things, to ensure long-term storage of vegetables without losing their presentation and consumer properties.

Vegetable and fruit storage facilities need a good ventilation system, specific temperature and air humidity. The conditions depend on the type of vegetables/fruits; dehumidifiers and air humidifiers (for example, so that the fruits do not dry out - if the warehouse is located in a warm, dry climate, do not rot - if the vegetable storage is located in a humid environment). Below is a table with temperature/humidity requirements and shelf life for vegetables and fruits.

NTP APK 1.10.12.001-02 Standards for technological design of enterprises for the storage and processing of potatoes and fruits and vegetables

Design temperature, humidity and gas conditions

| Products | Temperature in the product mass, °C | Relative humidity, % | Estimated shelf life, days. |

| 1 | 2 | 3 | 4 |

| Potato: | |||

| - food, | +3 | 90-95 | 270 |

| - seed | +3 | 90-95 | 240 |

| Root vegetables (carrots, beets, radishes, rutabaga, turnips) | |||

| food | 0 | 90-95 | 270 |

| Queen cells | 240 | ||

| White cabbage | |||

| food | 0 | 90-95 | 270 |

| Uterine | 0 | 90-95 | 210 |

| Food onion | 0 | 70-80 | 270 |

| Mother onion | +3 | 60-80 | 240 |

| Onion sets, onion selections | |||

| warm storage method | +18 | 50-70 | 240 |

| cold storage method | 0 | 70-80 | 240 |

| warm-cold storage method | +18 | 50-70 | 120 |

| 0 | 70-80 | 90 | |

| Food garlic | 0 | 70-80 | 210 |

| Seed (spring) | +18 | 60-70 | 195 |

| +2 | 60-70 | 45 | |

| Pomaceae: | |||

| Apples | |||

| early varieties | 0 | 85-95 | 60-120 |

| late varieties | 0 | 85-95 | 150-240 |

| Pears | |||

| early varieties | 0 | 85-95 | 30-60 |

| late varieties | 0 | 85-95 | 90-120 |

| Grape | 0 | 90-95 | 90-120 |

| Stone fruits: | |||

| Cherry | 0 | 90-95 | 10-25 |

| Apricots, peaches | 0 | 90-95 | 15-30 |

| Plum | 0 | 90-95 | 30 |

| Berries: | |||

| strawberries, raspberries | 0 | 85-90 | 5 |

| currants, gooseberries | 0 | 85-95 | 15 |

| Relative humidity, % | Estimated shelf life, days. | |||||

| CO2 | O2 | N 2 | ||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Pome fruits: | ||||||

| - apples | 1 | 1-5 | 3 | 92-96 | 95-98 | 180-270 |

| - pears | 1 | 2-3 | 3 | 94-95 | 95-98 | 120-180 |

| Stone fruits: | ||||||

| - cherry | 1 | 3 | 3 | 94 | 95-98 | 50-60 |

| - cherries | 1 | 3 | 3 | 94 | 95-98 | 50-60 |

| - plum | 1 | 3 | 3 | 94 | 95-98 | 50-90 |

| - peaches | 0 | 2-3 | 3 | 94-95 | 95-98 | 30-45 |

| Grape | 0 | 3 | 3 | 94 | 90-95 | 120-210 |

| White cabbage | 1 | 1-5 | 3 | 92-96 | 95-98 | 210-240 |

| Carrot | 1 | 3 | 3 | 94 | 90-95 | 150-210 |

| Beetroot | 0 | 1-5 | 3 | 92-96 | 90-95 | 150-180 |

| Onion | 0 | 1-5 | 2-3 | 92-97 | 95 | 210-240 |

| Garlic | 0 | 3-5 | 3 | 92-94 | 85 | 180-240 |

| Tomatoes | 12-15 | 0-1 | 3-4 | 95-96 | 95 | 45-60 |

Tips for use

The experience gained by gardeners and gardeners during the operation of IR heaters in greenhouses allows us to draw certain conclusions regarding their use:

- with proper operation of such a heating source for greenhouse plantings, the germination rate of seedlings increases by 40%;

- with the help of infrared rays it is possible to maintain optimal humidity and a favorable microclimate in the greenhouse at elevated temperatures, since IR radiation does not dry out the air;

- with the help of the correct location of IR equipment, it becomes possible to warm the soil to a depth of 7 cm, which cannot be achieved with other types of heaters;

- With the help of these devices, it is possible to warm the soil up to +28°C so that the air temperature in the greenhouse does not exceed +21°C.

Important! For small greenhouses, it is advisable to use long-wave gas infrared equipment.

An efficient and gentle microclimate in the greenhouse, the infrared gas heater is distinguished by the availability of the fuel used and ease of maintenance. When designing a heating system for greenhouses, more and more gardeners are giving preference to this particular device.

Is it profitable to install IR in a greenhouse?

A heating device for greenhouses has its advantages and disadvantages.

Electrical devices are easy to use and make it possible to fully automate the heating process. But there are disadvantages, among which we can highlight the fact that electricity remains the most expensive energy carrier. IR devices for heating greenhouses consume a lot of energy and operate smoothly. After turning off the device, the temperature drops sharply. To maintain the desired temperature, the device must be constantly functioning. Gas-powered emitters are economical and practical. The main advantage of using gas is that IR devices do not dry out the air and have a positive effect on plants. Infrared emitters are ideal for heating greenhouses. Infrared heating has long been used for industrial purposes as the most economical and practical option for a beneficial effect on plants.

The device must be purchased in packaging and there should be no damage. If possible, check and turn it on in the presence of the seller. A heater that makes loud noises when operating should raise doubts. Once you have purchased the device, do not run home until you receive the documents in your hands: a receipt and a warranty card with the company’s seal.

It must indicate the model and brand of the heater. Always choose proven devices, giving preference to popular brands, and create favorable conditions for growth for your plants, and then they will delight you with a variety of harvests.

Pros of heating a garage with an infrared heater

Option 3 heating with gas

The main advantage of gas is that it is more stable in terms of supply, but the final cost of products from the greenhouse can surprise. Therefore, if heating a greenhouse with gas in winter lasts only a few weeks, then it is not necessary to pull it from a residential building and purchase expensive pipes for this. It will be enough to take a couple of cylinders for this purpose - they will last for a long time.

It is only important to remember that excess carbon dioxide can negatively affect the condition of plants, and therefore such a greenhouse must be well ventilated. And to remove combustion waste, it is necessary to use an exhaust device so that a constant flow of oxygen into the greenhouse is ensured

And so that the lack of oxygen does not lead to the cessation of the combustion process and the release of gas into the air, it is advisable to use heating devices with an automatic protective device - the sensors will immediately operate as soon as the gas supply to the burner stops.

The best heat guns for a greenhouse

Heat guns also belong to the floor type of heaters, but they heat not due to infrared radiation, but due to the flow of hot air. Such equipment cannot be placed very close to plants. Due to the presence of a fan, the air in the greenhouse is constantly mixed, so all sprouts will be equally warm. Heat guns are used in huge greenhouses, since one such model can replace several infrared ones in terms of performance.

Tropik-Line TPP5 (4.5 kW)

Rating: 4.9

This category was headed by a heater with a serpentine heating element with a power of 4500 W and a fan equipped with metal blades. Mechanical switches are provided to control the device. The left one sets the heating strength in steps, and the right one allows you to set the temperature in the greenhouse from 10 to 40 degrees. There is a handle at the back for carrying the device. The all-metal body makes the heater resistant to mechanical damage, and the powder coating protects against corrosion. The gun can operate on both 220 and 380 V. In reviews, buyers note the stability of the heater, which is ensured by a curved frame with legs equipped with rubber pads. The weight of 6.3 kg will not allow you to topple the device by accidentally catching it with your foot.

We recommend this heat gun for heating spacious greenhouses with an area of up to 50 m². Thanks to a powerful fan and 4.5 kW heating element, the device performs air exchange up to 440 m³/h.

Advantages

- simple and reliable mechanical control;

- anti-slip pads on the legs;

- increased power;

- iron body.

Flaws

- high price;

- For full operation you need a three-phase network.

Hyundai H-HG2-03-UI503

Rating: 4.8

The review continues with a heat gun for a greenhouse with a power of 3 kW, operating from 220 V. The air exchange capacity of the device is 300 m³/h. The square case has dimensions of 29x35x30 cm and is installed on a sliding tubular stand. At the top, the design is equipped with a handle with a rubber pad for easy carrying. The controls are located at the back, which users like because to adjust the temperature, they do not need to bring their hand to the front panel, which produces a hot stream of air.

Reviews show that the gun is stable on different surfaces in the greenhouse (barrel, chair, table) and takes up little space. Owners also praise the product for its “indestructibility.” The unit is capable of operating for 8 hours every day for many years, so the investment will be definitely justified and you will not have to waste time visiting the service center.

Advantages

- reliable mechanical control;

- when overheating, a protective shutdown is triggered;

- there is power adjustment;

- durable body.

Flaws

- For some, the rubber handle comes off easily.

Wester TB-3/5 (3 kW)

Rating: 4.7

Among the available heaters for the greenhouse, Wester TB-3/5 stands out with a power of 3 kW, which performs air exchange with a fan within 300 m³ per hour. The device operates on 220 V, so to connect it to the greenhouse you only need an extension cord that is plugged into a regular outlet. The cylindrical body is powder coated and has excellent corrosion resistance. S-shaped legs, along with a weight of 4.8 kg, ensure stable placement on any surface. The heater can be adjusted according to the strength of air heating and adjusted according to the angle of inclination. The switch is located on top and you don't have to put your hand under the hot stream to make changes.

Customers like the product in reviews due to its high-quality assembly, excellent scratch-resistant coating, and an extended 5-year warranty if you register the model on the manufacturer’s website.

Advantages

- the ability to change the angle of the gun;

- convenient top switch location;

- all hot elements are covered with steel mesh;

- Automatically turns off when overheated.

Flaws

- When you first turn it on, the paint burns a little and stinks.

Ballu BHP-P2-3 Limited Edition

Rating: 4.6

The Ballu brand produces a limited series of high-quality air guns BHP-P2-3 with a power of 3 kW. The dimensions of the cylinder with stand are 31x38x29 cm and the model weighs 4.8 kg. The tube with heating element and fan can be rotated almost 90º upward, which is convenient for supplying a hot stream to the ceiling of the greenhouse, and not to the trunks of plants. To fix it in a given position, there are “lambs” that should be tightened tightly. Judging by the reviews, customers like the heater due to its double-walled housing, which increases its rigidity. Thanks to this, the casing does not rattle during operation, and also does not deform from heating.

The greenhouse gun is the leader in terms of power and performance ratio. With the same 3 kW, the heater produces 400 m³ per hour, which exceeds the performance of competitors with equal power by 100 m³/h. We recommend this product for greenhouses with an area of up to 35-40 m², so that your flowers or crops ripen as quickly as possible.

Advantages

- convenient plastic handle for moving;

- tilt angle adjustment;

- there is a thermostat;

- increased productivity.

Flaws

- The “lambs” on the stand gradually become loose.

Timberk TIH RE8 2M (2 kW)

Rating: 4.5

Finally, a heater with a power of 2000 W, performing an air exchange of up to 140 m³/h. The unit is equipped with a thermostat in the upper part of the casing and stepwise adjustment of the heating force. The thick handle allows you to grab the gun and move it, even if it has been running all day and gets very hot. The manufacturer has equipped it with protection against overheating and anti-slip pads on the legs. Although the product warranty is only 1 year, the developers claim that the model is designed for 10 years of operation. Reviews indicate that such guns work in workshops all day long without failure, which means that in the greenhouse they will provide the necessary microclimate and will not fail.

The heater is noted for the optimal combination of price and quality. You can buy it cheaper by 500-1000 rubles. than analogues. A heating element with a power of 2 kW will provide slightly lower electricity consumption, which is especially important if you are growing something in a greenhouse only for your family and not for sale.

Advantages

- convenient switches at the top of the case;

- overheat shutdown is triggered;

- temperature and power can be adjusted;

- attractive price.

Flaws

- It's easy to knock over due to the weight of 3.5 kg.