Italian gas boilers Ferroli are products of one of the strongest European manufacturers.

The equipment manufactured by this company demonstrates high quality and stable operation; all components and parts of Ferroli gas boilers are assembled on the basis of advanced technologies and fully meet the most stringent technical requirements.

Each unit is equipped with an extensive self-diagnosis system, consisting of a network of sensors that are located on all critical components and parts of the boiler.

If any malfunction occurs or the unit leaves the set mode, the self-diagnosis system immediately reacts by notifying the user using an alphanumeric code on the boiler display.

Let's take a closer look at her work.

How to set up and adjust a Ferroli gas boiler

Boiler Ferroli Diva f. After ignition, some noise appears, but immediately disappears. What is the reason? In operation for two years. This noise didn't exist before.

To determine the cause of the noise, we recommend calling a specialist. There could be several reasons, including lack of maintenance.

Ferroli divatop 60 atmospheric with boiler. What is anti-clock mode and how to adjust it? It goes off for no reason every 2 minutes.

The anti-clock mode is used to prevent frequent switching on/off of the unit. If you cannot configure the equipment yourself, we recommend contacting a specialized organization.

If possible, please advise on this issue. Ferroli Fortuna pro 24f. It doesn’t matter what temperature the coolant is, it turns on, runs for 2-3 minutes, turns off and then turns on immediately. Doesn't work for long, turns off for a few seconds and then turns back on. However, it does not reach the set temperature. We changed temperature sensors, changed boards and more than one. In general, only the gas valve and piezo ignition (electrode), also known as a flame sensor, have not yet been touched.

There may be a problem with the smoke exhaust system.

Should the Ferroli Fortuna boiler respond to the opening of the cold water tap?

The dual-circuit unit is switched on to prepare hot water when the flow sensor is triggered. Therefore, when you turn on only cold water (without adding hot water), it should not turn on.

Do I need to buy a boiler with a power reserve?

The power required for heating depends on the area of the room and its heat loss. When selecting equipment, take into account the weather conditions of the climatic zone, and use average temperature indicators. Users are concerned about whether the unit’s power will be enough if there is severe frost in winter. It is recommended to add no more than 20-25% to the calculated figure. Excessive excess increases the number of boiler starts and stops. The user will not use it at full capacity all the time. This means that the equipment will operate with low efficiency and more fuel will be consumed.

Why does a heating boiler need a pump?

The heating system can be built in two ways: with natural or forced circulation of coolant. Heated water naturally moves upward; when it cools, it moves downward through the pipes. The advantage of such heating is energy independence. The disadvantage is the low coolant pressure in the system, so there are restrictions on the length of the pipeline. Forced circulation occurs by moving water using a pump. With it, the system can be built in any home. It is more efficient due to the high speed of water circulation. Heating of rooms occurs faster and more evenly. Heating is easier to install, since various wiring diagrams are allowed; the expansion tank can be installed anywhere. During operation, the pump consumes electricity. If it is turned off, circulation will stop.

We want to buy a Ferroli gas boiler for installation, but we can’t choose between two models: Domina N and Fortuna F. How do they differ from each other?

Fortuna models are wall-mounted boilers with an open combustion chamber. They also come complete with pipes for a smoke separation system. It should also be noted that they have a reduced noise level.

We have a boiler for a private home Diva F16 with a ROMEO control panel connected to it. The temperature is set on the remote control to 23C, and in principle the unit keeps it exactly that way. But I don't like his work itself. When the system temperature is 23.1C, for some reason the burner turns on and heats up to the specified 65 degrees. There are obviously extra clocks. Observations have shown that heating takes a very short time (2-0-30 seconds), and it works on its own through the bypass pipe (no water enters the system). But if the temperature in the rooms drops to 22.8C, then heating and operation proceed as expected. Why is this happening?

We recommend checking the operation of the system without the remote control. If the problem persists, then you have the “comfort” mode turned on. Turn it off.

I would like to know what quality the Ferroli Fortuna F24 pro gas boiler has. We heard that they may make noise and rattling during operation. Is it so? And if so, is it possible to reduce it by installing the chimney according to a separate scheme? Or is it worth paying attention to some other model? And another question: is a voltage stabilizer needed? If necessary, please tell me its power.

We would recommend you to buy Ferroli Diva F 13-16-20-24 kW (you can choose any power, as it is adjusted on site). As for the stabilizer, look at the voltage of the incoming network. If there are jumps, it is better to install it. We also recommend paying attention to the Arena model. It differs from Diva only in controls (no display and control by rotary controls).

Repair and maintenance of the wall-mounted Ferroli Domina N boiler was required due to the fact that it does not see the contacts on the thermostat opening. Rebooting doesn't help. It works as it did, maintaining the temperature that was set manually. When connecting, I had to install a jumper, since it did not want to start due to attempts to monitor the temperature sensor readings. Now there is a need to restore this function. What should I do?

Remove the cover and look at the terminal box to the right of the board. Find two white wires there attached to the board. There, from below, they should be connected by wiring - this is the same jumper. You can install a thermostat instead. If you have two terminal blocks, then one of them is for the outside temperature. Look for exactly the one where there is extra wiring.

I decided to do maintenance on the Ferroli Diva C 32 heating boiler. Reason: two of the four gaskets leaked in the secondary heat exchanger. After inspection, I was left puzzled by the technical solution: why only 2 bolts were installed on all four gaskets. I tried to tighten them, but it didn't change anything. And at the beginning of the cycle, when heating is in progress, the unit makes an incomprehensible loud noise.

This problem happens on other models as well. The reason is an uninstalled mixer. The water was drawn through a ball valve, and the pressure in the system was 4 atm. If the tap was suddenly turned off, a water hammer occurred. In your case, installing mixers that will help limit the flow rate will help.

Tell me how the pressure in the system is measured by the Ferroli Domina N gas wall-mounted boiler, and also, more importantly, does it implement its transmission via the OT interface? This is why I need this. I installed OpenTherm interface. It has a pressure of 1.4 bar. When I add water or there is a drop in pressure in the system, the pressure gauge works correctly. As I understand it, this may be due to fairly warm weather and rare switching on of the unit? But yesterday the system stopped by mistake because the pressure dropped below the set value.

OT support is not implemented for Domina N models of the first years of production. It all depends on what the fee is. 39848640 - DBM33 control board for model F (without OpenTherm). 39848641 - DBM33 control board for model C/FN (with OpenTherm). Your boiler has a simple relay control that operates in the “on/off” mode. And it reacts only to changes in the set pressure. Namely, at a pressure of 0.8 bar, a short circuit occurs. But it physically cannot receive anything from Open Therm, since it is not a hall sensor.

I want to install a boiler in a private house, and the planned installation location is the basement. Initially, I chose a gas model with a closed chamber and a coaxial chimney. But the store told me that in my case its installation is impossible, since the top of the chimney pipe must be raised above the ground by at least 2 meters. In my case, this is technically impossible to implement. To resolve this situation, the store suggested that I pay attention to the Ferroli Fortuna F24 Pro, arguing that its design would allow them to install systems without violating the installation rules. I would like to understand why he is so good?

There are no special design differences in this model. This is the most common unit, which has two heat exchangers and a closed combustion chamber. Operating power 24 kW. There is a table that shows all the recommended distances from the point where combustion products are released into the atmosphere through the outer wall of a gasified room without installing a vertical duct from gas-fired heating equipment with a sealed combustion chamber and a device for forced removal of combustion products. Absolutely any wall-mounted gas boiler can be equipped with a separate smoke removal system. It’s just that on the model recommended to you, the necessary pipes are already included in the kit.

Condensation models

Ferroli condensing equipment is available in the Econcept, Energy and Bluehelix series. These are already single-circuit units, among which there are also options for increased power. For example, the Econcept model is capable of delivering up to 300 kW. Features of condensing devices include the presence of weather-compensating automation and a large liquid crystal display. In addition, the Ferroli gas wall-mounted boiler in the Econcept series has an aluminum heat exchanger and a ceramic burner. The use of these materials is due to less stringent safety requirements. Actually, purchasing a condensing unit is beneficial from the point of view of wide functionality and increased ergonomics. The user will be able to view all the main operational parameters, use boiler modes depending on the time of year, and control the connected boiler using a remote control.

Main malfunctions of Ferroli gas boilers

The design of Ferroli boilers is distinguished by well-thought-out and high-quality elaboration of all components and parts.

However, any system has weak points, and gas boilers are no exception..

The operating conditions of some parts of the units are very complex; temperature loads contribute to the occurrence of fatigue of metals and other materials.

According to experts, the most common malfunctions include:

- The boiler does not turn on. There may be different reasons and ways to eliminate them, one of the most common problems.

- Blood pressure drops or rises. This is a serious problem that leads either to a coolant leak, which causes overheating and blocking of the boiler, or to excess pressure and blocking. Particularly dangerous is the increase in pressure, which can cause parts of the unit to burst.

- Fan or circulation pump failure. The loss of both functions means the system is unable to operate - the inability to remove smoke causes sudden overheating and blocking, and the lack of fluid movement has the same consequences, only detected by other sensors.

- Problems with the electronic control board. The cause of these problems is most often an unstable supply voltage or lack of quality grounding. The boiler electronics are very sensitive to any changes in operating mode. When drops or jumps appear, it begins to produce a continuous series of errors that do not repeat when restarted. Often, a static charge accumulates on the housing, which is transmitted through ground to the control board and ionization electrode, which causes error A02 to appear (the system sees a flame when there is none). The solution to the problem is to completely disconnect the boiler from the power system for some time and restore (or create) high-quality grounding.

In addition to those listed, there are a lot of problems with the combustion mode:

- Flame too small.

- Spontaneous start of combustion.

- There is no DHW heating.

- A sharp flash of flame with a pop.

All these problems are associated with deterioration in gas supply due to clogged injectors, failure of a thermocouple or fuel valve coil.

Wall models

This is one of the most common types of boiler equipment, which in the line of the Italian brand is represented by the Diva, Divatop Domina, etc. models. Due to its affordable price and simple design, the Arena model is in greatest demand. This is a Ferroli gas double-circuit wall-mounted boiler, which has two heat exchangers. The combustion chamber of such models can be open or closed, depending on the modification. The design itself allows for high heat transfer, but there are other advantages of boilers of this type precisely as conceived by Italian designers.

In particular, developers use a primary heat exchanger made of copper, and its secondary counterpart is made of stainless steel. Branded parts are also used as components. For example, a valve from a three-speed circulation pump is from the WILO brand. To ensure stable operation, the Ferroli double-circuit gas boiler is equipped with a control board that is resistant to changes in the network. Taken together, the listed components ensure high equipment reliability and safety during operation.

All main error codes and their interpretation and solution

Let's consider the main errors of Ferroli gas boilers and options for eliminating them:

| Code | Decoding | Ways to solve the problem |

| A01 | No flame (ignition attempt failed) | Check the presence of gas in the line, open the gas supply valve, |

| A02 | False presence of flame (voltage detected at the ionization electrode when the burner is off) | Check the condition of the ground loop or the presence of condensation drops on the control board |

| A03 | Boiler overheating | Wash the heat exchanger, check the condition of the circulation pump |

| A06 | No flame after ignition cycle | Check the gas supply system, clean the gas burner nozzles |

| A08 | Coolant temperature sensor failure | Replace element |

| A09 | Gas valve failure | Check functionality, replace element |

| F04 | Flue gas thermostat overheating | Clean the chimney, check the operation of the fan |

| F05 | Failure of the smoke removal system, fan shutdown | Replace fan |

| F08 | Primary heat exchanger overheating | Rinse the heat exchanger and, if necessary, replace it |

| F10 | Break or short circuit of the exhaust temperature sensor | Restore contact or replace sensor |

| F11 | Break or short circuit of the DHW temperature sensor | Restore contact or replace sensor |

| F14 | Malfunction of sensor No. 2 direct line of the heating circuit | Restore contact or replace sensor |

| F34 | The supply voltage dropped to 180 V | Check the line, install a stabilizer or uninterruptible power supply |

| F37 | Exhaust pressure drop | Detect heating agent leak and fix it |

| F40 | Excessive exhaust pressure | Check the condition of the expansion tank |

| F47 | Open or short circuit of the exhaust gas pressure switch | Restore or replace the relay |

| F50 | Problems with the control board | Replace control board |

Ferroli boiler errors are divided into critical (A) and non-critical (F). Those with the letter A lead to independent blocking of the boiler, but those with the letter F do not.

Operating instructions - how to start correctly

The operation of Ferroli boilers does not differ in any specific actions or procedures.

The owner is only required to organize periodic maintenance, clean the body and interior of the boiler, and maintain the burner nozzles in proper order.

The procedure for starting the boiler is similar to the procedure for igniting other gas units.

A special feature is the need to maintain a pause between startup attempts, during which code D3 or D4 appears on the display (50 or 30 seconds).

The first code occurs after a critical error appears and the unit is blocked.

Until the required time interval has been met, a repeated restart is not possible.

The second code appears between attempts to start normally, if the previous one was unsuccessful.

This is usually due to air in the pump, piping or heat exchanger . Attempts are repeated until the air is removed from the boiler.

Warranty repair

While the warranty period has not yet expired, the owner has the right to receive free repairs and maintenance. Repair may be refused if the following rules and conditions have been violated:

- ventilation was not organized;

- grounding is not done;

- factory seals are broken;

- there is damage on the case, such as dents and scratches;

- high indoor humidity;

- the boiler room is very dusty;

- power surges in the network;

- main gas is of low quality or with pressure drops;

- the oven was overheating.

In all other cases, you can contact the service department responsible for Ferroli boilers in your city:

- Moscow – “Thermo-Prestige”.

- St. Petersburg - "Energo Garant".

- Yekaterinburg (and 80 km around) – “Hat House”.

- Novosibirsk - "GUDT TeploVodoMontazh".

How to setup

The basic settings of the Ferroli boiler are carried out at the manufacturer . At the first start, additional adjustments are made to the parameters of all communications to ensure full compliance with the operating modes of the system and the supply of resources - gas, water, voltage.

The upper and lower limits of temperature and pressure of liquids, gas, and other important parameters are also determined.

Most actions are performed from the external control panel; the casing has to be opened only when carrying out complex repair work or to connect a room thermostat.

Pegasus

Page 3

- Image

- Text

Pegasus

1. Operating instructions……………………………………………………….

4

1.1 Introduction…………………………………………………………………………………………………………. 4 1.2 Control panel………………………………………………………………………………….. 5 1.3 Switching on and off…………… …………………………………………………………………………………. 5 1.4 Regulation…………………………………………………………………………………………….. 6 1.5 Maintenance…………… ………………………………………………………………………………….7 1.6 Malfunctions……………………………………………………… ……………………………………………………….. 7

Yes

2. Installation…………………………………………………………………………………………………………..

8

2.1 General recommendations……………………………………………………………………………………….. 8 2.2 Installation location……………………… …………………………………………………………………………………….. 8 2.3 Hydraulic connections…………………………………………………………… ………………………………. 8 2.4 Gas connection…………………………………………………………………………………………………………9 2.5 Electrical connections……………… …………………………………………………………….10 2.6 Connection to the chimney……………………………………………………… ………………………… eleven

3. Maintenance……………………………………………………………………….

12

3.1 Regulation…………………………………………………………………………………………………………… 12 3.2 Starting the boiler………………… …………………………………………………………………………………..14 3.3 Maintenance……………………………………………………… ………………………………………………………..15 3.4 Troubleshooting…………………………………………………………… ………………………. 18

¿

0

4 Technical characteristics……………………………………………………….

20

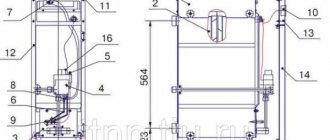

4.1 Dimensions and connections………………………………………………………………………………….. 20 4.2 General view and main components……………………… ……………………………………………………………… 21 4.3 Technical data table …………………………………………………………………………………. 22 4.4 Diagram

>1

……………………………………………………………………………………………………..23

4.5 Electrical diagrams……………………………………………………………………………………… 24

ABOUT

3

The boiler does not start (the burner does not turn on)

Problems with starting a boiler occur most often, since there are many reasons for such a situation.

Among them may be:

- The gas supply valve is closed.

- Gas valve problems.

- The burner nozzles are clogged with soot.

- The control board has failed.

- The boiler is blocked due to a problem with a component.

Most possible causes are detected by the self-diagnosis system and display the corresponding code.

However, some possible reasons - failure of the gas supply system, a closed valve and other mechanical obstacles may not be noticed by the system, so you should independently verify that it is ready for operation . In addition, it is necessary to take into account the phase dependence of the boiler and the need for grounding.

Sometimes, after connections have been made, the wires on the panel are mixed up.

Video on the topic

Italian gas boilers Ferroli are products of one of the strongest European manufacturers.

The equipment manufactured by this company demonstrates high quality and stable operation; all components and parts of Ferroli gas boilers are assembled on the basis of advanced technologies and fully meet the most stringent technical requirements.

Each unit is equipped with an extensive self-diagnosis system, consisting of a network of sensors that are located on all critical components and parts of the boiler.

If any malfunction occurs or the unit leaves the set mode, the self-diagnosis system immediately reacts by notifying the user using an alphanumeric code on the boiler display.

Let's take a closer look at her work.

Why does blood pressure drop?

A drop in pressure in the boiler can be due to three reasons::

- The appearance of a leak in the heating circuit (including in the boiler itself). The peculiarity of this option is the constancy of the process, since the coolant will not stop leaving, no matter how much the system is recharged. In this case, you need to find the location of the leak. First of all, you need to check the condition of the drain tap or valve to see if it is open or damaged. If no problems are found in this unit, the entire heating circuit is checked sequentially. Sometimes they forget to close the drain valve on radiators, fistulas appear in pipelines, and connections fail. It is most difficult to detect a leak if the tap supplies a water-heated floor system embedded in a concrete screed. You can detect the problem by a wet spot on the floor or ceiling of the lower floor, and to do this you often have to remove the floor covering or suspended ceiling.

- Circulation pump failure. This problem is immediately detected by the self-diagnosis system, and it is easy to check the functionality of the pump. It is enough to carry out a visual inspection of the element and take appropriate measures.

- Expansion tank membrane rupture. In this case, the pressure will drop until the coolant fills the entire volume, after which the process will stop. Then an uncontrolled increase in pressure is possible, especially intense as the temperature of the heating agent increases. If it turns out that the problem element is the expansion tank, urgent measures must be taken to repair or replace the unit. Otherwise, with thermal expansion of the liquid, the heat exchanger or other element of the system will fail, which will require significant costs for repairs and restoration of the boiler’s functionality.