Using the correct and suitable fuel consumption formula, you can easily heat your house with gas cylinders. A gas boiler running on propane can heat a room no worse than a unit configured for regular mains gas. When installing equipment, you must remember about the oxygen regulator, since according to the standards, more of it should be supplied to the unit than to a conventional boiler. In order to guarantee the uninterrupted and safe operation of such a device, boilers are equipped with special devices that stop the operation of the device in the event of an emergency. Another feature that significantly distinguishes a liquefied gas installation from a natural gas boiler is that the burner in it has a significantly smaller diameter, and, as a result, lower gas pressure that comes from the cylinders.

The nuances of heating with gas cylinders

Cylinder heating at home

Properly organized heating using gas cylinders is important for houses with permanent residence, as well as for summer cottages. Liquefied gas is used as an energy carrier, which differs in its properties from natural gas.

In order to heat a private house using gas cylinders with your own hands, you need to familiarize yourself with the features of its organization. An important step is the choice of boiler, since it must be adapted specifically for this type of gas. In addition, the following factors are taken into account:

- Estimated consumption volume. Directly affects the consumption when heating with gas cylinders and their reserve to ensure heat supply;

- Preparing the container storage area. Safety measures must be observed;

- Organization of gas transportation from cylinders to the boiler. Properly organized individual heating from gas cylinders should be safe;

- Selecting a supplier for filling gas cylinders.

If you carefully read all the reviews when heating a house with gas cylinders, you can note the complexity of the configuration and installation of this type of heating supply. Therefore, it is necessary to calculate the parameters of all elements in advance so that after their installation they can ensure normal operation of the system.

What is the difference between gas holder liquefied fuel and main gas

Main fuel is methane in gaseous state. The temperature of the natural substance corresponds to the environment. Liquefied gas is a mixture of butane and propane. It is strongly cooled to the state of a liquid with various chemical additives. The storage and transportation of liquefied and carbon gas are quite different.

Ground gas holder Main gas Main gas

Natural gas does not require significant processing before delivery to consumers. The liquefied substance requires gasification. To do this, you will need to install an evaporation unit. There are submersible, cabinet evaporators, as well as ring-type equipment for converting liquid fuels. At the same time, the cost of gas tank fuel is significantly higher than that of main fuel.

Connection cost

The size of the gas holder should allow heating the house throughout the year. The cost of a tank with a volume of 6.5 m3 is about 180-240 thousand rubles (it all depends on the manufacturer of the gas tank). You can save money by purchasing a used gas tank. To connect to the central main pipe, you will need to pay several times more, even if the communications are located close to the house. The highway's capacity is limited, so you must first obtain permission and draw up a project.

Energy efficiency and cost of maintenance

The operating and maintenance costs of the systems are approximately the same. A house with an area of 100 m2 requires 3000-3100 m3 of natural gas or 1000 m3 of LPG. But the cost of methane is several times less than liquefied gas, so the annual costs are almost equal.

When boilers operate, a minimal amount of soot and soot is formed, so cleaning is rarely carried out. When operating a gas tank, a small amount of electricity is required. To heat a large private house, it is better to connect to the central gas pipeline (if available). To heat a small country house, you can use an autonomous tank.

The best manufacturers and models: characteristics and prices

The country of manufacture determines the functionality and quality of the unit: given that it is purchased for many years to come, you should not waste your money on dubious equipment offered by the Chinese market. It is better to opt for proven options from European or Russian manufacturers.

Protherm Gepard 23 MOV

Well-known two-circuit mounted model with a power of 23 kW. It has an open combustion chamber (natural draft) and a copper plate heat exchanger: more thermally conductive and resistant to corrosion. Excellent, considering the price category, the automation allows you to fine-tune the operation of the boiler and efficiently consume fuel (max 1.9 l/h).

Cost: 39,870 – 42,480 rubles.

Manufacturer: Protherm (Proterm), Slovakia.

Bosch Gaz WBN6000-24C RN S5700

The German BOSCH with a power of 24 kW is made of higher quality materials and is not demanding on the quality of fuel and coolant. It is fully adapted to Russian conditions: it is resistant to changes in voltage, pressure and sudden cold snaps (down to – 35 °C). Economical gas consumption (max 1.5 l/h) is ensured by a modulated fan, a three-speed pump, and thermal insulation of the housing.

Cost: 36,900 – 38,460 rubles.

Manufacturer: Bosch Thermotechnik (Bosch Thermotechnik), Germany-Russia.

Buderus Logamax U072-18K

We can say that this inexpensive single-circuit boiler unit is one of the best liquefied gas boilers for heating a private home: with a power of 18 kW, it consumes fuel very moderately (max 1.5 l/h). And the built-in membrane expansion tank and three-way valve make it easy to convert it to domestic hot water. At the same time, the model is known for its high reliability, character

Cost: 26,200–31,840 rubles.

Manufacturer: Buderus (Buderus), Germany-Russia.

BAXI SLIM 1.150 I

The famous Italian floor-standing boiler of low power (15 kW) is known for its minimal gas consumption (max 1.1 l/h). It is already equipped from the factory with weather-compensating automation, a cast iron heat exchanger and a control module, with an integrated self-diagnosis option. And another important plus is its modest dimensions: for example, its width is only 35 cm.

Cost: 62,090 – 71,300 rubles.

Manufacturer: Baxi (Baxi), Italy.

Wester Lemax Clever-30

A domestic single-circuit wall-mounted device with a power of 30 kW, which does not depend on the availability of electricity. It can work in a system with both forced and natural coolant circulation, and continuous smooth flame modulation from 30% to 100% can significantly reduce fuel consumption (max 1.7 l/h). With such high efficiency, it is also distinguished by reliability close to European manufacturers.

The only significant drawback is the steel heat exchanger, which has a limited resource (10-14 years).

Cost: 34,250 – 40,500 rubles.

Manufacturer: Lemax (Lemax), Russia.

How to heat a house with liquefied gas

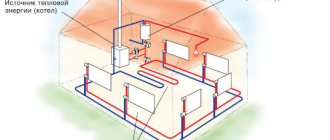

In essence, the organization of such heating is not much different from heating with main gas. A conventional water heating circuit is installed. The whole problem lies in the gas supply device, which has its own characteristics. As a rule, the regulatory framework of the countries of the post-Soviet space requires the completion of a project for the installation of a system and its approval before commissioning.

In accordance with the Rules, fuel in gas cylinders is placed outdoors, in a closed cabinet with the appropriate inscription. The supply line goes from this cabinet to the heat generator, whose burner device is adapted for burning LPG. Containers can be connected to the main line in various ways:

- through gearboxes;

- using special gas fittings.

In the first case, it is important to choose a reducer that is able to provide the necessary gas flow for the heating unit. This is not difficult to do, the exact gas consumption is indicated in the passport for the boiler or burner, and the reducer must be selected based on it. Only such heating with gas cylinders creates a lot of inconvenience:

Only such heating with gas cylinders creates a lot of inconvenience:

- fuel leaves all cylinders at the same time, the container where the reducer provides the greatest pressure is emptied fastest;

- to control the remaining fuel, you need to constantly visit the cabinet and observe the pressure gauge readings;

- according to the operating rules, you cannot release bottled gas to the end; you should “catch” the moment when the minimum limit is reached and close the reducer valve;

- A separate reducer must be installed for each vessel.

It is more convenient and safer to install gas fittings designed for individual and group installations. It makes it possible to empty the cylinders one by one, with them automatically disconnecting from the main line when the lower pressure limit is reached. At the user's request, the system is equipped with a remote electronic display installed inside the cottage. The display shows the remaining fuel and allows you to change liquefied gas in cylinders on time, and do this without stopping the heat generator.

Gas cylinders in winter

If gas cylinders are located outside the house, then in winter at subzero temperatures the pressure of liquefied gas decreases and the boiler may simply turn off. To prevent this from happening, the cylinders are installed in a special cabinet with good ventilation, insulated with non-flammable materials. Also suitable for this purpose are detached non-residential buildings with minimal heating. When using cylinders, safety precautions should be observed:

Special cabinet for installing cylinders

- It is prohibited to heat containers with gas using open fire;

- There should not be a basement or cellar near the cylinders, since liquefied gas sinks down when leaking, has no odor and can accumulate to an explosive concentration;

- It is advisable to install a gas leak sensor;

- Storage of full containers is allowed at a distance of 10 m from the living space;

- Storing empty cylinders in the house is prohibited;

- Once every 4 years, it is necessary to check the cylinders for integrity and tightness.

Pros and cons of running a boiler using propane cylinders

The main advantage of connecting to LPG is the speed of installation and the absence of strict regulations related to operation. There is no need to obtain an operating permit, as well as to complete design documentation, which is required for a trunk connection.

Judging by consumer reviews, heating with liquefied gas also has its disadvantages:

- The need to control the fullness of cylinders. For normal operation of a gas boiler you need 3-4 gas cylinders. Monitoring exactly when the gas will run out is quite problematic without additional equipment. If you plan to constantly operate the system, it is better to spend money and connect the boiler to several cylinders through a ramp and reducer.

- Gas cost - compared to the main connection, LPG heating costs are slightly higher, but less than when using an electric boiler.

- Features when connecting to a propane tank. According to the PB, you will need to take the containers to another ventilated room or outside, which is not always convenient. It is necessary to separately purchase a device for connecting at least four gas cylinders to the boiler, as well as control and control valves.

- Conversion - not all boilers can be converted to LPG with the same efficiency. Replacing the burner will cost approximately 30-40% of the total cost of the boiler.

- The need to attract qualified specialists. Only a licensed specialist can connect several propane cylinders into a single network, change the burner and make the connection correctly.

Some of the above disadvantages apply equally to connection to the main gas pipeline.

Calculation of power and temperature of a warm water floor

Advantages and disadvantages of units

Boilers running on liquefied gas are cheaper than appliances using other types of resource.

Among the advantages of the equipment are such parameters as:

- Complete independence from centralized fuel supplies and regular price increases for utility services. The autonomy of the system ensures the absence of emergency situations.

- High level of efficiency - on average 92-95% and up to 97% for individual models.

- Quiet burner - for comparison, the burner device of a diesel boiler produces a noise effect of 60-75 dB.

- Easy to maintain . The equipment does not require labor-intensive and expensive maintenance, replacement of the fuel filter and nozzle, reconfiguration of the burner and cleaning of the heat exchanger.

- Possibility of working through main gas - in the future you can not buy a new boiler, but transfer the existing one to a centralized supply of blue fuel.

- Duration of operation - the service life of floor-mounted ones is up to 25 years, wall-mounted ones - 15-20 years, subject to qualified installation, compliance with operating rules and timely service.

- Safety of liquefied gas devices - the fuel does not ignite even when the container it contains is heated. Combustion occurs only at the moment of mixing the substance and oxygen, and this happens directly in the burner and only in it.

There are completely energy-independent products on sale that allow you to organize a full-fledged heating system in hard-to-reach conditions, for example, in remote forest areas or high in the mountains.

Of the disadvantages of devices, the following positions are the most significant:

- the need for constant high-quality work to connect the boiler to 3-4 propane cylinders using a reducer and ramp;

- It is not advisable to place containers with liquefied gas near the boiler - it is better to place them in nearby rooms equipped with a good ventilation system, or take them outside and install them in a special box;

- care and caution required when connecting the cylinder, since all operations are performed manually and require the use of physical force;

- subsequent conversion of some boiler models to use regular gas is expensive (replacing the burner costs 30-40% of the total price of the boiler);

- installation of the unit and connection to gas supply communications must be done by a licensed specialist with experience.

The balance of pros and cons must be considered in each individual case and, based on the conclusions drawn, a decision must be made regarding the advisability of purchasing this or that type of equipment.

Calculation of the number of gas cylinders for heating

Types of heating cylinders

One of the significant disadvantages of such heat supply is the constant replenishment of fuel reserves. Therefore, it is necessary to calculate in advance how many cylinders are needed for the boiler. There is no exact method for this. But there are a number of ways in which you can determine approximate fuel consumption.

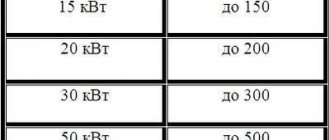

To determine the consumption when heating with gas cylinders, you must read the technical documentation of the boiler. It indicates fuel consumption for both natural and liquefied gas. Usually in the latter case, manufacturers give the flow rate in kg/hour. For boilers with a power of 24 kW it is about 3.5 kg/hour.

In addition, the intensity of fuel consumption is taken into account. On average, to maintain normal temperatures in winter, the heating supply of a private house with bottled gas operates from 12 to 16 hours a day. If the heating season is about 100 days, the total consumption for a 24 kW boiler will be equal to:

Those. On average, you will need 1 cylinder per day for a heating boiler with a capacity of 50 liters. This is the maximum fuel consumption, which can be reduced as follows:

- Installation of automatic gas supply;

- Purchase of modern models of boilers with high efficiency;

- Insulating the house to reduce heat losses.

But even these measures will not greatly affect fuel consumption. Almost all reviews about heating with gas cylinders indicate the relevance of installing this type of heating only in houses with a small area and non-permanent residence.

The table shows how many cylinders are needed for a heating boiler depending on the area of the house.

Number of cylinders 50 l, pcs.

These are not final numbers. For each heating system, an individual calculation is made of how many cylinders are needed for the boiler. It is also necessary to take into account the correct filling of the container. All liquid is first removed and the weight of the empty cylinder is measured.

When filling a cylinder, you can check its filling level by measuring the temperature level. The area where there is a gas mixture will cool the cylinder.

Choosing a boiler for balloon heating

Heating boilers using liquefied gas

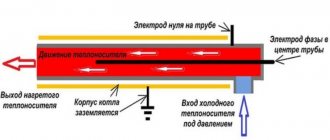

Currently, manufacturers do not produce narrow-profile heating boilers using bottled (liquefied) gas. However, equipment designed for natural gas cannot be used without prior modification.

Before purchasing a boiler, you must make sure that the package includes a kit for adapting equipment for propane. The set includes nozzles with a wider nozzle and a kit for attaching them to the burner. The reinstallation procedure can be performed independently only if this is provided for by the design.

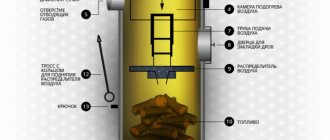

There are several types of gas heating boilers using bottled gas, which differ in operational and technical characteristics:

- Burner type - open or closed . It is best to purchase heating boilers using bottled gas with a closed burner. For their operation, air is taken from the street using a coaxial pipe;

- Installation - wall or floor . Most models with power up to 24 kW are wall mounted;

- Number of circuits . To supply heat to your dacha with gas cylinders, you can purchase an inexpensive single-circuit boiler. If you plan to live in the house permanently, it is recommended to buy a double-circuit model with hot water supply.

You can preliminarily calculate the flow rate for heat supply with gas cylinders by reading the technical data sheet of the equipment. However, manufacturers often provide maximum flow rate at maximum equipment power. The lower the burner operating intensity, the less fuel will be consumed.

Gas heating boilers using bottled (liquefied) gas with a cast iron heat exchanger have the best performance indicators. It will last much longer than steel.

How to reduce gas consumption?

If suddenly your gas costs do not suit you, then the following recommendations will help you optimize them:

- Start insulating your home. The better you insulate your house, the less heat you will lose to the street.

- Check windows and doors for possible cracks. A lot of heat is lost through such structures

- If you use an open heating system with a tank on the roof, then convert the heating system to a closed one. A significant amount of heat is also lost through the roof.

- If you have a simple floor-standing boiler, then replace it with a wall-mounted one. Costs can also be reduced by 10-30%.

- Have your heating system serviced. Sometimes this can also have a positive effect on gas consumption. This is especially true for the boiler itself.

Alternative heating with gas from cylinders: making the right choice

If you have a boiler that runs on propane to heat your dacha, then it is very difficult to accurately determine the gas consumption it needs. Often this indicator depends on the method of insulating the room. If the winter is harsh, the figure will, of course, increase. If you have insulated your house well enough and there are no severe frosts outside, then you will use gas with great savings.

Many people prefer to heat their house with a gas boiler because it is very profitable

To calculate the approximate propane consumption for heating a room, use the formula, which shows that to obtain 1 kW of energy you will need about 0.1 kg of propane.

The fuel consumption of a gas boiler running on propane will please you much more than what you would have to pay to heat the same house using electricity. It is considered the most economical to use main gas, but it is not always possible to connect to a common centralized gas supply system. In this case, heating the room with a propane boiler will be the most sensible idea. When purchasing a heating unit, be sure to take an interest in user reviews, consult with experts, and ask consultants to give you a full description of the device and the possibility of converting it to liquefied bottled gas. Before you finally make a decision in favor of installing gas equipment, be sure to carefully weigh all the important arguments, calculate fuel consumption, and only then proceed with installation steps.

Organization of heating from gas cylinders

To make gas heating using cylinders, you need to choose a suitable boiler, since not every equipment is capable of using liquefied gas as a heat source. This requires a special burner designed to operate from a cylinder. It is recommended to choose a device with a power of 10-20 kW, depending on the area of the heated premises.

The gas boiler is connected to the cylinder using a special reducer. The consumption is approximately 1.8-2 m³ per hour, in the case of a conventional gearbox - 0.8 m³/hour.

You can also use a burner designed to operate from the main pipeline, but in this case you have to adjust the valve for proportional gas supply, since the pressure in the main line is lower. In addition, in such devices the hole in the valve is larger. Each burner, designed for heating with gas from cylinders, is regulated in its own way. A detailed description can be found in the instructions for this equipment. In order to save money, you can also use old boilers, but you need to replace the jet in them with another product that has a smaller hole.

When purchasing a burner, you need to take into account that some stores are trying to sell more expensive devices, arguing that the selected product will not run on liquefied gas. In this case, you need to look at the instructions for the selected device.

Decor

The design of a gas stove for a cylinder is nominal - there is no need to visit any authorities, the requirements are easy to fulfill. The first was announced - the distance to the cylinder is at least 0.5 meters. Second: there must be at least 2 meters to the main lines - water supply, sewerage, metal heating pipes. That's all.

There are two options for official registration:

- When you fill up a new cylinder at a municipal gas station (not for cars, but specifically for refueling household gas cylinders), the station employee will fill out the paperwork for you. You will need to provide the address (at least approximately) and explain where the stove is located and where the cylinder is located. Here you have to be careful, at least say that it is worth it according to the rules. Yes, the cylinder must be purchased at one of the Gorgaz stores and you will need the registration number of the car on which this cylinder will be transported.

- In some localities there is a machine that changes empty cylinders for filled ones. These people can draw up the documents. The difference is that they know the address.

For many, a gas stove for a summer house under a cylinder has been standing for years even without such “design”. But in this case, you will refill the cylinder yourself, without using the services of municipal gas stations or exchange machines. Also, if it is necessary to repair or maintain the stove, or reconfigure it, you will need to somehow resolve the issue of design (usually there are no problems) or use the services privately.

Liquefied gas consumption

A house with an area of about 100 m2 can be heated with liquefied gas using a 10 kW boiler. To obtain 1 kW of heat energy, the consumption of 100-120 g/min of liquefied gas will be required at 100% boiler load. If the duration of the cold season is approximately 7 months, then the approximate estimated consumption for the entire season will be about 5 tons

.

But in fact, the consumption will be almost half as much - the automation switches the heater to an economical mode when the room temperature is sufficient or in accordance with the timer readings.

When comparing the costs of heating a cottage or house from a main gas pipeline, heating with gas cylinders will be about 5-6 times more expensive. But in the end it will still be cheaper than heating with electricity.

If you look at the cost of gas in liquid state, then heating a country house from cylinders can be considered not the worst replacement for liquid fuel and electric systems. Moreover, if the region has problems with solid fuel or its cost is too high.

Gas cylinders with a volume of 50 liters

Heating with liquefied gas is the best solution if gasification of a populated area is planned in the near future, since then there will be no need to purchase a boiler again. In addition, you will gain personal experience in handling a gas boiler.

Safety Reviews

Liquefied gas is heavier than air. If it leaks from a cylinder, it collects above the floor surface, and you can feel it in the room when it reaches a critical point, which is accompanied by the risk of explosion. For this reason, it is better to install gas outdoors, placing it in a metal compartment. The cylinder must be oriented vertically.

If you decide to use liquefied gas heating, consumers are advised to equip the device for their placement with ventilation holes. It is strictly prohibited to place cylinders under the house in the basement, this also applies to holes in the yard. Buyers are warned when using liquefied gas against some possible scenarios. For example, heating a cylinder with heating elements or electrical appliances is strictly prohibited if it is frozen. In order to prevent exposure to ultraviolet radiation, the structure with the installation should be located on the outside of the home, preferably on the north side.

The nuances of heating with gas cylinders

Bottle heating at home

Properly organized heating using gas cylinders is important for houses with permanent residence, as well as for summer cottages. Liquefied gas is used as an energy carrier, which differs in its properties from natural gas.

In order to heat a private house using gas cylinders with your own hands, you need to familiarize yourself with the features of its organization. An important step is the choice of boiler, since it must be adapted specifically for this type of gas. In addition, the following factors are taken into account:

- Estimated consumption volume. Directly affects the consumption when heating with gas cylinders and their reserve to ensure heat supply;

- Preparing the container storage area. Safety measures must be observed;

- Organization of gas transportation from cylinders to the boiler. Properly organized individual heating from gas cylinders should be safe;

- Selecting a supplier for filling gas cylinders.

If you carefully read all the reviews when heating a house with gas cylinders, you can note the complexity of the configuration and installation of this type of heating supply. Therefore, it is necessary to calculate the parameters of all elements in advance so that after their installation they can ensure normal operation of the system.

To heat a dacha with gas cylinders, it is recommended to use containers with a maximum volume of 50 liters. But at the same time, you should consider the method of transporting them to the refueling site.

Types of products by location

Equipment operating on liquefied fuel can be floor-mounted or mounted. Each option has specific characteristics that make it attractive and practical under certain conditions.

Having this information in hand, owners can independently determine which device is most suitable for them, and then purchase it in a specialized store.

Option #1: floor equipment

Floor-standing devices are the most widespread. These are high-power units that can provide comfortable heat and hot water not only to standard residential buildings, but also to large-sized country cottages.

The main operating element of the devices is a pressurized gas burner. It has a good degree of efficiency and has high heat dissipation.

Floor-standing devices exhibit stable operation even with a strong drop in gas pressure in the system and reliably serve in intensive use for 15 to 25 years, depending on the manufacturer

The boilers are equipped with a cast iron or steel heat exchanger. The cast iron element is heavy and has a long service life. A steel object is much lighter, but exhibits fragility, sensitivity to mechanical damage and shock, and lasts for a shorter period of time.

In addition to basic elements, progressive modules contain all kinds of auxiliary equipment that increase operational safety. These are sensors for monitoring the draft level, coolant volume and presence of flame, as well as thermostats that block operation in the event of an abnormally high level of heating of the working fluid

Depending on the manufacturer, the device is equipped with a piezo or electronic ignition system. In the first option, the device is started manually by pressing a button.

In the second case, activation occurs automatically, and the boiler does not consume excess fuel during operation, since the system does not have a pilot light with a flame burning continuously.

Detailed information on the selection and installation of floor-standing gas boilers is presented in the articles:

- Floor-standing gas heating boilers: types, how to choose, review of the best brands

- Do-it-yourself installation of a floor-standing gas boiler according to technical installation standards

Option #2: wall mounted devices

Boilers designed for wall mounting are compact in size and have a modern appearance. They take up a minimum amount of space and are suitable for placement in small rooms with complex layouts.

The installation of a mounted boiler is always carried out by a specialist who has experience in such work. The equipment must be installed in accordance with the safety requirements for domestic gas systems

Functionally, wall-hung gas units are no different from floor-mounted ones, however, they have slightly less power and are not very suitable for use in large, spacious houses. But they use fuel economically, while providing a high level of comfort in the living space.

Types of propane boilers

There are three types of units on the household equipment market. These are single-circuit, double-circuit and condensing boilers. They perform similar tasks, but differ in design and functionality.

Features of single-circuit devices

A boiler with one circuit is intended only for heating a room and is usually installed where water heating is solved in some alternative way.

The cost of single-circuit boilers is slightly lower than that of similar devices with two circuits. This is due to the fact that the equipment performs only a narrowly focused function - heating the home

The module is equipped with a closed combustion chamber, and during operation the boiler flame is enriched with oxygen coming from the room where the equipment is located. The materials waste during the combustion process are discharged to the street through a vertical chimney specially equipped for this purpose.

Nuances of double-circuit products

Devices equipped with two circuits effectively heat residential premises of any size and provide households with hot water. The coolant is heated by two burners, ignited using an igniter equipped with a built-in system of piezoelectric elements.

When the flame lights up, the temperature sensor is activated. Upon reaching certain indicators, it gives a signal to the automation, and access to the combustion chamber is closed.

If the unit has a closed combustion chamber, for correct operation and timely removal of combustion products it is necessary to install a coaxial chimney with a forced draft. This design will ensure a uniform flow of oxygen to the wick and ensure stable combustion

Waste materials and acidic impurities leave the room through a chimney or through a ventilation outlet.

How condensing units work

A condensing-type boiler supplies both heating and hot water for domestic purposes to a living space, but does it somewhat differently than a double-circuit boiler. In a condensing device, cold water, once in a heat exchanger, is heated by a burner and hot air.

A condensing boiler is a high-tech type of equipment and is very economical in fuel consumption. The exhaust gas temperature at the burner is 40°C, and the efficiency level reaches 97%. At the same time, heat loss does not exceed 0.5%

Then half of the liquid goes into the heating system communications, and the second half goes to the taps for washing, washing and other household needs. After going through a full cycle, the water from the radiator returns to the heat exchanger and the whole procedure is repeated again.

How to connect a gas boiler to a propane tank

Installing a gas boiler for autonomous heating using bottled gas is much easier than using mains fuel. There are several rules regarding fire safety, equipment reconfiguration and power calculations that require strict compliance.

Unauthorized installation is not recommended. It's better to invite a specialist. Provided that the boiler is properly connected and re-equipped, installation work will take only a few hours.

Is it possible to install gas cylinders in the boiler room?

The norms and rules for installing a cylinder are regulated by industrial safety requirements. In particular, it states that containers with liquefied gas cannot be located in the same room as heating appliances.

- Cylinders should be taken to an adjacent room or outside, installed in a special cabinet.

- Empty gas cylinders should be stored outside the building. It is optimal if the containers are refilled immediately.

- If cylinders installed in a cabinet outside freeze, the storage walls should be insulated using non-combustible thermal insulation. Heating containers or cabinets with open fire is strictly prohibited.

- The gas cylinder can be installed at a distance of at least 2 m from the heating boiler.

- It is prohibited to store compressed gas cylinders near the boiler room. Containers can only be stored in a specially equipped room located no closer than 10 meters, equipped with ventilation and without pits or a basement. This requirement is due to the fact that propane is heavier than air and, when leaking, accumulates at floor level. If there are pits or a basement, the gas concentration will become critical, which is enough to cause an explosion.

- Operation of cylinders - complete exhaustion of LPG from the container is not allowed. Every 4 years it is required to carry out certification of the tightness of cylinders and the integrity of their walls.

Do I need to reconfigure the boiler for propane?

A conventional gas cylinder boiler only works if certain conditions are met and conversion is carried out. There is no need to reconfigure the equipment, but you will need to install additional fittings to stabilize the gas pressure.

Not every boiler is able to run on LPG

You should pay attention to the technical documentation. An essential requirement is the ability of the unit to operate at a reduced gas pressure of 3-4 mBar

What is required to switch the boiler to gas from a cylinder

For normal operation of the LPG boiler, several important conditions will need to be met:

- Replacing nozzles or burners. Gas-cylinder water heating equipment designed to operate exclusively on LPG is not produced. Some manufacturers make universal units equipped with an electronic processor. To switch from mains gas to cylinders, you simply need to change the cartridge. But more often, conversion will require replacing the nozzles or the entire burner.

- Gearbox installation. Liquefied gas is pumped into cylinders under pressure, resulting in a transformation from a gaseous to a liquid state. To transform it back, you will need to lower the pressure. The gearbox is designed for this purpose.

- Gas valve - in some models, connection and operation of a domestic gas boiler using bottled gas is possible only by replacing this unit.

A conventional gas reducer is not suitable for conversion. A gas heating boiler can operate from conventional bottled gas only when a unit is installed with a flow rate of 1.8-2 m³/hour.

Gas boiler using bottled gas

Boilers using bottled gas

An autonomous heating system is both an opportunity to save money and the ability to independently set the room temperature at any time of the year.

But situations where frosts can strike in mid-May (and central heating is turned off in April) are not uncommon for us lately. It’s at moments like these that you realize: autonomous heating is a necessity. The only question that arises is: what type of boiler to choose? The answer suggests itself - gas. It is no secret that this resource is the cheapest and most cost-effective in comparison with others. But what to do when your house cannot be connected to the gas mains. There is a way out - you can use bottled gas boilers. We will talk about them further.

Advantages and disadvantages of bottled gas boilers

Gas boilers have long proven themselves in the market. They have a number of significant advantages compared to other types, although, of course, they are not without some disadvantages.

Among the main advantages of gas boilers, the following are worth highlighting:

- low cost of gas itself;

- high efficiency (due to the low content of sulfur compounds in the gas);

- easy operation;

- a wide range of boilers of different models and manufacturers.

In addition, during combustion, gas emits very few harmful substances that can harm human health. Such boilers work properly for much longer, due to the fact that they are less susceptible to corrosion than other types.

Among the disadvantages, they note the need to build a chimney through which combustion products will be discharged. Also, for installation in an apartment building you will need to obtain permission. Although in most cases electric boilers are not allowed to be installed in such houses at all, since the electrical network may simply not withstand such a load.

When should bottled gas boilers be used?

Another disadvantage of gas boilers is the mandatory presence of a main gas network. But as we mentioned above, this problem can be solved - you can use gas cylinders. In this case, there is no need to install additional spare parts: gas boilers are usually designed for both main and bottled gas supply. Unfortunately, bottled gas boilers cannot be used for constant heating of a room. This is rather a temporary solution until the gas pipeline is installed. Let's figure out why.

In order to heat a room of one hundred square meters, it will be necessary to use about two cylinders of gas per week. Simple calculations will show that up to 9 cylinders will be needed per month to heat such a house. And the total cost of refueling them will exceed the cost of main gas, if only because of transportation costs. However, using even bottled gas will be cheaper than operating an electric boiler.

The inconvenience lies in the need to constantly replace cylinders. Of course, many of these boilers provide for the use of a group at once (up to four cylinders), but even these will have to be changed over time and sent for refueling.

The use of boilers running on bottled gas can be a good solution for a permanent heating source, perhaps only for a country house that you rarely visit in winter. If there is no gas main in that area and the house will only be heated for a few weeks in winter, then don’t even think twice about it - install a boiler with cylinders.

Features of connecting and choosing bottled gas boilers.

Considering that a gas boiler using bottled gas and a boiler using main gas are the same type of boiler, the rules for installing and selecting this heating element on different gas sources are the same.

Boiler selection

When buying a gas boiler, consider the following parameters:

- number of circuits: there are single-circuit boilers designed exclusively for heating, and double-circuit boilers that can also heat water;

- installation type: floor or wall;

- combustion chamber type: open or closed;

- boiler power.

It is worth considering that when choosing a boiler that will operate on bottled gas even for a short time, you need to pay attention to the operating pressure. You will need a boiler that can perform its functions even at low pressure (3-4 mbar). The efficiency indicator is also taken into account, especially in the case of using cylinders. It is best to choose boilers with high efficiency - about 90-95%.

Features of installing gas boilers

The boiler must be installed taking into account the following requirements:

- the boiler is installed in a room with a ceiling height of at least 2.3 meters;

- the boiler should be placed from the wall at a distance of 50 centimeters;

- the boiler can be installed in rooms larger than 8 sq.m.;

- in the room where the boiler will be installed, there must be a window for ventilation and a door, access to which is always free.

With the right choice, proper installation and careful operation of a boiler running on bottled or main gas, you will receive a cost-effective and non-toxic source of heating. This means that your home will always be cozy and comfortable, regardless of the weather outside.

06/11/2013 at 14:06

Subtleties of organizing home heating with gas cylinders: rules for storing fuel, choosing a boiler and reviews from owners

Despite the emergence of new methods of heat supply, gas heating still remains the best option for both a country house and an apartment. But it is not always possible to connect to the distribution main. The way out of this situation is to heat a private house with gas cylinders. To do this, you need to choose the right boiler, calculate fuel consumption and read reviews.

The nuances of heating with gas cylinders

Bottle heating at home

Properly organized heating using gas cylinders is important for houses with permanent residence, as well as for summer cottages. Liquefied gas is used as an energy carrier, which differs in its properties from natural gas.

In order to heat a private house using gas cylinders with your own hands, you need to familiarize yourself with the features of its organization. An important step is the choice of boiler, since it must be adapted specifically for this type of gas. In addition, the following factors are taken into account:

- Estimated volume of consumption . Directly affects the consumption when heating with gas cylinders and their reserve to ensure heat supply;

- Preparing the container storage area . Safety measures must be observed;

- Organization of gas transportation from cylinders to the boiler . Properly organized individual heating from gas cylinders should be safe;

- Selecting a supplier for filling gas cylinders.

If you carefully read all the reviews when heating a house with gas cylinders, you can note the complexity of the configuration and installation of this type of heating supply. Therefore, it is necessary to calculate the parameters of all elements in advance so that after their installation they can ensure normal operation of the system.

To heat a dacha with gas cylinders, it is recommended to use containers with a maximum volume of 50 liters. But at the same time, you should consider the method of transporting them to the refueling site.

Choosing a storage location for gas cylinders

Cylinder connection diagram

Before deciding on the method of storing gas cylinders, it is necessary to correctly select their capacity. Currently, containers with a capacity of 5, 12, 27 and 50 liters can be used. If heating a private house with bottled gas will be regular, it is best to purchase containers with a maximum volume of 50 liters.

To supply gas, a line is made from the place where the cylinders are stored to the boiler. You can use several containers at once by installing a gas reducer on each. It should include two pressure gauges. One of them is necessary to verify the pressure inside the cylinder, and the second shows this value at the outlet. Using the shut-off valve, the intensity of the fuel supply is regulated.

Reducer for cylinders

The location for choosing their storage directly depends on how many cylinders are needed for the heating boiler. The estimated number of containers depends on the following indicators:

- Total area of the house;

- Heat losses in the building;

- Minimum temperature in winter.

An important point is the place where the gas heating boiler using bottled gas will be installed. The length of the supply line should be minimal in order to reduce the likelihood of its depressurization and optimize gas consumption.

In addition to heating boilers, gas convectors can be used to heat the house. But they need to be installed in each room, which is not entirely convenient for a large building.

Separate room for cylinders

Storing gas cylinders at home

The best way to store gas cylinders for heating is to prepare a separate room. The rules for arrangement and requirements for it are described in detail in SNiP 2.04.08-87 . Therefore, before installing heating using gas cylinders, you must read this document.

The best option is if the storage room is located in close proximity to the boiler installation site. In this way, the supply line can be made as short as possible. It is also necessary to ensure the following storage conditions for containers for heating a private house from gas cylinders with your own hands:

- No flammable or lubricants should be stored in the premises;

- It is prohibited to use any heating devices - convectors, heaters. The exception is pipes and radiators for water heating;

- Providing fresh ventilation. The average air exchange rate is 12 m³/hour per 1 m² of room;

- Each cylinder must be placed on a pallet. This is necessary to maintain stability in case of possible fluctuations in the capacity during gas release.

To ensure safety, the premises must be locked. Fuel supply for heating a private house with bottled gas occurs via a pipeline. If flexible hoses are used for this, kinks must be avoided during installation.

Heating boilers using bottled gas can be installed in the kitchen or in a separate boiler room. Fuel storage space should not be located in basements or basements.

Requirements for a cabinet for storing gas cylinders

Storing cylinders in cabinets

An alternative to the method described above is the use of special metal cabinets. This is relevant for heating a dacha with gas cylinders with low fuel consumption.

It is recommended to purchase a ready-made design, since it will take into account the requirements from GOST 15860-84. They are as follows:

- Ventilation. To do this, the cabinet design must have ventilation holes;

- Eliminating the possibility of sunlight hitting gas cylinders. This can lead to an increase in temperature on their surface;

- All elements of individual heating from gas cylinders must be made of non-combustible materials. The same applies to storage cabinets;

- Presence of warning signs and inscriptions.

How long does a 50 liter gas cylinder last for heating? It all depends on the nominal consumption of the boiler. But despite this, you can only store two cylinders in one cabinet. The optimal dimensions of the structure in this case will be 2000*1000*570. Before installing the cabinet, it is necessary to make a separate foundation. Its dimensions should exceed the dimensions of the structure by 15-20 cm.

The installation rules for heating a private home from gas cylinders with your own hands are also observed:

- The minimum distance from doors and windows should be 5 m;

- The wall to which the cabinet will adjoin is made of non-combustible materials.

Be sure to make special ventilation gaps on the surface of the foundation. Experts recommend grounding the structure to remove possible static voltage.

The design of the cabinet for heat supply using gas cylinders must include fastening elements for containers.

Calculation of the number of gas cylinders for heating

Types of heating cylinders

One of the significant disadvantages of such heat supply is the constant replenishment of fuel reserves. Therefore, it is necessary to calculate in advance how many cylinders are needed for the boiler. There is no exact method for this. But there are a number of ways in which you can determine approximate fuel consumption.

To determine the consumption when heating with gas cylinders, you must read the technical documentation of the boiler. It indicates fuel consumption for both natural and liquefied gas. Usually in the latter case, manufacturers give the flow rate in kg/hour. For boilers with a power of 24 kW it is about 3.5 kg/hour.

In addition, the intensity of fuel consumption is taken into account. On average, to maintain normal temperatures in winter, the heating supply of a private house with bottled gas operates from 12 to 16 hours a day. If the heating season is about 100 days, the total consumption for a 24 kW boiler will be equal to:

Those. On average, you will need 1 cylinder per day for a heating boiler with a capacity of 50 liters. This is the maximum fuel consumption, which can be reduced as follows:

- Installation of automatic gas supply;

- Purchase of modern models of boilers with high efficiency;

- Insulating the house to reduce heat losses.

But even these measures will not greatly affect fuel consumption. Almost all reviews about heating with gas cylinders indicate the relevance of installing this type of heating only in houses with a small area and non-permanent residence.

The table shows how many cylinders are needed for a heating boiler depending on the area of the house.

Number of cylinders 50 l, pcs.

These are not final numbers. For each heating system, an individual calculation is made of how many cylinders are needed for the boiler. It is also necessary to take into account the correct filling of the container. All liquid is first removed and the weight of the empty cylinder is measured.

When filling a cylinder, you can check its filling level by measuring the temperature level. The area where there is a gas mixture will cool the cylinder.

Choosing a boiler for balloon heating

Heating boilers using liquefied gas

Currently, manufacturers do not produce narrow-profile heating boilers using bottled (liquefied) gas. However, equipment designed for natural gas cannot be used without prior modification.

Before purchasing a boiler, you must make sure that the package includes a kit for adapting equipment for propane. The set includes nozzles with a wider nozzle and a kit for attaching them to the burner. The reinstallation procedure can be performed independently only if this is provided for by the design.

There are several types of gas heating boilers using bottled gas, which differ in operational and technical characteristics:

- Burner type - open or closed . It is best to purchase heating boilers using bottled gas with a closed burner. For their operation, air is taken from the street using a coaxial pipe;

- Installation - wall or floor . Most models with power up to 24 kW are wall mounted;

- Number of circuits . To supply heat to your dacha with gas cylinders, you can purchase an inexpensive single-circuit boiler. If you plan to live in the house permanently, it is recommended to buy a double-circuit model with hot water supply.

You can preliminarily calculate the flow rate for heat supply with gas cylinders by reading the technical data sheet of the equipment. However, manufacturers often provide maximum flow rate at maximum equipment power. The lower the burner operating intensity, the less fuel will be consumed.

Gas heating boilers using bottled (liquefied) gas with a cast iron heat exchanger have the best performance indicators. It will last much longer than steel.

Reviews about heating the house with gas cylinders

Parallel connection of cylinders

Reading reviews about heating with gas cylinders will help determine the relevance of installing this heating system. But it is necessary to take into account their subjectivity - negative ones are often associated with the wrong choice of equipment and violation of installation rules.

It should be remembered that the operation of individual heating from gas cylinders largely depends on the professionalism of installation and configuration of the equipment:

- We purchased a small country house of 44 m², with ordinary stove heating. There was a lot of hassle with it - constant monitoring of the stove, soot and soot. We tried switching to electric heating using convectors, but it turned out to be expensive. Monthly expenses increased to 6,500 rubles. I arranged the final version of the heat supply using gas cylinders. Costs dropped to 3,000 rubles/month. The only drawback is that the containers need to be constantly refilled;

- To heat the house, I installed balloon heating myself. I purchased two storage boxes, installed gearboxes, and ran a pipe to the boiler in the house. But I noticed that the calculated consumption is significantly lower than the actual one. I installed dependent automation (budget option), replaced the burner in the boiler with an injection one. Consumption decreased by 20-22%;

- After installing balloon heating in the first winter, I was tormented with rearranging the gearboxes to connect the filled containers. They suggested a way out - install several cylinders with reducers and connect each one to the main line. As soon as the gas runs out in one of them, open the tap and connect the next one. The scheme is convenient and simple. I recommend it to everyone.

An alternative to balloon heating can be the installation of a gas holder - a special container for storing gas. But for this you need to obtain permits. Only a certified company can service and fill the gas tank.

In the video you can see an example of balloon heating at home:

How a gas boiler using bottled gas works, operating features

Is it possible to connect a gas boiler to a cylinder?

A gas boiler for heating a house from a cylinder is offered by many European and domestic manufacturers. German Buderus, Viessmann and some other European models are universal and can operate on both main and bottled gas.

But, basically, consumers are offered boilers designed to operate exclusively on mains gas. In this case, it will be necessary to re-equip the system: replace the nozzles or completely change the burner to make it possible to use liquefied gas.

Cylinders as the main source of propane

An autonomous gas boiler using gas cylinders is quite easy to install. The connection diagram is the same as in the case of the main pipe. The only thing that needs to be taken into account during installation is fire safety regulations, which are somewhat different from those for the operation of natural gas.

A significant disadvantage of using household cylinders is the need to refill them regularly. On average, the container lasts no more than two days, after which it needs to be disconnected and taken to a gas station for refueling. You can reduce the frequency of trips by connecting several cylinders to a single network. Modern boilers allow connecting from two to six containers simultaneously.

The cylinders are not connected directly, but through a special reducer, which allows maintaining a stable pressure sufficient for the uninterrupted operation of gas heating boilers running on bottled gas.

The propane cylinder mating ramp allows you to increase the simultaneous number of connected containers to 10 pcs.

Connecting cylinders to reserve

Another disadvantage of a heating system running on liquefied gas is the need to constantly monitor the fullness of the cylinders. There are situations when the gas runs out right at night, the heating system quickly cools down, which causes inconvenience to the owners of the house.

To prevent this from happening, the boiler is powered from a propane cylinder through a special ramp, which allows you to install 1-10 cylinders in reserve. The operation scheme of the node is as follows:

- The ramp is a two-arm collector dividing the containers into two groups.

- The initial gas intake comes from the main group.

- After the end of propane, the ramp automatically switches the boiler operation to reserve tanks and issues a mechanical signal.

- After filling and connecting the containers to the manifold, the main working group of cylinders is automatically turned on.

An in-line gas cylinder installation is quite convenient to use and allows you to automate the boiler operation process as much as possible, increasing its battery life.

How to connect a gas boiler to a propane tank

Installing a gas boiler for autonomous heating using bottled gas is much easier than using mains fuel. There are several rules regarding fire safety, equipment reconfiguration and power calculations that require strict compliance.

Unauthorized installation is not recommended. It's better to invite a specialist. Provided that the boiler is properly connected and re-equipped, installation work will take only a few hours.

Is it possible to install gas cylinders in the boiler room?

The norms and rules for installing a cylinder are regulated by industrial safety requirements. In particular, it states that containers with liquefied gas cannot be located in the same room as heating appliances.

- Cylinders should be taken to an adjacent room or outside, installed in a special cabinet.

- Empty gas cylinders should be stored outside the building. It is optimal if the containers are refilled immediately.

- If cylinders installed in a cabinet outside freeze, the storage walls should be insulated using non-combustible thermal insulation. Heating containers or cabinets with open fire is strictly prohibited.

- The gas cylinder can be installed at a distance of at least 2 m from the heating boiler.

- It is prohibited to store compressed gas cylinders near the boiler room. Containers can only be stored in a specially equipped room located no closer than 10 meters, equipped with ventilation and without pits or a basement. This requirement is due to the fact that propane is heavier than air and, when leaking, accumulates at floor level. If there are pits or a basement, the gas concentration will become critical, which is enough to cause an explosion.

- Operation of cylinders - complete exhaustion of LPG from the container is not allowed. Every 4 years it is required to carry out certification of the tightness of cylinders and the integrity of their walls.

Do I need to reconfigure the boiler for propane?

A conventional gas cylinder boiler only works if certain conditions are met and conversion is carried out. There is no need to reconfigure the equipment, but you will need to install additional fittings to stabilize the gas pressure.

Not every boiler is able to operate on LPG. You should pay attention to the technical documentation. An essential requirement is the ability of the unit to operate at a reduced gas pressure of 3-4 mBar.

What is required to switch the boiler to gas from a cylinder

For normal operation of the LPG boiler, several important conditions will need to be met:

- Replacing nozzles or burners. Gas-cylinder water heating equipment designed to operate exclusively on LPG is not produced. Some manufacturers make universal units equipped with an electronic processor. To switch from mains gas to cylinders, you simply need to change the cartridge. But more often, conversion will require replacing the nozzles or the entire burner.

- Gearbox installation. Liquefied gas is pumped into cylinders under pressure, resulting in a transformation from a gaseous to a liquid state. To transform it back, you will need to lower the pressure. The gearbox is designed for this purpose.

- Gas valve - in some models, connection and operation of a domestic gas boiler using bottled gas is possible only by replacing this unit.

A conventional gas reducer is not suitable for conversion. A gas heating boiler can operate from conventional bottled gas only when a unit is installed with a flow rate of 1.8-2 m³/hour.

How to calculate the volume and number of cylinders for a boiler

As practice shows, for a house of 100 m², gas consumption will be approximately 2 cylinders per week. Accordingly, for a house of 200 m², consumption will increase to 4 units. A gas heating boiler consumes 9 (100 m²) -18 (200 m²) propane cylinders per month, depending on the total heated area. The calculation of the required number of containers is carried out taking into account this coefficient.

Thus, installing a gas boiler room in a house using propane cylinders for 100 m² will require simultaneously connecting at least 4 cylinders (2 working and 2 reserve), for 200 m² 8-10. To ensure maximum ease of use, the connection equipment set must include a ramp.

You can accurately calculate the need for a boiler running on bottled gas using the technical documentation provided by the manufacturer. At least, European concerns indicate in the equipment instructions the consumption of LPG after the unit has been re-equipped.

Gas cylinders must be refilled with propane after the container is 90% empty. Gas production is completely prohibited.

Which boiler is better to choose when heating with propane cylinders?

Experience in using boilers from gas cylinders has shown that not all equipment operates equally successfully on LPG after conversion. Increasing efficiency during operation is quite problematic. Therefore, it is necessary to choose the right heating equipment.

- The principle of operation is that condensation equipment is the most economical and adapted for operation on LPG. The boiler operating time from the cylinder increases by an average of 15-20%. Condensing equipment is designed to operate at low gas pressure and often does not require replacement of the burner and nozzle.

- Number of circuits - you should choose a single-circuit boiler exclusively for heating rooms, and a double-circuit boiler for heating water.

- Purpose - the best option is equipment whose operating instructions contain permission to connect the boiler to the cylinder. Re-equipment of conventional water heating units, as a rule, leads to excessive fuel consumption and is not economically profitable. Boiler manufacturers offer all the necessary fittings for connecting cylinders; they are included in the kit or purchased separately.

A condensing boiler is the best option for constantly heating a house using LPG. For temporary heating, with a view to further switching to main gas, other types of boilers can be used, provided that they can operate at reduced gas pressure.

Conversion of the boiler from natural to bottled gas should only be carried out by a specialist. Independent re-equipment leads to rapid breakdown of equipment and increases the likelihood of fire and explosion hazards.

Pros and cons of running a boiler using propane cylinders

The main advantage of connecting to LPG is the speed of installation and the absence of strict regulations related to operation. There is no need to obtain an operating permit, as well as to complete design documentation, which is required for a trunk connection.

Judging by consumer reviews, heating with liquefied gas also has its disadvantages:

- The need to control the fullness of cylinders. For normal operation of a gas boiler you need 3-4 gas cylinders. Monitoring exactly when the gas will run out is quite problematic without additional equipment. If you plan to constantly operate the system, it is better to spend money and connect the boiler to several cylinders through a ramp and reducer.

- Gas cost - compared to the main connection, LPG heating costs are slightly higher, but less than when using an electric boiler.

- Features when connecting to a propane tank. According to the PB, you will need to take the containers to another ventilated room or outside, which is not always convenient. It is necessary to separately purchase a device for connecting at least four gas cylinders to the boiler, as well as control and control valves.

- Conversion - not all boilers can be converted to LPG with the same efficiency. Replacing the burner will cost approximately 30-40% of the total cost of the boiler.

- The need to attract qualified specialists. Only a licensed specialist can connect several propane cylinders into a single network, change the burner and make the connection correctly.

Some of the above disadvantages apply equally to connection to the main gas pipeline.

Is it possible to connect a gas boiler to a cylinder?

A gas boiler for heating a house from a cylinder is offered by many European and domestic manufacturers. German Buderus, Viessmann and some other European models are universal and can operate on both main and bottled gas.

Cylinders as the main source of propane

An autonomous gas boiler using gas cylinders is quite easy to install. The connection diagram is the same as in the case of the main pipe. The only thing that needs to be taken into account during installation is fire safety regulations, which are somewhat different from those for the operation of natural gas.

A significant disadvantage of using household cylinders is the need to refill them regularly. On average, the container lasts no more than two days, after which it needs to be disconnected and taken to a gas station for refueling. You can reduce the frequency of trips by connecting several cylinders to a single network. Modern boilers allow connecting from two to six containers simultaneously.

The cylinders are not connected directly, but through a special reducer, which allows maintaining a stable pressure sufficient for the uninterrupted operation of gas heating boilers running on bottled gas.

The propane cylinder mating ramp allows you to increase the simultaneous number of connected containers to 10 pcs.

Connecting cylinders to reserve

Another disadvantage of a heating system running on liquefied gas is the need to constantly monitor the fullness of the cylinders. There are situations when the gas runs out right at night, the heating system quickly cools down, which causes inconvenience to the owners of the house.

To prevent this from happening, the boiler is powered from a propane cylinder through a special ramp, which allows you to install 1-10 cylinders in reserve. The operation scheme of the node is as follows:

- The ramp is a two-arm collector dividing the containers into two groups.

- The initial gas intake comes from the main group.

- After the end of propane, the ramp automatically switches the boiler operation to reserve tanks and issues a mechanical signal.

- After filling and connecting the containers to the manifold, the main working group of cylinders is automatically turned on.

An in-line gas cylinder installation is quite convenient to use and allows you to automate the boiler operation process as much as possible, increasing its battery life.

Advantages

Numerous reviews from owners of private houses, cottages, and garages explain the growing popularity of bottled gas heating by the following factors:

- environmental friendliness and compliance with all state standards and regulations;

- autonomy and safety of heating;

- stability of operation and pressure level;

- economical fuel consumption and ease of control;

- possibility to heat water for household needs

Reasons for high performance

Heating from a gas cylinder has high efficiency due to the fact that the energy carrier easily passes from a liquid aggregate to a gaseous state. Therefore, the heating system is completely independent, which gives the owners of a private house or cottage the opportunity to use it at their own discretion and in any conditions.

Nuances of use

It will be possible to use gas cylinders for space heating even at the stage of building a house - this is convenient in case of construction in the cold season. To ensure safe use of the energy carrier, it is recommended to follow certain operating rules. For example, during sleep it is recommended to turn off the gas supply or at least reduce it.

Additionally, this will reduce energy consumption

Gas cylinders require periodic refilling: special attention must be paid to its quality. Some station employees do not fill the cylinders completely, which is why owners are forced to overpay - be careful if you use the services of such stations

Reviews about the main benefits

In suburban homes, the presence of gas cylinders does not surprise anyone. People continue to use such fuel in the kitchen if gas is not supplied to the house. But recently you can hear that homes are heated with liquefied petroleum gas. The purchase and installation of equipment and heating systems of this kind have become available to the general public.

If people do not have the opportunity to use centralized gas for heating, they install appropriate equipment to provide heating with liquefied gas. Consumers emphasize that this type of fuel use has certain advantages. Firstly, you will have the opportunity to make heating autonomous, refusing to use a centralized supply. Secondly, gas can be used all year round. Thirdly, as consumers emphasize, the system will have high operational reliability and quality.

Calculation of gas consumption

To achieve comfortable heat in the house, fuel consumption must be at least 1 kW per 10 m2. Let's consider how much fuel is needed for a house of 100 m2. The boiler must have a power of at least 10 kW; to produce 1 kW of heat, the equipment consumes up to 0.12 kg/hour of fuel. Thus, the consumption per hour for the entire area is 1.2 kg, which is equal to 28.8 kg per day.

The approximate volume of a 50-liter cylinder is 22 kg; it turns out that heating with propane will cost the owner of the house 9 cylinders per week. It is expensive. But there is an amendment: enhanced mode is required only when the system is warming up, then a properly adjusted boiler will require no more than 8 kg of gas per day, that is, consumption is reduced by 3-4 times.

To maintain comfortable heat in a 100 m2 house, which is well insulated, the entire system is regulated and equipped with automatic switches, 3 gas cylinders per week are enough. At the same time, the temperature in the rooms inside the building will be maintained at +22 C, provided that outside it is down to -20 C.

Automatic adjustment allows you to reduce the temperature when there are no people in the room. For example, in a dacha in winter, a thermometer reading of +5 C is enough to keep the heating system in working order. In this case, one bottle lasts for 7-10 days.

Fuel cost

Before installing the described type of heating, you must calculate the cost of gas. The price of a liter of fuel is constantly changing, today it is approximately 15 rubles. On average, gas consumption from the reservoir for heating is 25 liters per year per square meter. If you are interested in the question of how much liquefied gas for heating costs, then you should take into account that for a small house of 100 square meters you will need approximately 2,400 liters per year, which is 36,000 rubles.

Safe Operation

It is prohibited to use heaters, electric heaters, heating cables, etc. as a means of heating heating cylinders.

Tanks with fuel reserves can only be stored inside separate cabinets, the top of which is drilled to form ventilation. It is recommended to insulate the structure from the inside on the sides and below with polystyrene foam, without covering the ventilation holes. It is not allowed to insulate the cylinders themselves by heating them from the outside, even if they are partially covered with frost.

Frozen cylinders

It is important to follow the rules for filling tanks so that equipment does not explode at home. Immediately after assembling the heating unit, it is necessary to check for leaks

Immediately after assembling the heating unit, it is necessary to check for leaks.

Gas pipes must have walls 2 mm or more thick, and in places where they pass through the wall, before pulling the pipeline, a special case with soft filling or a piece of pipe of a slightly larger diameter is placed. In the latter case, the voids are filled with construction foam.

The best wall-mounted gas boilers

This section presents single-circuit room heating systems placed on the wall. They are compact and easy to maintain, although they have some limitations in functionality.

Viessmann Vitopend 100-W A1HB003

4.9

★★★★★ editorial assessment

89% of buyers recommend this product

The A1HB line includes three boilers with a capacity of 24, 30 and 34 kW. This is enough to heat a home with an area of up to 250 m2. All cases are equally compact: 725x400x340 mm - such units have a place in any room.

Viessmann boilers are assembled on a single modular platform, which simplifies their installation and maintenance. In addition, there is no need to leave additional space near the body, so any Vitopend can be combined with kitchen furniture if there is a free corner for it.

Advantages:

- Low gas consumption - no more than 3.5 m3/h in the older model;

- The valve body is equipped with quick-release connectors;

- Automatic power adjustment depending on the outside temperature;

- Efficiency up to 93%;

- New coaxial chimney system with frost protection;

- Intelligent control with self-diagnosis function;

- Possibility of switching to liquefied gas.

Flaws:

There is no remote control panel.

Viessmann provides the opportunity to choose a boiler for an apartment of any size. The appearance and dimensions for the entire line are absolutely the same - the models differ only in performance and, accordingly, gas consumption.

Baxi Eco Four 1.24 F

4.8

★★★★★ editorial assessment

88% of buyers recommend this product

See review

Despite the prestige of the brand, the Eco Four model is relatively inexpensive. The boiler has a flat body measuring 730x400x299 mm, which allows it to be hung flush with kitchen cabinets. When used in northern latitudes, such a unit can heat an apartment up to 150 m².

Fourth generation boilers were developed taking into account our operating conditions. That is why the presented model operates even when the inlet gas pressure is reduced to 5 mBar. In addition, it has two separate thermostats: for heating radiators and for the “warm floor” system.

Advantages:

- Built-in water flow meter;

- Pump with air vent and post-circulation mode;

- It is possible to connect to solar collectors;

- Dual-mode thermal control;

- Pressure switch for protection against low coolant pressure;

- You can connect a remote thermostat and remote control.

Flaws:

Low-informative built-in display.

As for Baxi, Eco Four's price is very attractive. In addition, this is an excellent solution for placement in a small kitchen or studio apartment.

Vaillant AtmoTEC Plus VU 240/5-5

4.7

★★★★★ editorial assessment

87% of buyers recommend this product

This boiler has all possible means of protection: gas control, pressure switch with safety valve, pump air vent. Here, overheating of the medium and combustion chamber, freezing of liquid in the system and in the chimney are completely excluded. The built-in auto-diagnostics helps monitor the correct operation of all systems.

AtmoTEC is adapted for operation in Russia: it takes into account the low quality of main gas and can operate on LNG. The programmer control is fully automated, and the panel itself is covered with a neat decorative cover.

Advantages:

- Volumetric expansion tank 10 l;

- Low gas consumption – 2.8 m³/h (or 1.9 m³/h when connected to a cylinder);

- Almost eternal chrome-nickel burner;

- Possibility of combination with other heaters;

- The minimum side clearance during installation is 1 cm.

Flaws:

Classic (atmospheric) chimney.

The boiler dimensions of 800x440x338 mm and a maximum power of 36 kW are more suitable for a private home than for a city apartment. Although in a spacious kitchen there will be no problems with its placement.

Rating of popular models and manufacturers

Siberia boiler , manufactured at the domestic enterprise JSC Rostovgazoapparat, is the best-selling module among all those presented on the gas equipment market today.

It is a non-volatile unit with a highly reliable Eurosit automation system, made in Italy and fully adapted to domestic operating conditions.

The Siberia device consists of durable, high quality materials. The layer of thermal insulation coating available on all models makes operation safe and protects the user from burns and other potential injuries.

The heat exchange tank is boiled automatically and due to this it has increased strength. Double-circuit boilers are equipped with a flow-through copper circuit for efficient heating and subsequent supply of hot water to the system.

The module is controlled at an intuitive level and does not create difficulties even for those users who are not familiar with technology.