Elena Arkhangelsk Review: positive

In the summer of 2005, our family purchased a new Keber KS-GV-10 gas boiler from the local building materials store “Slavyane”, but we installed it, for a number of objective reasons, only a year later.

Finally, we stopped freezing in winter! Before this, we had an old KS-TG-16 unit. We went to bed dressed, especially when there was severe frost, and we often got sick, especially our son. Now these problems are a thing of the past.

The living area of the house is 48 sq. m. m, total – 54 sq. m. If you open the door to the rooms, then it becomes very comfortable in the unheated corridor. And of course, the boiler provides us with hot water during the heating season.

We wanted to ensure that there was hot water during the non-heating season. Knowledgeable people suggested that to do this, you need to cut a tap into the pipe, which would shut off the heating system. In this case, only running water for domestic needs would be heated, and the heating would remain untouched. We haven’t decided yet whether we will do this, since the boiler has been in operation for the eighth year - maybe we’ll have to replace it soon.

The only thing that failed during its entire operation was the thermocouple. It broke after a year of operation, but after replacing it, the boiler has been operating smoothly ever since.

We are currently only in the process of installing a gas meter, so we do not use gas sparingly, that is, we can turn it on at full power, especially when hot water is needed, and then sometimes we forget to turn it down. Therefore, when we are at home, we have the windows open in all our rooms - both warmth and fresh air at the same time.

According to reviews from friends, wall-mounted boilers are more economical - maybe we will change them soon, since this year our Keber began to “puff”. They called a friend who specializes in gas equipment. Performed routine maintenance, rebuilt and cleaned the automation. Everything works fine now, so we'll wait for a replacement for now.

Pressure testing and washing

Pressure testing is not always done due to the lack of a special pump and the reluctance to call a team, but if the heating fails in the midst of cold weather, the costs can be much higher!

It is especially important to check a new system and one that, on the contrary, has been in use for several years. The cost of crimping in construction companies is from 3000 rubles

Additionally, they may charge a fee for visiting the site (about 2 thousand rubles). By the way, a manual pressure testing pump will cost 4.5 – 6 thousand rubles

The cost of crimping in construction companies is from 3,000 rubles. Additionally, they may charge a fee for visiting the site (about 2 thousand rubles). By the way, a manual pressure testing pump will cost 4.5 – 6 thousand rubles.

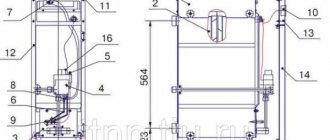

Technical characteristics and device

Keber boilers are distinguished by their reliable assembly and long service life. The manufacturer provides a 15-year warranty. Also, units of this brand are characterized by high efficiency.

The Keber gas boiler equipment includes:

- stable heating of the coolant;

- maximum complete combustion of fuel.

In addition, these elements are distinguished by high anti-corrosion properties.

Due to the fact that Keber boilers have gas burners, the size of their fuel chambers is smaller than that of similar heating devices produced by other manufacturers. Thanks to the special design of the Danko automation, fuel burns as efficiently as possible, even if the flame height reaches 7 cm.

Also included in the package is the Arbat automatic system, which is responsible for regulating the operation of heating equipment and its safety. There are five levels of protection. If the pressure in the water or gas supply system decreases, the unit will turn off automatically. The design of the automation is simple, which has a positive effect on its reliability, and in case of problems, repairs will be simple.

It is worth saying that, if desired, users can order from the boiler manufacturer Keber a model with a more expensive, but at the same time more reliable and high-quality Italian Eurosit automation. Such units can operate practically without third-party intervention.

The assortment of the company that produces Keber boilers includes a wide selection of models of different powers: 10, 12.5, 16, 20 kW, etc.

Let's look at the technical characteristics of the device using the example of the Keber 12.5 floor-standing model:

- type of execution - floor-standing;

- combustion chamber - open;

- power - 12.5 kW;

- Efficiency - from 85%;

- mechanical control;

- — 1.62 m³;

- weight - 39 kg;

- heated area - 125²;

- The maximum water pressure in the heating system is 3 bar.

Gas non-volatile boiler KS-G Keber 12.5 with EUROSIT automation

What other safety regulations are there?

- Do not disassemble or dismantle gas appliances yourself.

- Handle the power cord carefully.

- Do not place foreign objects on the device.

- Don't stand on the boiler. Do not stand on chairs, tables or other unstable objects to clean the wall-mounted boiler.

- Monitor the coolant and add it to the system on time.

- Be careful - in some modifications the use of antifreeze is prohibited.

- If you smell gas, immediately turn off the gas and open windows and doors. Leave the boiler room and call the gas service.

- turn the thermostat knob counterclockwise to align the “star” icons on the panel knobs;

- smoothly press the thermostat knob in the axial direction until it stops and hold it;

- continue to hold the thermostat knob pressed for at least 10 seconds. (until when it is released the igniting burner goes out);

- release the thermostat knob (the ignition burner should be lit);

- turn the thermostat knob counterclockwise towards position “7”, the main burner should light up.

Switching off the boiler with automatic “EuroSit 630”

- it is necessary to smoothly turn the temperature setting knob clockwise until the white asterisk aligns with the “asterisk” sign on the panel;

Putting the boiler into operation with the MiniSit 710 automation

- make sure that the gas valve on the gas pipeline in front of the boiler is closed;

- make sure that the boiler is turned off - the thermostat knob is in the ignition position;

- open the tap on the gas pipeline supply;

- press the ignition button and keep it pressed;

- press the piezo lighter button several times (the burner should light up);

- continue to hold the ignition button pressed for at least 10 seconds. (until when it is released the igniting burner goes out);

- release the ignition button (the ignition burner should be lit);

- turn the temperature setting knob counterclockwise towards position “7”, the main burner should light up.

Attention: if the ignition burner goes out, the ignition operation should be repeated again, but not earlier than after 3 minutes.

Turning off the boiler with automatic “MiniSit 710”

- you need to smoothly turn the temperature setting knob clockwise and press the shutdown button;

- it is necessary to close the tap on the gas pipeline inlet.

Putting the boiler into operation with the Kare automatic system

- make sure that the gas valve on the gas pipeline in front of the boiler is closed;

- turn the temperature sensor adjustment knob counterclockwise until it stops;

- open the tap on the gas pipeline supply;

- press and hold the solenoid valve trigger button;

- press and release the piezo lighter button (you may have to press several times until the igniter starts to burn);

- When the ignition burner starts to burn, continue to hold the solenoid valve start button for at least 30 seconds. (until when it is released the igniting burner goes out);

- by turning the nut on the ignition burner, you need to achieve a blue flame on the burner;

- turn (smoothly, effortlessly) the thermostat knob to the right until the main burner lights up;

- set the desired temperature.

Attention: if the ignition burner goes out, the ignition operation should be repeated again, but not earlier than after 30 seconds.

Turning off the boiler with automatic “Kare”

- it is necessary to smoothly turn the thermostat handle to the left until it stops;

- it is necessary to close the tap on the gas pipeline inlet.

Putting the boiler into operation with the Sit 820 NOVA mv automation system

- press and turn the round control knob to the “asterisk” position (ignition);

- press the control handle all the way and, without releasing it, press the piezo igniter button. Do not release the handle for 10 - 15 seconds;

- release the handle and check that there is a flame on the pilot burner;

- if there is no flame, repeat the ignition procedure, increasing the time you press the control handle;

- to turn on the main burner, turn the control knob counterclockwise to the “flame” position;

Peculiarities

The ATEM brand has invested all its efforts in the development and production of high-quality devices for autonomous heating. For more than 27 years, the company has been providing heat to its consumers in the form of Zhytomyr gas boilers. Since the introduction of the first boiler, a huge rebranding has been carried out, the device has received changes from the internal base of spare parts to the external design. Today, the Zhitomir boiler is a neat, small-sized unit with switching instructions that even a child can handle. The main quality inherent in boilers of this brand is the quality and reliability of the device. Product specifications have also changed as new technologies emerge. Not only these components, but also many other facts allowed the ATEM brand to receive the European Quality award.

About the manufacturer

Since 2006, Keber gas boilers have been produced by the domestic company, which is part of the Tactical Missile Arms OJSC corporation. These heating devices are well adapted to Russian operating conditions; they operate smoothly even in places characterized by very low temperatures.

If necessary, such heating devices can be used for heating premises in the Far North.

Keber's product range includes both household and industrial models.

Single-circuit and double-circuit units are distinguished. The first are used exclusively for heating, while others provide the room not only with heat, but also with hot water.

Who releases

The Keber boilers are produced by the Russian company, which is part of the Tactical Missile Arms OJSC corporation. This company was registered in 2004. That is, it has been operating on the market for about 15 years. This company exclusively supplies heating equipment to specialized stores. Products from this manufacturer have received very good reviews from consumers. Heating units from Zvezda-Strela Trading House LLC are actually very popular among the population.

In addition to the boilers themselves, this manufacturer supplies the market with components for them. It will be absolutely easy for owners of country houses to find spare parts for Keber equipment if necessary.

Technical parameters of Atem gas boilers

Atem company produces:

- floor-standing gas boilers Zhytomyr;

- wall-mounted devices ().

Units installed on the floor are also divided into single-circuit and double-circuit. Devices with two circuits can heat water for two or three consumers at low costs. See the technical characteristics of all Zhytomyr floor-mounted gas boilers in total.

The productivity of the hot water supply circuit of floor-standing installations with two lines is from 175 to 1400 l/h with a temperature difference of the heated liquid of 35 °C. The device can be equipped with a circulation pump, which is installed as a function. Parameters of the model range of double-circuit gas boilers Zhytomyr parapet type in the table.

Parapet 2-circuit units provide warm water flow from 160 to 345 l/h with a liquid temperature difference of 35 °C.

From the tables we can conclude and make sure that the wall-mounted and floor-standing boilers of this manufacturer are adapted to the conditions of low gas pressure in pipelines, and this is their huge advantage. A significant disadvantage is the maximum pressure of the coolant in the heat exchanger, which is possibly quite low. For boilers mounted on the floor, this is up to 2 kgf/m², and for mounted boilers, up to 0.7 kgf/m². While imported analogues can operate at system pressure up to 3 kgf/m². Therefore, you can make sure that Atem gas equipment is more suitable for gravity systems and small houses with one or two floors.

Experts do not recommend buying wall-mounted devices for two-story cottage buildings, since there simply won’t be enough pressure for high-quality operation of the system.

Design Features

The main elements of the Zhitomir boiler are:

- a housing in which the main components and equipment are installed;

- gas burner unit located in the firebox. Here gas combustion occurs and heat flow is released;

- recuperative heat exchanger, in which heat exchange occurs between combustion products and coolant;

- gas exhaust system, its responsibilities include removing combustion products outside the boiler and releasing them into the chimney.

In order to increase the efficiency of heat transfer, the gas boiler Atem Zhytomyr 3 has the following design features.

- The heat exchanger pipes made of heat-resistant steel have a rectangular cross-section; this device allows you to increase the contact area of the flue gas and the coolant.

- The counter movement of coolants was organized, this solution made it possible to increase the efficiency of the heat exchange device to 92%;

- To increase the area of interaction between combustion products and the coolant, as well as to prevent the accumulation of soot on the surface of the steel pipes of the ATEM boiler heat exchanger, turbulators are installed. Soot accumulates on the lower surface of the turbolizers, while the pipe walls remain clean. To remove soot, you need to periodically remove the turbolizers and clean them of soot.

- Gas double-circuit turbocharged boilers in Zhitomir have a coil of copper pipelines around the heat exchange heating pipes.

To organize a stable gas combustion process, a POLIDORO gas burner device is used. Its distinctive feature is a single-stage atmospheric burner. The edges of the burners themselves are made of heat-resistant steel, which allows you to maintain the combustion mode at different gas supplies to the firebox. Even at low gas consumption, the heating of the edges is sufficient to maintain stable combustion.

The gas supply mode is regulated by the EUROSIT gas valve. This device automatically switches the gas supply to the burners depending on the temperature of the coolant. The user independently sets the temperature of the coolant, focusing on the temperature in the open air. As the ambient temperature decreases, the temperature of the coolant increases.

Sources

- https://www.stroy-podskazka.ru/otoplenie/kotly/zhitomir/

- https://ProfiTeplo.com/gazovye/56-kotly-zhitomir.html

- https://SpetsOtoplenie.ru/gazovoe-otoplenie/gazovye-kotly-evropejskogo-proizvodstva/chto-nado-znat-pro-gazovyj-kotel-zhitomir.html

- https://teplospec.com/gazovoe-otoplenie/kak-zapustit-gazovyy-kotel-vpervye.html

- https://microklimat.pro/otopitelnoe-oborudovanie/kotly/kak-vklyuchit.html

Posting rules

- The area of the room in which the heater is installed is at least 7.5 m².

- Ceilings - from 2.2 m.

- There must be a window providing access to air from the street.

- The door should open in the direction of movement of the person leaving the room.

- It is prohibited to install switches in the boiler room. If they are already installed, you will have to take them outside the premises.

- It is necessary to equip supply and exhaust ventilation. For every m³ of fuel consumed - 15 m² of air.

- The distance from the heater to elements capable of burning is 25 cm or more. To non-combustible elements - 5 cm. From the chimney to combustible parts - 40 cm, to non-combustible parts - 15 cm.

- The device is mounted on a perfectly flat plane, without slopes.

Let's move on to cleaning the column

Turn off the gas supply valve to the boiler. Using wrench No. 10, unscrew the fastening screw under the boiler door and remove the door.

Disconnect the wire connecting the piezoelectric element and the ignition electrode.

Using key No. 10, unscrew the thermocouple clamp. Using wrench No. 9, unscrew the thermocouple from the valve.

Note:

It is necessary to ensure that the thermocouple does not turn while unscrewing.

We note the depth of insertion of the nozzle into the main burner so as not to disturb the boiler settings.

Using wrench No. 17, unscrew the nut securing the copper tube from the burner to the valve. Using wrench No. 10, unscrew the ignition electrode from the pilot burner and the copper tube from the pilot burner and valve. Using a flat-head screwdriver, unscrew the two screws securing the pilot burner.

The gasket installed under the pilot burner has become unusable. It will need to be replaced.

Remove the nozzle from the pilot burner.

Tip: if the nozzle is stuck, you can lightly tap the burner with a key.

We unscrew the four screws securing the main burner to the boiler body and the screw securing the housing to be able to remove the main burner.

Lowering the main burner down, remove the copper tube from the valve.

Remove the main burner.

Remove the thermometer sleeve from the boiler body.

Using wrench No. 10, unscrew the four screws securing the top cover of the boiler and remove it and the insulation sheet under it.

Unscrew the two nuts securing the flue to the boiler body.

Remove the terminals from the draft sensor.

We remove the gas duct.

We remove the swirlers from the boiler heat exchanger. We clean them with a brush. If necessary, use a metal brush.

Clean the outer part of the heat exchanger with a metal brush. We clean the heat exchanger channels with a brush to the full depth. Clean the bottom of the heat exchanger with a brush. We also clean the gap between the boiler body and the floor. We clean the loose debris using a vacuum cleaner.

Using wrench No. 13, loosen the screw that fixes the depth of insertion of the nozzle into the main burner and remove it.

We clean the burner with a brush and a brush, and clean its holes with a vacuum cleaner. We clean the flue of dust from the outside and inside.

We clean the outer surface of the nozzle with a brush, then clean the nozzle holes with a needle or wire.

Note: The needle should be smaller in diameter than the nozzle hole. Even a slight increase in the diameter of the nozzle hole can affect the combustion mode.

We install the main burner in place.

We install a copper tube with a nozzle and attach its nut to the gas valve.

Only after this do we secure the nozzle to the burner at the mark using wrench No. 13.

Note:

This sequence is necessary in order not to strip the threads in the valve body.

Finally tighten the nut of the copper tube with wrench No. 17.

Clean the pilot burner with a metal brush.

This is how the thermocouple should be installed in the pilot burner (the tip of the thermocouple opposite the flame).

We install the pilot burner on a new gasket.

Before installing the nozzle into the pilot burner, it must be slightly rubbed against the tip of the copper tube for better sealing. The nozzle should also be cleaned or purged.

We connect the copper tube to the pilot burner and to the valve using a number 10 wrench.

The remaining parts of the boiler are assembled in the reverse order. When connecting, the ignition electrode should not be clamped with a key; it is enough to do it by hand, since it is made of ceramic and can easily crack.

We carry out control washing of all compounds. It will be possible to check the tightness of the connections of the copper tubes to the main and pilot burners only when the boiler is turned on.

Rules for filling the system with water before turning on the gas boiler

Before lighting a gas boiler and turning on the heating system, it is first filled with cold coolant, which, after heating, will circulate through the pipes and radiators. During the first launch, everything is carefully checked so that further operation is uninterrupted and the equipment does not require repairs.

These pressure parameters can be changed as they depend on the manufacturer's requirements for the operating pressure in the heating system. But filling with cold water does not end there, since replenishment will be required after the structure is freed from air pockets.

Precautionary measures

Despite the desire of manufacturers to ensure the safety of gas appliances, they can still become a source of danger. The Ministry of Emergency Situations regularly reminds owners of any gas-powered equipment about the following precautions:

- You need to buy gas-powered appliances from organizations that have the appropriate sales license.

- Installation should only be carried out by specialists from the relevant services.

- The kit should include an instruction manual.

- It is prohibited to change the design of the device in any way.

- A technical inspection must be carried out annually.

- It is prohibited to reduce ventilation openings in windows and walls.

- If there are sealed windows, it is necessary to organize air flow.

- Materials that can quickly ignite should not be stored in the boiler room.

- It is prohibited to increase the coolant temperature above 90°C.

Removing air pockets before lighting a gas boiler

Before lighting a gas boiler, you need to fill the heating structure with liquid cold coolant. But just filling with water is not enough. It will either not work, or the degree of heating of the room will be insufficient. A full first start is impossible without releasing the air accumulated in the system. Often modern gas boilers have a special system that automatically bleeds air when filled. But often its effectiveness is insufficient: you will still need to manually reset the air locks. Only after this can you start.

It is necessary to remove air pockets before turning on the gas boiler not only from the heating unit, circulation pump, but also from all heating radiators. The process should begin with batteries - for this, as mentioned above, they will be equipped with Mayevsky cranes. They are opened by placing a container underneath. First, a slight whistle will be heard, indicating that air is gradually leaving the system. After removing the plugs, water begins to flow. Then the taps are closed. A similar procedure should be done with each of the radiators. “How to choose a Danko boiler - types of heating gas boilers, features, advantages.”

When air is removed from the batteries, the pressure gauge needle should settle at a certain value. Before lighting a gas boiler, coolant should be added to the system and thus recharged. “How to turn on the Lemax boiler - operating rules.”

Ignition instructions

Heaters differ in the type of ignition, so when starting different modifications there are some nuances. Before turning on the device, you need to read the ignition instructions to ensure everything is done correctly. Let's look at ignition using the example of the Italian boiler "". Before turning it on, it is important to check the system for leaks. For this purpose, the thermostat is turned on to maximum so that the switching occurs automatically. Ariston ignition process:

- the device is connected to the power supply, and the heating regulator is set to the desired temperature value;

- When the pump is turned on, a slight noise is heard;

- when all air pockets in the pipes are eliminated, the noise will disappear;

- When the electric ignition is triggered, the boiler turns on automatically.

Varieties

Today, several types are involved in the production of Zhytomyr boilers - parapet (wall-mounted) and floor-mounted. In turn, floor products also have divisions into single-circuit and double-circuit.

Floor-standing

If a gas boiler is needed only for heating purposes, attention should be paid to single-circuit models. They are unpretentious, practical and economical

The equipment of the single-circuit boiler “Zhitomir” primarily involves imported components. Thanks to them, the device can be turned on and off if necessary. And if there is a need, in addition to heating, to have hot water in direct access, you will need to choose from dual-circuit options.

In terms of their technical characteristics, floor-standing boilers mostly have the following similarities:

- the maximum temperature limit is +90 degrees;

- efficiency is 92%;

- gas pressure – 635 Pa.

But when choosing a model you definitely like, you need to consider its specific characteristics and capabilities.

Wall mounted

The same separation as in floor-standing boilers is also present in wall-mounted boiler models. They can also be single-circuit or double-circuit. The efficiency of all devices is the same. The same applies to gas pressure.

But it’s still worth considering their characteristics p>

- the power of parapet boilers must be no less than 5 kW and no more than 20 kW;

- the coolant in the device is no more than 17.5 liters;

- depending on the chosen model, natural gas consumption is considered; according to the standard - 0.56–1.67 cubic meters per hour;

- profitability due to imported automation.

For its part, the manufacturer provides a wide range of boilers to choose from, but the Zhitomir-3 KS-G-020 SN model is still in great demand. This device differs from its counterparts not only in terms of availability in terms of price, but also has clear technical data. The design of the device is designed in a minimalist style; the appearance of the boiler looks like a cabinet. It should only be placed on the floor. On the front of the model there is a small door behind which hides a button for turning on and adjusting the device settings. In the same part there is a control window, with the help of which you need to monitor the performance indicators of the boiler.

The basic package includes a housing, which also includes heat exchanger elements. On the outside, it is covered with heat-insulating material and a casing made of steel. The burners are presented in two pieces: one is the main one, and the second is the ignition one. The package includes a gas duct and an automatic gas valve, which is responsible for safety during operation.

Turning on the boiler

- The gas boiler is plugged into an outlet.

- The switch must be set to zero.

- The gas supply is turned on (the tap on the gas pipe is opened).

Further actions may differ for different models of gas boilers.

For example, the switch for Aton or Danko boilers needs to be set to the “star” icon, press the entire switch and hold it for 5-10 seconds.

Then, without releasing the switch, press the button located nearby.

The unit will respond with a characteristic click and hum. After which the regulator is released and the required power is set.

To turn on the Baxi boiler, you also need to turn on the gas, plug in the plug and press the “Start” button. The operating sound will appear. You need to give the device a little time, and it will automatically ignite the flame. After that, you need to press the power button again and connect the heating circuit (the corresponding icon will appear on the display). Finally, using the buttons, the desired temperature is set.

We will look at the types of generators for gas boilers here.

To organize a full-fledged heating system in a private house, it is necessary to install a boiler. The article https://microklimat.pro/otopitelnoe-oborudovanie/kotly/kak-vybrat-dlya-chastnogo-doma.html discusses the main criteria for choosing heating equipment.

Self-diagnosis

The process of operating heaters is simplified if they have a self-diagnosis function. Almost all European manufacturers have equipped their products with it.

For example, German “” heaters, displaying error codes on the display, allow the user to quickly understand the cause of the problem and take measures to eliminate it. If code A7 appears on the screen, it is clear that the hot water temperature sensor is faulty.

If A8 is displayed, the connection to the BUS bus is broken. This function greatly simplifies the use of gas equipment, making it easier and more comfortable.

Malfunctions of Keber gas boilers

Of course, any equipment can fail. Keber boilers are no exception. Let's look at the most common problems that owners of such equipment have to face:

- Unstable work . This problem is usually solved by cleaning the nozzle. In some situations, it is necessary to check the meter, since it may not allow gas to enter the system in the required quantity.

- The gas burner goes out a few minutes after being turned on. There can be many reasons that lead to this, but most often it is due to the failure of the traction sensor. It is best to contact specialists.

- There is no gas supply to the injectors. If you purchased a boiler with an Arbat automatic, then most likely the stem is jammed in the middle part of the structure. You can drop a little machine oil yourself, then check the automation for gas leaks. If the above steps are unsuccessful, then you should contact a specialist.

1. 2. 3. 4.

When arranging a heating structure, many homeowners prefer installing double-circuit gas boilers

These heating units, when installed in modern models, are reliable, they are economical and allow you to provide hot water supply in the house, but it is important to know how to start a gas boiler correctly the first time.

Dangerous situations

The greatest danger is a malfunction associated with the operation of the burners. If the flame goes out, gas may accumulate in the room, which will subsequently cause an explosion. Reasons for the fire going out:

- gas pressure has dropped below the permissible norm;

- no draft in the chimney;

- the supply voltage has disappeared;

- The pilot light went out.

In an emergency, it is necessary to immediately shut off the fuel supply to the burners - automatically or manually. Modern versions are equipped with automation devices necessary for prompt shutdown of equipment. The operation of such devices is not only convenient, but also safe.

How to prevent gas accumulation indoors

Modern safety standards provide for the installation of gas analyzers in boiler rooms; they are necessary for signaling when gas appears in the room. A special electronic valve reacts to their signals, automatically stopping the flow of fuel to the burners.

Characteristics

Today, products represented by Zhitomir boilers are the most modern and in demand. To understand why this particular brand has received consumer recognition, it is necessary to consider the model range in more detail. Each individual piece of equipment has a huge advantage over similar devices from other manufacturers. There are disadvantages in Zhitomir boilers, as in any product, but the presence of advantages outweighs the significance, showing that the equipment has much more advantages.

Gas boilers "Zhitomir" have a number of advantages, due to which they are in high demand on the market.

- The heat exchanger of the device is steel. Thanks to this, the water receives maximum heat that is generated during the combustion of gas.

- The design of the burner is thought out to the smallest detail. It is this feature that helps to increase the productivity of the device, and the level of emission of harmful impurities is minimal.

- Imported automation of each boiler allows us to achieve the most suitable characteristics.

- Ease of device management. There are no unnecessary buttons or switches.

- The design of the equipment is developed according to the latest fashion. The boiler does not take up much space, and in appearance it looks like a small bedside table that fits into any environment.

- During the production process, each individual model undergoes several stages of international standard testing. And after completing all tests, he receives a quality certificate.

Many settings in the Zhytomyr boiler system allow you to choose the optimal and comfortable state for yourself. Special sensors, which the system is also equipped with, monitor the safety of the device and uninterrupted operation. Considering all the advantages described above, we can safely say that Zhitomir boilers are ideal for heating private houses and will do their job well in apartments and other rooms. It is worth noting that not only the beautiful design and ease of use attract consumers, but also the price issue.